कस्टम पार्ट्स मैन्युफैक्चरिंग समाधान

रोबोटिक्स कंपोनेंट्स मैन्युफैक्चरिंग सेवा

Neway CNC मशीनिंग, 3D प्रिंटिंग, वैक्यूम कास्टिंग, डाई कास्टिंग, और इंजेक्शन मोल्डिंग का उपयोग करके रोबोटिक्स कंपोनेंट्स मैन्युफैक्चरिंग प्रदान करता है। हम उच्च परफॉर्मेंस और टिकाऊपन के लिए डिज़ाइन किए गए प्रिसिजन पार्ट्स डिलीवर करते हैं जो उन्नत रोबोटिक्स अनुप्रयोगों के लिए उपयुक्त हैं।

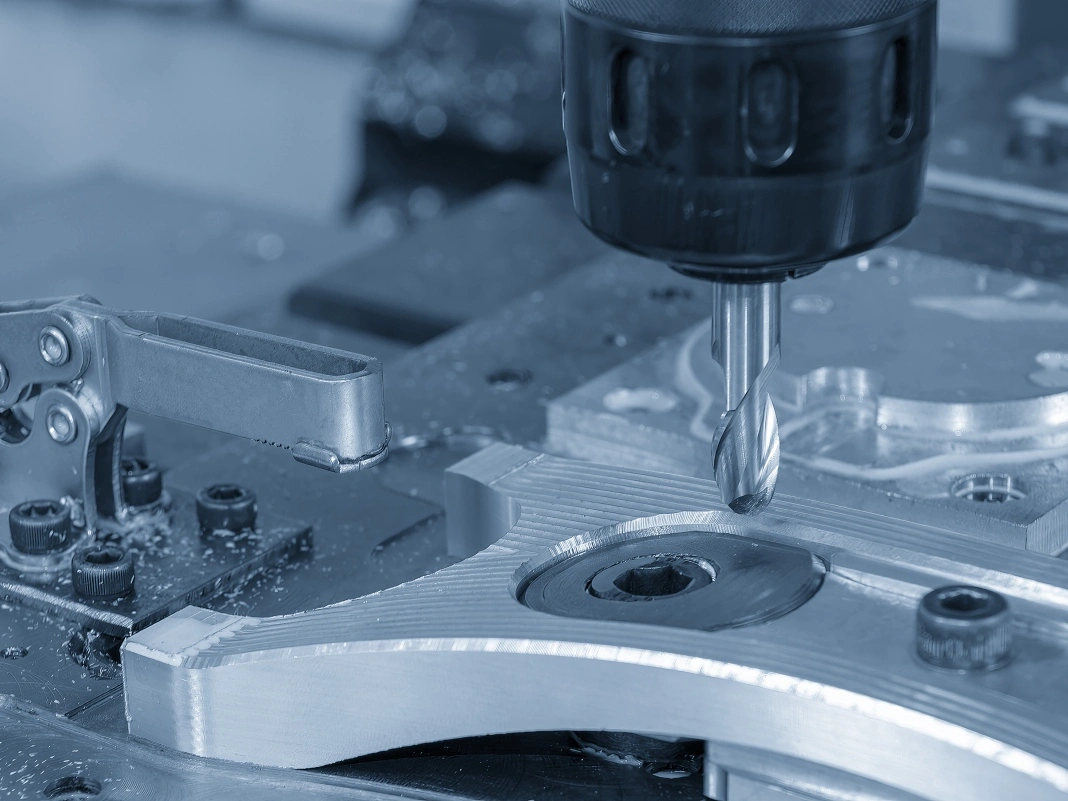

कस्टम रोबोटिक्स पार्ट्स मशीनिंग

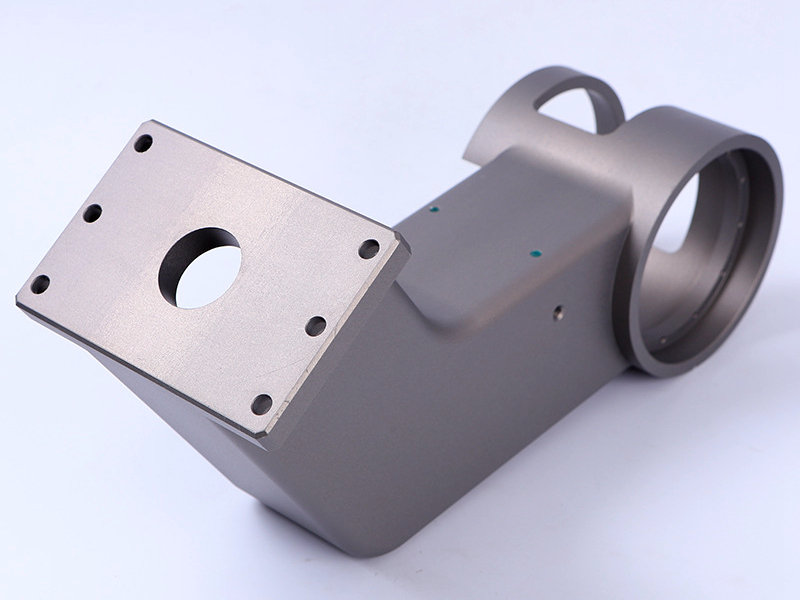

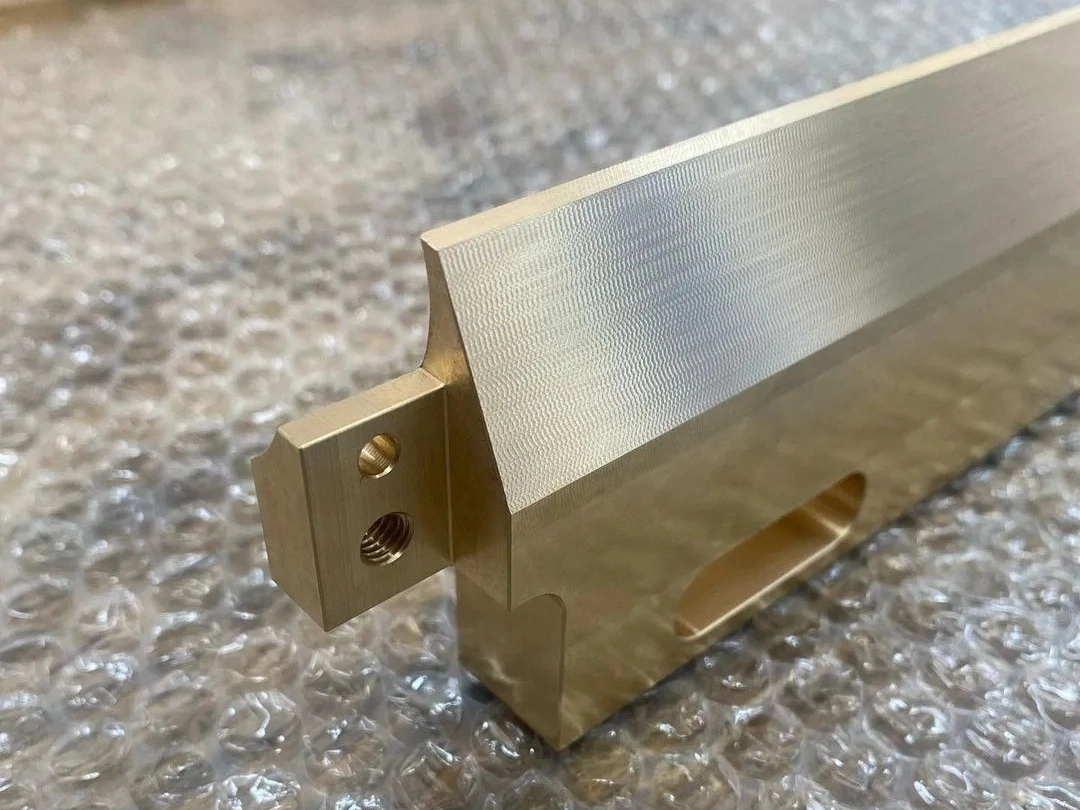

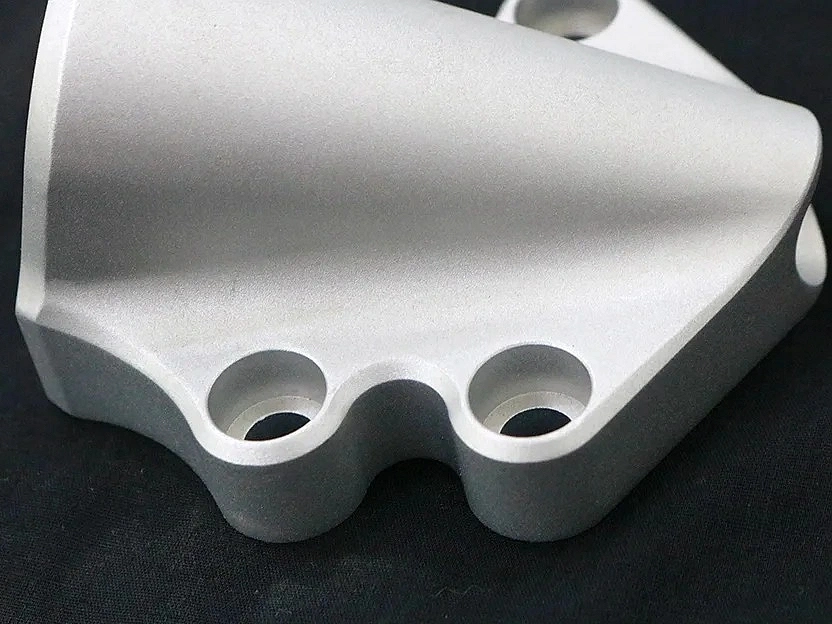

कस्टम रोबोटिक्स पार्ट्स मशीनिंग में मिलिंग, टर्निंग, ड्रिलिंग, और ग्राइंडिंग जैसे प्रिसिजन CNC प्रोसेस शामिल हैं जो रोबोटिक्स अनुप्रयोगों के लिए उच्च प्रदर्शन वाले पार्ट्स बनाते हैं। मल्टी-एक्सिस मशीनिंग और इलेक्ट्रिकल डिस्चार्ज मशीनिंग (EDM) का उपयोग करके हम जटिल, सटीक कंपोनेंट्स बनाते हैं जो रोबोटिक सिस्टम्स की कड़े तकनीकी आवश्यकताओं को पूरा करते हैं। हमारी सेवाएं विश्वसनीयता, टिकाऊपन और बेहतर कार्यक्षमता सुनिश्चित करती हैं।

