प्रिसीजन ऑन-डिमांड कस्टम CNC ग्राइंडिंग सेवा

हमारी ऑन-डिमांड प्रिसीजन CNC मिलिंग सेवा उच्च गुणवत्ता, विश्वसनीय और कुशल सुपरएलॉय, सिरेमिक, स्टेनलेस स्टील, एल्यूमीनियम, और टाइटेनियम पार्ट्स के लिए अनुकूलित है।

- रैपिड CNC ग्राइंडिंग प्रोटोटाइपिंग सेवा

- कम मात्रा CNC ग्राइंडिंग सेवा

- CNC ग्राइंडिंग बड़े पैमाने पर उत्पादन सेवा

- वन स्टॉप CNC ग्राइंडिंग सेवा

नि:शुल्क कोटेशन के लिए हमें अपनी डिज़ाइन और विशिष्टताएँ भेजें

सभी अपलोड की गई फ़ाइलें सुरक्षित और गोपनीय हैं

प्रिसीजन CNC ग्राइंडिंग अनुप्रयोग

प्रिसीजन CNC ग्राइंडिंग अनुप्रयोग उच्च सटीकता वाली मशीनिंग के लिए हैं, जिनमें पार्ट्स को सख्त टॉलरेंस और चिकनी सतह की आवश्यकता होती है। सामान्य अनुप्रयोगों में गियर्स, शाफ्ट्स, और एयरोस्पेस कंपोनेंट्स शामिल हैं, जो एयरोस्पेस, ऑटोमोटिव, मेडिकल, और औद्योगिक उपकरण जैसे उद्योगों में बेहतरीन प्रदर्शन सुनिश्चित करते हैं।

प्रिसीजन CNC ग्राइंडिंग के लिए प्रमुख सामग्री

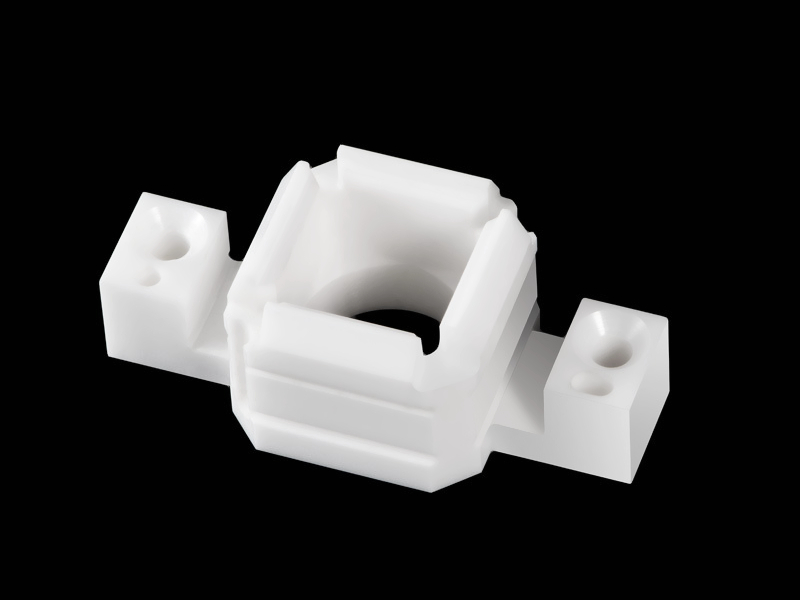

CNC ग्राइंडिंग सुपरएलॉय, टाइटेनियम, एल्यूमीनियम, कॉपर, ब्रास, ब्रोंज, कार्बन स्टील, स्टेनलेस स्टील, प्लास्टिक और सिरैमिक जैसी सामग्री के प्रिसीजन मशीनिंग के लिए व्यापक रूप से उपयोग किया जाता है। ये सामग्री उनकी टिकाऊपन, ताकत, और विभिन्न उद्योगों में बहुमुखी प्रतिभा के लिए चुनी जाती हैं। CNC ग्राइंडिंग उच्च सटीकता, चिकनी सतह और सख्त टॉलरेंस सुनिश्चित करता है, जिससे यह जटिल और उच्च प्रदर्शन वाले अनुप्रयोगों के लिए आदर्श है।

