Custom Parts Manufacturing Solutions

Industrial Equipment Parts Manufacturing Service

Neway offers Industrial Equipment Parts Manufacturing, providing CNC Machining, 3D Printing, Vacuum Casting, Die Casting, and Injection Molding. We deliver durable, high-precision components designed to meet the demanding needs of industrial applications.

Industrial Equipment Parts Machining

Industrial equipment parts machining involves precision manufacturing processes such as CNC milling, turning, drilling, boring, grinding, and EDM to create high-quality components. Utilizing multi-axis and precision machining techniques, these services ensure the production of complex and accurate parts for industrial machinery. The result is durable, reliable equipment parts optimized for performance and longevity in demanding applications.

Industrial Equipment Material Selection

Industrial equipment manufacturing requires durable materials that can withstand high stress and harsh environments. Key materials include superalloys for high-temperature resistance, titanium for strength-to-weight ratio, stainless steel for corrosion resistance, aluminum for lightweight components, and plastics for non-structural, insulating, or sealing applications.

Typical Surface Treatment for Industrial Equipment Parts

Typical surface treatments for industrial equipment parts include processes like anodizing, electroplating, powder coating, and PVD to enhance durability, corrosion resistance, and aesthetic appearance. Methods such as sandblasting, passivation, and polishing improve surface finish, while heat treatments and thermal barrier coatings offer thermal stability. These treatments ensure parts perform efficiently under demanding industrial conditions.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

