On-demand Precision CNC Milling Service

Our On-Demand Precision CNC Milling Service is tailored to meet the most exacting standards for industries requiring high-quality, reliable, and efficient superalloys, ceramic, stainless steel, aluminum, and titanium parts CNC milling solutions.

- Rapid Milling Prototyping Service

- Low Volume CNC Milling Service

- CNC Milling Mass Production Service

- One Stop CNC Milling Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

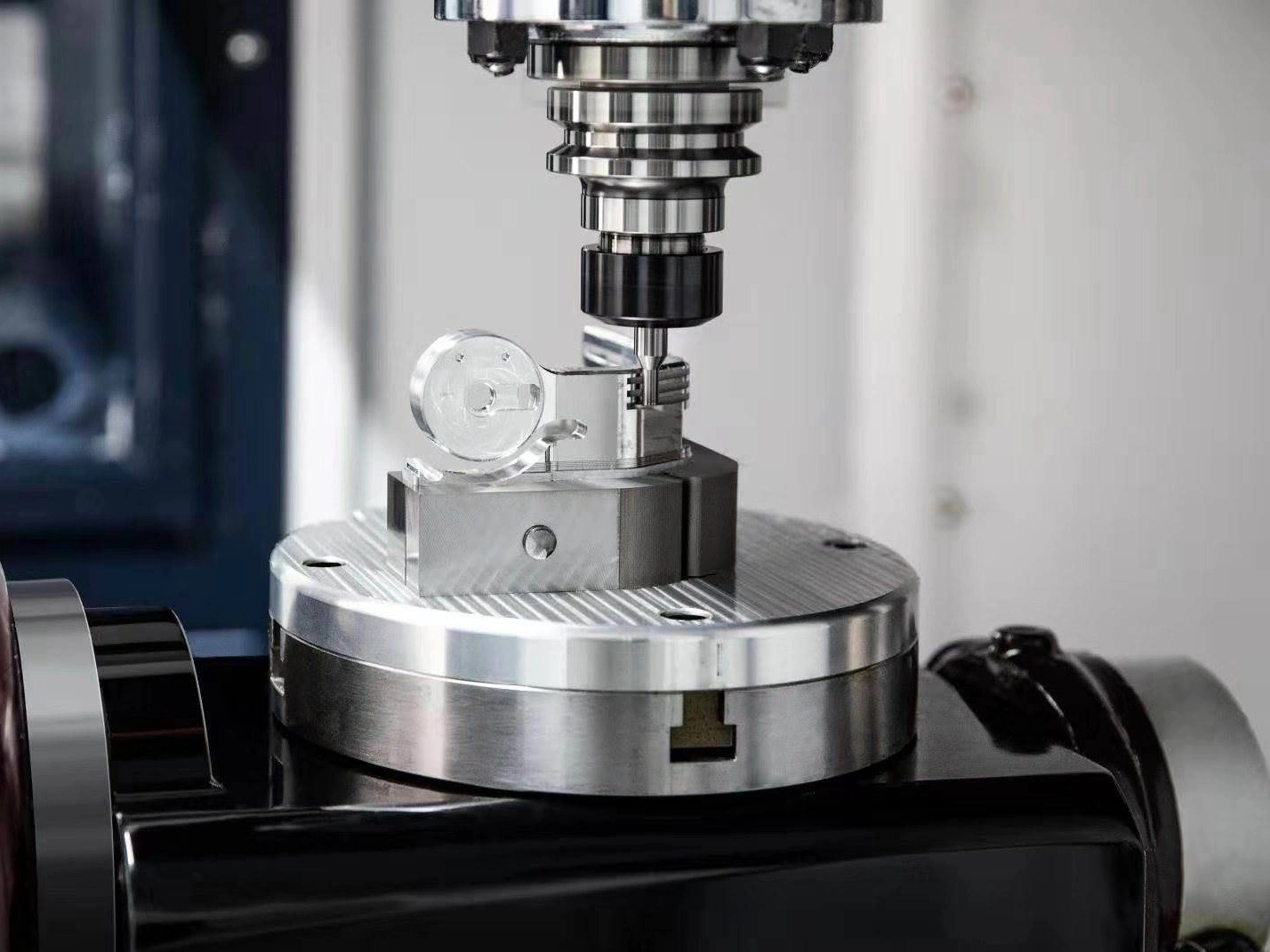

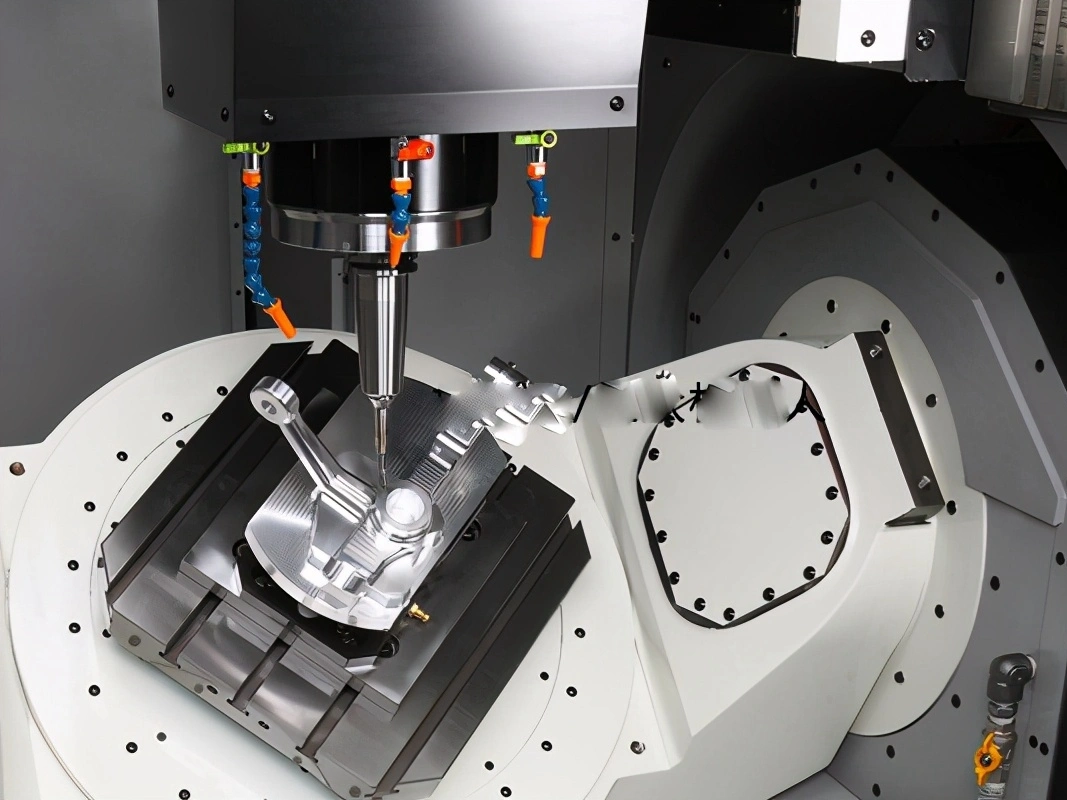

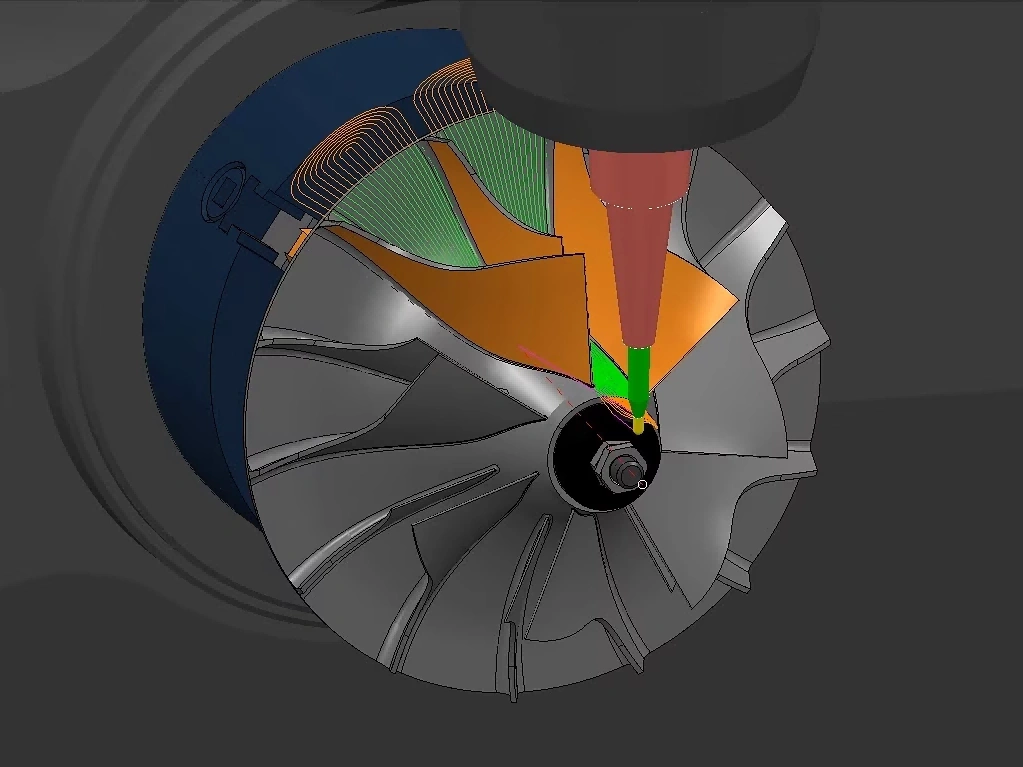

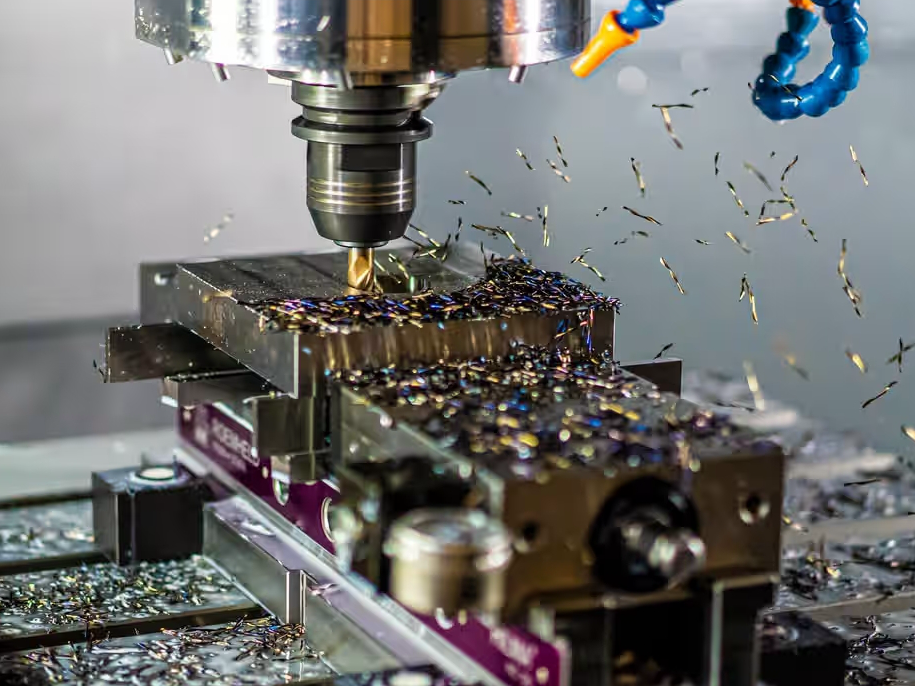

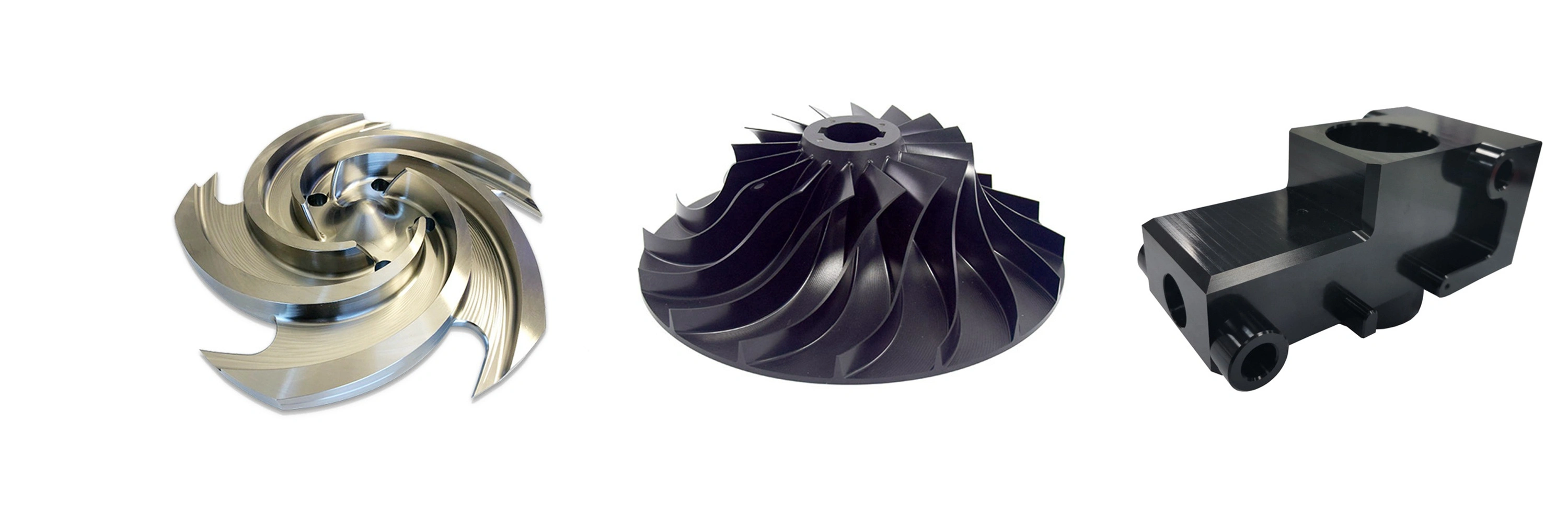

Multi-Axis CNC Milling Service

Our Multi-Axis CNC Milling Service offers advanced machining capabilities, using 3, 4, and 5-axis systems to create complex, precise parts. This service allows for intricate designs, tight tolerances, and superior surface finishes on