CNC ग्राइंडिंग पार्ट्स के लिए सतह उपचार

CNC ग्राइंडिंग पार्ट्स के सतह उपचार से टिकाऊपन, प्रदर्शन और रूप बढ़ता है। विकल्पों में पॉलिशिंग, प्लेटिंग और कोटिंग शामिल हैं जो पहनने के प्रतिरोध को बढ़ाते हैं, घर्षण कम करते हैं, और संक्षारण से सुरक्षा करते हैं, जिससे विभिन्न औद्योगिक अनुप्रयोगों में प्रिसीजन कंपोनेंट्स के लिए उच्च गुणवत्ता वाली फिनिश सुनिश्चित होती है।

और जानें

थर्मल कोटिंग

और जानें

एज़ मशीन

और जानें

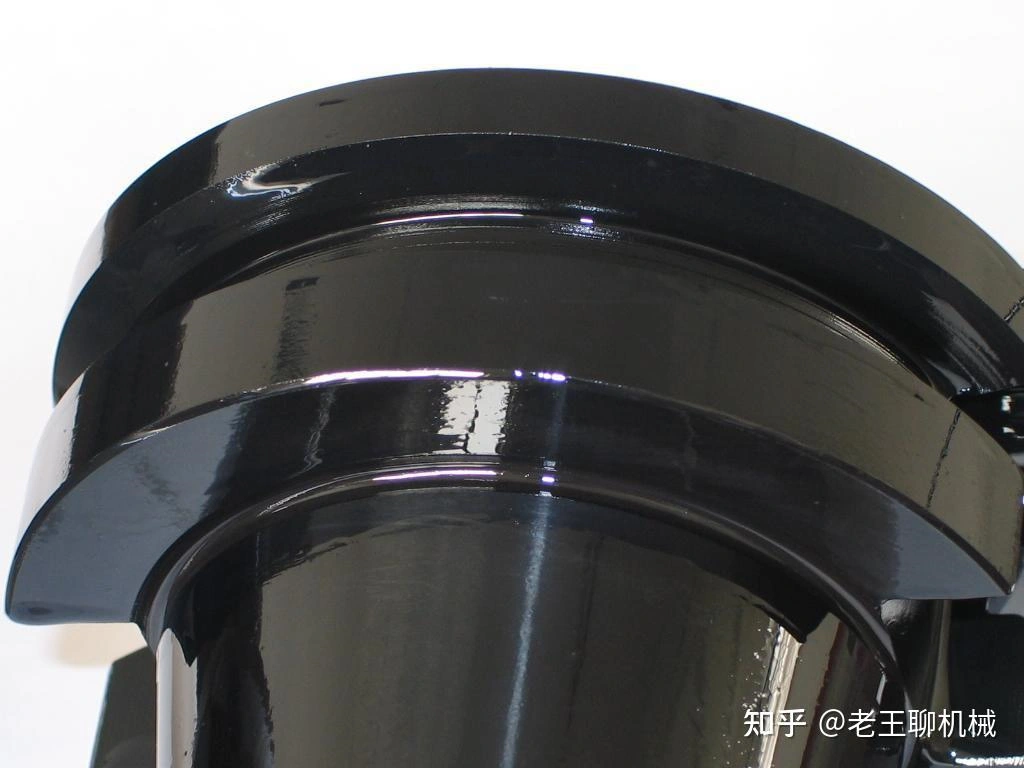

पेंटिंग

और जानें

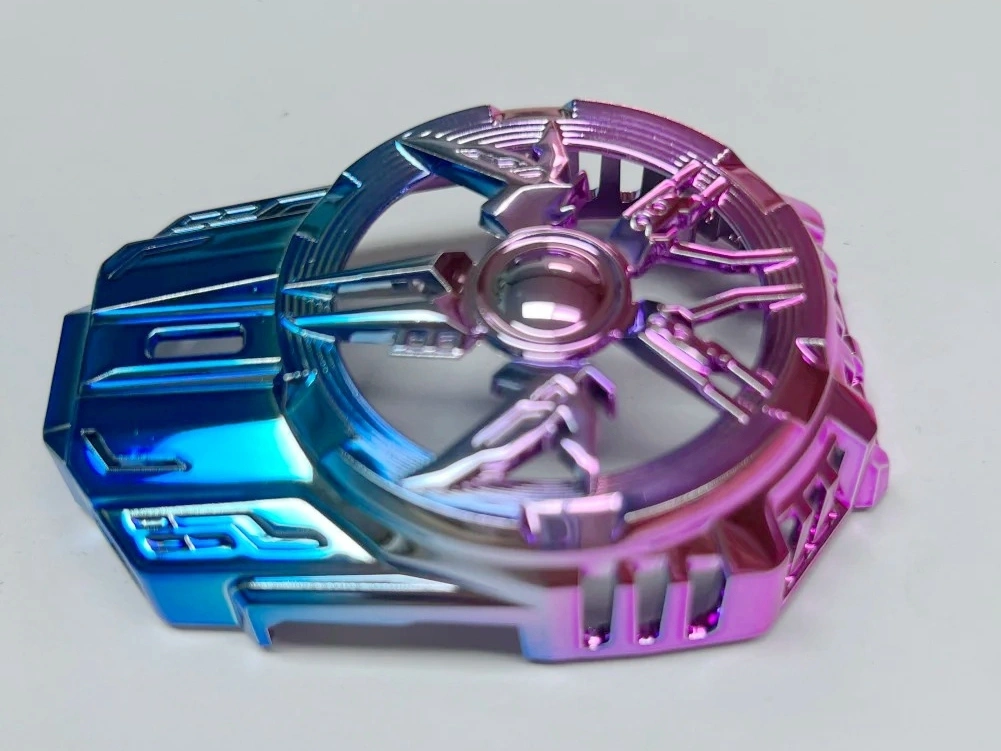

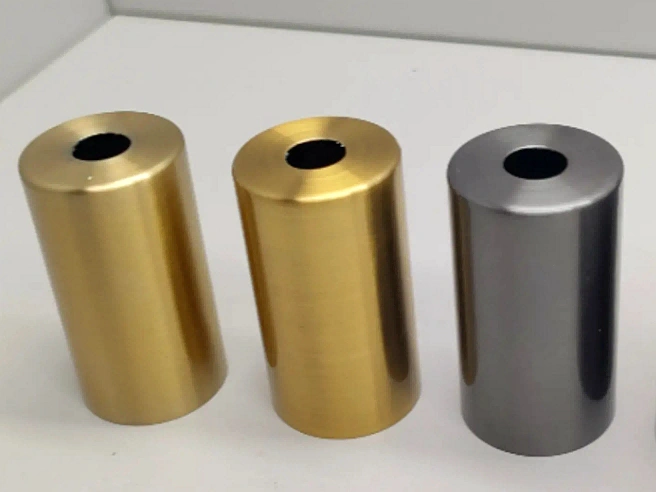

PVD (फिजिकल वेपर डिपोजिशन)

और जानें

सैंडब्लास्टिंग

और जानें

इलेक्ट्रोप्लेटिंग

और जानें

पॉलिशिंग

और जानें

एनोडाइजिंग

और जानें

पाउडर कोटिंग

और जानें

इलेक्ट्रोपॉलिशिंग

और जानें

पासिवेशन

और जानें

ब्रशिंग

और जानें

ब्लैक ऑक्साइड

और जानें

हीट ट्रीटमेंट

और जानें

थर्मल बैरियर कोटिंग (TBC)

