定制汽车零件加工

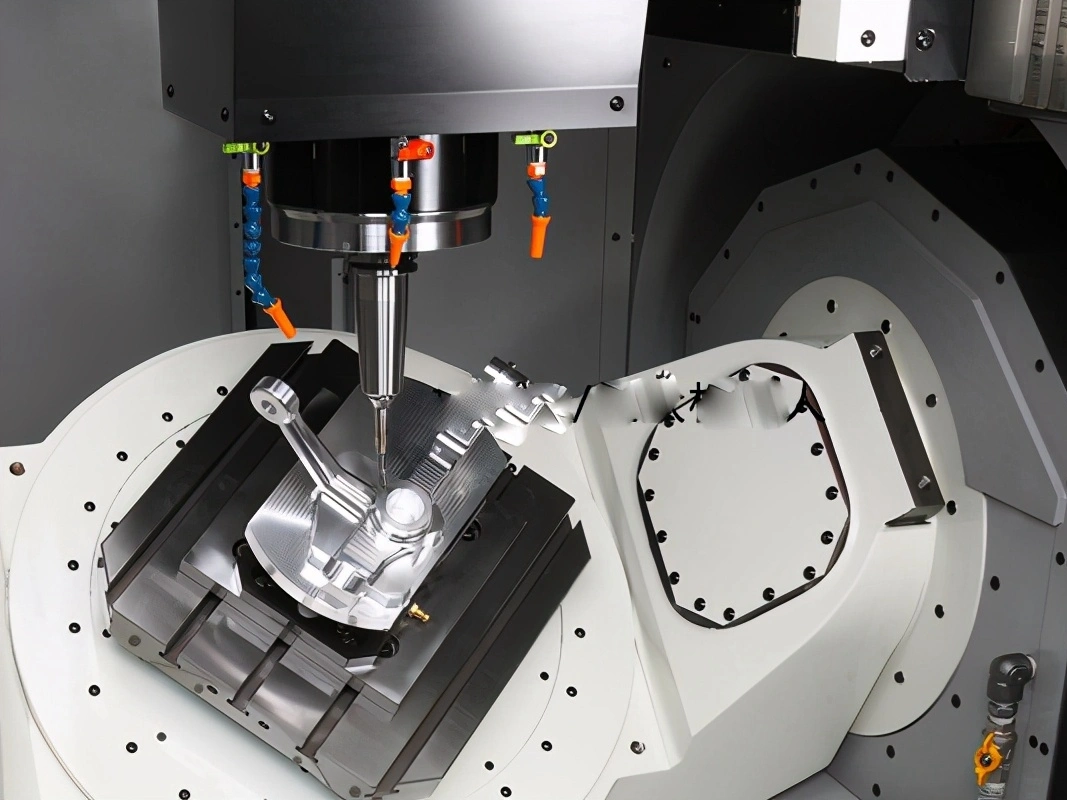

定制汽车零件加工涉及精密CNC工艺,如铣削、车削、钻孔和磨削,制造高质量汽车行业零件。通过多轴加工和电火花加工等技术,确保零件达到精确规格,实现最佳性能、耐久性和配合性。服务涵盖从原型到批量生产的广泛汽车应用。

