Custom Parts Manufacturing Solutions

Medical Device Parts Manufacturing Service

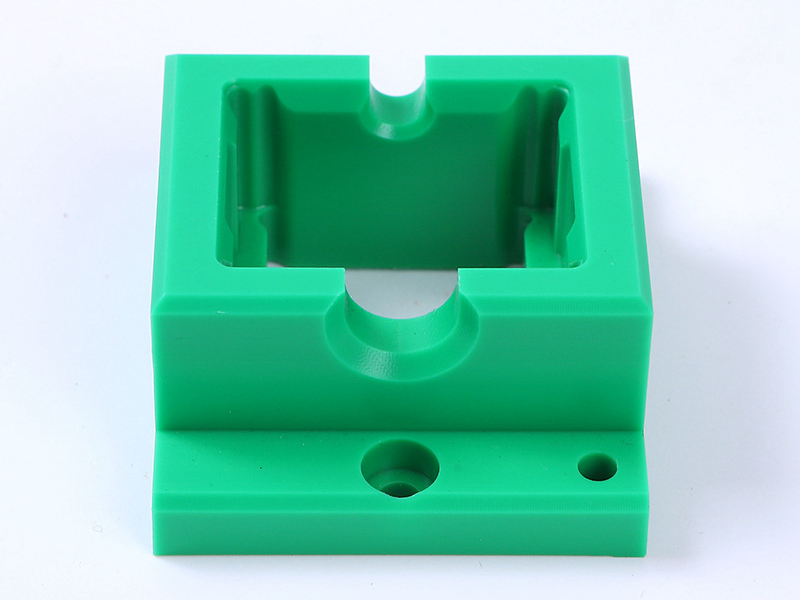

Neway specializes in Medical Device Parts Manufacturing, offering CNC Machining, 3D Printing, Vacuum Casting, Die Casting, and Injection Molding services. We ensure high-precision, biocompatible components that meet stringent industry standards, delivering reliable and durable solutions for the medical device sector.

