Precision CNC Milling and Boring Solutions for Carbon Steel Clamping Accessories in Automation

CNC Machining of Automation Clamping Accessories: Reliability in Motion Control

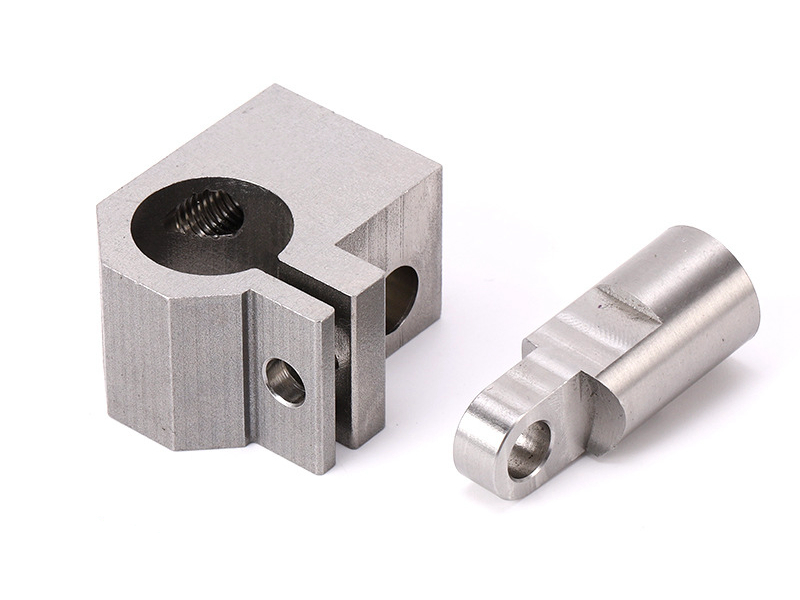

In automation systems, clamping accessories are mission-critical for precision positioning, motion stability, and load support. These components must withstand dynamic mechanical stress while maintaining exact tolerances. With CNC machining services optimized for automation industry applications, Neway provides robust carbon steel clamping parts manufactured to exacting industrial standards.

Using a combination of CNC milling and CNC boring, our engineers deliver structural components with precise flatness, concentricity, and long-term reliability.

Why Carbon Steel Is Ideal for Automation Clamping Components

Mechanical Strength and Rigidity

Carbon steel grades such as 1045 or 4140 offer high tensile strength (≥600 MPa) and toughness required for repetitive mechanical engagement. These alloys are cost-effective and easily machinable, making them suitable for medium- to high-load clamping structures in robotic arms, grippers, and positioners.

Stable Machinability and Dimensional Retention

Carbon steels provide excellent cutting consistency during roughing and finishing operations. With proper tool selection and coolant control, we maintain tolerance bands within ±0.01 mm for bore diameters and ±0.02 mm for milled flats, ensuring optimal fit with other moving components.

CNC Machining Process Workflow

High-Rigidity CNC Milling for Base Features and Key Slots

Our 3-axis and 4-axis CNC milling machines produce the planar geometries and interlocking features of clamping parts. Key slots, counterbores, and mounting faces are milled with flatness under 0.01 mm/100 mm. This ensures parallelism and alignment in actuated assemblies.

Precision CNC Boring for Alignment Holes and Shaft Passages

After rough milling, critical cylindrical features are finished with CNC boring to achieve H7 tolerance class fits. This is essential for components interfacing with dowel pins or rotating shafts. Using precision boring, we maintain consistent ID roundness and coaxiality between features.

As Machined Surface Finish and Post-Processing

For these components, an as machined surface finish is ideal. With Ra typically between 1.6–3.2 µm, the finish provides sufficient friction for clamping without the need for additional coatings. The surfaces are deburred, cleaned, and inspected for edge quality and contact integrity.

Optional corrosion-resistant treatments like black oxide or phosphating can be offered depending on the usage environment.

Dimensional Inspection and Quality Control

CMM verification of bore position and slot width

Full-dimensional reports and control plans are available for mass production

In-process SPC monitoring for ±0.01 mm critical fits

We offer documentation packages including COC, material traceability, and first article inspection (FAI) reports.

Why Choose Neway for CNC Automation Fixture Components

Proven experience in carbon steel CNC machining for high-load automation systems

Capability to hold IT7/IT8 tolerances across both prototype and production runs

One-stop CNC service from design review to final machining and cleaning

Low-volume manufacturing ready with short lead times and flexibility in revisions

Reliable support for mechanical integration and fixture validation testing

Commercial CNC Services for Automation Clamping Applications

We help automation OEMs and integrators manufacture precision clamping solutions that meet both functional and assembly requirements. Our integrated CNC services include:

CNC Milling and Boring Services: For tight-fit shaft interfaces and stable alignment slots

Carbon Steel Machining Services: Processing grades such as 1045, 4140, and 1215 with high dimensional consistency

Prototyping and Batch Production: Rapid validation of fixture concepts before full-scale manufacturing

Partner with Neway to reduce development cycles, improve component durability, and scale up production with engineering confidence.

FAQs

What tolerances can be achieved for carbon steel automation clamping components?

Which carbon steel grades are commonly used for CNC fixture parts?

Do you provide black oxide or other protective finishes for carbon steel components?

Can Neway assist with design for manufacturability for automation fixture parts?

What is the lead time for low-volume CNC production of clamping accessories?