医疗器械零件加工

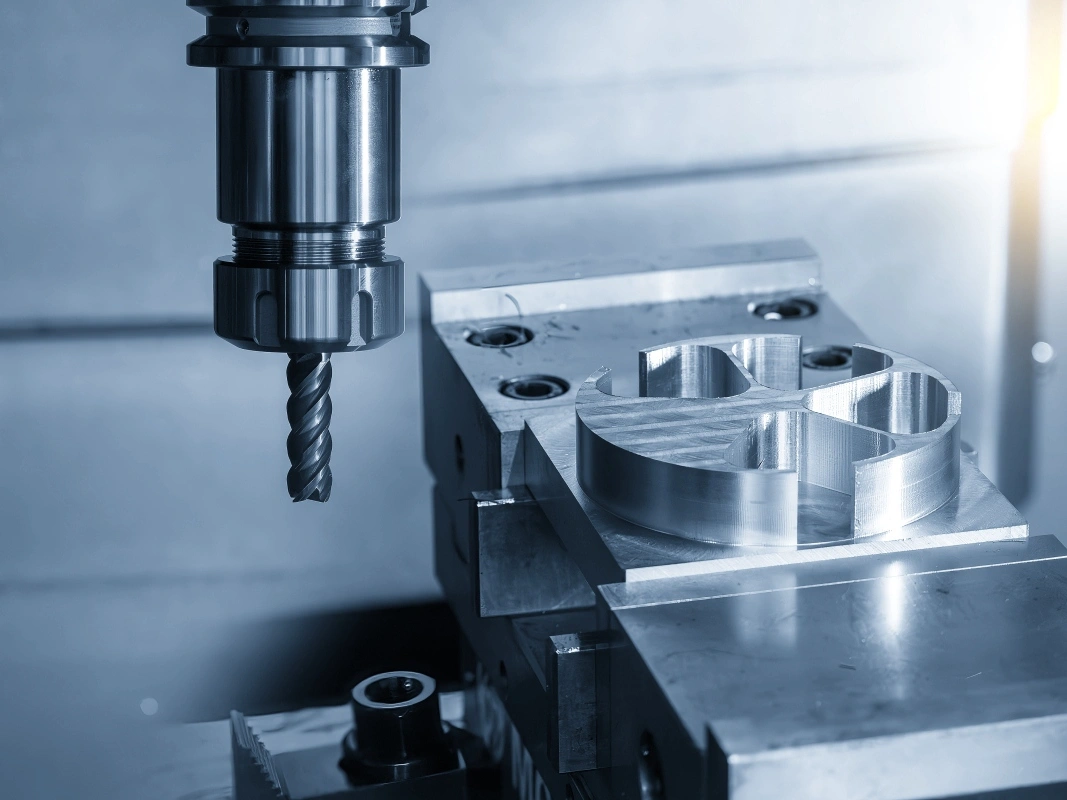

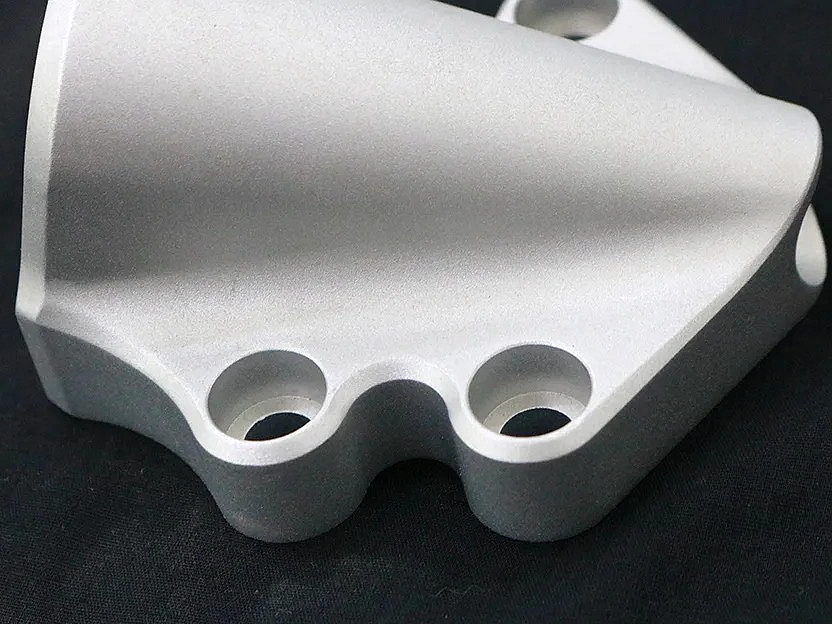

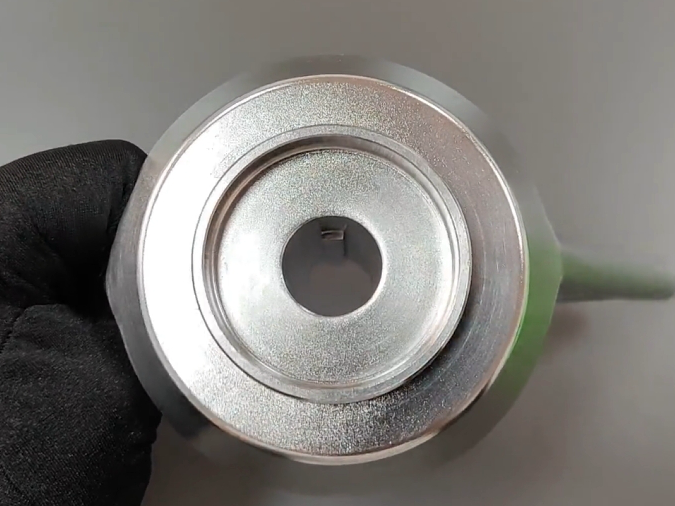

医疗器械零件加工涉及精确的CNC加工过程,如铣削、车削、钻孔和磨削,用于生产高质量的医疗应用组件。采用多轴和精密加工技术,以及电火花加工(EDM),确保紧密公差和可靠性。这些方法对于制造符合医疗行业严格安全和性能标准的零件至关重要。