रोबोटिक्स सामग्री चयन

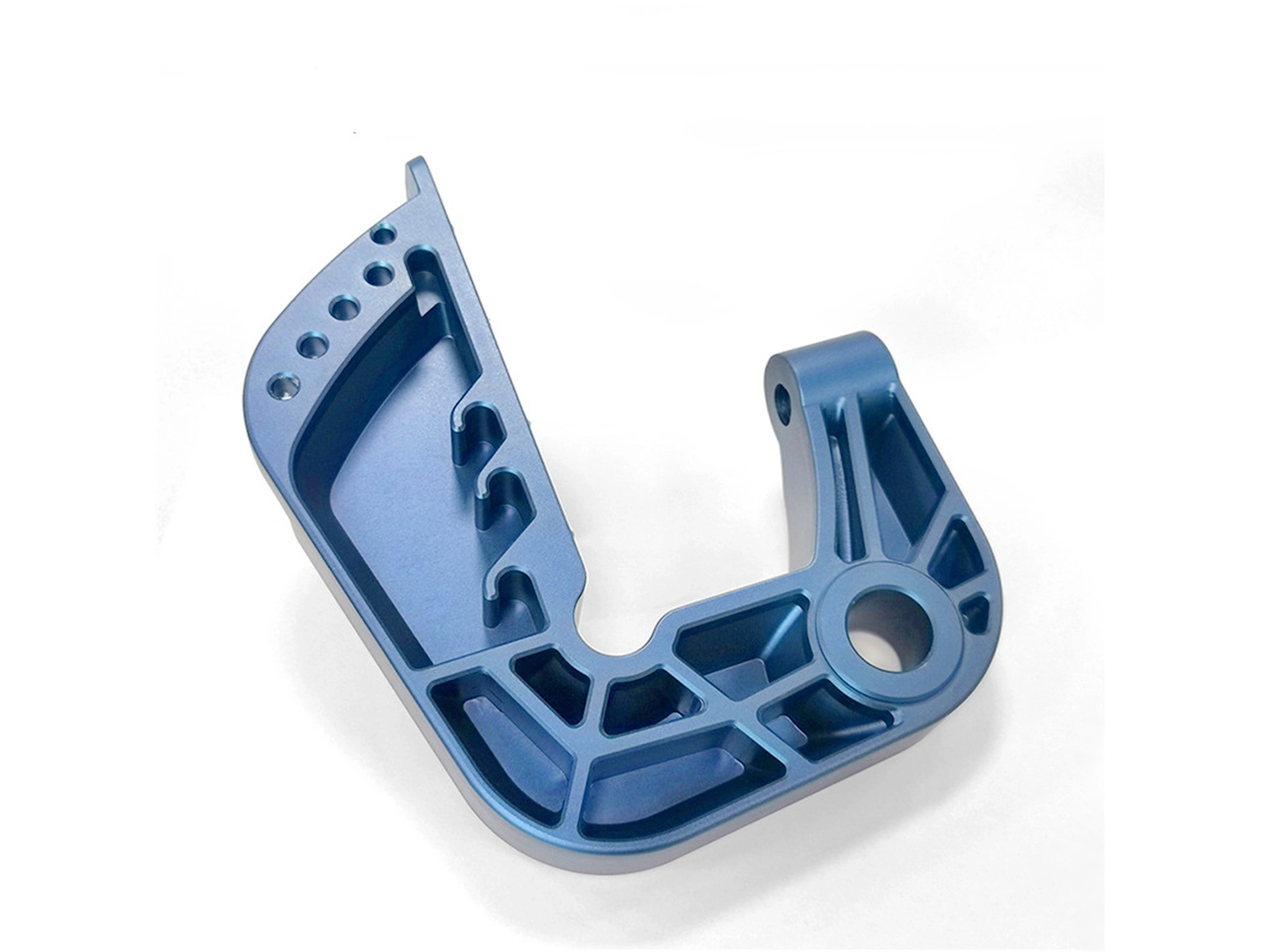

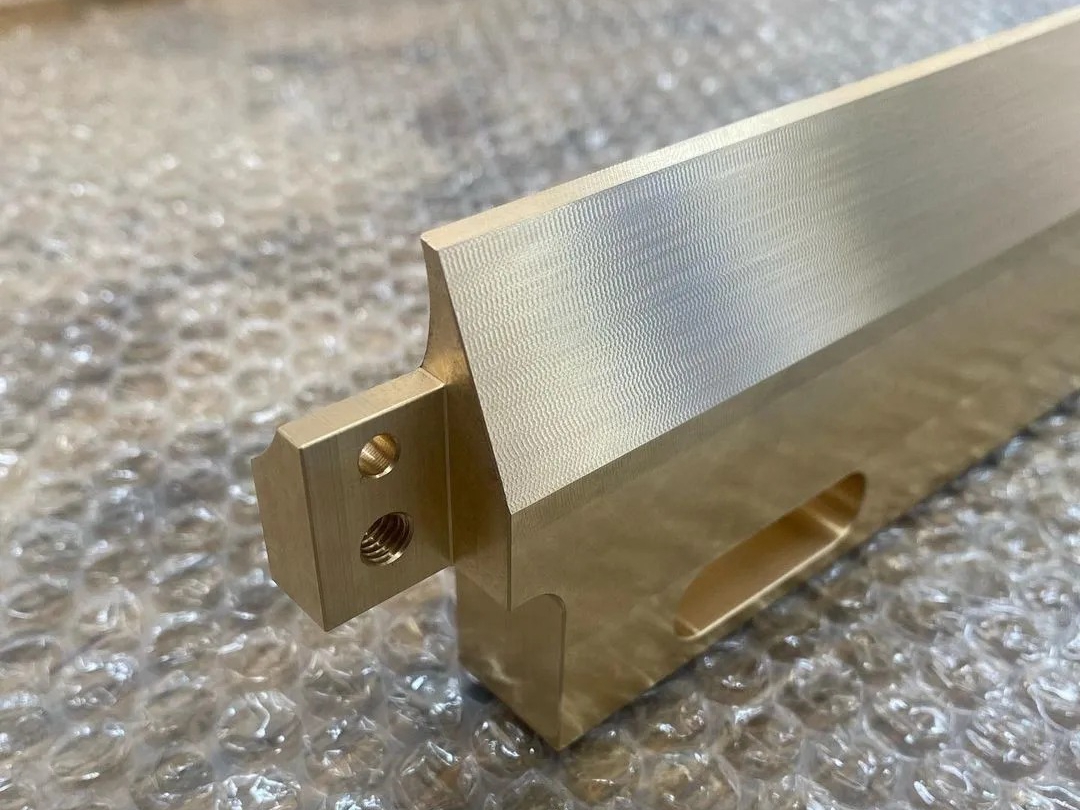

सुपरएलॉय, टाइटेनियम, एल्यूमीनियम, कॉपर, ब्रास, ब्रॉन्ज़, कार्बन स्टील, स्टेनलेस स्टील, प्लास्टिक, और सिरैमिक जैसी सामग्री रोबोटिक्स के लिए चुनी जाती हैं क्योंकि ये उच्च शक्ति, हल्के वजन, टिकाऊपन, घर्षण प्रतिरोध, और विद्युत चालकता प्रदान करती हैं, जिससे रोबोटिक्स अनुप्रयोगों में उच्च प्रदर्शन और सटीकता सुनिश्चित होती है।