और जानें

टंबलिंग

और जानें

एलोडाइन

और जानें

क्रोम प्लेटिंग

और जानें

फॉस्फेटिंग

और जानें

नाइट्राइडिंग

और जानें

गैल्वेनाइजिंग

और जानें

यूवी कोटिंग

और जानें

लैकर कोटिंग

और जानें

टैफलॉन कोटिंग

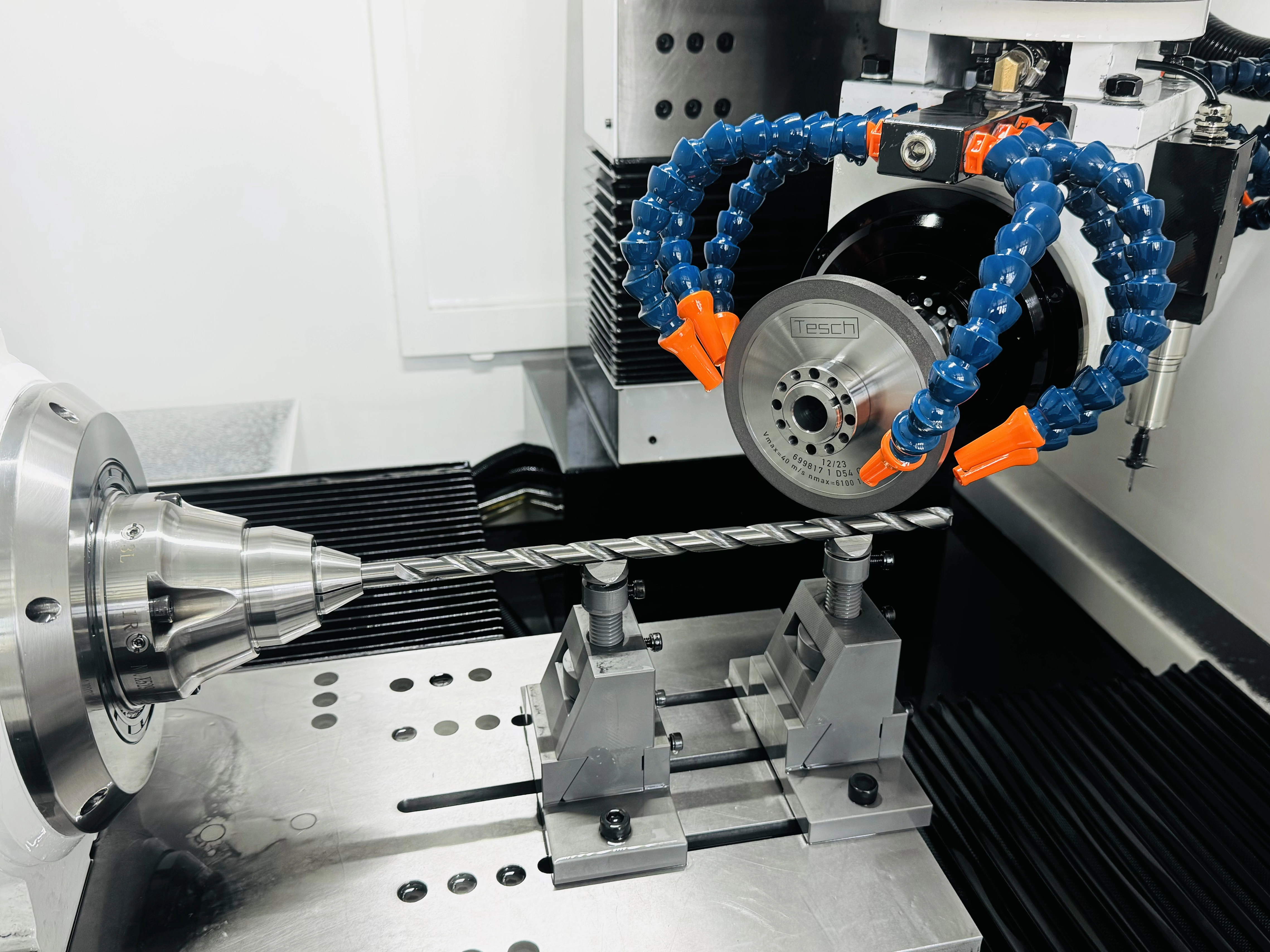

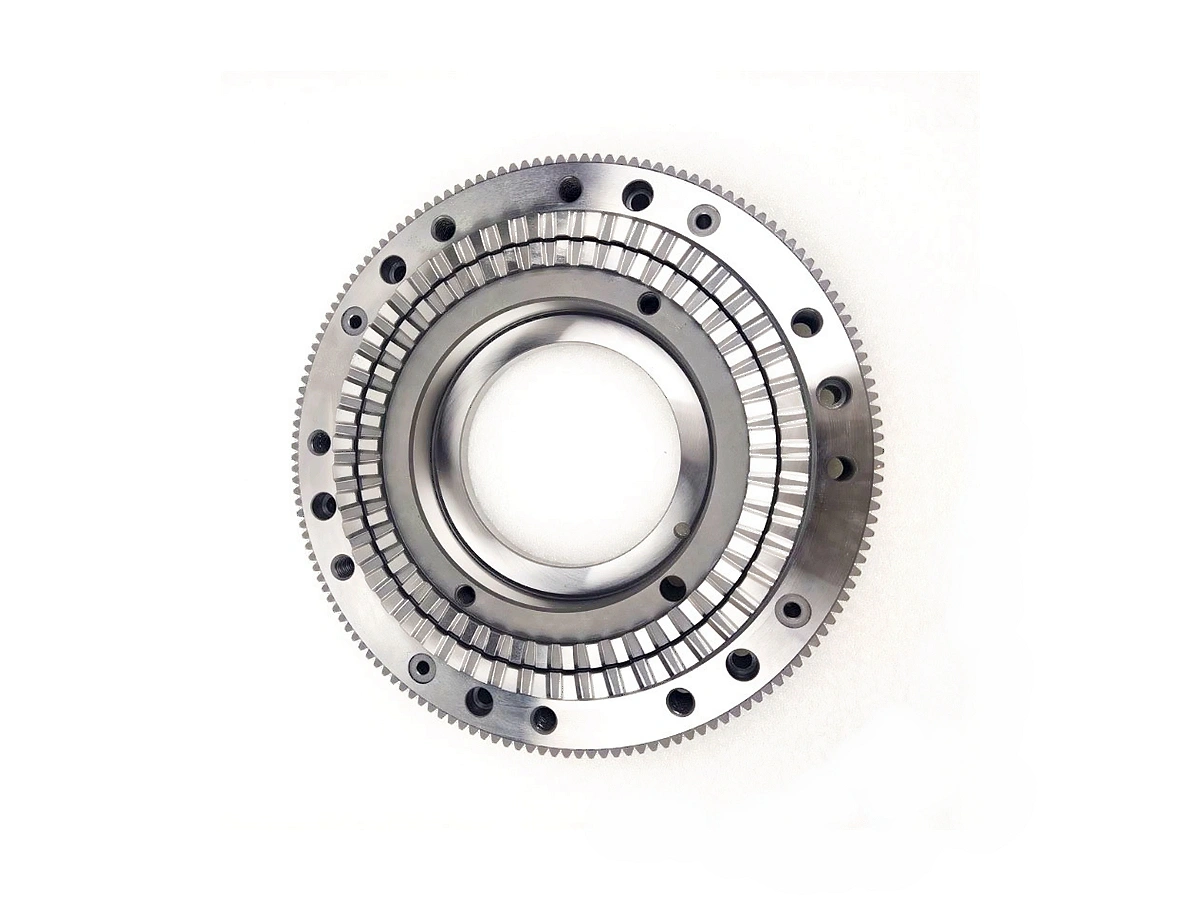

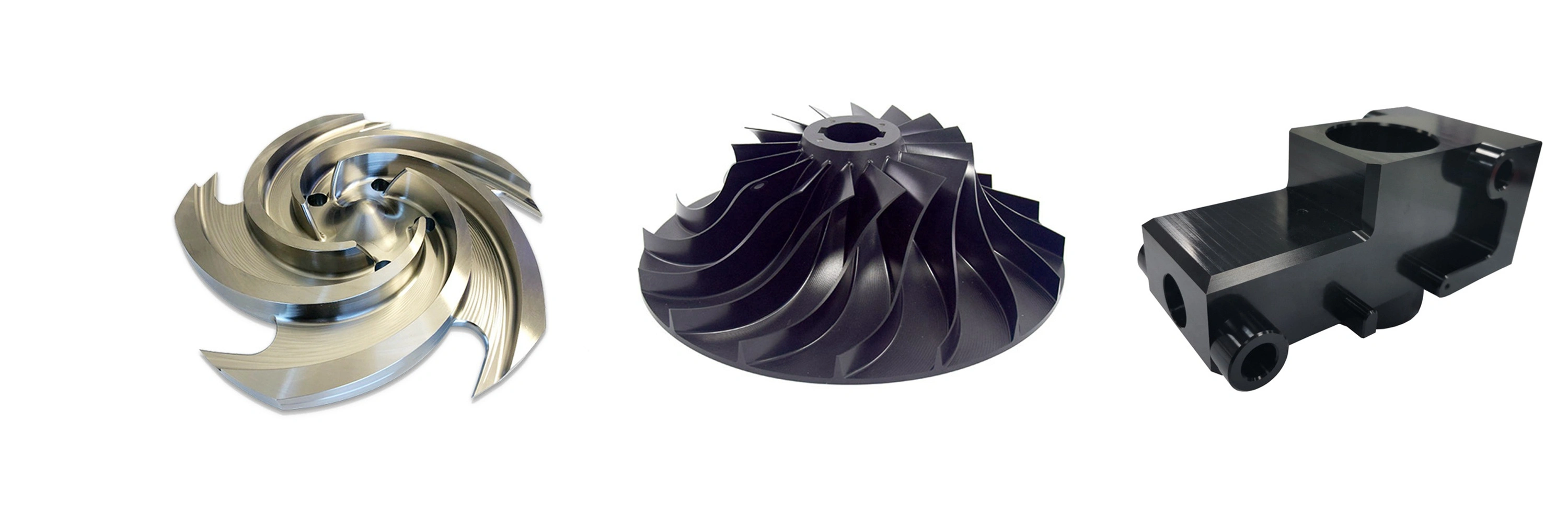

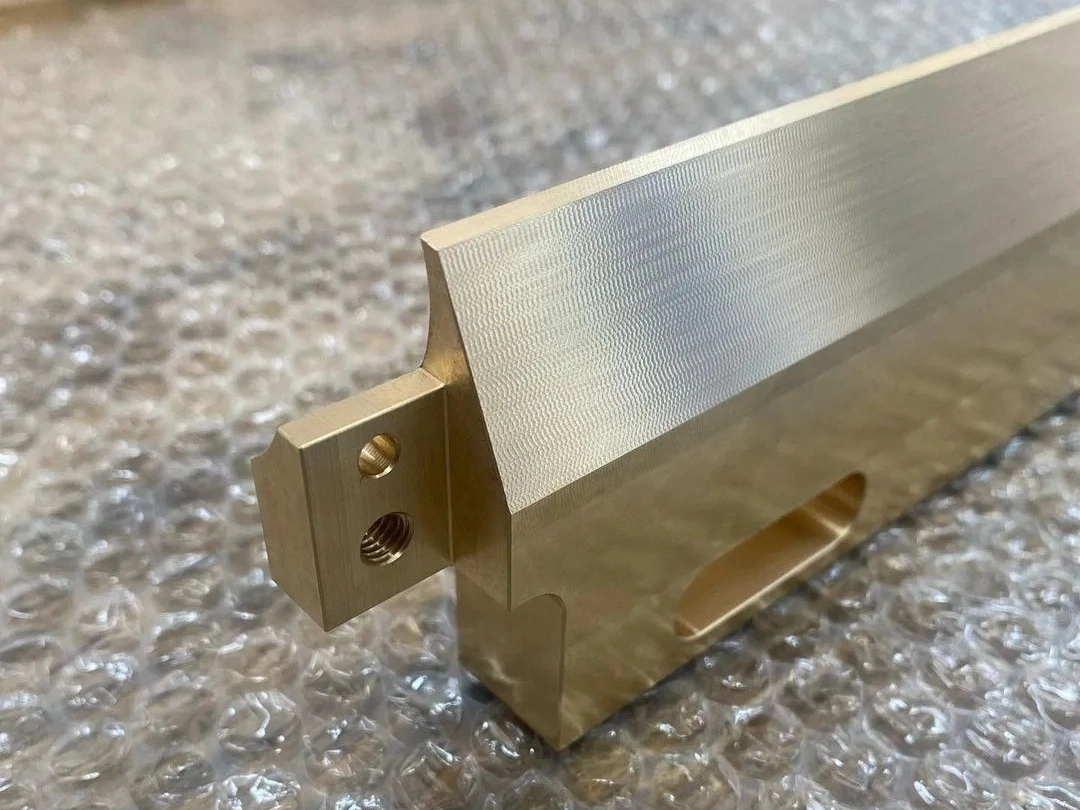

