Custom On Demand CNC Machining Service

Our Custom On-Demand CNC Machining Service offers flexible, high-precision machining solutions designed to meet the unique needs of your project. We offer from prototyping to one stop machining service.

- CNC Rapid Prototyping Service

- Low Volume CNC Machining Service

- CNC Machining Mass Production

- One Stop Machining Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

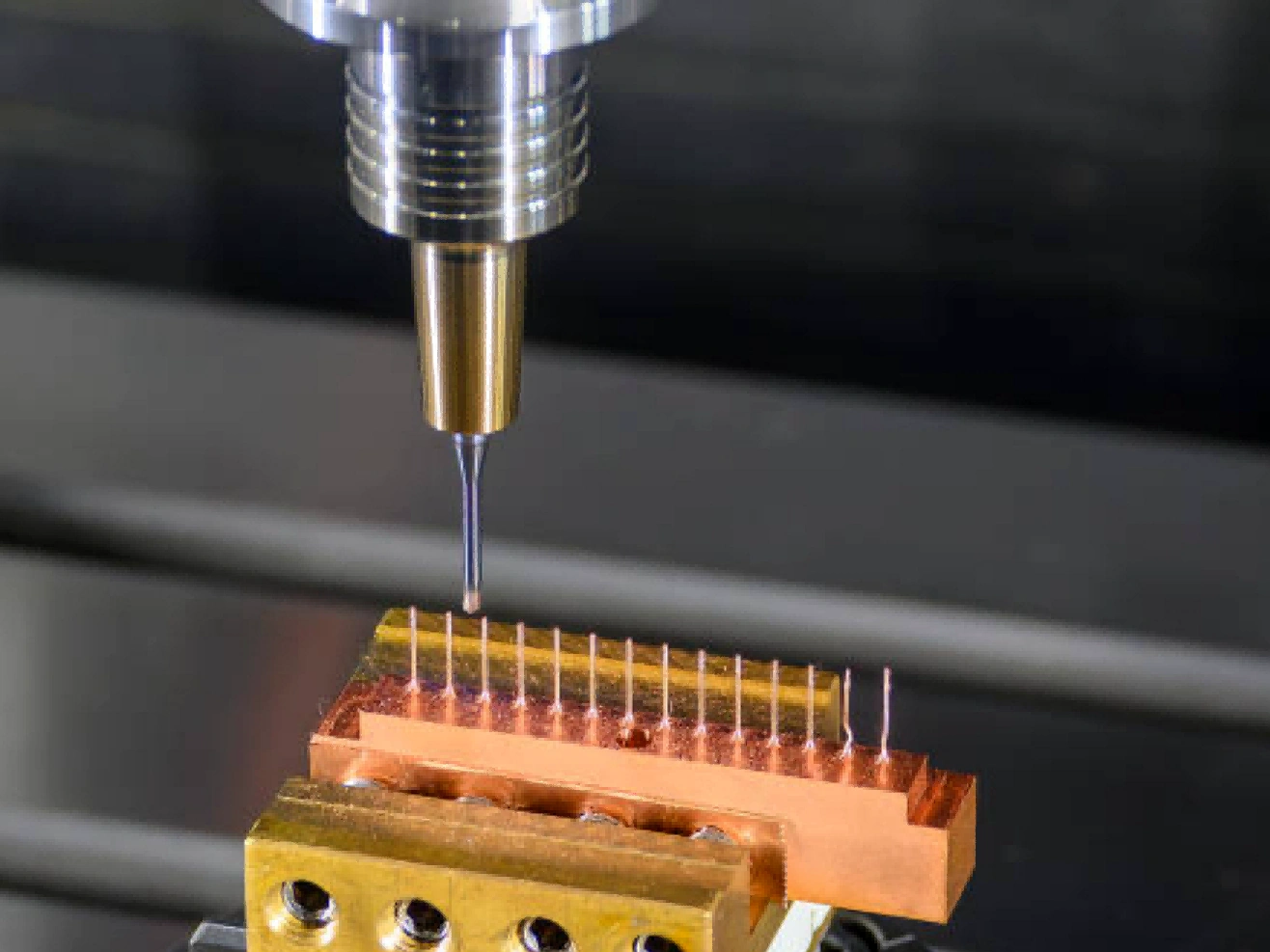

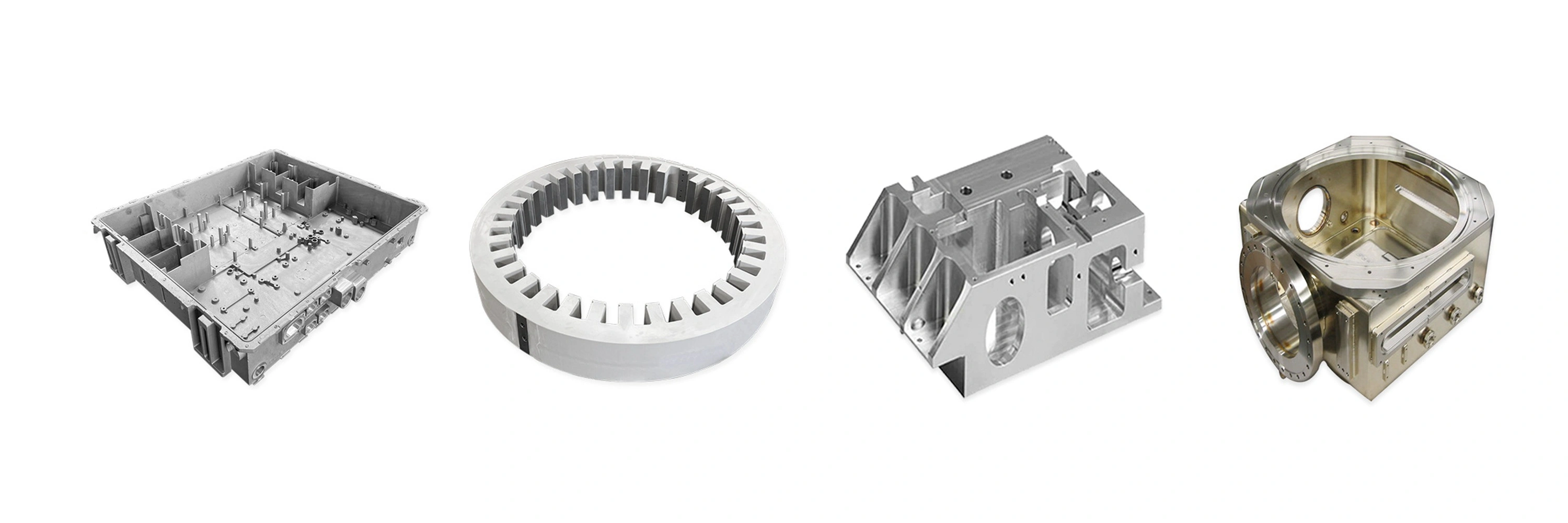

Custom Parts CNC Machining Service

Our Custom Parts CNC Machining Service delivers high-precision, tailored solutions for various industries. We specialize in manufacturing complex, custom-designed parts from metals like stainless steel, titanium, high-temperature alloys, and plastics and composites. Utilizing 3-axis, 4-axis, and 5-axis CNC machining, we achieve tight tolerances and intricate geometries with exceptional accuracy. Our services include rapid prototyping, small-batch production, and full-scale manufacturing, ensuring fast turnaround times and top-quality results.

