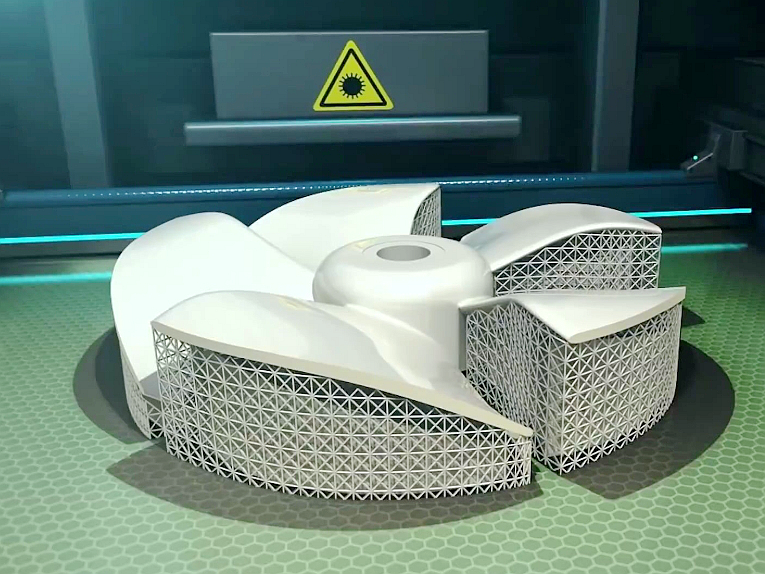

Neway व्यापक उपभोक्ता उत्पाद घटक निर्माण सेवाएं प्रदान करता है, जिसमें CNC मशीनिंग, 3D प्रिंटिंग, वैक्यूम कास्टिंग, डाई कास्टिंग, और इंजेक्शन मोल्डिंग शामिल हैं। हम उपभोक्ता वस्त्र उद्योग के लिए उच्च गुणवत्ता, टिकाऊ घटक प्रदान करते हैं, जो प्रत्येक उत्पाद में प्रिसिजन, प्रदर्शन और लागत-कुशलता सुनिश्चित करते हैं।

