精密在线陶瓷CNC加工服务

精密在线陶瓷CNC加工服务提供高精度、复杂设计能力及优异的表面质量。服务支持快速原型制作、缩短交期、降低生产成本,并能精准加工复杂且难加工的陶瓷材料。

发送您的设计和规格以获取免费报价

所有上传的文件均安全且保密

关于陶瓷CNC加工

陶瓷CNC加工具有高精度、复杂设计能力及优异表面质量。能制造复杂的陶瓷零件并实现严格公差,确保耐磨、热稳定和耐用性,适用于需要高性能的工业应用。

常用陶瓷材料

常用陶瓷材料具备极高硬度、高温耐受性、耐磨性及化学稳定性。其耐用性适合航空航天、汽车、电子及医疗等要求高精度和可靠性的领域。

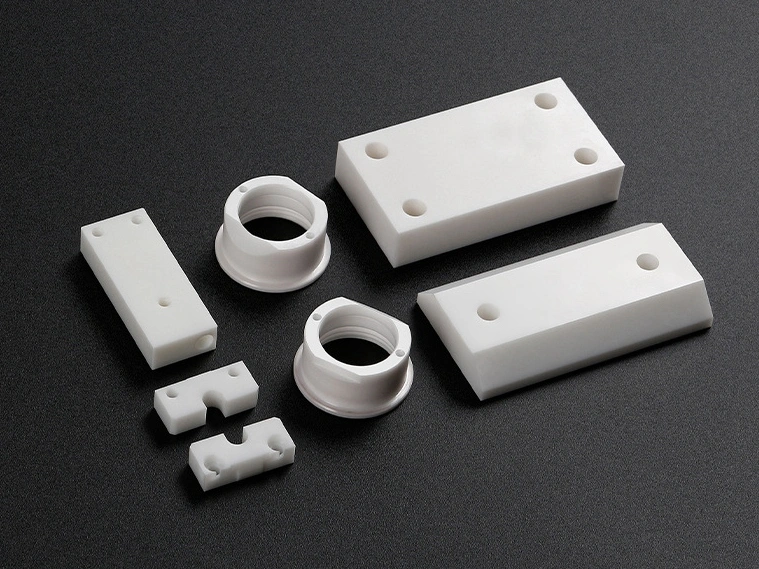

