カスタム部品製造ソリューション

発電部品製造サービス

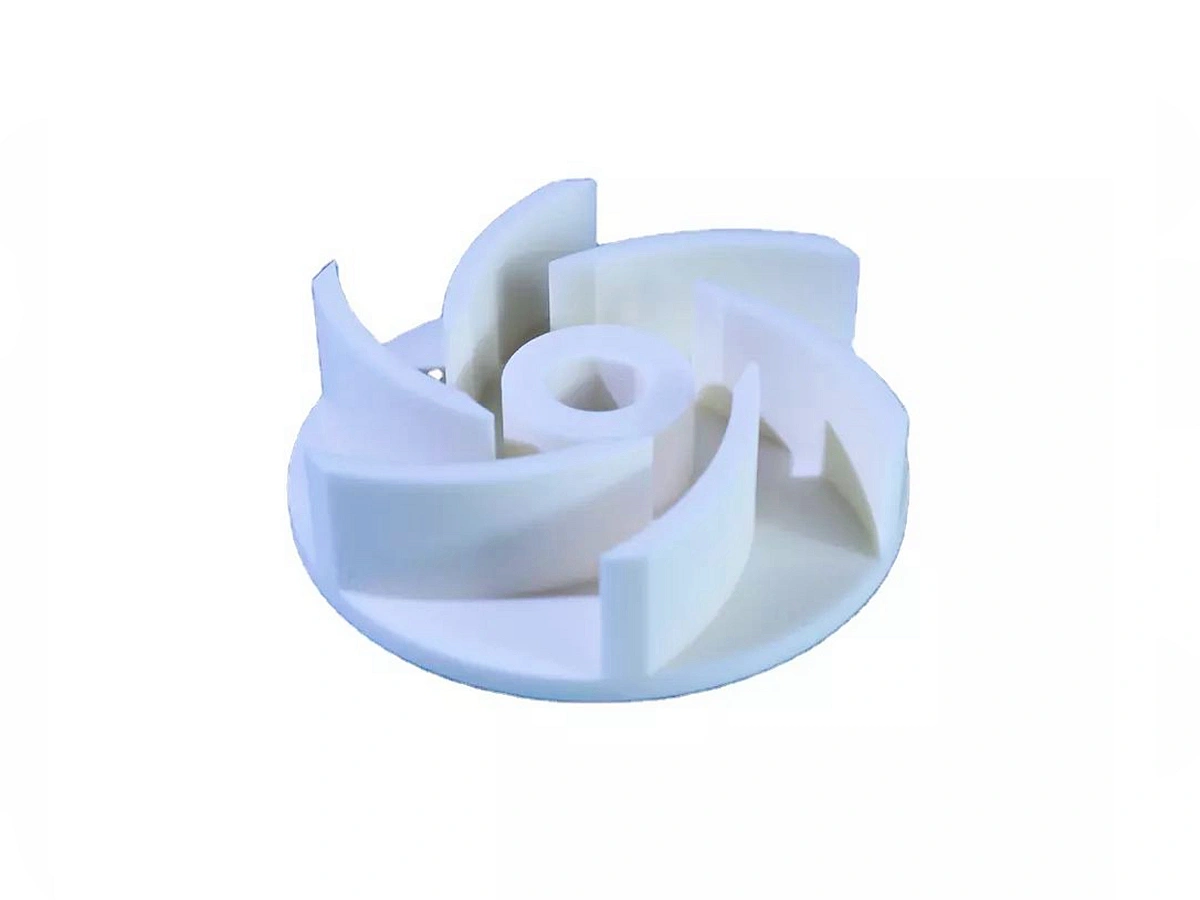