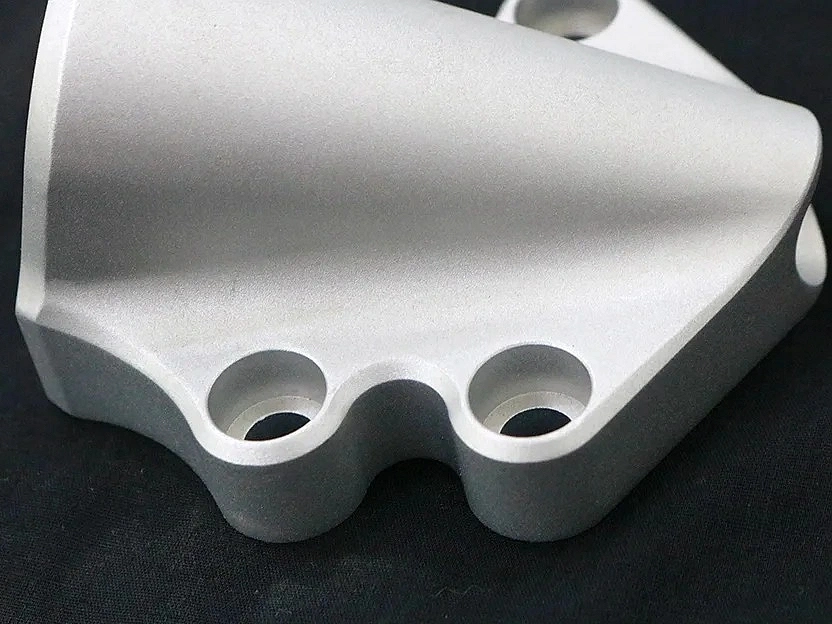

कस्टम CNC ग्राइंडिंग कंपोनेंट्स गैलरी

हमारी कस्टम CNC ग्राइंडिंग कंपोनेंट्स गैलरी में सटीकता से निर्मित पार्ट्स जैसे गियर्स, शाफ्ट्स, और बेयरिंग्स शामिल हैं, जिनमें बेहतरीन सटीकता और चिकनी सतहें हैं। प्रत्येक कंपोनेंट हमारे कड़े टॉलरेंस और जटिल विनिर्देशों को पूरा करने में दक्षता दिखाता है।