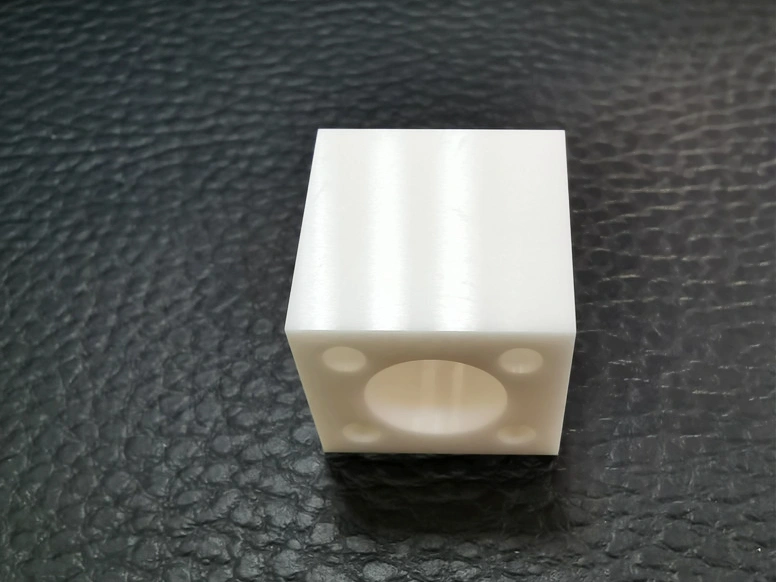

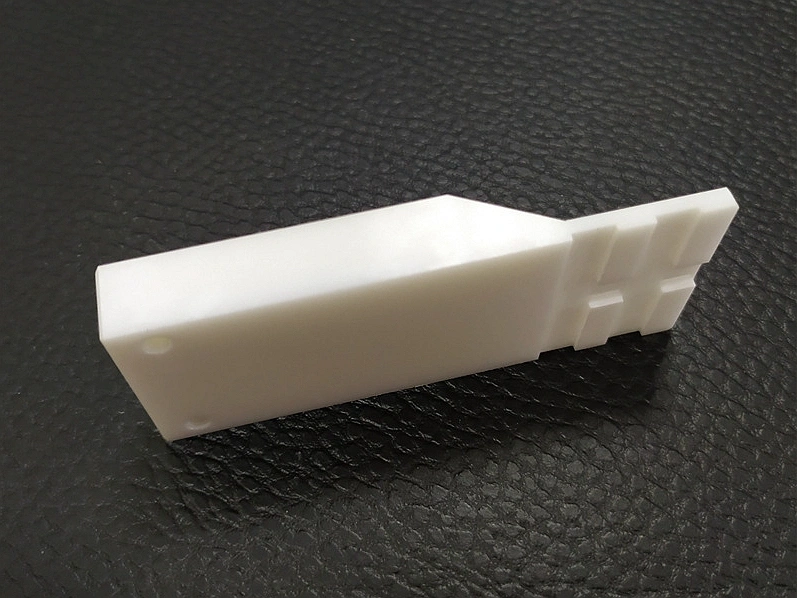

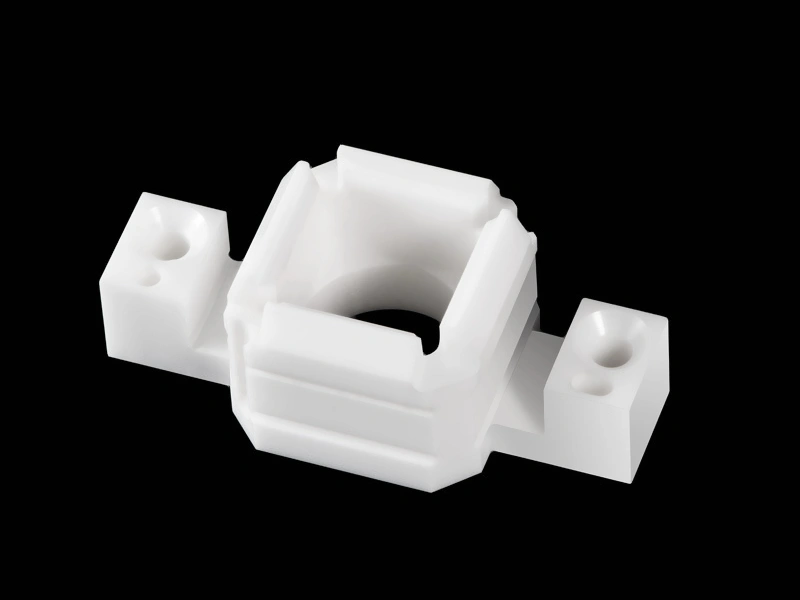

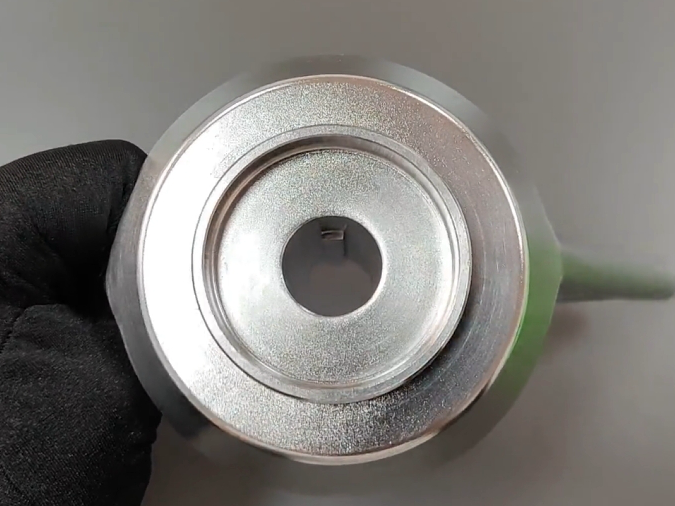

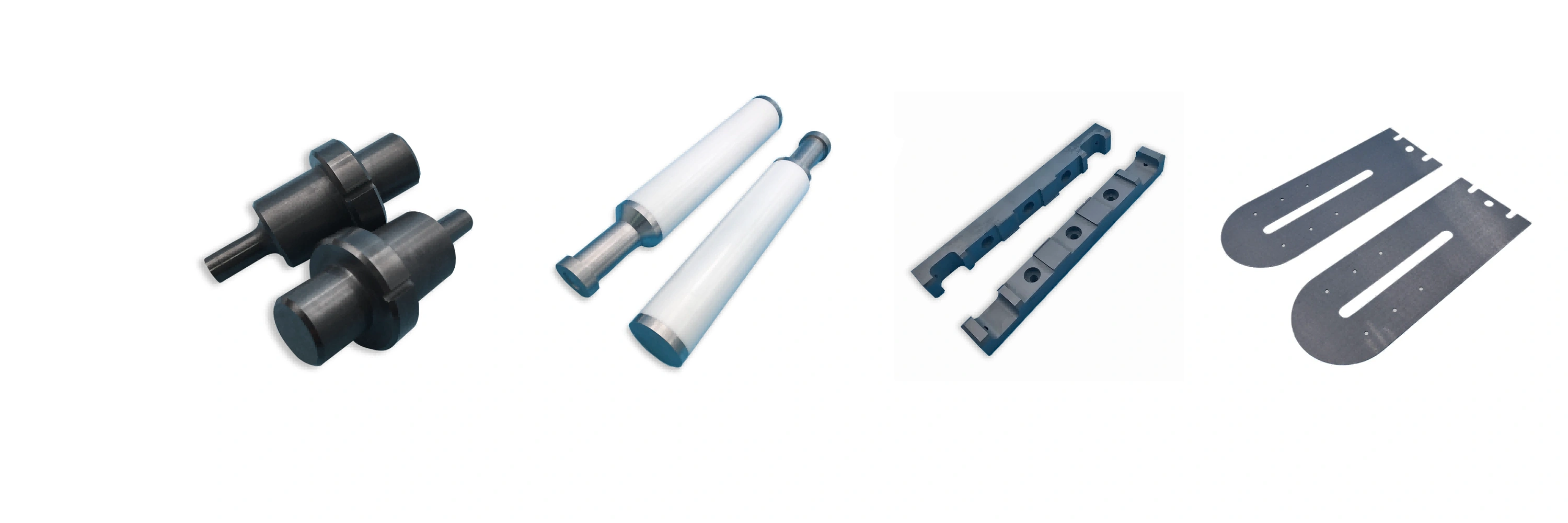

典型陶瓷CNC加工案例

典型陶瓷CNC加工案例展示了制造高精度、耐用零件及严格公差的能力。案例体现了氧化锆和氮化硅在航空航天、电子及医疗行业中的应用,确保在极端条件下的卓越性能。

今天就开始一个新项目吧

陶瓷CNC加工参数建议

陶瓷CNC加工参数建议确保加工精度、效率及材料完整性。优化主轴功率、进给速度、切削深度和刀具选择,降低刀具磨损、防止开裂、提升表面质量,同时通过冷却及振动控制提升加工表现。

陶瓷加工建议

陶瓷加工提供高精度、耐用性和极端条件下优异性能。关键建议包括保持适当公差、使用专用刀具,遵守最小壁厚及零件尺寸规范,确保航空航天和医疗等行业的可靠且成本效益高的生产。

Frequently Asked Questions

探索相关资源

Copyright © 2025 Machining Precision Works Ltd.All Rights Reserved.