उपभोक्ता उत्पाद भागों का मशीनिंग

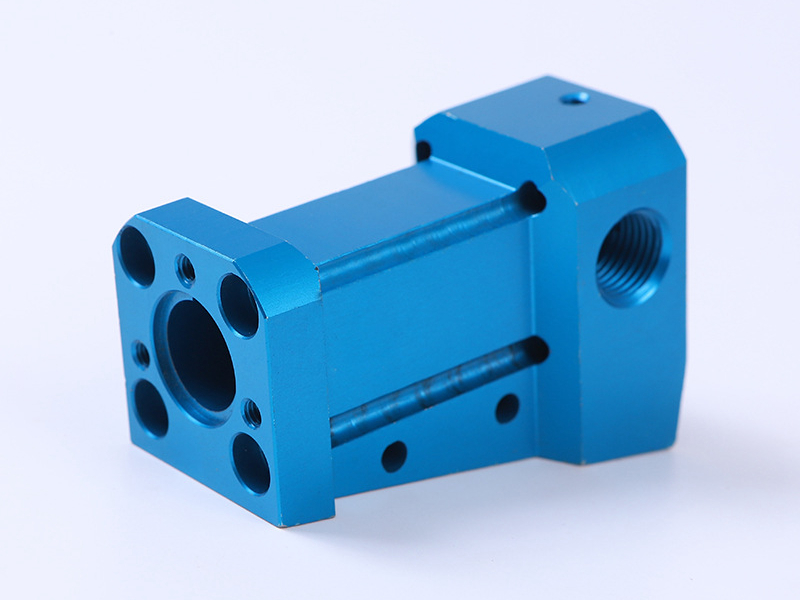

उपभोक्ता उत्पाद भाग मशीनिंग विभिन्न CNC प्रक्रियाओं का उपयोग करके घटकों का सटीक निर्माण है, जैसे कि मिलिंग, टर्निंग, ड्रिलिंग, और ग्राइंडिंग। ये उन्नत तकनीकें इलेक्ट्रॉनिक्स, उपकरण, और व्यक्तिगत डिवाइस जैसे उत्पादों के लिए उच्च सटीकता और गुणवत्ता सुनिश्चित करती हैं। मल्टी-एक्सिस मशीनिंग और EDM जटिल आकृतियों के लिए बेहतर सटीकता प्रदान करते हैं, जो आधुनिक उपभोक्ता वस्तुओं की मांगों को पूरा करते हैं।