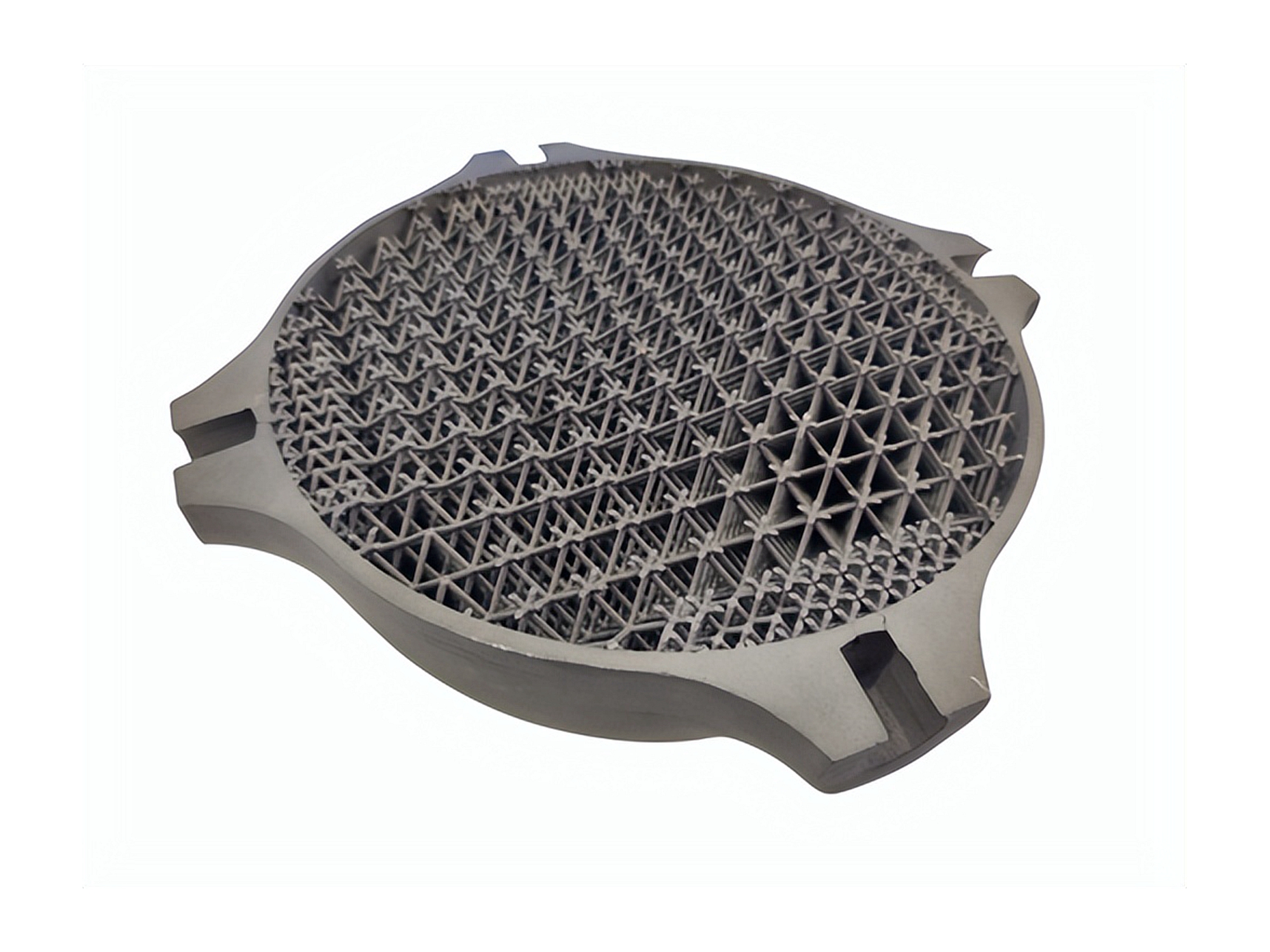

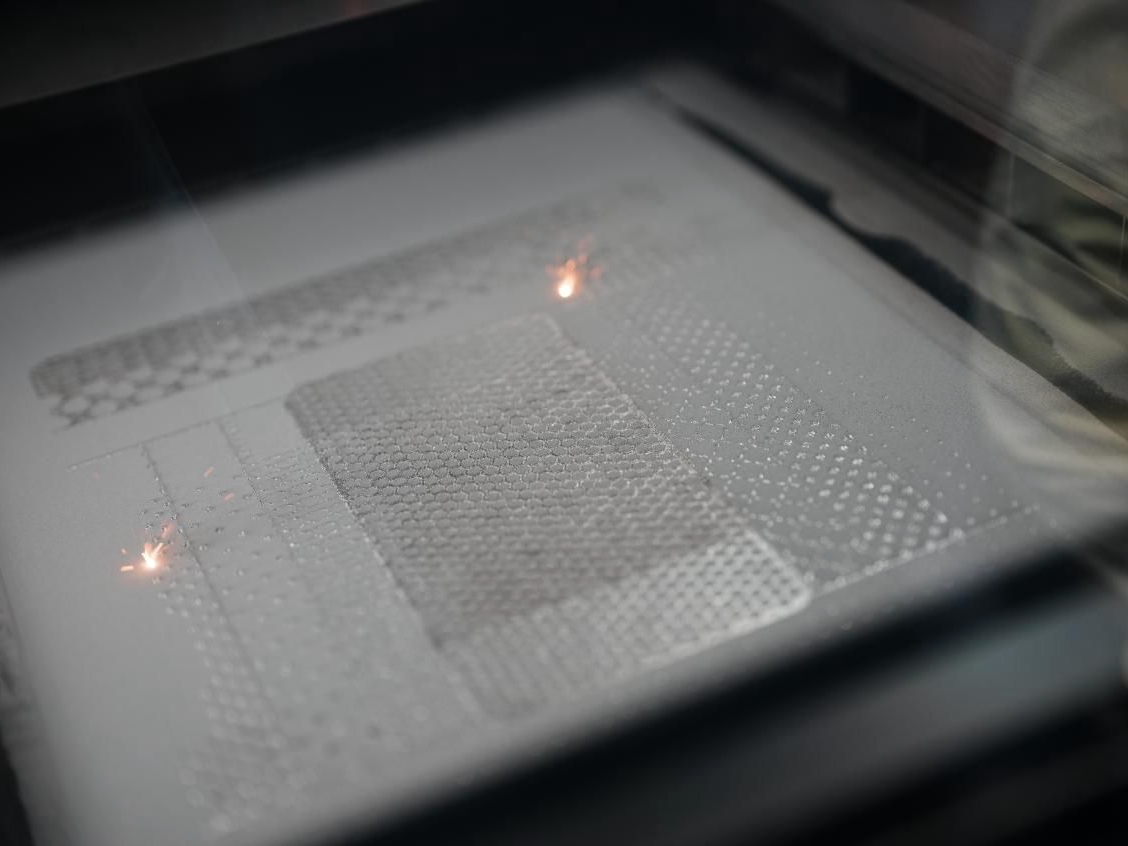