various materials, including high-temperature alloys, metals, ceramics, and plastics. We can machine parts from various angles in a single setup by utilizing multiple axes, reducing lead times and improving accuracy. This flexibility supports both prototyping and mass production, catering to diverse industries.

CNC Milling Materials

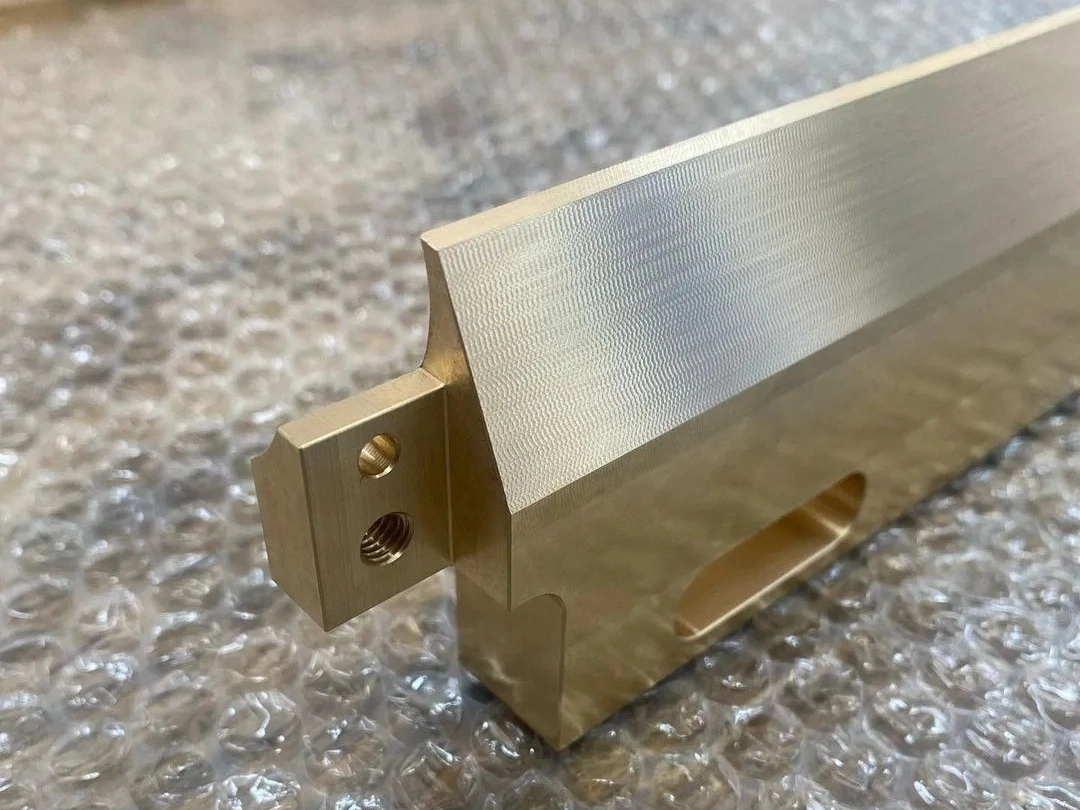

CNC milling materials encompass various metals, plastics, and ceramics, offering versatility for various applications. Common materials include aluminum, stainless steel, titanium, and high-temperature alloys for industries like aerospace and automotive. Plastics like ABS, nylon, and polycarbonate are used for lightweight, cost-effective prototypes. Ceramics are selected for their hardness and heat resistance in specialized applications. The choice of material depends on factors like strength, corrosion resistance, thermal properties, and specific machining requirements.