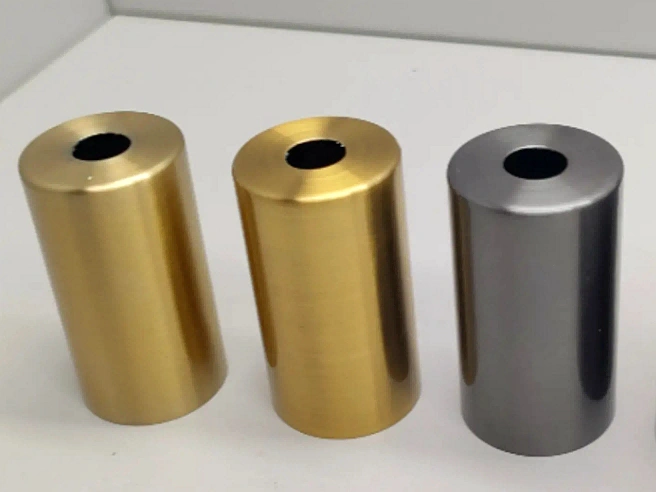

医疗器械材料选择

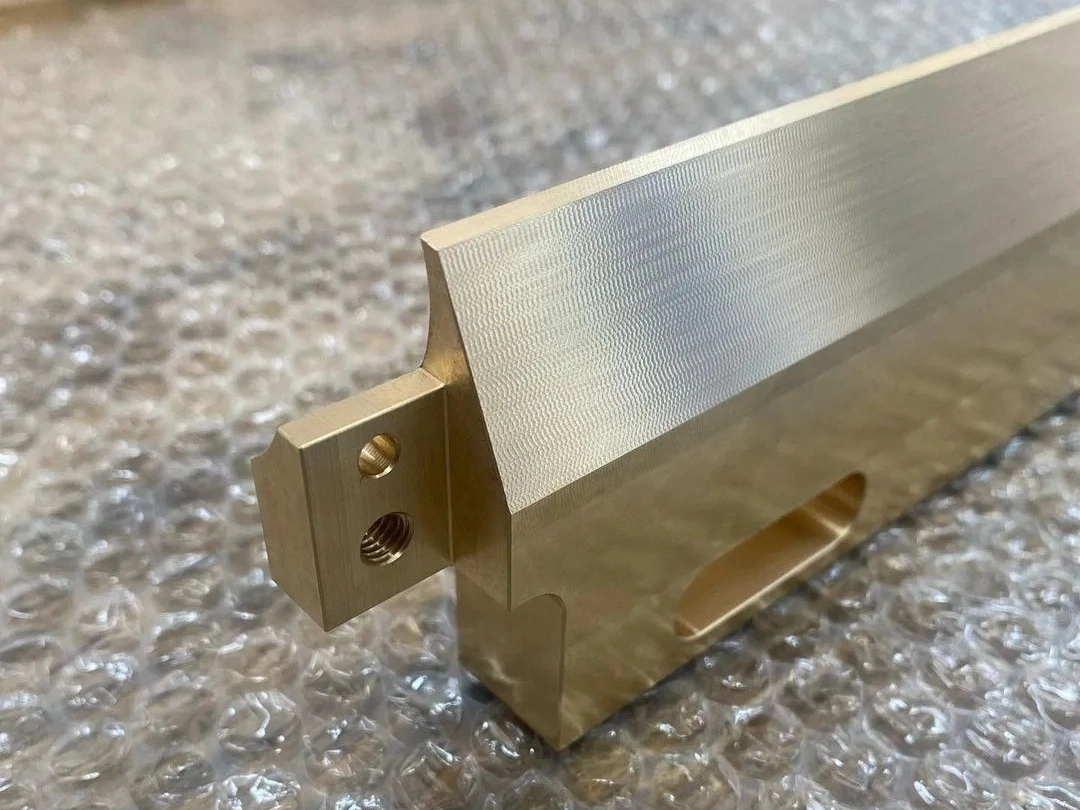

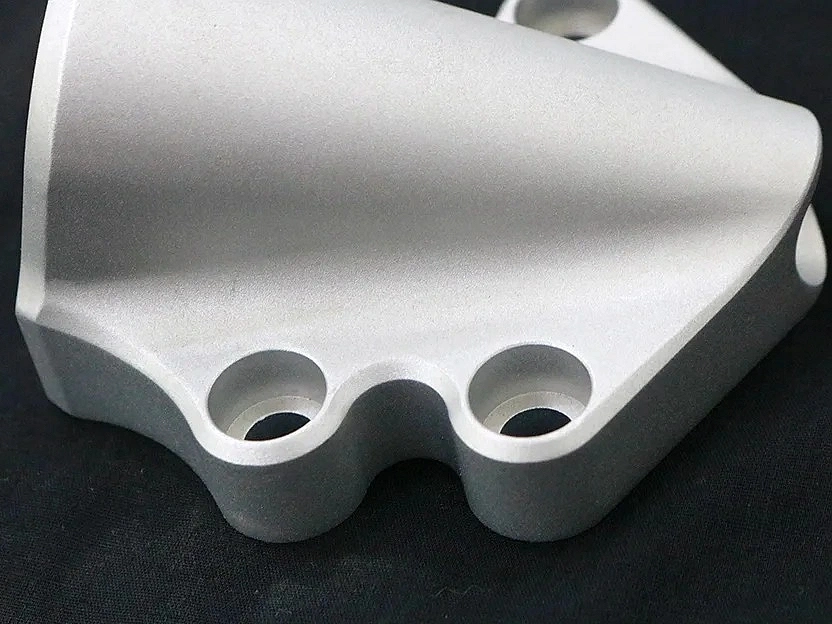