उपभोक्ता उत्पाद सामग्री चयन

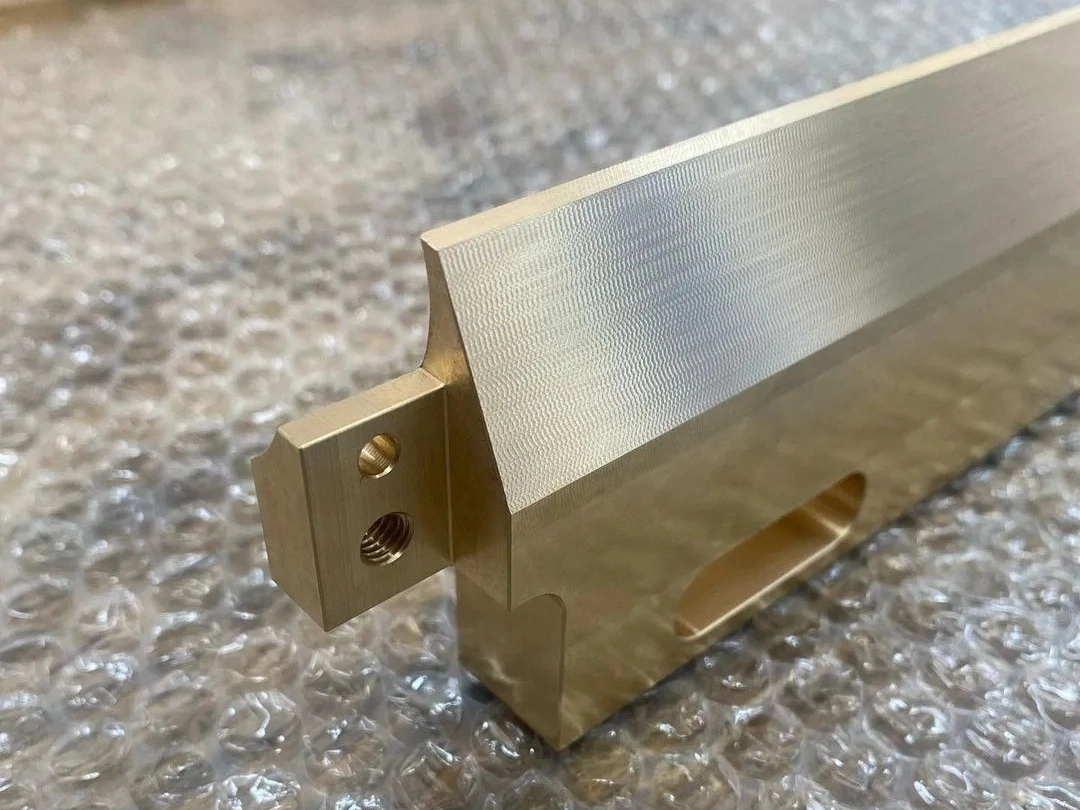

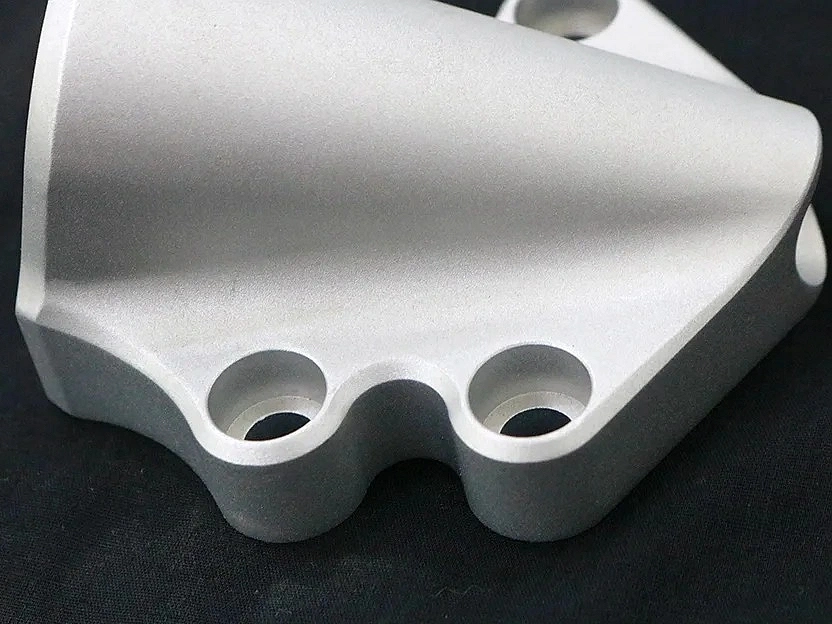

उपभोक्ता उत्पाद निर्माण में, सुपरएलॉय, टाइटेनियम, एल्यूमीनियम, कॉपर, ब्रास, ब्रॉन्ज़, कार्बन स्टील, स्टेनलेस स्टील, प्लास्टिक, और सेरामिक जैसी सामग्री टिकाऊ, कार्यात्मक, और सौंदर्यपूर्ण वस्तुओं जैसे कि किचनवेयर, इलेक्ट्रॉनिक्स, खिलौने, और सजावटी वस्त्र बनाने के लिए आवश्यक हैं।

उपभोक्ता उत्पादों के लिए सामान्य सतह उपचार

उपभोक्ता उत्पादों के लिए सामान्य सतह उपचार में पेंटिंग, इलेक्ट्रोप्लेटिंग, एनोडाइजिंग, और पाउडर कोटिंग जैसी तकनीकें शामिल हैं, जो सौंदर्य और टिकाऊपन बढ़ाती हैं। अतिरिक्त प्रक्रियाएं जैसे पॉलिशिंग, पासिवेशन, और UV कोटिंग फिनिश और पहनने के प्रतिरोध में सुधार करती हैं। विशेष आवश्यकताओं के लिए, PVD, सैंडब्लास्टिंग, और टेफलॉन कोटिंग जैसे विकल्प बेहतर प्रदर्शन प्रदान करते हैं, जबकि हीट ट्रीटमेंट सामग्री को मजबूत बनाते हैं ताकि वे लंबे समय तक टिक सकें।