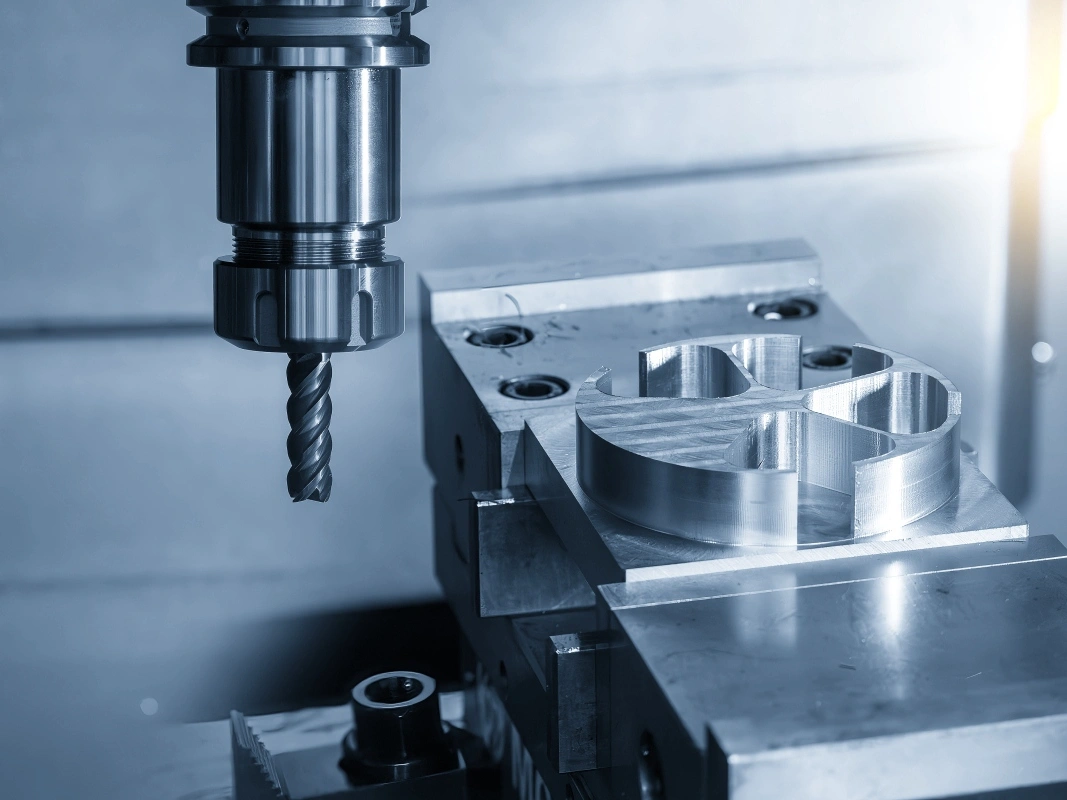

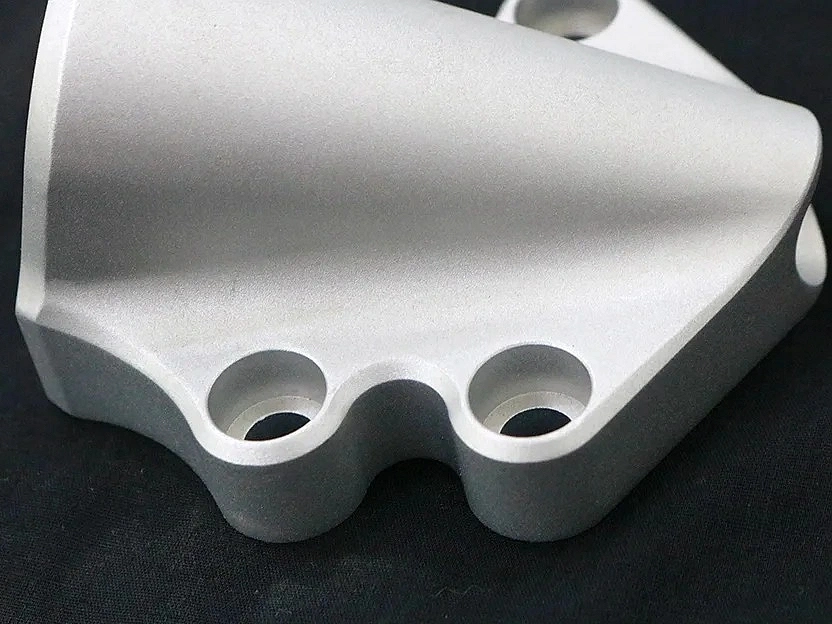

Medical Device Parts Machining

Medical device parts machining involves precise CNC processes such as milling, turning, drilling, and grinding to produce high-quality components for medical applications. Using multi-axis and precision machining techniques, along with Electrical Discharge Machining (EDM), ensures tight tolerances and reliability. These methods are essential for creating parts that meet stringent safety and performance standards in the medical industry.