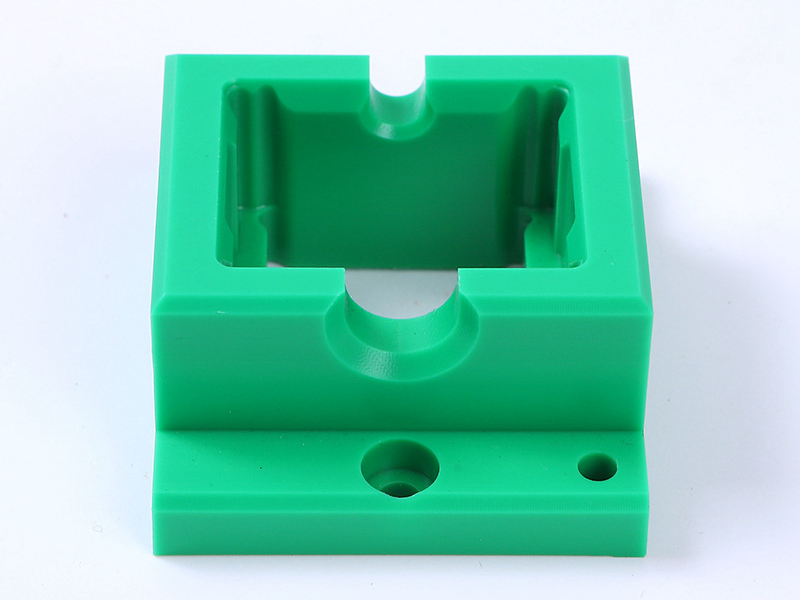

超级合金、钛、铝、铜、黄铜、青铜、碳钢、不锈钢、塑料和陶瓷等材料在医疗器械制造中至关重要。这些材料为植入物、外科工具、假体和医疗设备等组件提供耐用性、生物兼容性和精度。

