What’s the cost difference between 3-axis and 5-axis CNC machining?

What’s the Cost Difference Between 3-Axis and 5-Axis CNC Machining?

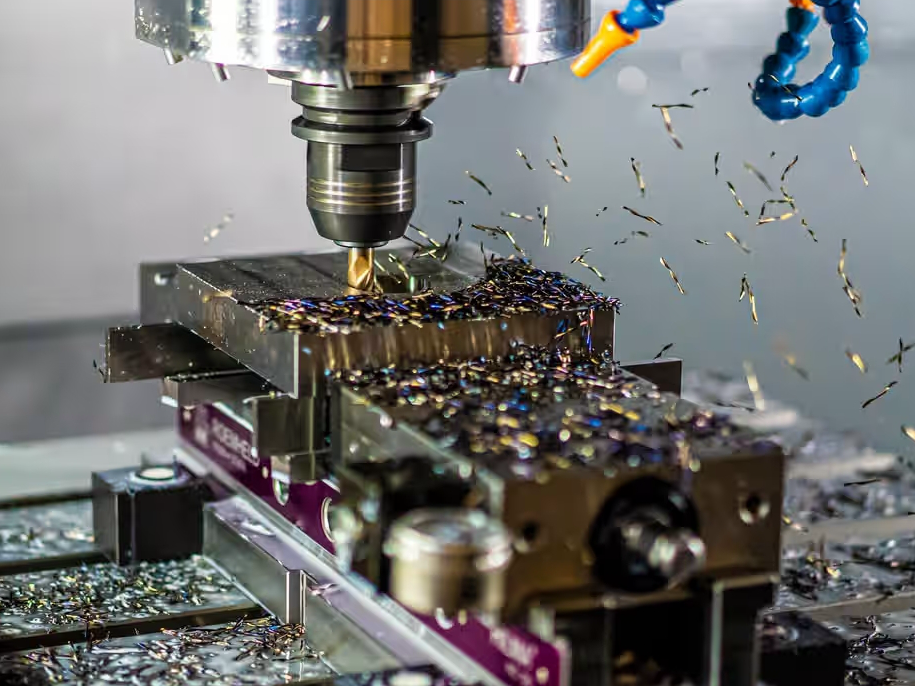

In CNC manufacturing, selecting between 3-axis and 5-axis machining depends heavily on part geometry, tolerance requirements, and volume. As engineers at Neway, we evaluate these choices using real production data and process benchmarks.

Machine Hourly Rate Comparison

The hourly rate for 5-axis CNC machining is typically 1.5 to 3 times higher than that of 3-axis equipment due to advanced capabilities and control complexity. Reference values are as follows:

Machine Type | Average Hourly Rate (USD) |

|---|---|

3-Axis CNC | $30 – $65 |

5-Axis CNC | $80 – $150 |

While the base rate is higher, 5-axis often compensates with faster processing and fewer setups.

Setup and Fixturing Efficiency

A key benefit of 5-axis machining is reduced setup time—up to 60% savings in some cases. Complex components requiring multiple re-clampings on a 3-axis machine can be completed in a single setup on a 5-axis platform. This minimizes labor and positioning error.

Machining Time and Toolpath Optimization

For angled holes, complex contours, or deep features, 5-axis machines provide smoother toolpaths and reduce tool repositioning. This can cut total machining time by 30–50%, especially on intricate parts such as turbine brackets or aerospace connectors.

Cost Case Study: Aluminum Aerospace Bracket

Item | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

Hourly Rate (USD) | $50 | $120 |

Machining Time (hr) | 3.0 | 1.2 |

Setup Time (hr) | 2.0 | 0.5 |

Total Estimated Cost (USD) | $250 | $198 |

In this case, 5-axis machining is 20% cheaper despite the higher hourly rate due to reduced time and setup complexity.

When 3-Axis Is More Suitable

For flat or prismatic parts, such as brackets or plates made from Aluminum 6061 or ABS, 3-axis machining is more cost-effective. It's ideal for high-volume production or low-complexity components.

Volume Considerations

For small batches of complex parts, 5-axis CNC is generally more economical in total cost.

For large-volume production of simple geometries, 3-axis CNC achieves lower unit pricing through scalability.

Manufacturing Services You May Need

Neway offers full-spectrum CNC capabilities, including 3-axis, 5-axis machining, precision machining, and CNC prototyping. We help you choose the right method based on complexity, material, and tolerance needs.