Painting

Learn More

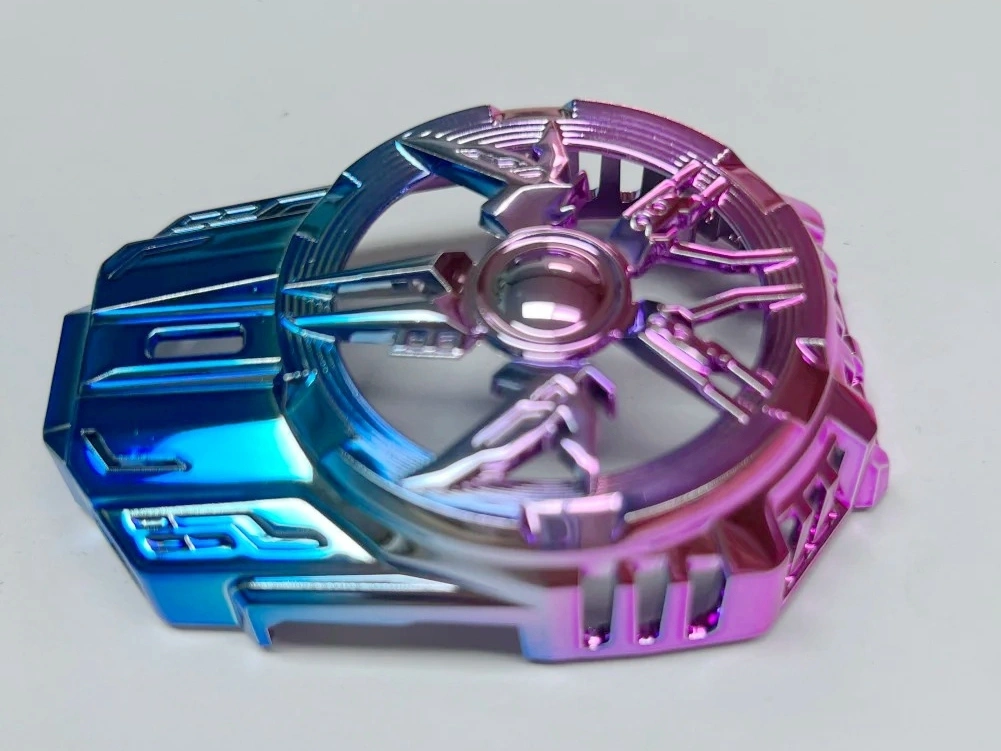

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

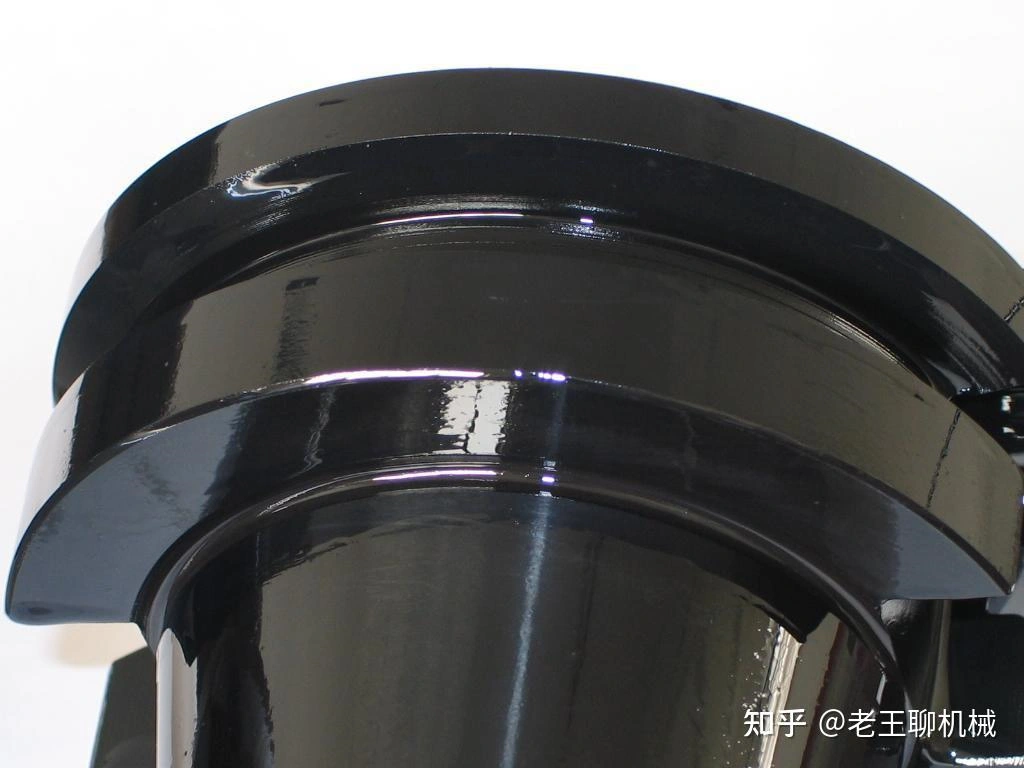

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

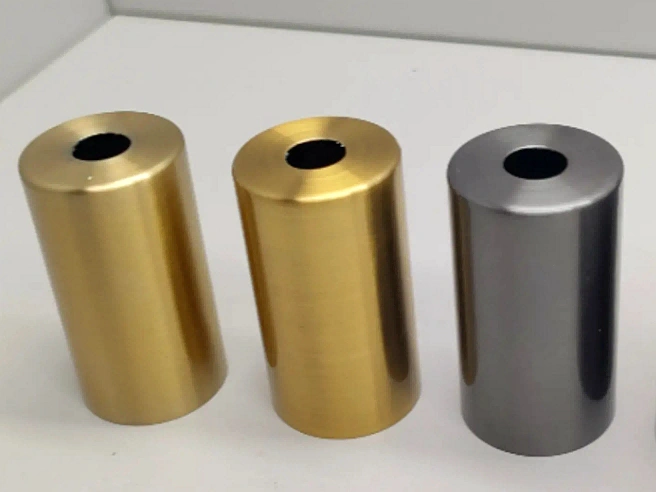

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

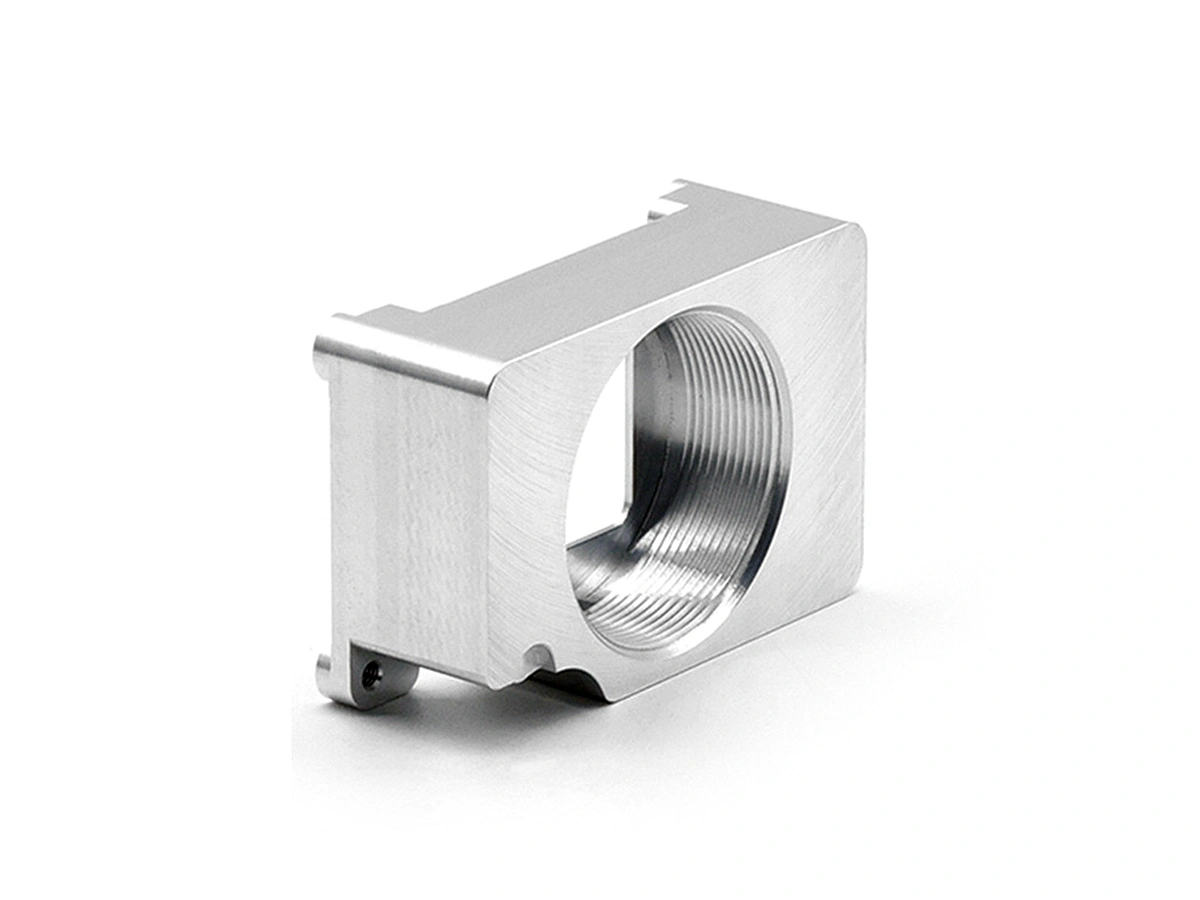