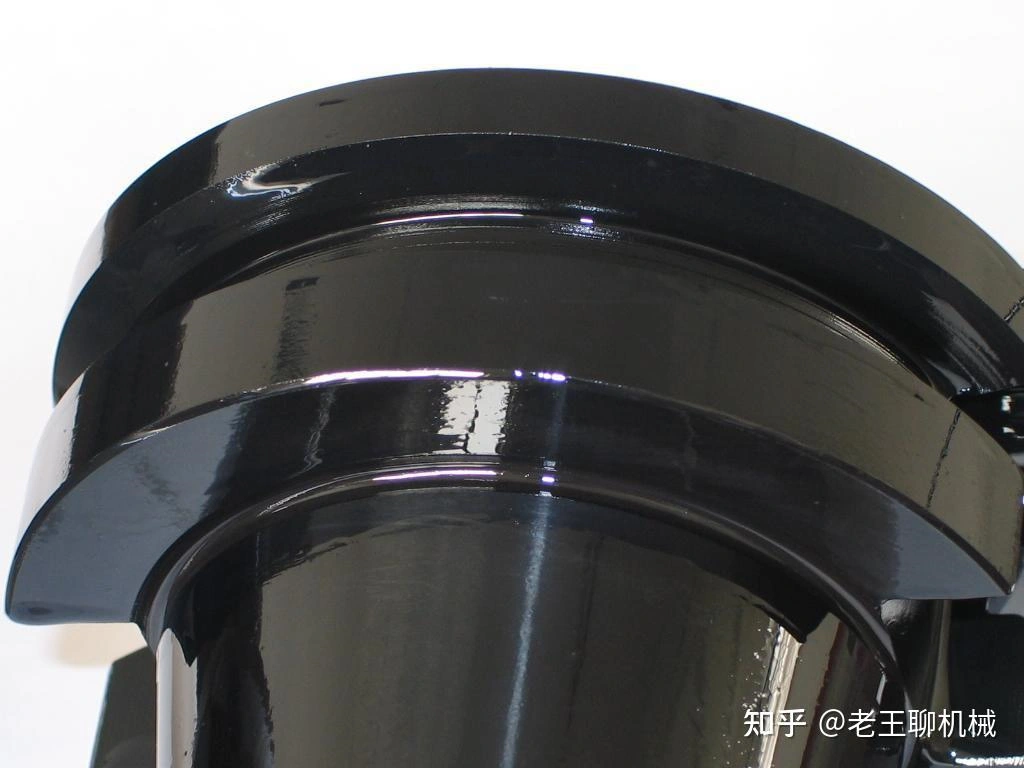

医疗器械零件典型表面处理

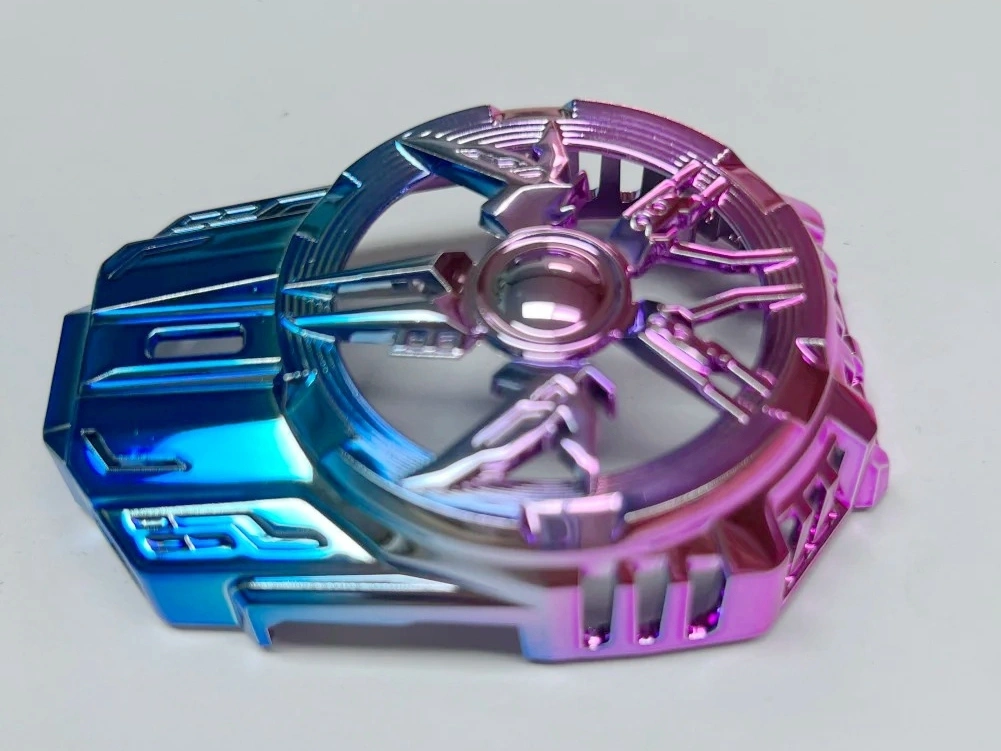

医疗器械零件的典型表面处理包括阳极化、电抛光、PVD、粉末涂层、钝化处理和热处理等工艺。这些处理可以提高生物兼容性、耐腐蚀性和耐久性。像电抛光和阳极化处理可以改善表面光滑度,而像特氟龙涂层或紫外线涂层则提供额外的保护,确保医疗器械符合严格的性能和安全标准。

医疗器械CNC加工解决方案

CNC加工在医疗器械中至关重要,制造精密组件,如外科工具、植入物和诊断设备,满足精度、生物兼容性和安全性的严格标准。

今天就开始一个新项目吧

医疗器械零件设计指南

医疗器械零件设计需要精确度、洁净度、符合规定和用户安全。本文概述了确保临床使用时功能可靠、易清洁并符合认证要求的工程原则。