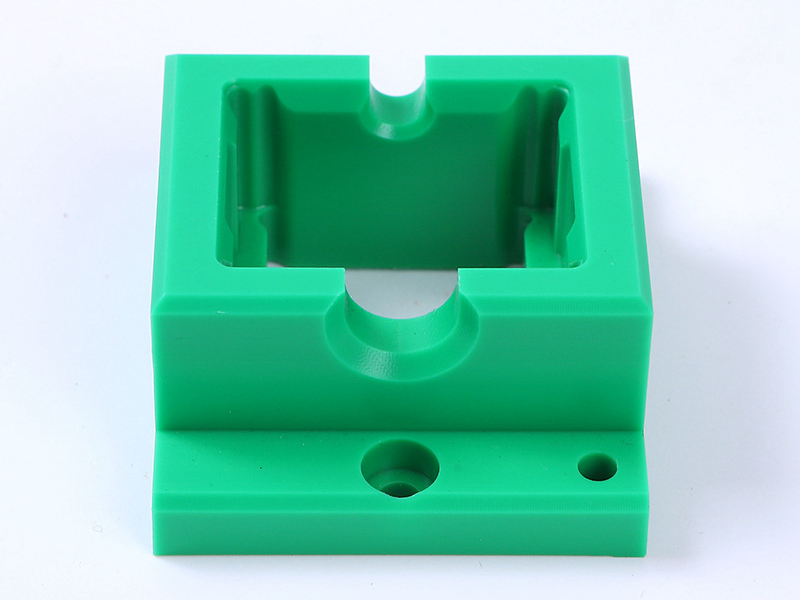

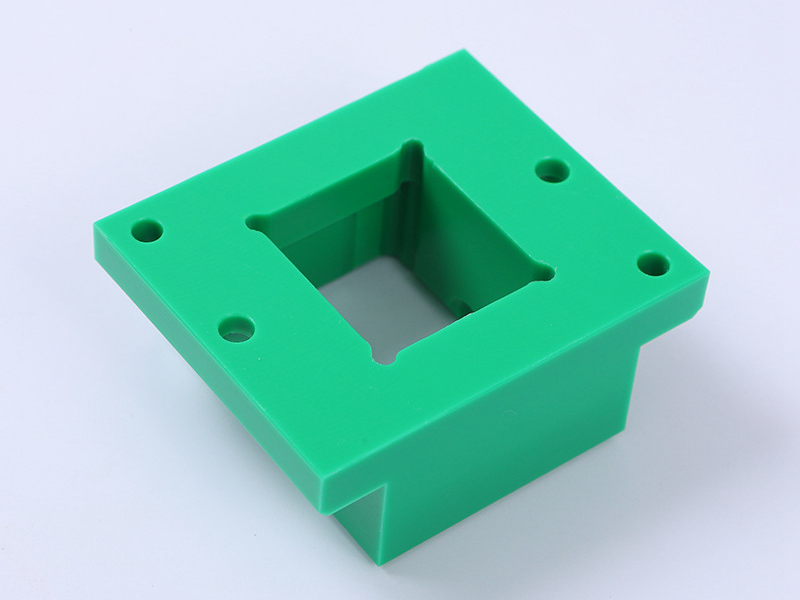

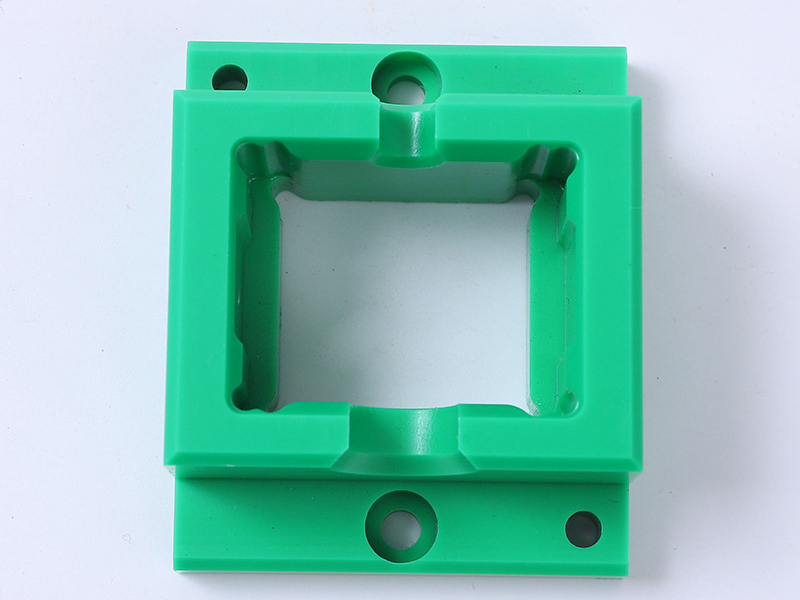

CNC Milling Solutions for POM Medical Equipment Brackets with As-Machined Surface Finish

CNC Machining of Medical Brackets: High-Performance Polymer Solutions for Medical Devices

Medical equipment brackets must offer dimensional accuracy, chemical resistance, and mechanical reliability to support sensitive instruments, housings, and motion assemblies. At Neway, we provide CNC milling services for complex bracket components using POM (Polyoxymethylene), tailored for medical device manufacturing.

With high dimensional stability and a smooth as-machined surface finish, POM brackets are ideal for structural integration in diagnostic, surgical, and therapeutic systems.

Why POM Is Ideal for Medical Equipment Bracket Applications

Dimensional Stability and Mechanical Performance

POM (commonly known as Delrin or Acetal) provides high stiffness, low friction, and excellent wear resistance. It maintains dimensional stability under thermal cycling, making it ideal for brackets that support enclosures, guides, or moving parts.

Tensile strength: ~70 MPa

Working temperature range: -40°C to 100°C

Low moisture absorption: <0.2%

Chemical and Sterilization Compatibility

POM resists most cleaning agents and disinfectants, ensuring compatibility with hospital-grade sterilization procedures. It does not degrade under contact with alcohols, diluted acids, or aldehydes commonly used in medical settings.

CNC Milling Process for POM Medical Brackets

High-Speed Milling for Polymer Geometry

Using sharp carbide tools and optimized spindle speeds, we mill features such as:

Mounting holes and slots

Curved contours and support ribs

Locating surfaces with flatness ≤ 0.02 mm

Thanks to POM’s machinability, we achieve excellent surface finish without secondary polishing.

Clean Edge Definition and Low Tool Pressure

Milling parameters are tuned to prevent melting, burring, or dimensional shift:

Feed rates: 600–1200 mm/min

Tool radius: 0.5–2.0 mm depending on profile

Tolerance: ±0.05 mm on most bracket features

Surface Finish: As-Machined for Medical Device Integration

An as-machined surface is ideal for POM parts, offering:

Smooth matte finish (Ra ~1.6–3.2 µm)

No additional cost or lead time

Clean edges suitable for mating with metal or polymer surfaces

For non-visible or low-friction interfaces, the natural as-machined finish provides sufficient smoothness without requiring polishing or coating.

Quality Control and Clean Manufacturing

Dimensional inspection using digital CMM and optical comparators

Visual inspection for burrs, feed marks, and edge uniformity

Material certificates for POM grades (e.g., FDA, ISO 10993 compliant)

Full documentation: COC, RoHS, REACH, CAD-to-part verification

Why Choose Neway for Medical-Grade POM Bracket Machining

Specialized in CNC machining of plastics for cleanroom-compatible components

One-stop manufacturing from design review to final packaging

Low-volume production for medical prototypes or pilot builds

Experience in ISO 13485–aligned workflows and medical documentation support

CNC Services for Medical Device Bracket Production

Neway offers a complete CNC solution for medical plastic components. Our services include:

CNC Milling of POM Materials: High-precision polymer machining with no warping or delamination

As-Machined Surface Finishing: Clean, consistent finish with no extra processing time

Medical Device Machining Services: Trusted partner for structural and functional medical components

We support OEMs and contract device manufacturers with consistent, traceable, and compliant medical bracket production.

FAQs

What tolerances can be achieved for CNC-milled POM medical brackets?

Is the as-machined surface suitable for medical-grade assembly and use?

Does POM withstand hospital cleaning agents and sterilization procedures?

Can Neway support FDA- and ISO-compliant POM material sourcing?

What is the lead time for prototype or small-batch POM components?