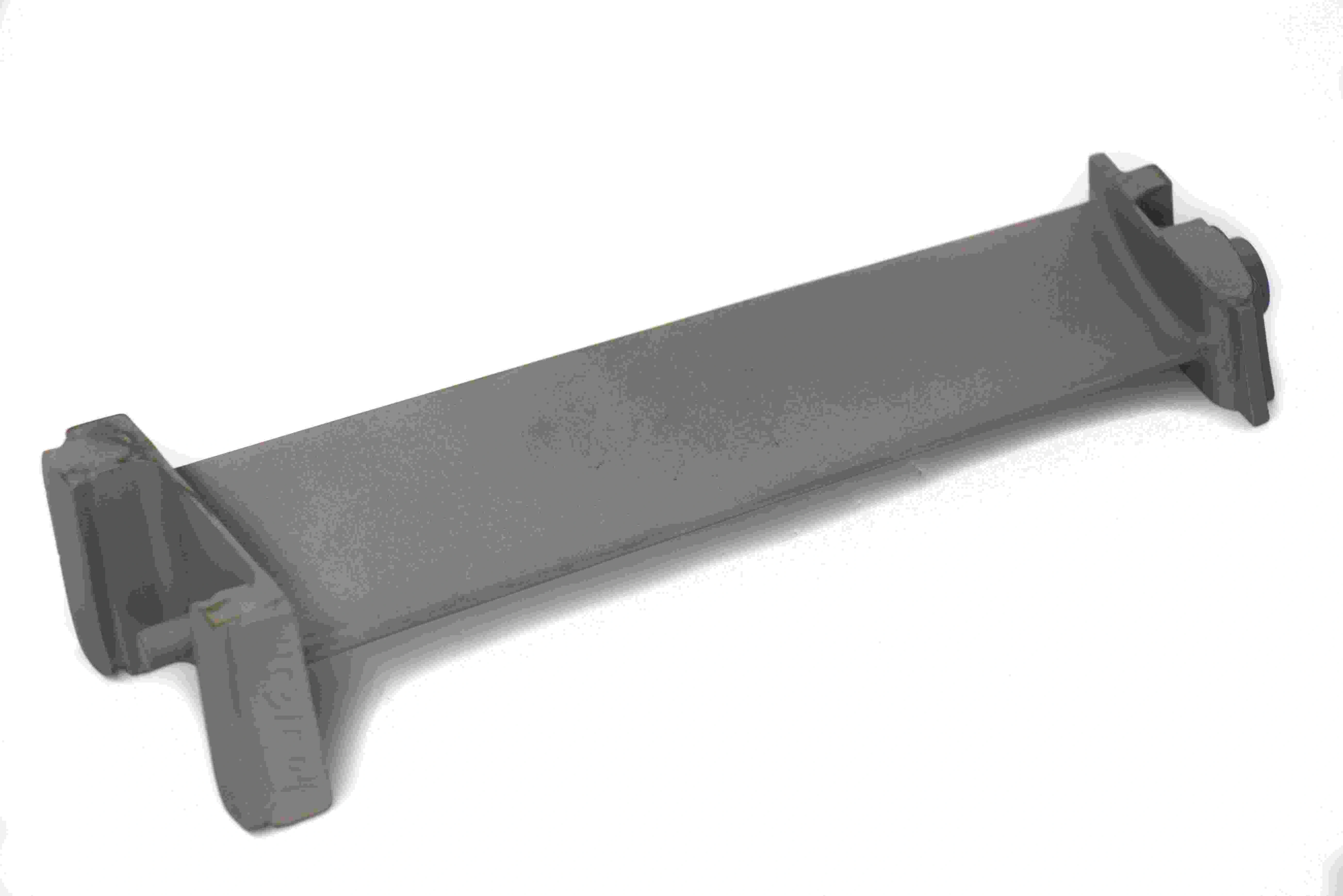

Newayは、高精度のCNC加工、高度な3Dプリント、高品質の鋳造を含む専門的な発電部品製造サービスを提供します。タービン、熱交換器、その他重要なコンポーネントに特化したソリューションで、最適な性能と耐久性を保証します。発電業界の厳しい要求を満たす高性能部品をお届けします。