और जानें

थर्मल कोटिंग

और जानें

मशीनिंग जैसा फिनिश

और जानें

पेंटिंग

और जानें

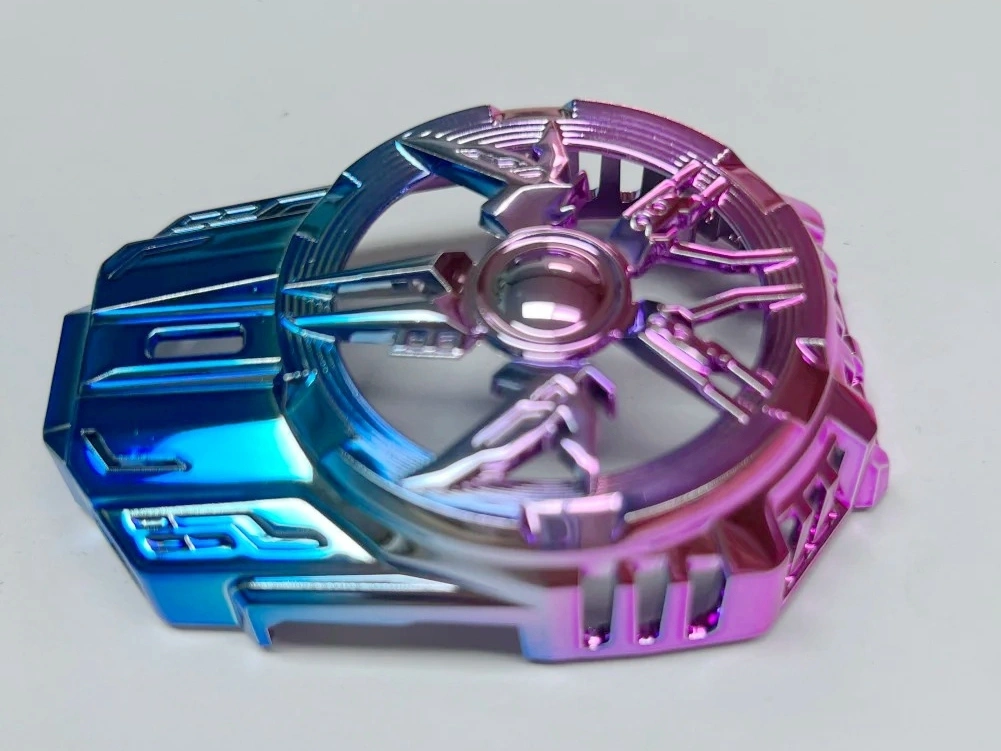

PVD (फिजिकल वेपर डिपोजिशन)