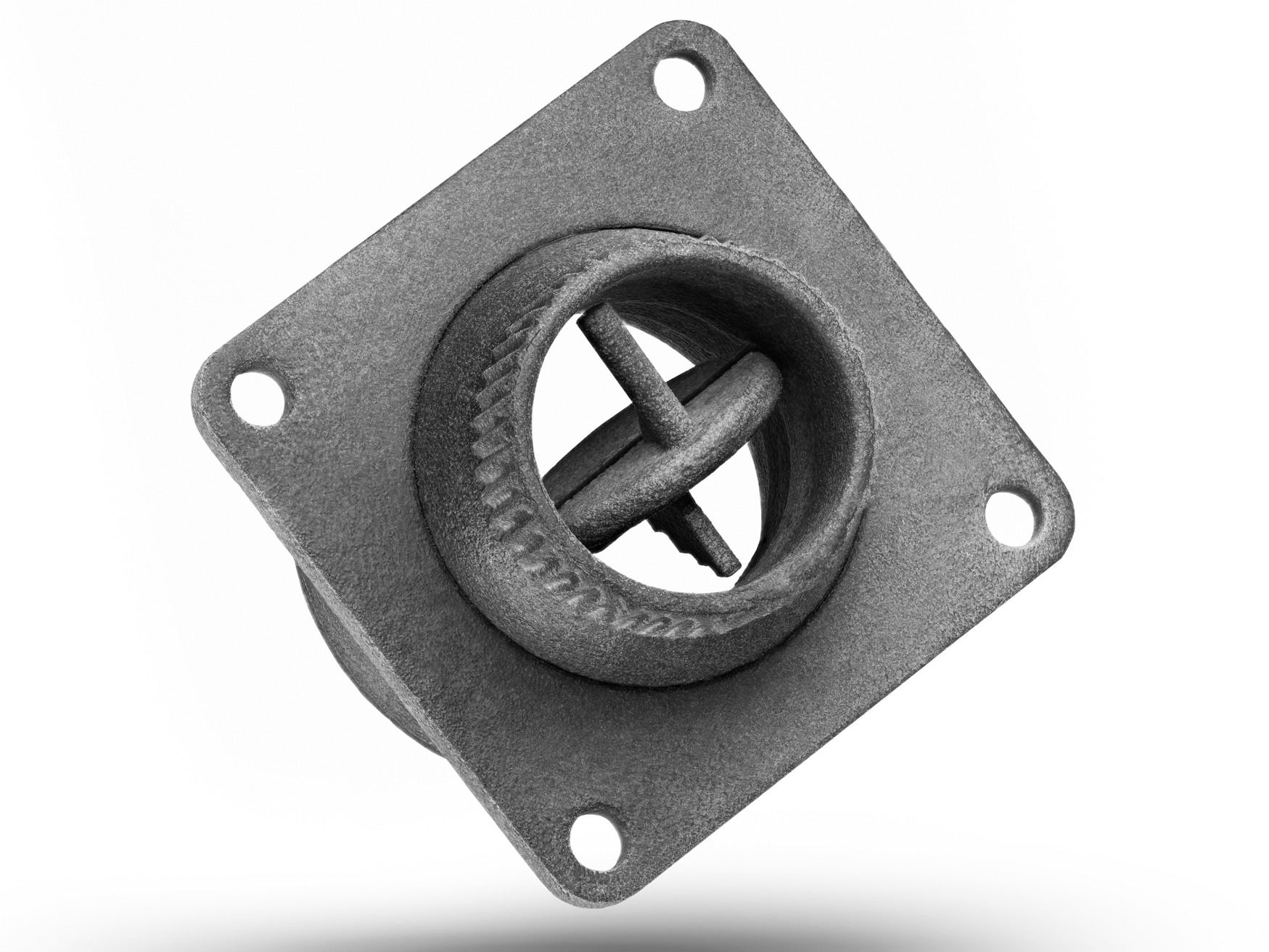

Custom Parts Rapid Prototyping

We specialize in CNC Machining Prototyping, 3D Printing, and Rapid Molding services to deliver high-precision prototypes quickly. Our advanced manufacturing techniques help streamline product development, ensuring accurate, reliable results. Whether you need functional prototypes, custom parts, or fast production, we provide tailored solutions to meet your design requirements and accelerate time-to-market.