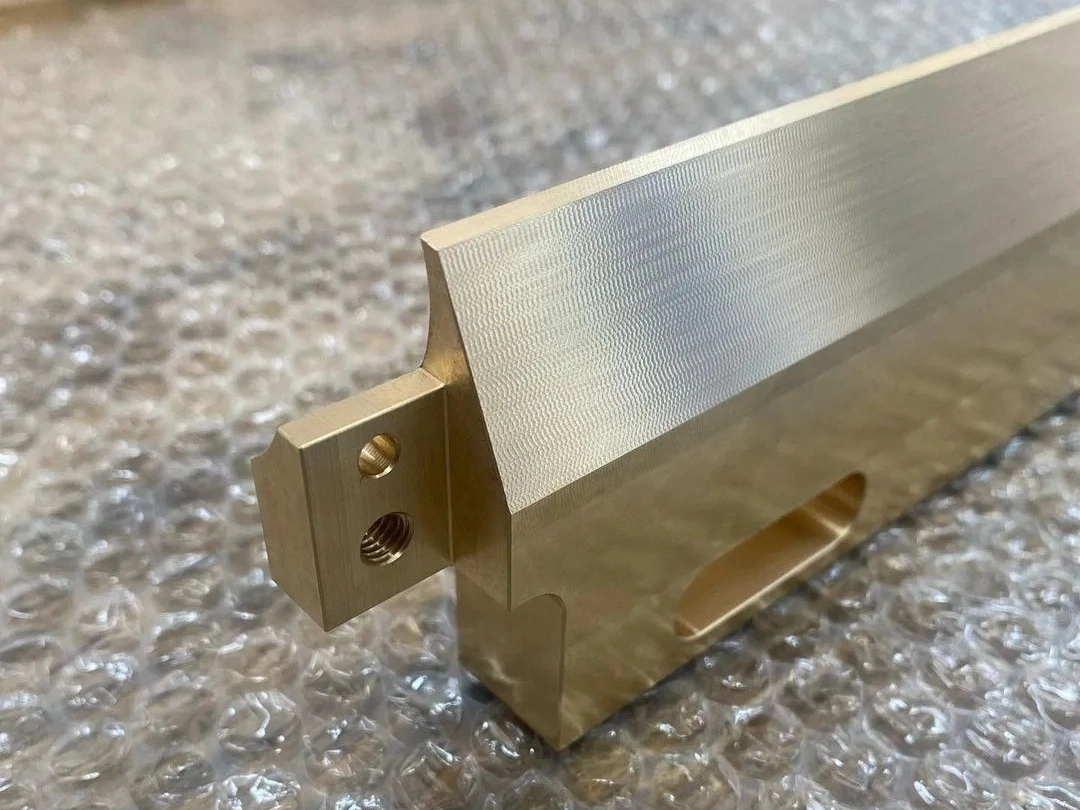

Medical Device Material Selection

Materials like superalloy, titanium, aluminum, copper, brass, bronze, carbon steel, stainless steel, plastic, and ceramic are crucial in medical device manufacturing. These materials provide durability, biocompatibility, and precision for components such as implants, surgical tools, prosthetics, and medical equipment.