और जानें

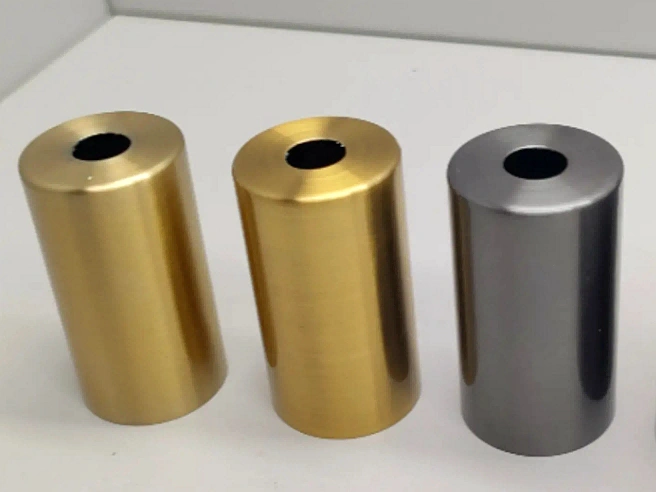

सैंडब्लास्टिंग

और जानें

इलेक्ट्रोप्लेटिंग

और जानें

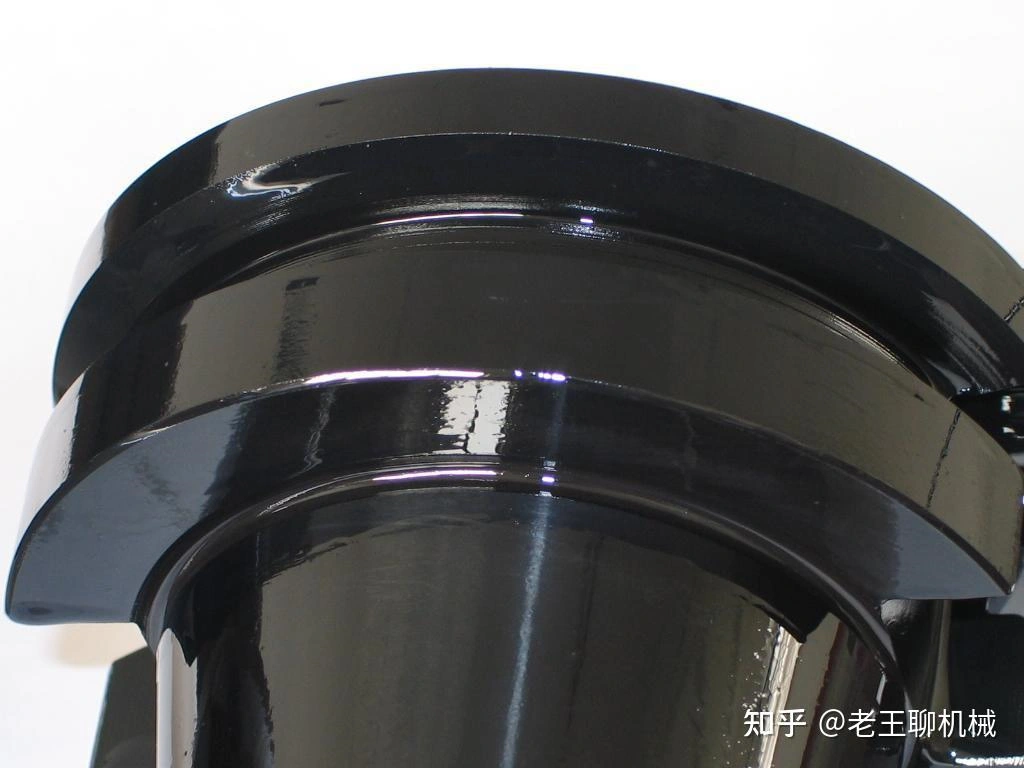

पॉलिशिंग

और जानें

एनोडाइजिंग

और जानें

पाउडर कोटिंग

और जानें

इलेक्ट्रोपॉलिशिंग

और जानें

पासिवेशन

और जानें

ब्रशिंग

और जानें

ब्लैक ऑक्साइड

और जानें

हीट ट्रीटमेंट

और जानें

थर्मल बैरियर कोटिंग (TBC)

और जानें

टम्बलिंग

और जानें

एलोडिन कोटिंग

और जानें

क्रोम प्लेटिंग

और जानें

फॉस्फेटिंग

और जानें

नाइट्रिडिंग

और जानें

गैल्वेनाइजिंग

और जानें

यूवी कोटिंग

और जानें

लैकर कोटिंग

और जानें

टेफलॉन कोटिंग

उपभोक्ता उत्पादों के लिए CNC मशीनिंग घटक

उपभोक्ता उत्पादों में, CNC मशीनिंग हाउसिंग, ब्रैकेट, और एनक्लोज़र जैसे भागों का निर्माण करती है, जो दैनिक इलेक्ट्रॉनिक डिवाइस, उपकरण, और सहायक उपकरण के लिए उच्च गुणवत्ता वाली फिनिश और सटीक सहिष्णुता प्रदान करती है।

आज ही नया प्रोजेक्ट शुरू करें

उपभोक्ता उत्पाद डिजाइन गाइड

उपभोक्ता उत्पाद डिजाइन में कार्यात्मक इंजीनियरिंग, निर्माण योग्यता, उपयोगकर्ता आराम, दृश्य पहचान, और वैश्विक अनुपालन शामिल हैं। यह गाइड तकनीकी सर्वोत्तम प्रथाओं को रेखांकित करता है ताकि बाजार-तैयार प्रदर्शन, उत्पादन योग्यता, और उपभोक्ता आकर्षण सुनिश्चित किया जा सके।

कस्टम उपभोक्ता उत्पाद निर्माण विचार

सफल कस्टम उपभोक्ता उत्पाद निर्माण के लिए इंजीनियरिंग व्यवहार्यता, दृश्य अपील, लागत दक्षता, और अनुपालन का सटीक एकीकरण आवश्यक है। यह गाइड स्केलेबल उत्पादन के लिए इंजीनियरिंग-केंद्रित सर्वोत्तम प्रथाएं प्रदान करता है।

Frequently Asked Questions

संबंधित संसाधन एक्सप्लोर करें

समाधान

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.