Custom CNC Milled Parts Applications

Custom CNC milled parts are tailored for specific applications requiring high precision and unique designs. Typical uses include aerospace components, automotive parts, medical devices, and industrial machinery. These parts are often made from metals, plastics, or ceramics and are essential for producing complex geometries, tight tolerances, and durable components in prototype and mass-production scenarios.

Surface Treatment for CNC Milled Parts

Surface treatment for CNC machined parts enhances durability, performance, and aesthetics by modifying the material’s surface. Standard techniques include anodizing, plating, coating, polishing, and shot peening. These treatments improve corrosion resistance, wear resistance, and surface hardness. For example, anodizing aluminum increases its resistance to corrosion, while shot peening improves fatigue resistance. Surface treatments are crucial for industries like aerospace, automotive, and medical devices, where component longevity and reliability are critical under harsh operational conditions.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

Painting

Learn More

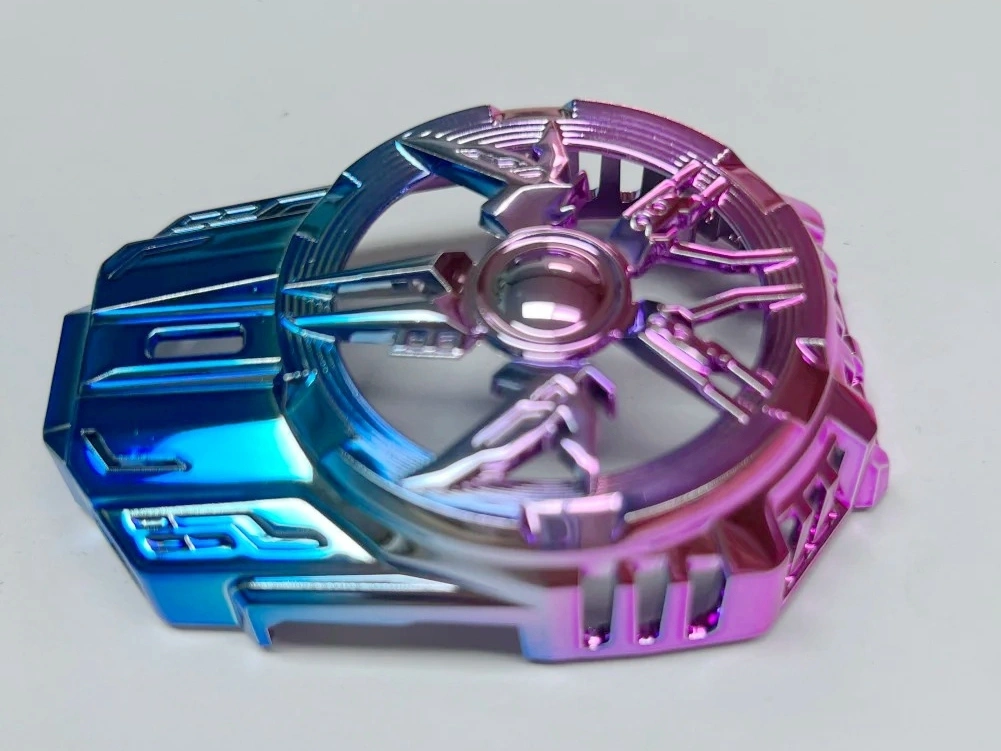

PVD (Physical Vapor Deposition)