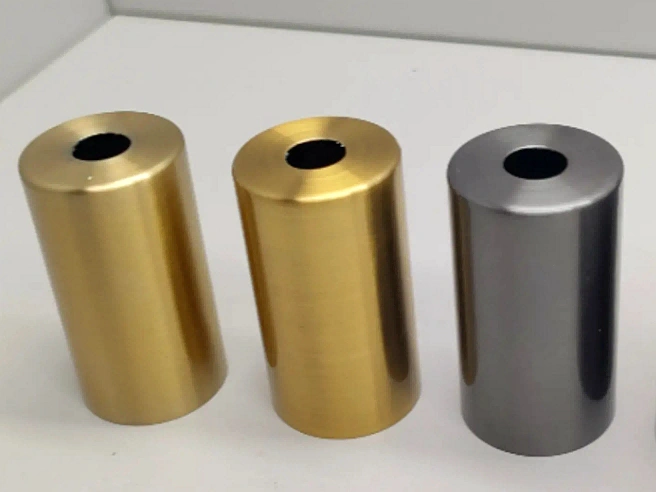

रोबोटिक्स उद्योग के लिए सतह उपचार

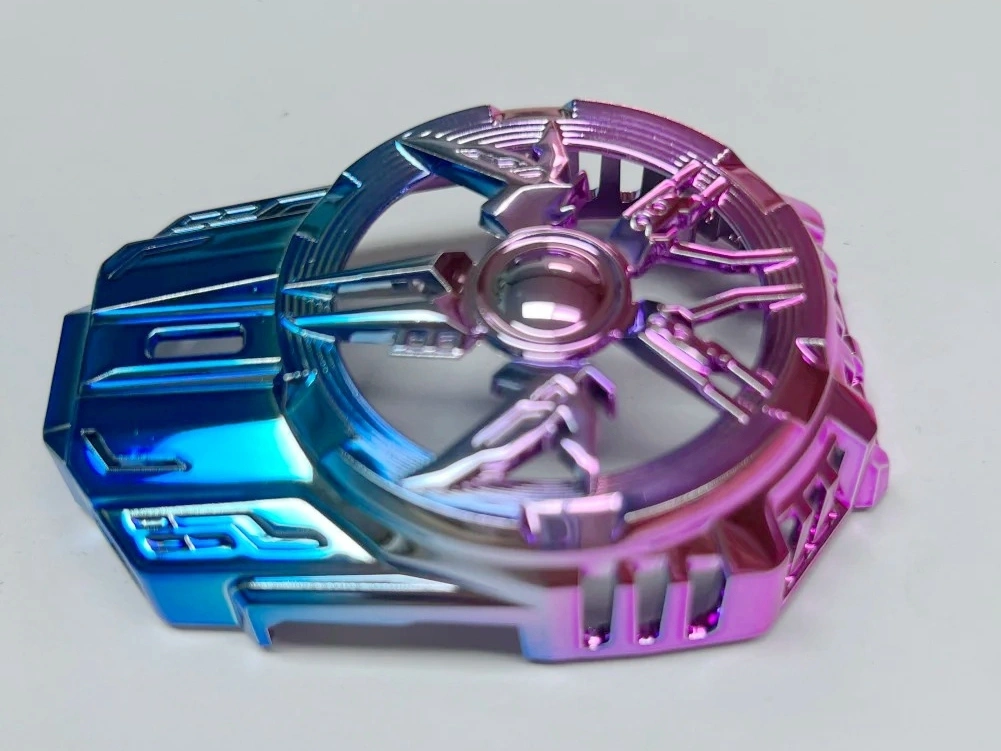

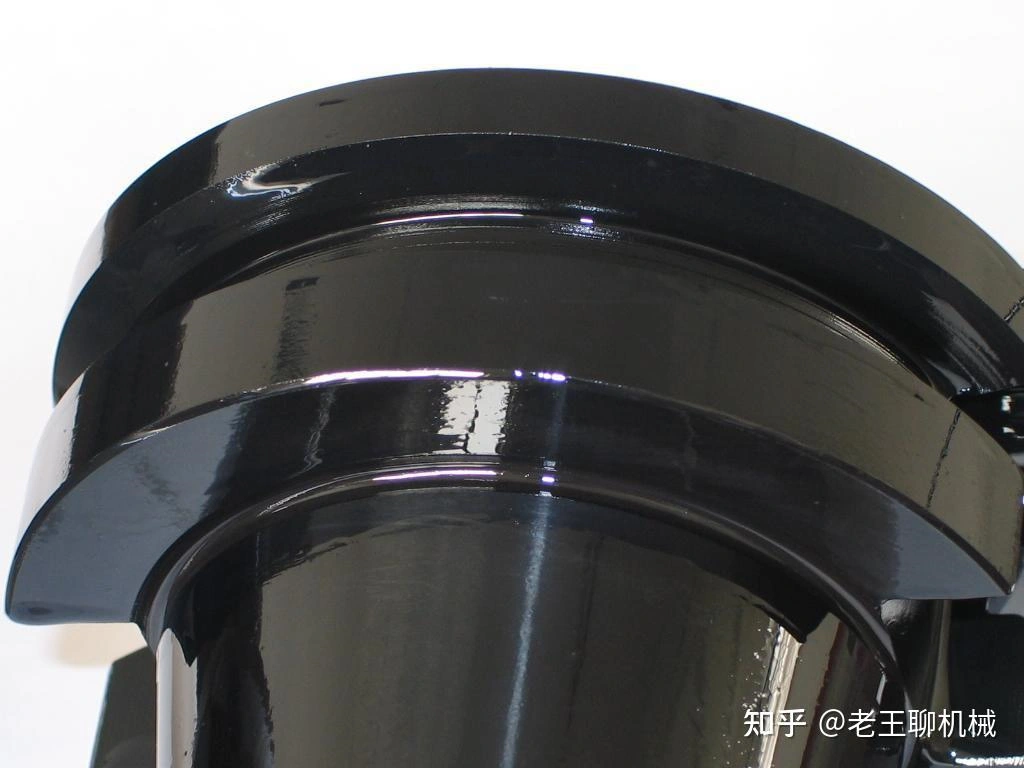

रोबोटिक्स उद्योग में सतह उपचार कंपोनेंट की टिकाऊपन, प्रदर्शन, और घर्षण व क्षरण प्रतिरोध को बढ़ाते हैं। एनोडाइजिंग, इलेक्ट्रोप्लेटिंग, PVD, और थर्मल बैरियर कोटिंग्स जैसी तकनीकें चरम पर्यावरणों से सुरक्षा सुनिश्चित करती हैं, जबकि पॉलिशिंग, ब्लैक ऑक्साइड, और सैंडब्लास्टिंग जैसी प्रक्रियाएं सौंदर्य और कार्यक्षमता में सुधार करती हैं। ये उपचार रोबोटिक पार्ट्स का जीवनकाल बढ़ाते हैं और मांग वाले अनुप्रयोगों में सुचारु संचालन सुनिश्चित करते हैं।

और जानें

थर्मल कोटिंग

और जानें

ऐज मशीनिंग फिनिश

और जानें

पेंटिंग

और जानें

PVD (फिजिकल वेपर डिपोजिशन)

और जानें

सैंडब्लास्टिंग

और जानें

इलेक्ट्रोप्लेटिंग

और जानें

पॉलिशिंग

और जानें

एनोडाइजिंग

और जानें

पाउडर कोटिंग

और जानें

इलेक्ट्रोपॉलिशिंग

और जानें

पासिवेशन

और जानें

ब्रशिंग

और जानें

ब्लैक ऑक्साइड

और जानें

हीट ट्रीटमेंट

और जानें

थर्मल बैरियर कोटिंग (TBC)

और जानें

टम्बलिंग

और जानें

अलोदिन

और जानें

क्रोम प्लेटिंग

और जानें

फॉस्फेटिंग

और जानें

नाइट्राइडिंग

और जानें

गैल्वेनाइजिंग