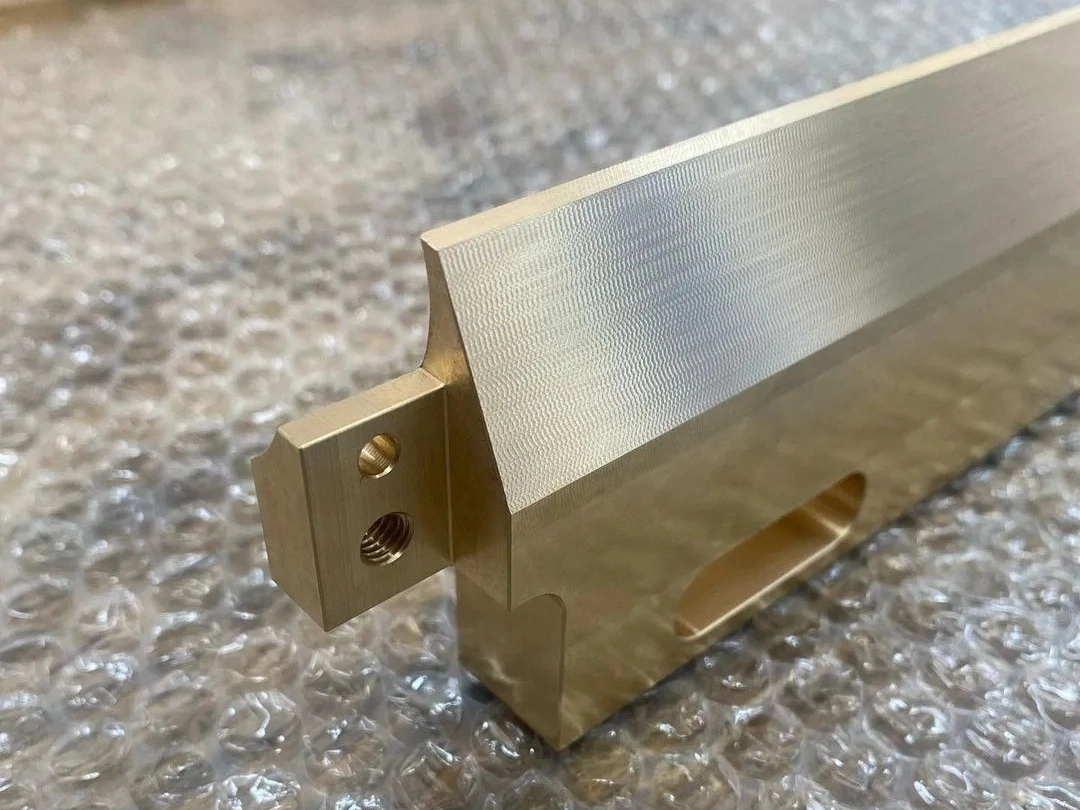

Machining Materials Available

We offer various machining materials for diverse industry needs, including metals, plastics, and composites. Our selection includes high-performance materials such as stainless steel (304, 316), aluminum alloys (6061, 7075), titanium alloys (Ti-6Al-4V, Ti-6-4), and nickel-based alloys (Inconel, Hastelloy) for aerospace, automotive, and high-temperature applications. We also work with engineering plastics like POM, ABS, and Nylon, as well as composite materials such as carbon fiber reinforced plastics (CFRP).

Surface Treatment for CNC Machined Parts

Surface treatment for CNC machined parts enhances performance, durability, and aesthetics. Common processes include polishing, which smooths surfaces for a shiny finish; anodizing, which increases corrosion resistance, especially for aluminum; and powder coating, providing a durable, decorative layer. Electropolishing improves smoothness and corrosion resistance, while passivation creates a protective oxide layer on stainless steel. PVD and electroplating offer decorative and functional coatings, such as gold or chrome. Other treatments like sandblasting, brushing, and black oxide improve surface texture, while heat treatment strengthens the material. These treatments optimize parts for specific industrial applications.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