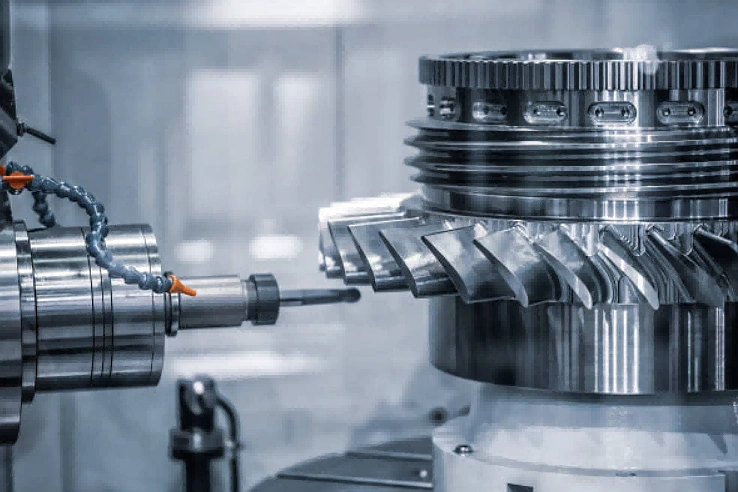

発電部品の加工

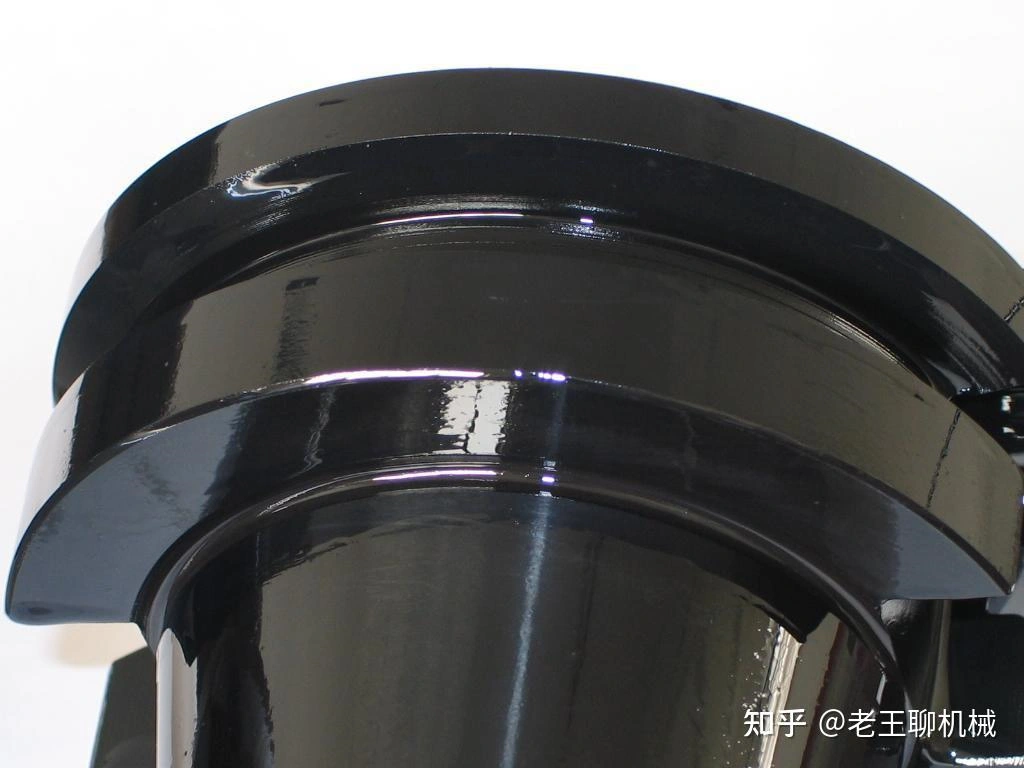

当社の発電部品加工サービスは、ミリング、旋削、穴あけ、ボーリング、研削、多軸加工などの高度なCNCプロセスを用いて、発電所向けに精密に設計された部品を提供します。電気放電加工(EDM)による複雑な形状の加工も対応し、発電業界の厳しい性能および安全基準を満たす高品質で耐久性のある部品を保証します。

