定制CNC加工零件应用:11大行业解决方案

引言

定制 CNC 数控加工在现代工业制造中发挥着至关重要的作用,能够为各行各业生产高精度零部件。从航空涡轮叶片到医疗外科工具,CNC 加工具备出色的尺寸精度、一致性与材料适用性,是原型开发和批量生产的理想工艺选择。

在 Neway,我们专注为航空、能源、汽车等苛刻领域提供完整的 CNC 数控加工服务。通过整合高端设备与完善的过程控制,我们的 精密加工解决方案 能够满足复杂几何结构和各类行业标准的严格要求。

1. 航空:高温工况与轻量化 CNC 零部件

在航空航天领域,CNC 加工可以实现复杂几何形状和严苛公差,对安全性和性能都至关重要。钛合金、Inconel 高温合金和铝合金等材料因其优异的比强度和耐热性而被广泛采用。

典型应用:

涡轮叶片:通常采用 Inconel 718 或 Hastelloy X 等耐热高温合金加工成型,对叶型轮廓要求极高,以优化气流并承受超过 1000°C 的工作温度。

机体结构件:由 7050 铝合金或 5 级钛合金(Titanium Grade 5)加工而成的轻量化结构,在不显著增加重量的前提下提升整体强度。

发动机零件:如压气机盘和喷油器等高应力部件通常采用 极紧公差 加工,公差往往控制在 ±0.005 mm 以内,以满足严格的法规和工况要求。

Neway 借助先进的 多轴 CNC 加工 能力,尤其擅长加工复杂轮廓和下刀困难区域,这些结构常规工艺几乎无法实现。

2. 电力与能源:面向能源系统的高精度关键零部件

CNC 加工是制造热电、核电以及可再生能源系统高性能零部件的基础。这些部件在高载荷、腐蚀介质及极端温度下服役,对材料与尺寸稳定性有着毫不妥协的要求。

典型应用:

燃气涡轮部件:采用 Inconel、Rene 系列等耐热 高温合金 精密加工,同时兼顾气动效率和抗热疲劳性能。

换热器:由 铜合金 和不锈钢 CNC 铣削成型的冷却板、管板,在保证高效换热的同时,在压力波动工况下保持结构稳定。

涡轮密封圈:采用 Stellite 6 等耐磨合金 CNC 精加工而成的关键间隙件,能在热循环条件下实现极小摩擦损失和更长使用寿命。

借助 精密 CNC 磨削服务,Neway 可确保密封面和接触面达到所需的平面度与圆度,为密封装配提供可靠基础。

3. 石油与天然气:严苛环境下的高可靠性 CNC 零部件

在石油天然气行业,上下游工况普遍面临极高压力、强腐蚀和严重磨损。CNC 加工通过高强度材料与专用涂层组合,确保在恶劣环境中实现长期稳定运行。

典型应用:

阀门部件:采用高精度 CNC 车削并结合 电解抛光 工艺加工的阀芯、阀座等零件,可实现平稳流量调节与优异抗腐蚀性能,常用材料包括双相不锈钢与 Inconel 625。

耐蚀管路:通过 CNC 铣削加工的管接头与螺纹接头通常配合 钝化 处理,是海上平台与炼化装置中关键的连接元件。

钻头:由工具钢或硬质合金基复合材料精磨成型的钻头,通过 CNC 加工确保同心度与表面耐磨性,满足深井钻进的严苛要求。

Neway 强大的 CNC 车削 与 CNC 钻削 能力,可高效加工螺纹、内部流道和复杂几何结构,在烃类介质和机械冲击工况下仍能保持结构完整性。

4. 消费品:服务于日常生活的高外观 CNC 零部件

在消费品制造领域,CNC 加工不仅保证尺寸精度和功能可靠性,还能提供优异的外观与触感。其对金属与塑料等多种材料的加工能力,使产品设计更具灵活性,也便于维持批量生产的一致性。

典型应用:

消费电子:智能手机、笔记本电脑和相机框架等铝合金外壳通过 CNC 铣削加工实现结构强度与轻薄外观,随后可配合 阳极氧化 或 喷砂 等表面处理提升质感。

厨房电器:功能件如把手、支架与刀片多采用 不锈钢 CNC 加工,以获得优异的耐腐蚀性和机械强度,并结合 抛光 工艺实现精致外观。

凭借丰富的表面处理与精细加工经验,Neway 可为消费品牌提供可直接进入量产阶段的 CNC 原型件,并实现从试产到规模化生产的顺畅过渡。

5. 医疗器械:服务生命科技的超精密 CNC 加工

医疗器械对生物相容性、尺寸精度和法规符合性有极高要求。CNC 加工能够生产高公差等级的外科工具和植入物,常用高纯金属和高性能聚合物材料。

典型应用:

外科手术工具:如手术刀、镊子和骨钻等通常由 316L 不锈钢通过 多轴 CNC 加工 制造,以获得符合人体工学的外形和镜面级表面质量。

假体:个性化假体关节和固定支架通常采用 5 级钛合金(Titanium Grade 5)精铣加工,兼具高强度、轻量化和优异生物相容性,并可通过 PVD 涂层 进一步提升耐磨性。

骨科植入物:通过 CNC 车削与铣削工艺,稳定制造脊柱棒、骨钉及关节置换件等关键部件,并配合符合 ISO 标准的三坐标检测系统(CMM)验证尺寸完整性与重复性。

Neway 针对每一件 医用级 CNC 零件 提供全流程追溯与过程控制,从原型开发到量产,全程满足行业特定要求。

6. 农业机械:面向重载设备的耐用 CNC 解决方案

农业机械通常在高磨损、扬尘与冲击频发的环境中运行。CNC 加工为其提供所需的结构强度与耐磨寿命,确保设备运行可靠、维护周期更长。

典型应用:

拖拉机零件:传动轴、衬套与动力总成部件通常采用 1045、4140 等合金钢进行 CNC 铣削与车削,以承受田间作业中的冲击载荷与疲劳载荷。

机架结构件:播种机、喷雾机等设备上的结构连接件和安装支架多采用 碳钢 板材或铸件 CNC 加工,再配合 发黑处理 或喷涂工艺提升防护能力。

通过将镗削、钻削与磨削工艺整合,Neway 能够交付经久耐用的 CNC 零件,以满足季节性高强度作业和复杂地形工况的需求。

7. 汽车:为可靠性、速度与安全而生的 CNC 加工

汽车行业的零部件需在动态载荷、热循环以及严苛装配公差下长期工作。CNC 加工是制造各类功能件和性能升级部件的关键工艺。

典型应用:

发动机零件:活塞、壳体和机油泵轴等部件通常以 1040、1060 等碳钢加工,随后通过 磨削 工艺确保圆度和表面完整性。

底盘件:如结构支座与横梁等通常由铝合金 CNC 铣削成型,再进行 阳极氧化 以提升耐腐蚀性。

排气系统:不锈钢管路组件(如排气歧管与支架)多采用 CNC 车削 加工,并结合 发黑处理 或 热处理,以增强热稳定性和防护性能。

凭借在高强度材料和多工序组合方面的丰富经验,Neway 能为主机厂和售后市场提供一致质量的零部件,包括复杂总成和定制 原型件。

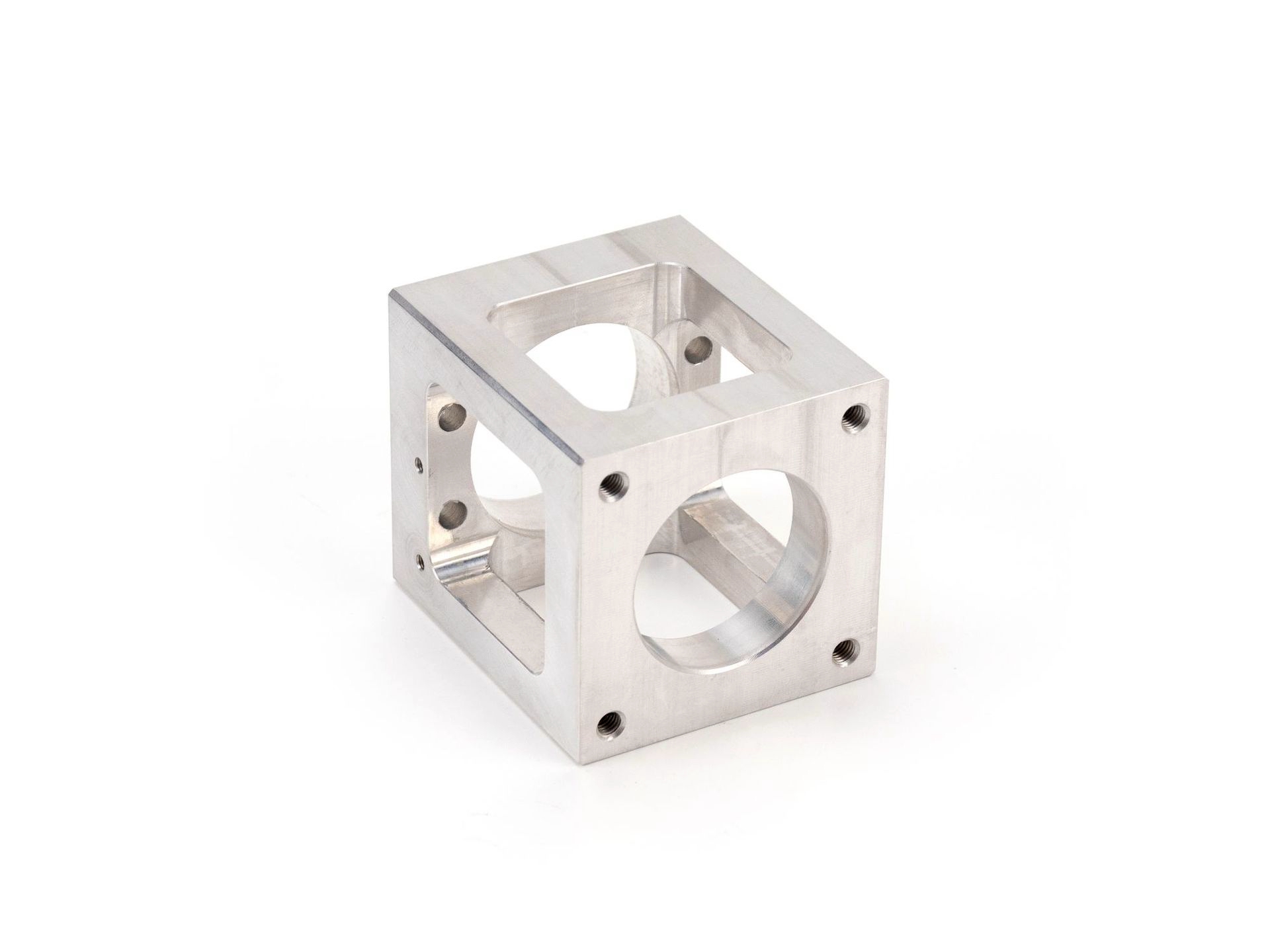

8. 机器人:支撑智能运动系统的精密 CNC 加工

机器人系统需要轻量、紧凑且高精度的机械结构,以确保快速响应、重复定位精度和安全性。CNC 加工可以为机器人总成提供微米级精度,并灵活集成多种材料。

典型应用:

机械臂:采用 6061 铝合金 CNC 铣削加工的连杆和壳体,借助 多轴加工 实现多自由度运动所需的轻量化与刚度。

结构连接件:自动化级机械臂中广泛使用 CNC 车削的嵌件和支架,既满足 严格公差 要求,又通过 阳极氧化 或 粉末涂层 等表面处理获得更高防护性能。

Neway 通过兼顾机械精度与可扩展的 小批量制造 能力,为机器人 OEM 提供从原型验证到批量放大的理想支持。

9. 自动化:智能制造中的高精度 CNC 零部件

自动化系统集成了传感器、执行器与控制硬件,这些组件依赖紧密的机械配合与稳定质量。CNC 加工可确保装配平台具备高精度定位、良好重复性和简洁的结构布置。

典型应用:

传感器壳体:多采用铝合金和塑料材料,通过 多轴加工 获取复杂内部结构和各类接口孔位。

控制面板:PLC 与操作界面的安装结构多采用碳钢或不锈钢 CNC 加工,再结合 发黑处理 或 喷漆 以提升耐久性与外观。

Neway 提供经 CMM 认证的自动化级零部件,确保在工业环境下稳定运行,并在批次间保持极小的质量波动。

10. 工业设备:面向重载工况的高耐久 CNC 零件

重型机械与工厂设备需要经久耐用的 CNC 零部件,以承受高载荷、振动和磨蚀环境。合理的材料选择与表面工程设计是保证工业现场零件寿命的关键。

典型应用:

机械传动件:齿轮、拨叉、壳体与凸轮等部件通常由 碳钢 或合金钢精密加工,并配合 热处理 或 渗氮 等工艺提升强度与耐磨性。

泵体:叶轮和泵壳多采用 不锈钢 或青铜材料 CNC 铣削,以确保抗腐蚀能力和精确的流道轮廓。

Neway 通过稳定的 CNC 车削、镗削和磨削能力,为客户提供定制零件生产及老旧部件替换,确保尺寸的一致性与互换性。

11. 核工业:面向安全关键核电部件的 CNC 加工

核能系统对材料完整性、加工精度以及文件可追溯性都有极高要求。CNC 加工可以在辐照和高温环境下依然满足复杂几何与 ±0.005 mm 级别的高精度需求。

典型应用:

反应堆压力容器:采用耐辐照的 不锈钢 或 Inconel 高温合金 制造的容器法兰和上盖,通过 CNC 铣削与车削满足 ASME 第 III 卷等核级标准。

高温密封件:由 Stellite 和 Hastelloy 等合金加工而成的密封零件,再结合 热障涂层 处理,以获得优异的耐腐蚀、耐磨与隔热性能。

Neway 的核级 CNC 部件通过三坐标测量(CMM)、超声检测 和 X 射线检测 等手段进行验证,确保在极端工况下仍具备可靠的结构与尺寸稳定性。