आज ही नया प्रोजेक्ट शुरू करें

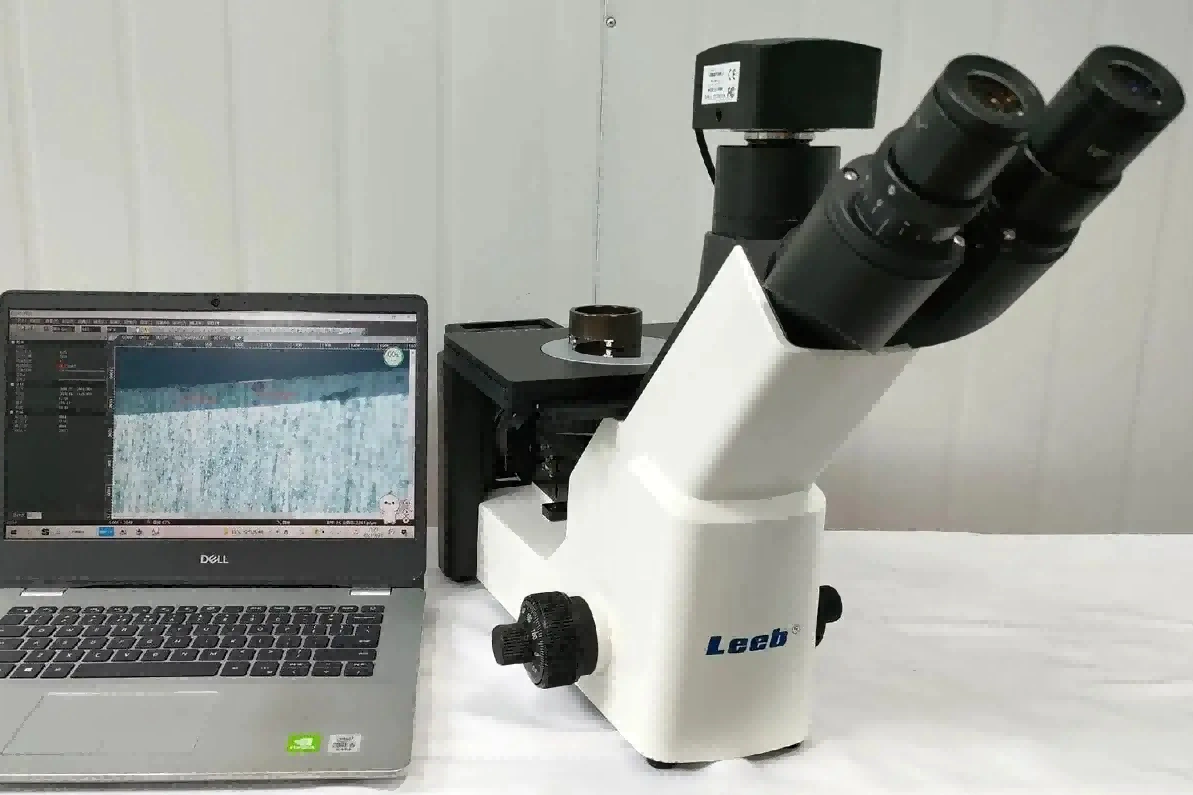

CNC ग्राइंडिंग टॉलरेंस

CNC ग्राइंडिंग टॉलरेंस महत्वपूर्ण कंपोनेंट्स के लिए सटीक आयाम और उच्च गुणवत्ता वाली फिनिश सुनिश्चित करता है। सामान्य टॉलरेंस ±0.1 मिमी तक होते हैं, जबकि प्रिसीजन ग्राइंडिंग ±0.005 मिमी से ±0.02 मिमी तक सटीकता प्राप्त करता है, जो एयरोस्पेस, ऑटोमोटिव, और मेडिकल जैसे उद्योगों की सख्त आवश्यकताओं को पूरा करता है।

CNC ग्राइंडिंग डिज़ाइन मार्गदर्शन

CNC ग्राइंडिंग डिज़ाइन मार्गदर्शन मशीनिंग दक्षता और उच्च सटीकता परिणाम सुनिश्चित करता है। मुख्य विचारों में रेडियस, होल डिज़ाइन, सतह फिनिश, टॉलरेंस, और दीवार मोटाई शामिल हैं, जो एयरोस्पेस, ऑटोमोटिव, और मेडिकल जैसे उद्योगों के लिए सटीक कंपोनेंट उत्पादन सक्षम करते हैं।

Frequently Asked Questions

संबंधित ब्लॉग एक्सप्लोर करें

संबंधित संसाधन एक्सप्लोर करें

समाधान

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.