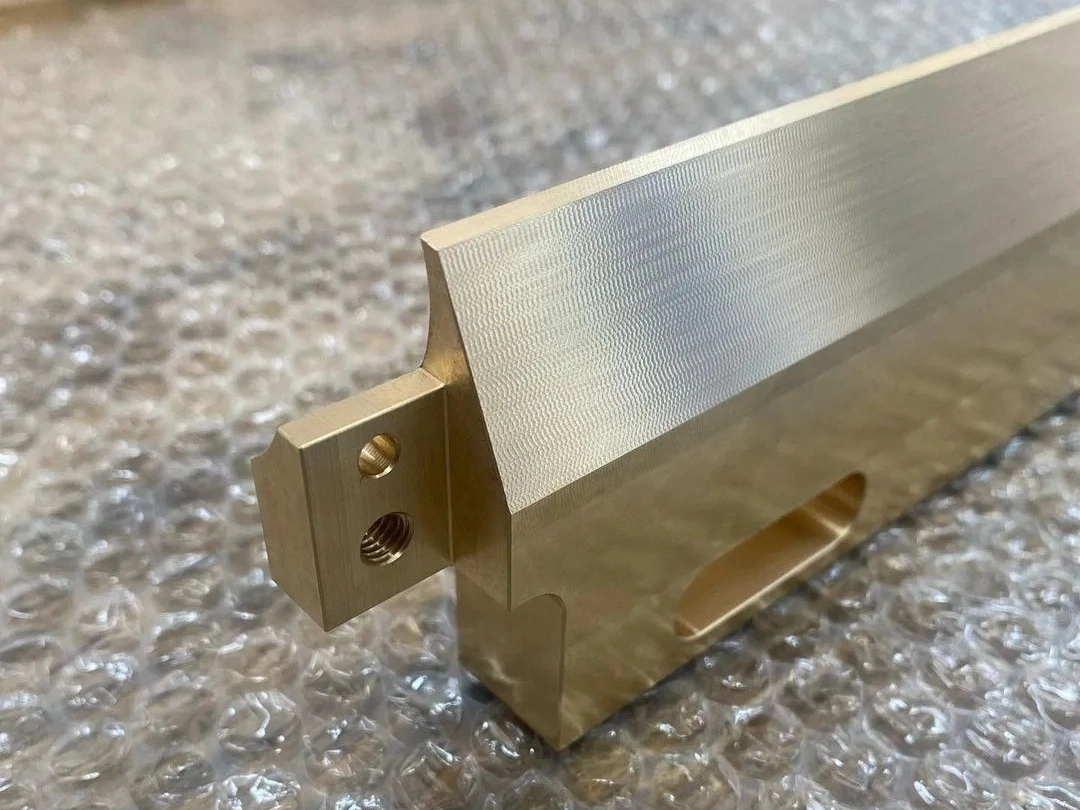

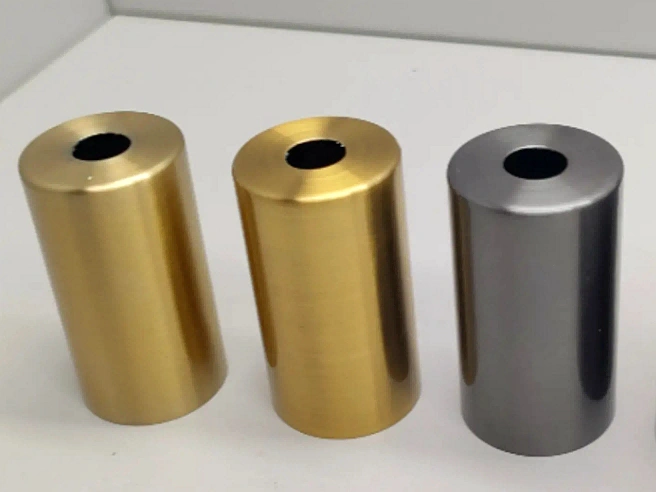

発電用材料の選択

発電用途には、スーパーアロイ、チタン、アルミニウム、銅、真鍮、青銅、炭素鋼、ステンレス鋼、プラスチック、セラミックなどの高性能材料が必須であり、タービン、発電機、熱交換器、電気システムの耐久性、耐熱性、耐食性のある部品製造に適しています。