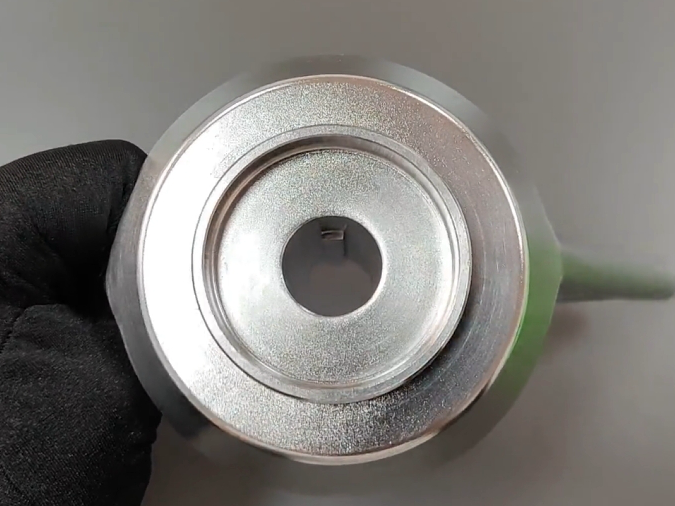

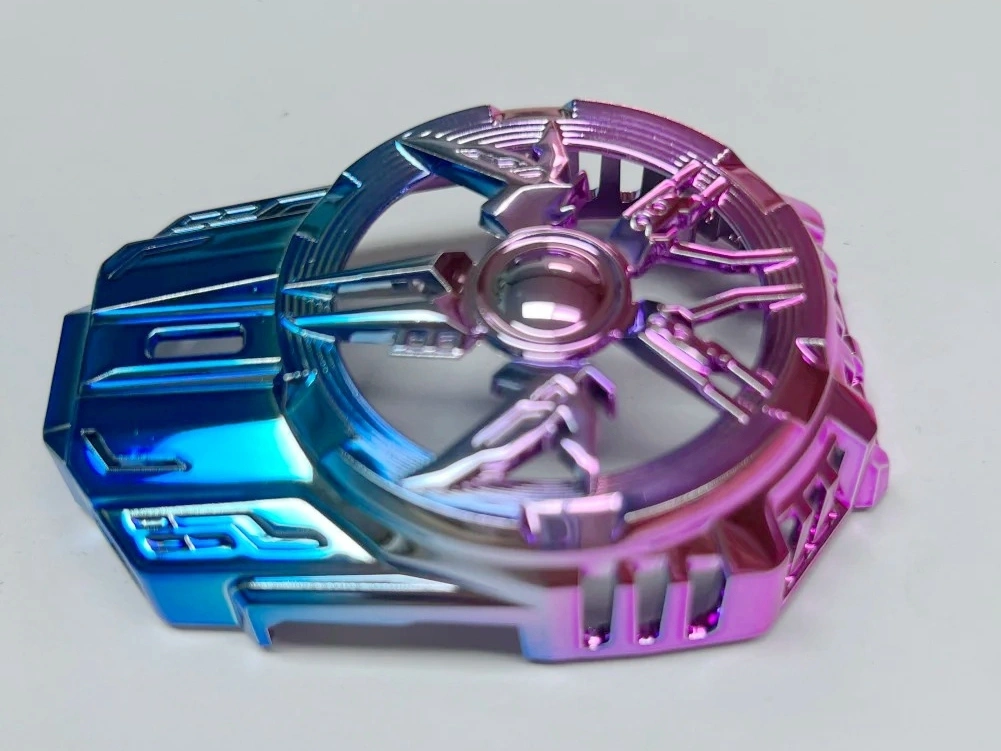

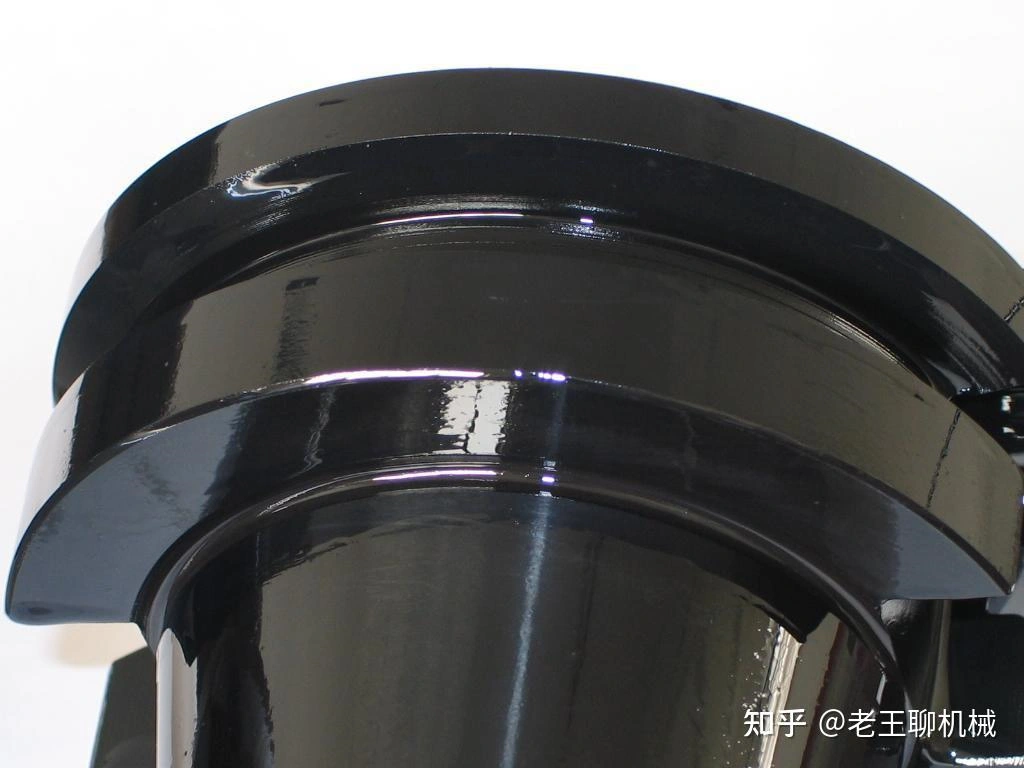

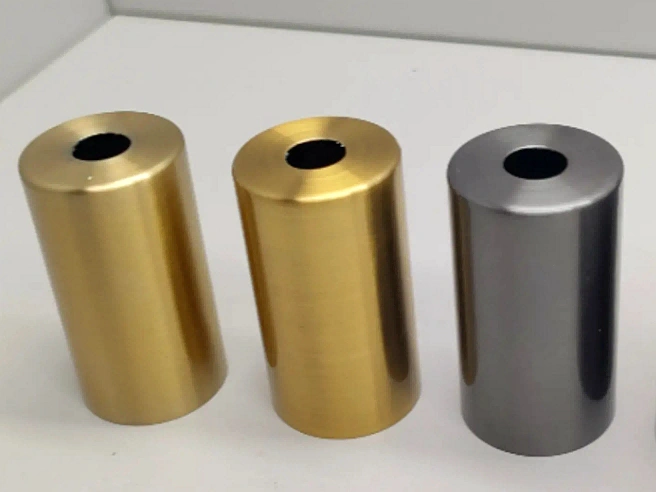

Typical Surface Treatment for Medical Device Parts

Typical surface treatments for medical device parts include processes like anodizing, electropolishing, PVD, powder coating, passivation, and heat treatment. These treatments enhance biocompatibility, corrosion resistance, and durability. Techniques such as electropolishing and anodizing improve surface smoothness, while coatings like Teflon or UV coatings provide additional protection, ensuring medical devices meet stringent performance and safety standards.

Learn More

Thermal Coating

Learn More

As Machined

Learn More

Painting

Learn More

PVD (Physical Vapor Deposition)

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

Passivation

Learn More

Brushing

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Thermal Barrier Coating (TBC)

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