Learn More

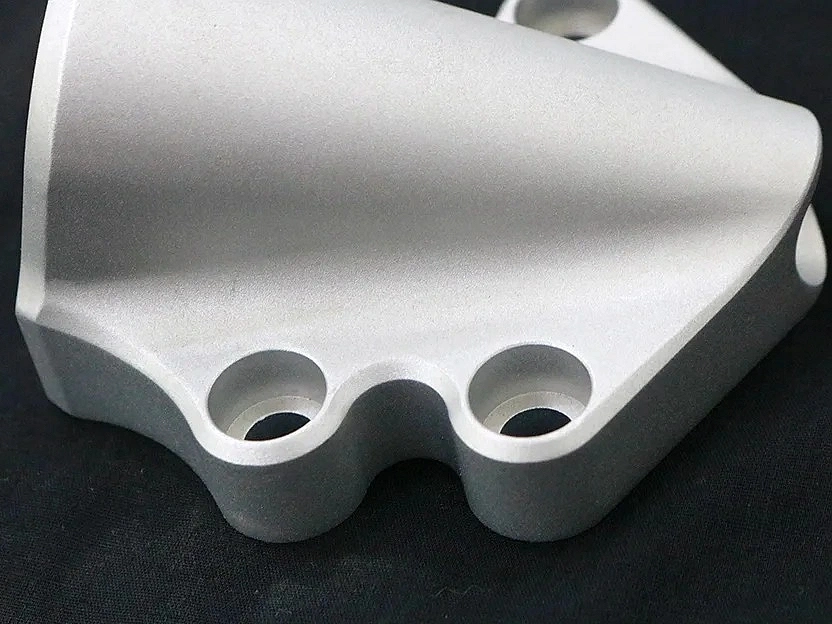

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

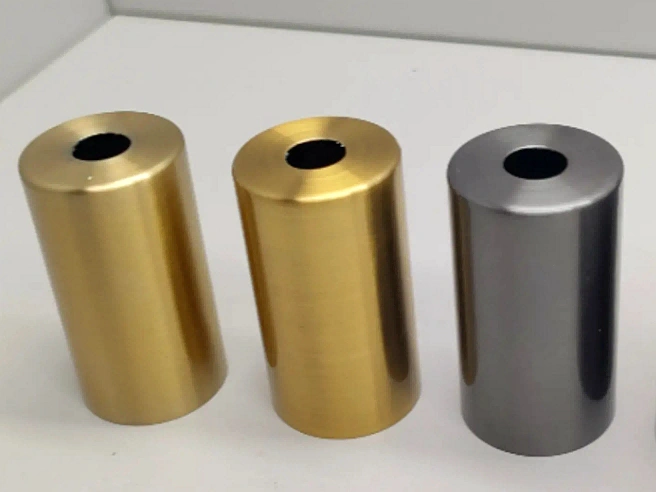

Brushing

Learn More

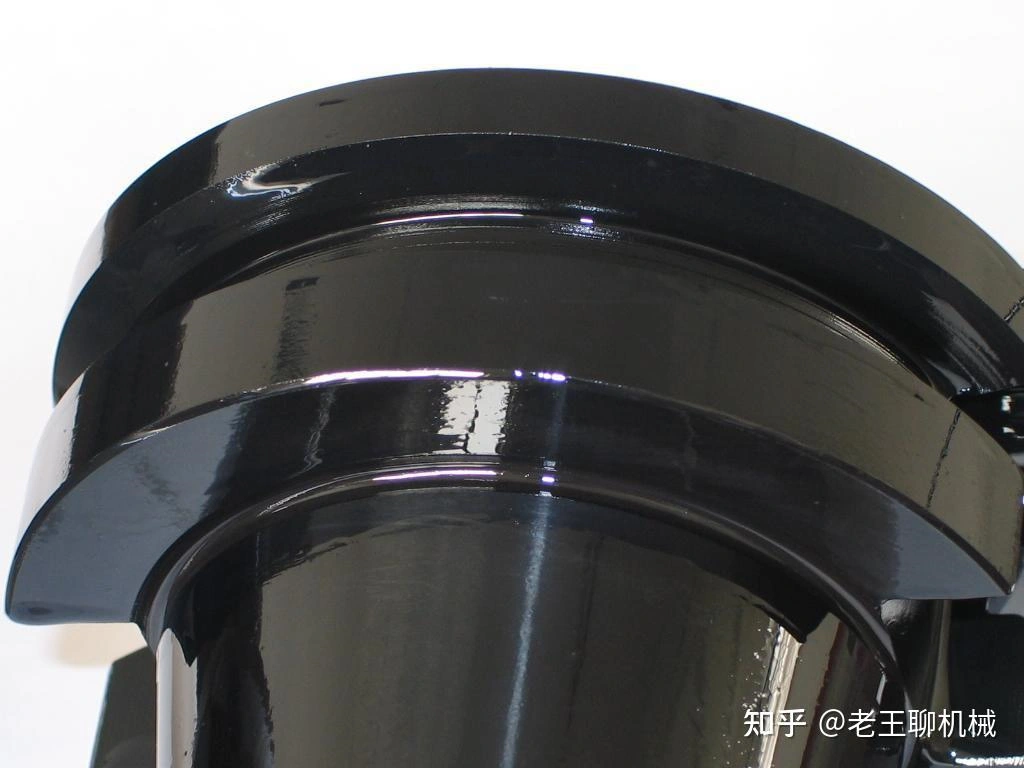

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

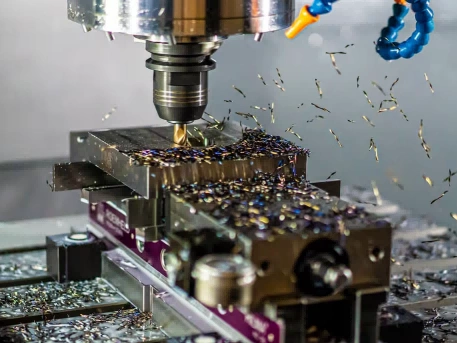

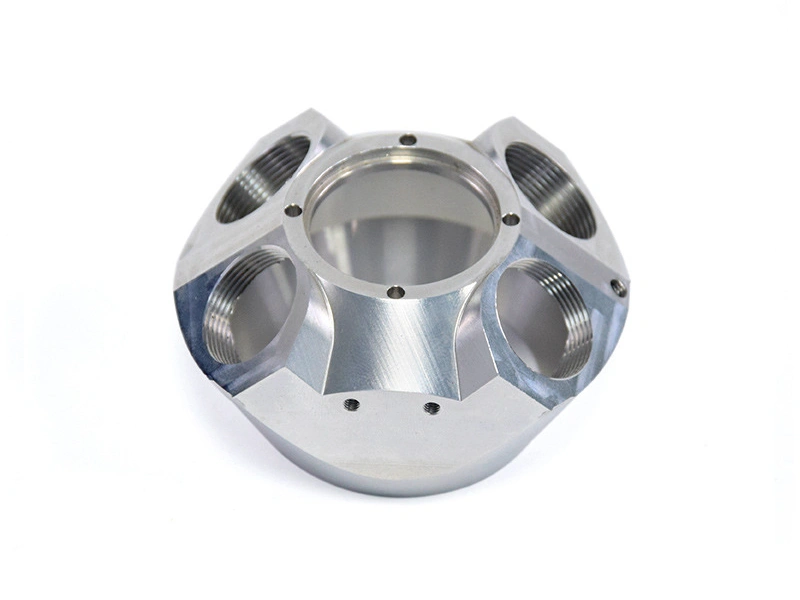

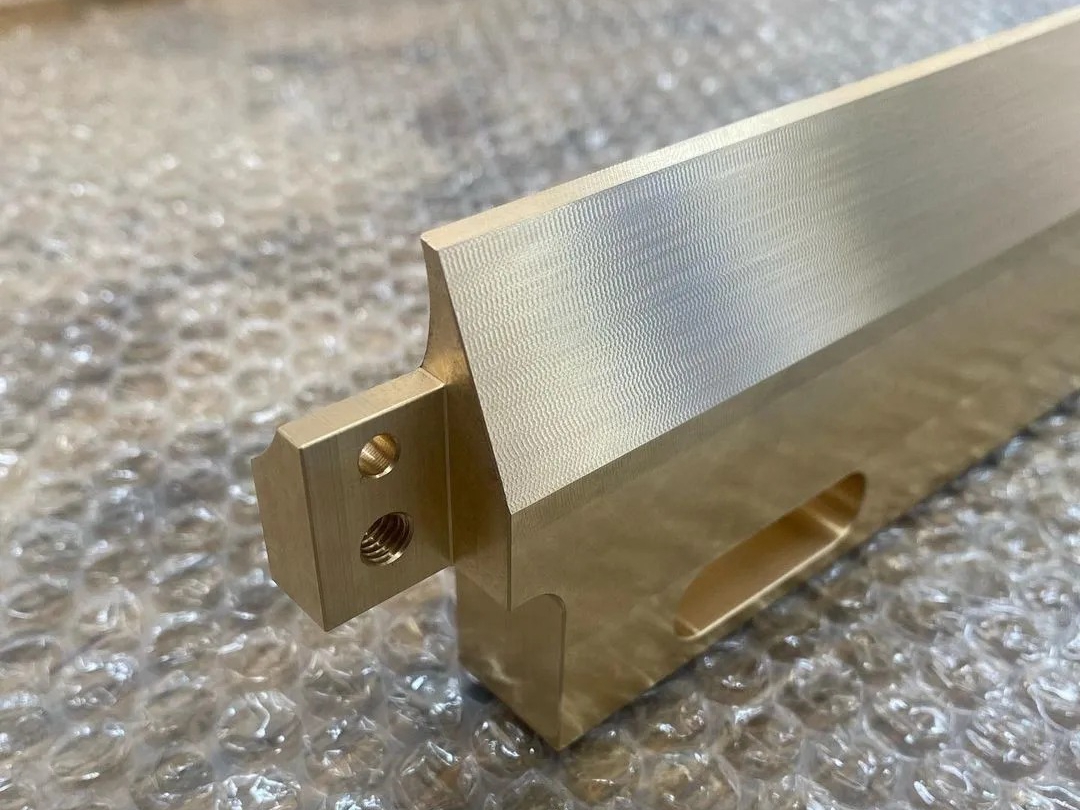

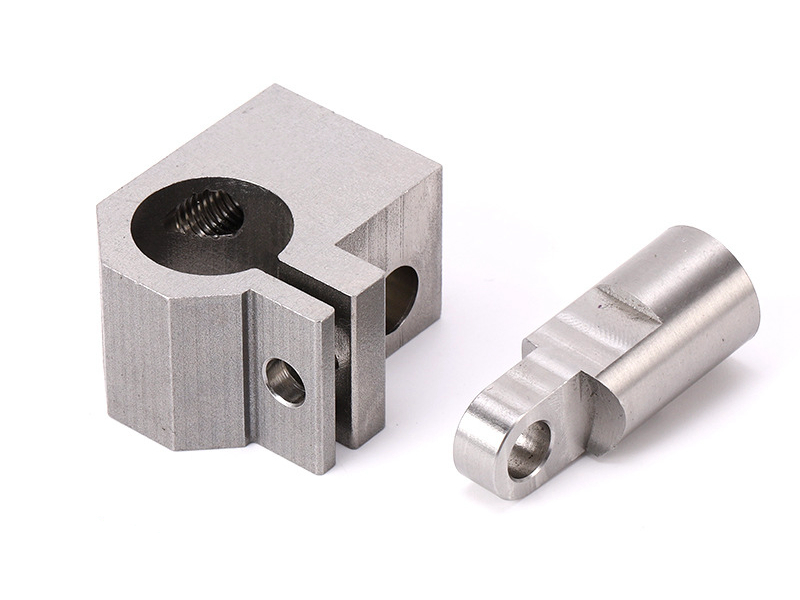

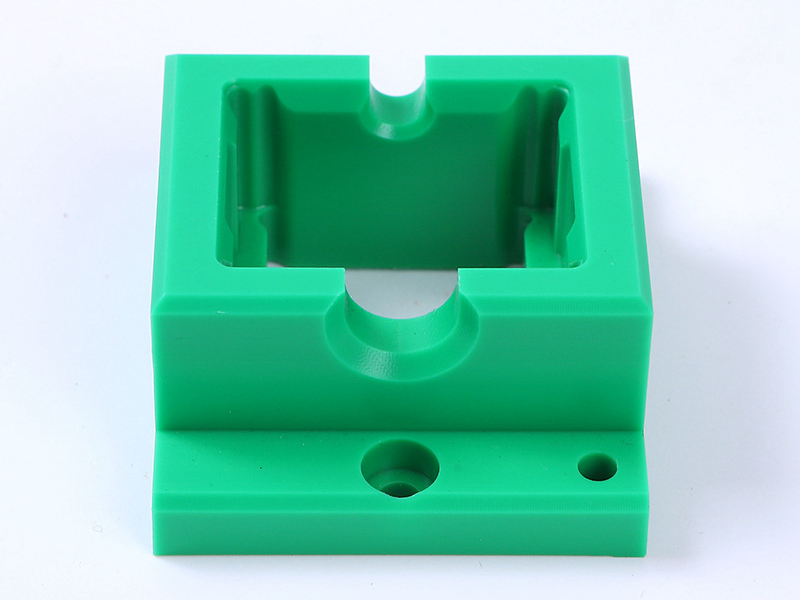

CNC Milling Components Gallery

The CNC Milling Components Gallery showcases a variety of precision-engineered parts produced using advanced milling techniques. The gallery highlights components made from diverse materials, featuring intricate designs and complex geometries, emphasizing high accuracy, efficiency, and quality in the aerospace, automotive, and manufacturing industries.

Let's Start A New Project Today

CNC Machining Tolerance

CNC machining tolerance refers to the allowable variation in part dimensions during the machining process. Tight tolerances ensure high precision, which is crucial for components requiring exact fit and function, especially in aerospace, automotive, and medical devices.

CNC Milling Design Suggestion

CNC Milling Design Suggestions focus on optimizing part geometry for efficient machining. Key points include using appropriate radii, considering hole depth-to-diameter ratios, minimizing excessive tolerances, ensuring tool access, and simplifying shapes to improve precision, reduce cost, and enhance part functionality.

Frequently Asked Questions

Explore Related Blogs

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.