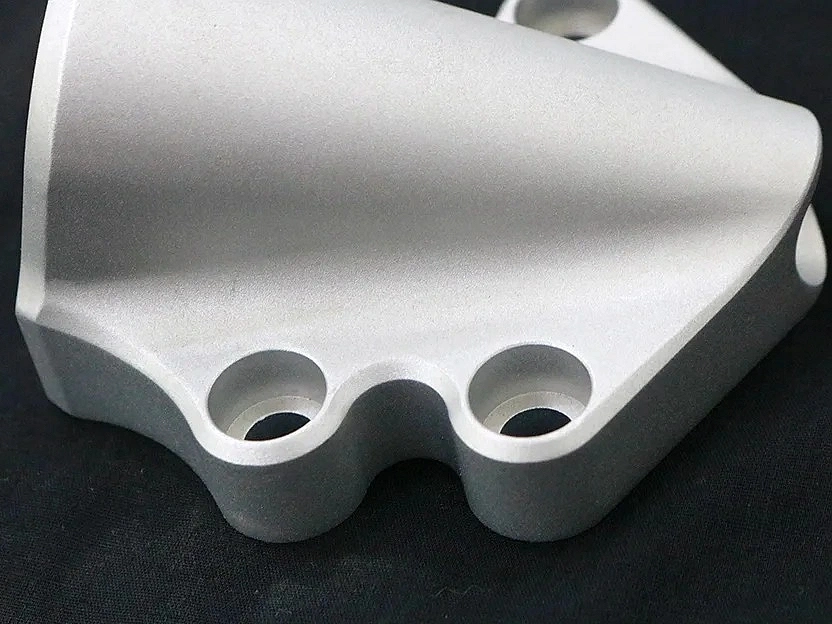

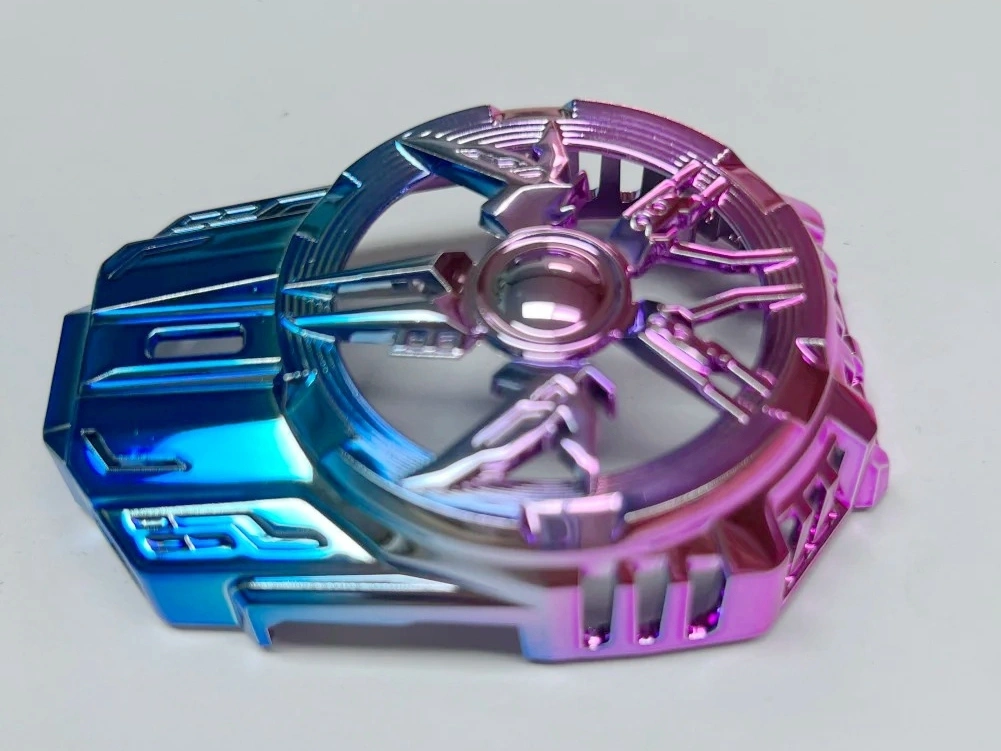

発電業界向け表面処理

発電業界の表面処理は、過酷な条件にさらされる部品の耐久性、耐腐食性、および性能を向上させます。熱コーティング、陽極酸化、電気めっき、PVDなどの技術が部品を摩耗、熱、酸化から保護します。これらの処理により信頼性が高まり、メンテナンスコストが削減され、タービン、熱交換器、バルブなどの重要設備の寿命が延長されます。

発電システム向けCNC加工部品

発電において、CNC加工はタービンブレード、発電機部品、熱交換器などの信頼性と効率性を重視した部品の製造に不可欠です。

本日新しいプロジェクトを開始しましょう

発電部品設計ガイド

発電部品の設計には、高温、圧力、機械的応力に耐えうる高性能材料と精密な工学設計が必要です。本ガイドは、信頼性が高く効率的で規制遵守した発電部品の設計ベストプラクティスをまとめています。

カスタム発電部品製造の考慮事項

発電部品のカスタム製造には高性能材料、精密な設計、厳格な規制遵守が求められます。本ガイドは、耐久性と高効率を兼ね備えた発電用部品の製造における重要な考慮事項をまとめています。