UV Coating

Learn More

Lacquer Coating

Learn More

Teflon Coating

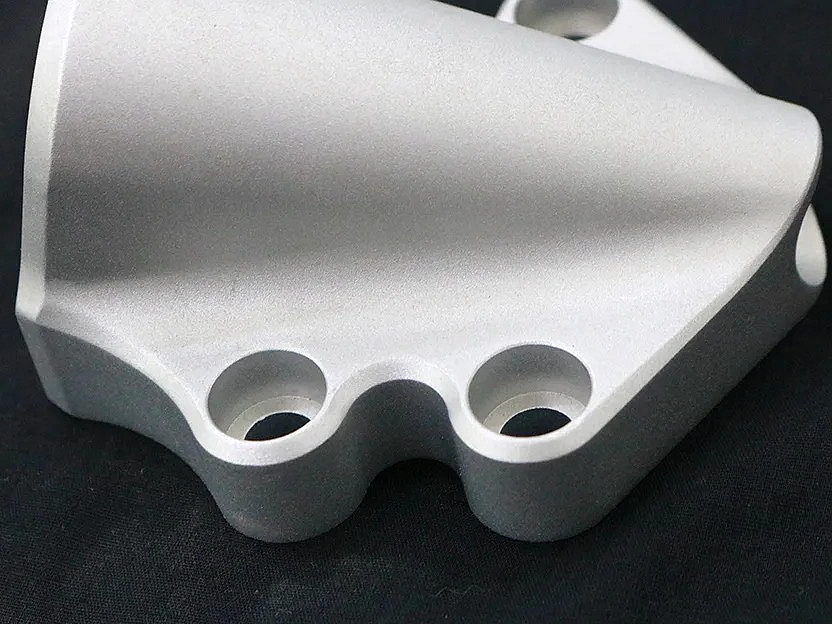

Medical Device CNC Machining Solutions

CNC machining is crucial in medical devices, fabricating intricate components like surgical tools, implants, and diagnostic equipment, meeting strict standards for precision, biocompatibility, and safety.

Let's Start A New Project Today

Guide to Medical Device Parts Design

Medical device part design demands precision, sterility, regulatory compliance, and user safety. This guide outlines engineering principles to ensure reliable function, cleanability, and certification readiness for clinical use.

Custom Medical Device Parts Manufacturing Considerations

Custom manufacturing of medical device parts requires exceptional process control, biocompatibility, and regulatory alignment. This guide outlines critical production strategies to ensure safety, precision, and certification readiness.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.