Painting

Learn More

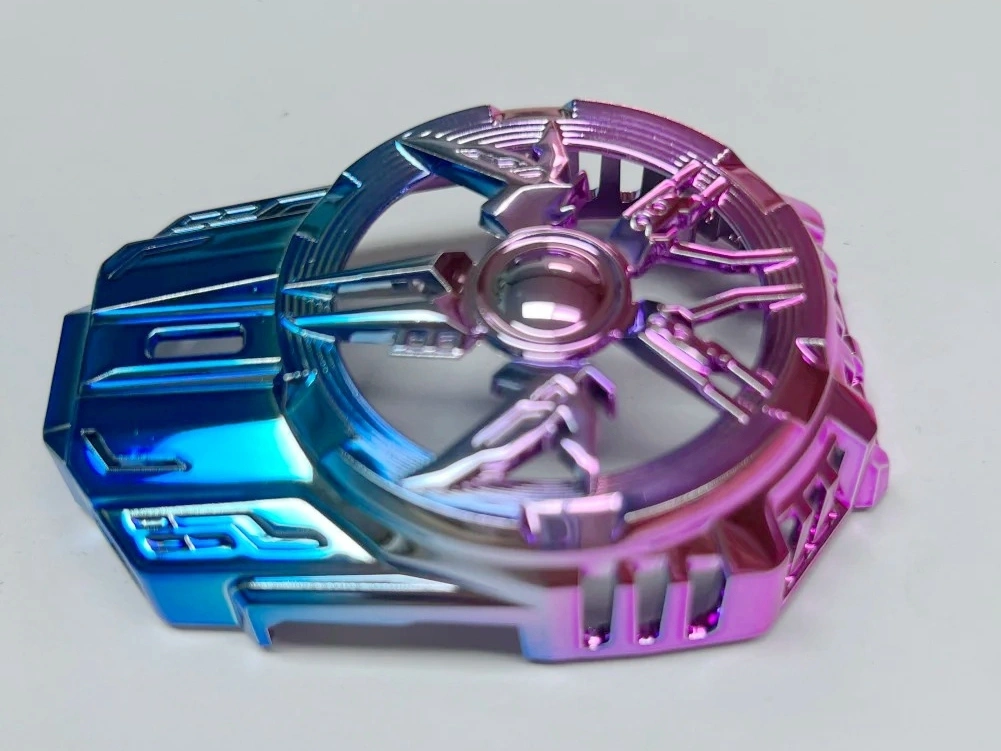

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

Electroplating

Learn More

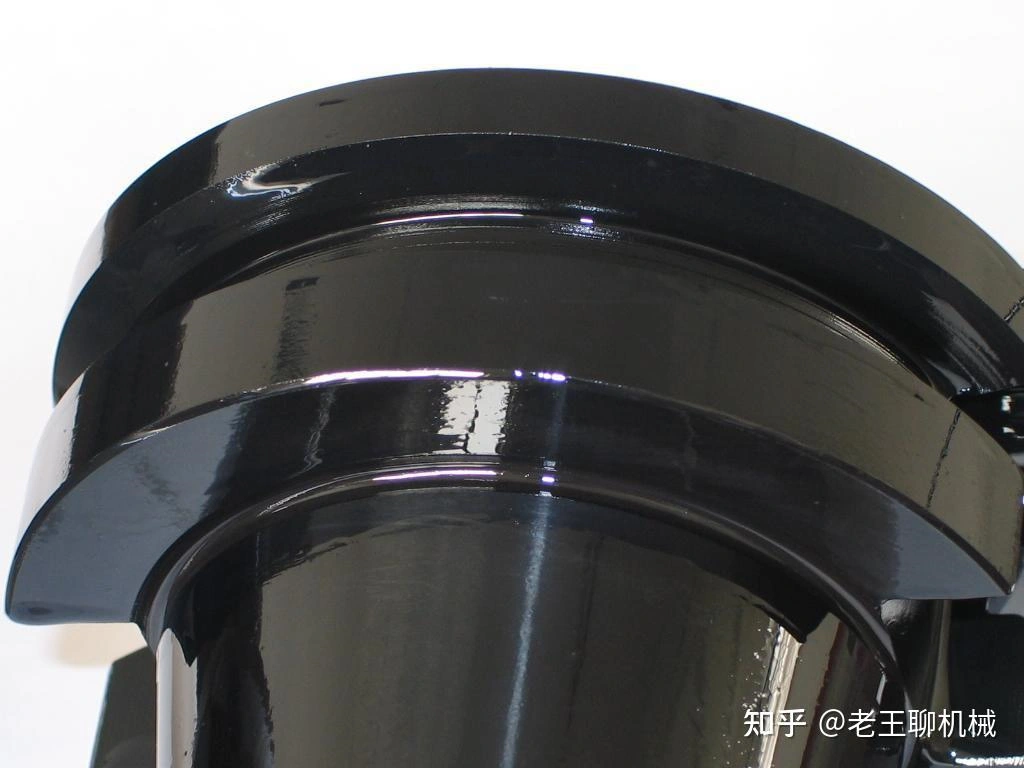

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

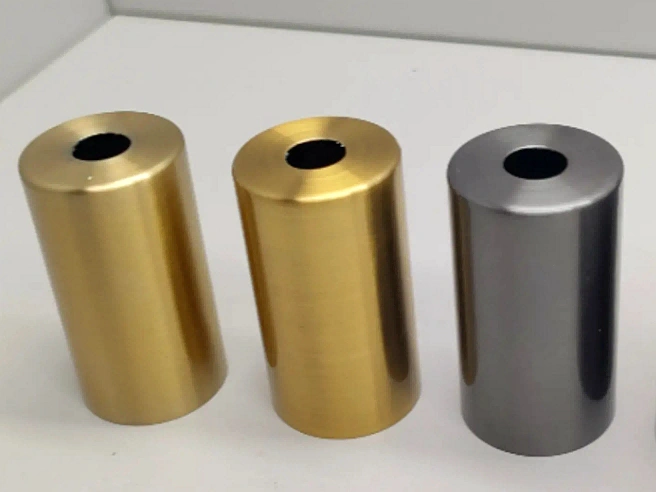