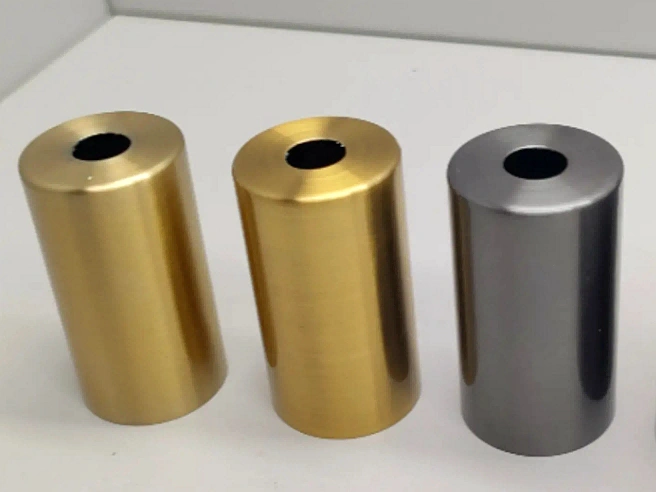

汽车材料选择

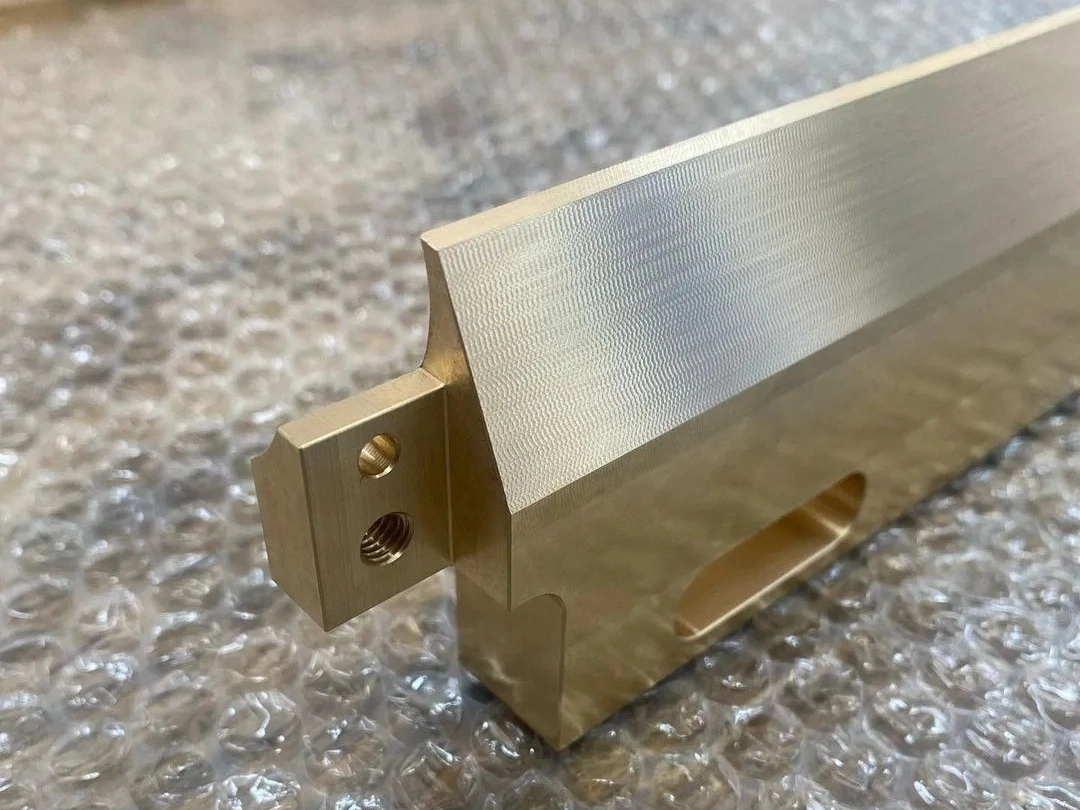

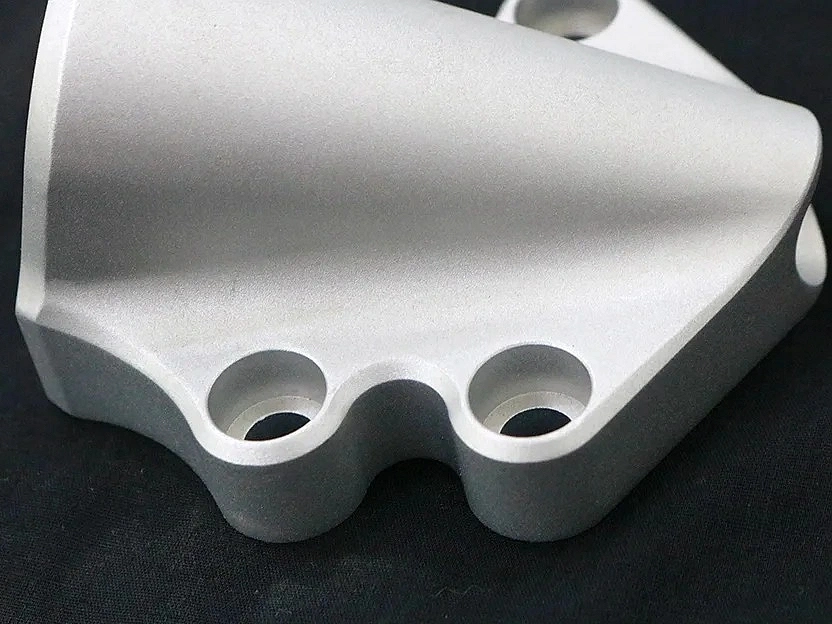

超级合金、钛、铝、铜、黄铜、青铜、碳钢、不锈钢、塑料和陶瓷等材料因其强度、轻量化、耐久性、耐腐蚀性和耐热性被选用于汽车零件,确保汽车应用中的高性能和安全性。

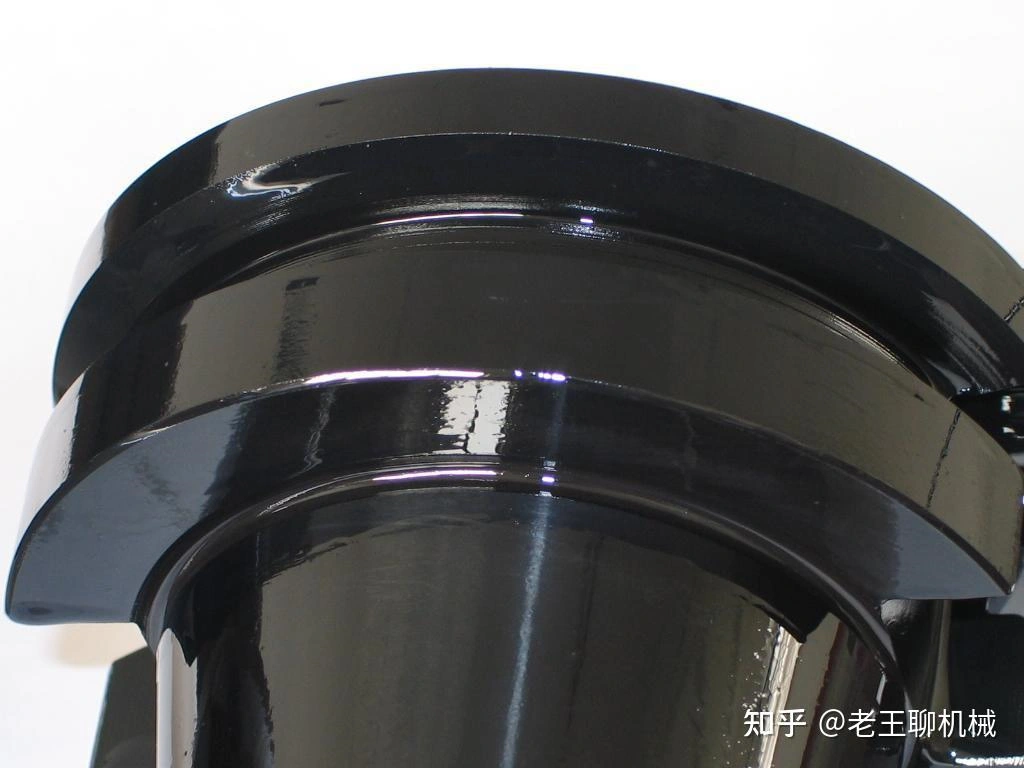

汽车零件典型表面处理