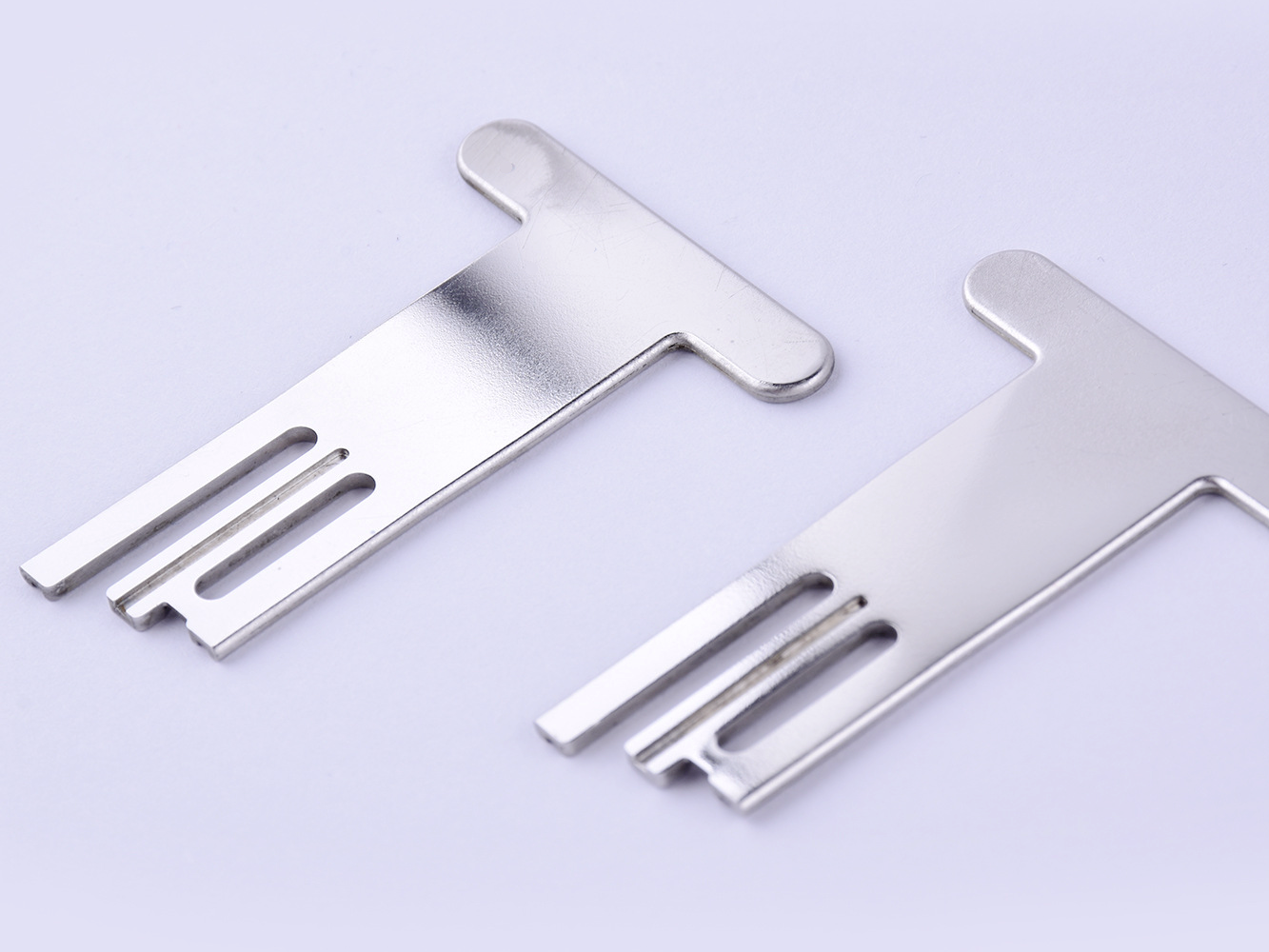

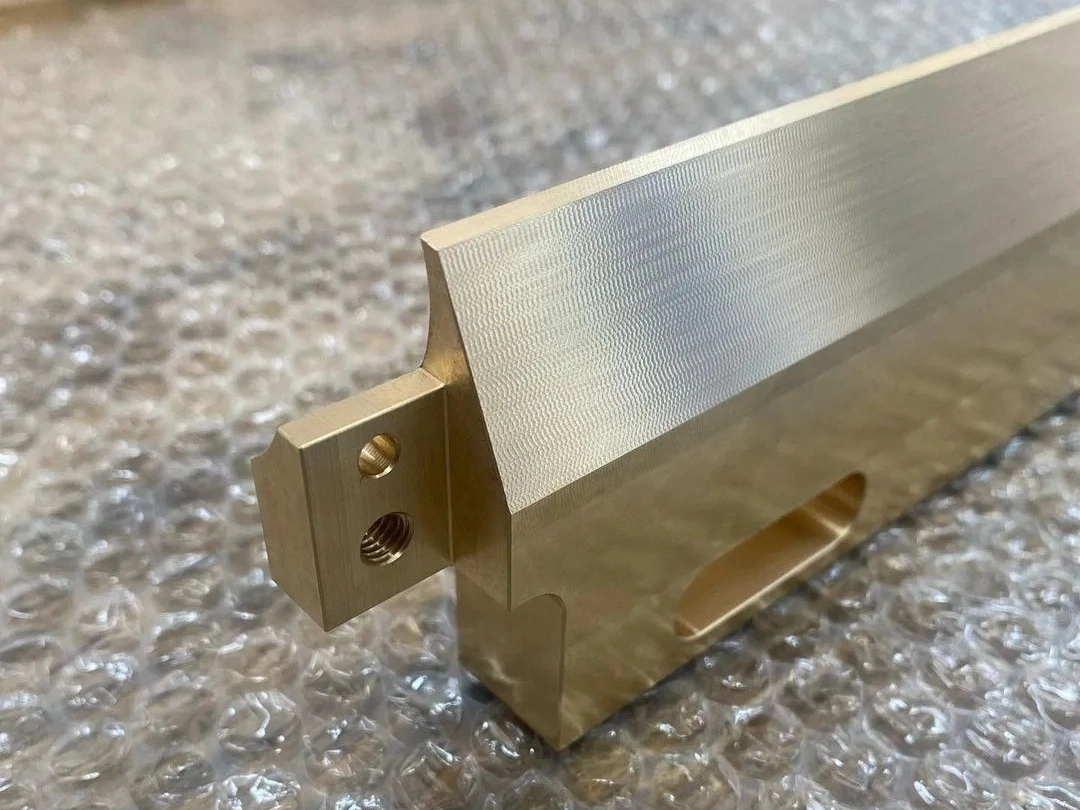

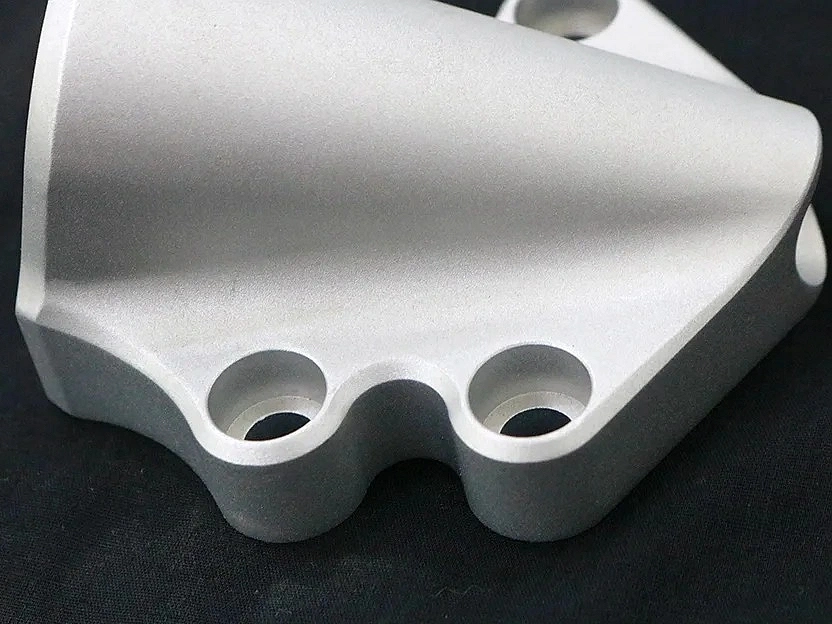

CNC Machined Industrial Equipment Parts

Industrial equipment benefits from CNC machining in producing parts like pumps, valves, and compressors, providing high-strength, precision-engineered components that ensure smooth operation and longevity.

Let's Start A New Project Today

Guide to Industrial Equipment Parts Design

Industrial equipment parts require design strategies that ensure high structural integrity, manufacturing precision, serviceability, and compliance. This guide details best practices for high-load, precision-machined, and field-operational components.

Custom Industrial Equipment Parts Manufacturing Considerations

Precision manufacturing of custom industrial equipment parts requires robust materials, process stability, tight tolerances, and global compliance. This guide outlines engineering-driven production principles for scalable, high-performance parts.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.