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

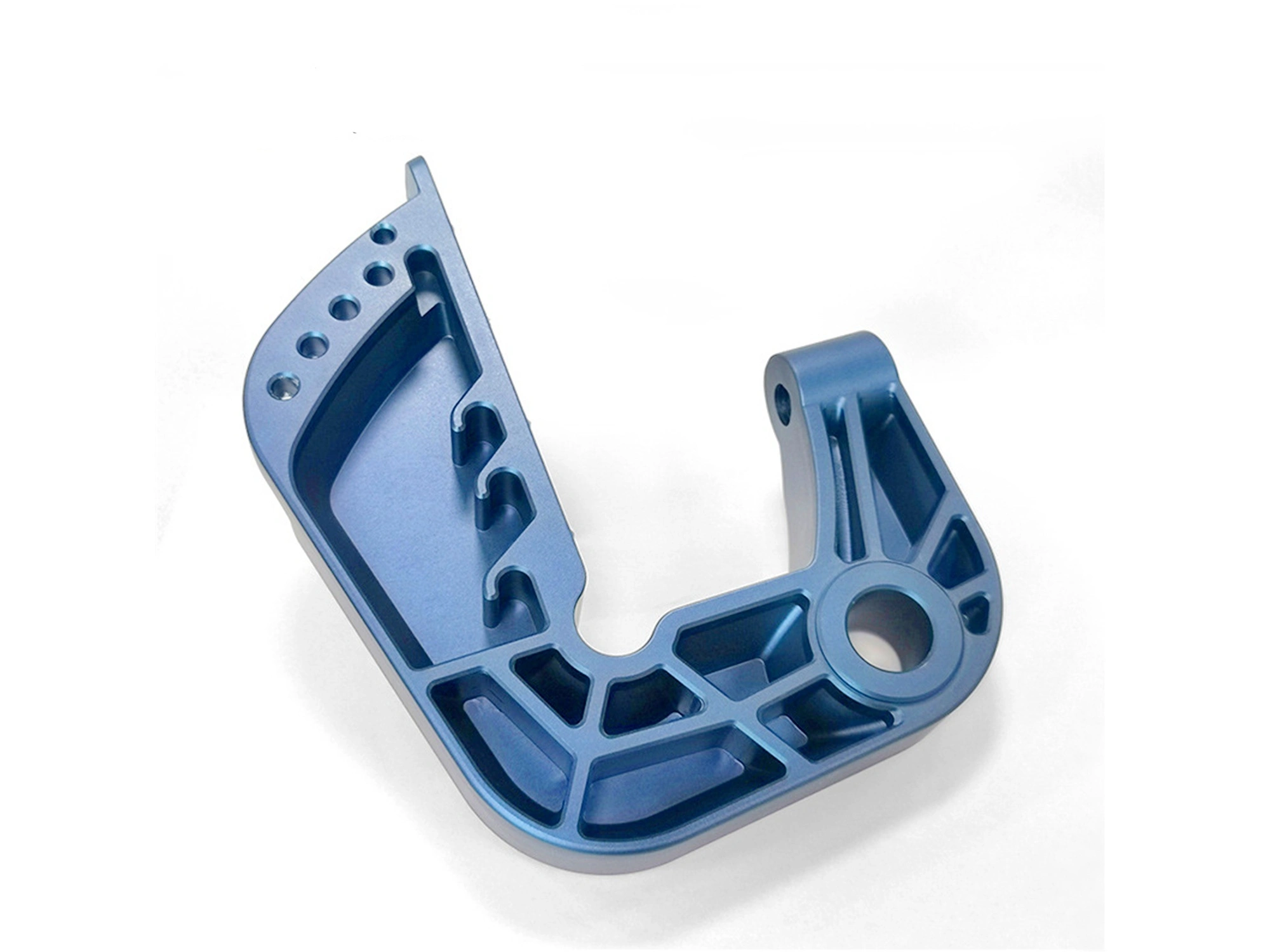

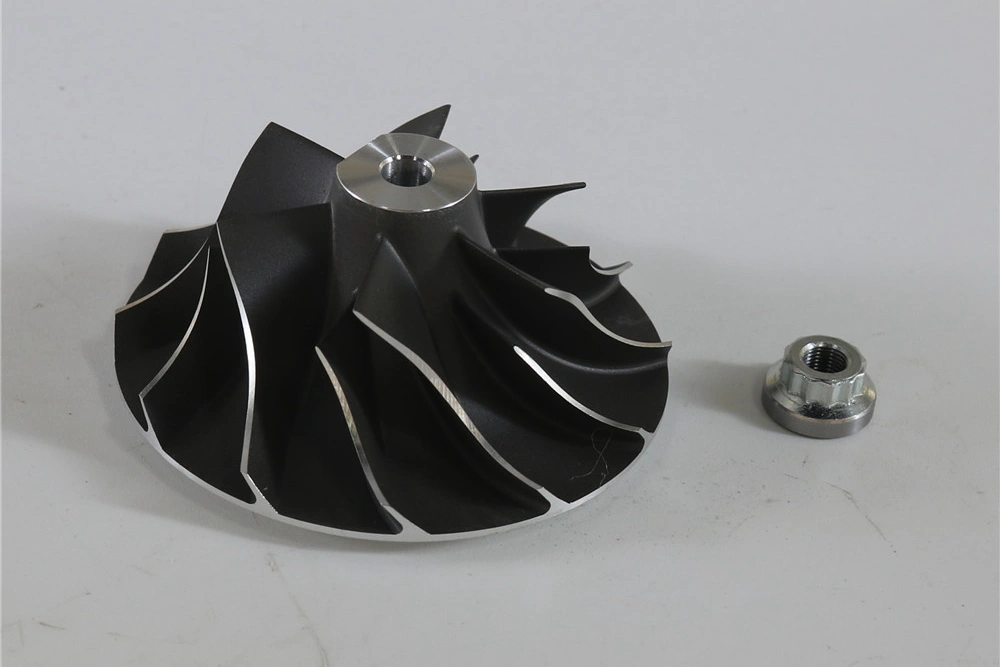

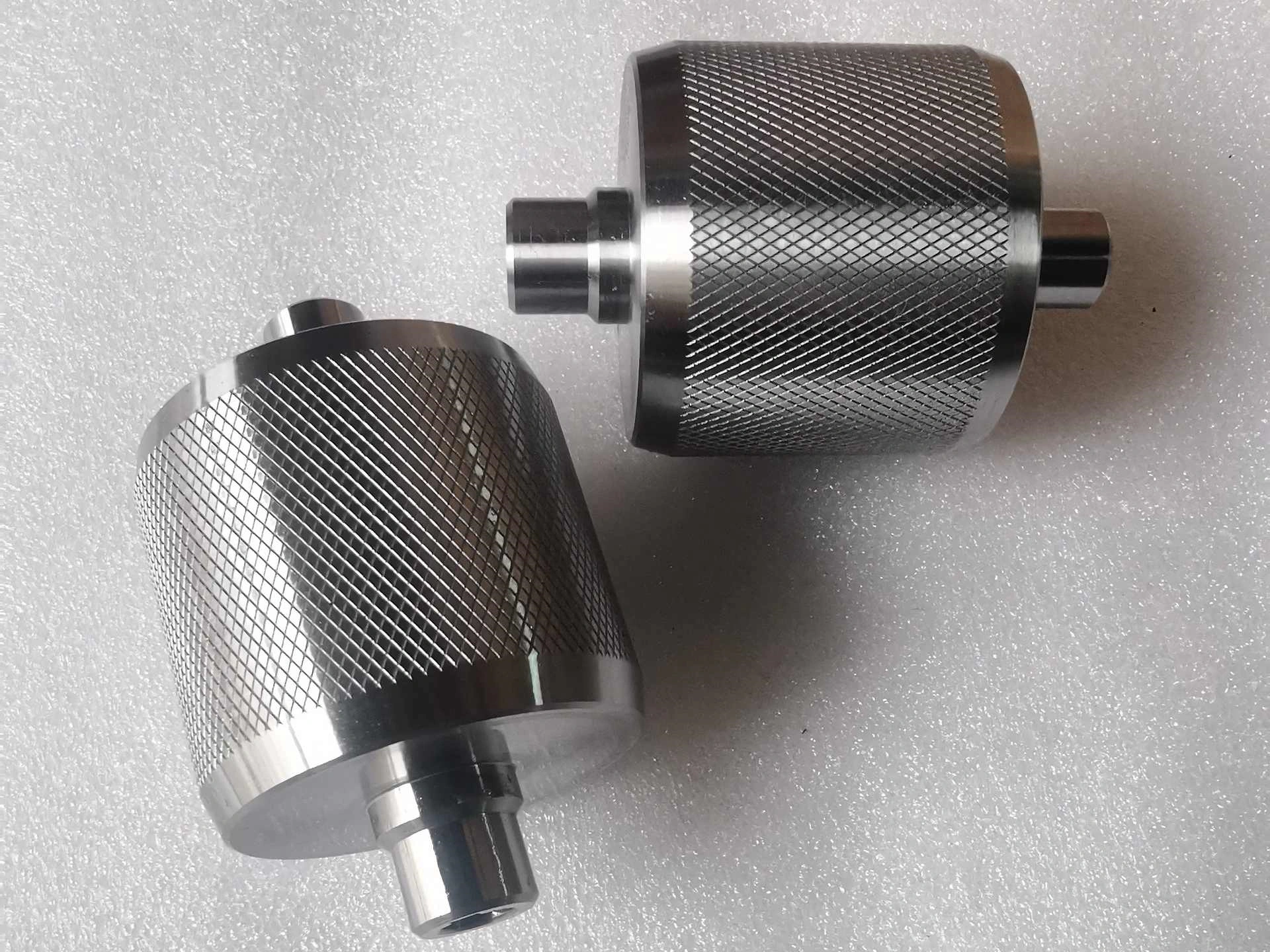

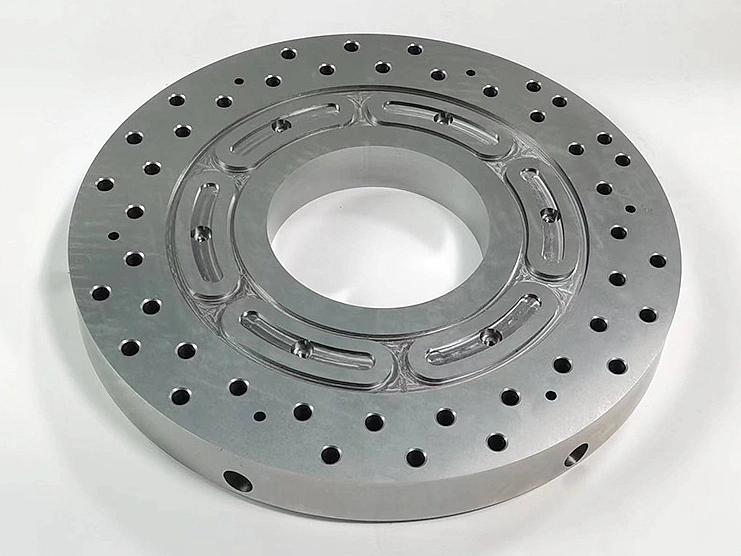

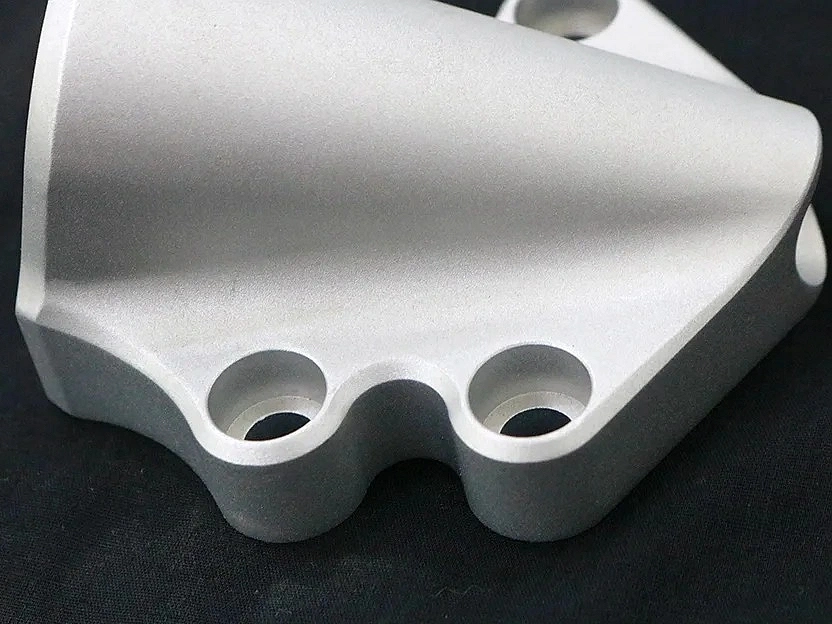

CNC Machined Custom Components

We specialize in CNC machined custom components, delivering high-precision parts tailored to your design requirements. We ensure tight tolerances, excellent surface finishes, and complex geometries using advanced CNC technology. Our custom solutions cater to various industries, including aerospace, automotive, and medical, providing fast turnaround times and cost-effective solutions for prototypes and production components.

Let's Start A New Project Today

Explore Related Blogs

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.