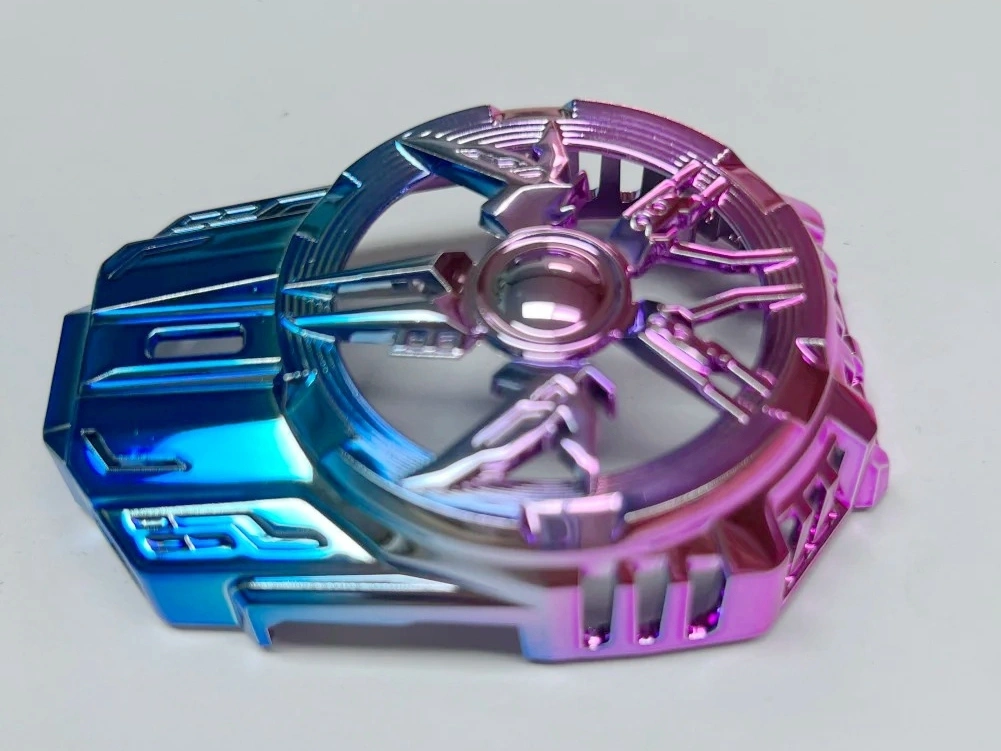

汽车零件的典型表面处理包括阳极氧化、电镀、粉末涂层和PVD等方法,以增强耐久性、耐腐蚀性和美观性。热处理、黑色氧化和喷砂等处理提升强度和性能,抛光、滚筒和清漆等表面处理提供平滑且视觉吸引的表面。这些处理确保零件满足严格的汽车标准。

汽车CNC加工组件

CNC加工为汽车行业提供精密零件,从发动机部件到悬挂系统,确保每辆车的高性能、可靠性和安全性。

今天就开始一个新项目吧

汽车零件设计与制造指南

汽车零件设计要求疲劳耐久性、成本效益、尺寸控制和工艺兼容性。本指南概述了关键设计原则,确保汽车批量生产中的可靠性能和制造性。