और जानें

UV कोटिंग

और जानें

लैकर कोटिंग

और जानें

टेपलॉन कोटिंग

रोबोटिक्स के लिए CNC मशीनिंग पार्ट्स

रोबोटिक्स अनुप्रयोगों में प्रिसिजन आवश्यक है, और CNC मशीनिंग एक्टुएटर्स, गियर्स, और फ्रेम्स जैसे मुख्य कंपोनेंट्स प्रदान करता है, जो औद्योगिक ऑटोमेशन और रोबोटिक सिस्टम्स के लिए प्रदर्शन और सटीकता को अनुकूलित करता है।

आज ही नया प्रोजेक्ट शुरू करें

प्रिसिजन रोबोटिक्स पार्ट्स मैन्युफैक्चरिंग विचार

रोबोटिक्स पार्ट्स का प्रिसिजन निर्माण उच्च सटीकता वाली सामग्री, कड़े सहिष्णुता, और उन्नत इंजीनियरिंग की मांग करता है ताकि सुचारू और प्रभावी गति सुनिश्चित की जा सके। यह गाइड विश्वसनीय और उच्च प्रदर्शन वाले रोबोटिक कंपोनेंट्स बनाने के लिए आवश्यक मैन्युफैक्चरिंग विचारों को रेखांकित करता है।

रोबोटिक्स पार्ट्स डिज़ाइन गाइड

रोबोटिक्स के लिए पार्ट्स डिज़ाइन में सटीकता, टिकाऊपन, और प्रदर्शन की आवश्यकता होती है। यह गाइड विश्वसनीय और प्रभावी रोबोटिक कंपोनेंट्स बनाने के लिए प्रमुख इंजीनियरिंग सिद्धांतों को रेखांकित करता है, जिसमें सामग्री, सहिष्णुता, गति डिज़ाइन, और अनुपालन शामिल हैं।

Frequently Asked Questions

संबंधित संसाधन एक्सप्लोर करें

समाधान

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.