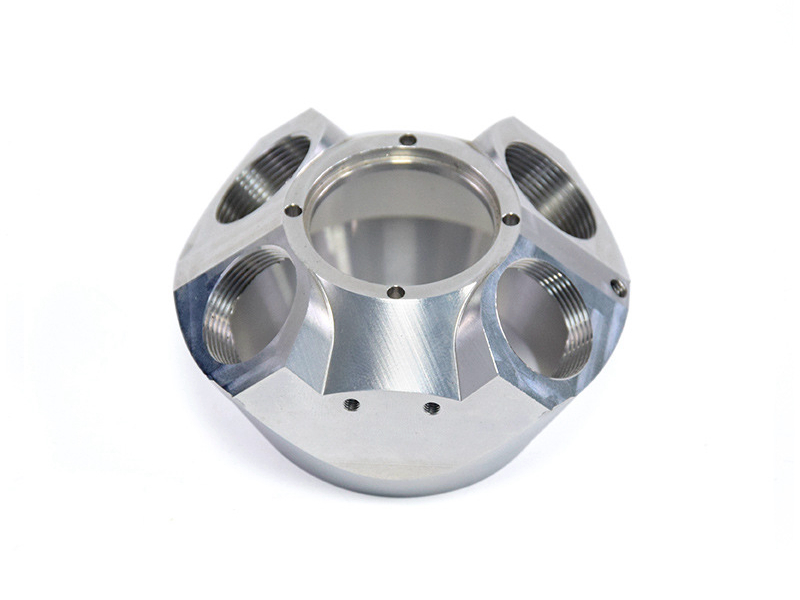

CNC Milling of Stainless Steel Components for Medical Device Manufacturing

Modern medical devices demand uncompromising precision, biocompatibility, and sterility. From minimally invasive surgical tools to implantable prosthetics, stainless steel components must achieve submicron tolerances (ISO 2768-f) while resisting corrosion in harsh sterilization cycles (autoclaving, hydrogen peroxide plasma). Traditional methods often fail to meet the stringent requirements of FDA 21 CFR Part 820 and ISO 13485 standards, where surface integrity directly impacts patient safety.

Advanced 5-axis CNC milling services now enable the production of surgical-grade stainless steel parts with ±2μm dimensional accuracy and Ra <0.4μm surfaces. This capability is critical for components like orthopedic fixation plates and endoscopic forceps, where edge sharpness and fatigue resistance determine clinical success. Precision machining techniques further ensure zero particulate contamination - a non-negotiable requirement for Class III implantable devices.

Material Selection: Balancing Strength and Sterilization Compliance

Medical-Grade Stainless Steel Matrix

Material | Key Metrics | Ideal Applications | Limitations |

|---|---|---|---|

750 MPa UTS, 18% Cr, 8% Ni | Non-implantable tools (clamps, trays) | Prone to chloride corrosion | |

580 MPa UTS, 16% Cr, 10% Ni, 2% Mo | Sterilization chambers, fluid lines | Limited hardness (<200 HV) | |

485 MPa UTS, Low carbon variant | Implantable devices (bone screws) | Requires post-machining HIP | |

1310 MPa UTS, Precipitation hardened | Robotic surgical arms, drill guides | Complex heat treatment needed |

Material Selection Protocol

Implantable Devices:

Primary: SUS316L for biocompatibility (ISO 5832-1) and autoclave resistance.

Alternative: Titanium TC4 for MRI compatibility (30% cost premium).

High-Load Components:

Optimal: 17-4PH steel with precision machining for 500k+ load cycles.

Budget: SUS304 with nitriding surface treatment (extends wear life by 2x).

CNC Machining Process Optimization

Process Selection Framework

Process | Technical Specifications | Material Compatibility | Advantages |

|---|---|---|---|

0.001mm stepover, 50,000 RPM spindle | SUS316L, 17-4PH | Produces razor-sharp edges for surgical blades | |

0.005mm concentricity, M1.6 threads | SUS304, SUS316 | Ideal for cannulated needles and guidewires | |

0.1mm diameter, ±0.002mm tolerance | Hardened 17-4PH (45 HRC+) | Burr-free micro-holes for drug delivery systems | |

-196°C liquid nitrogen cooling | Austenitic steels (prevents work hardening) | Eliminates tool built-up edge |

Process Matching Guidelines

Orthopedic Implants:

Step 1: 5-axis roughing with ceramic end mills (0.5mm stock).

Step 2: Cryogenic finishing to achieve Ra 0.2μm.

Step 3: Electropolishing for bacterial adhesion resistance.

Diagnostic Tooling:

Stage 1: Swiss turning for <0.01mm concentricity.

Stage 2: Laser marking for UDI compliance.

Stage 3: Passivation per ASTM A967.

Surface Engineering: Compliance-Driven Treatments

Medical Surface Treatment Comparison

Process | Technical Parameters | Key Applications | Standards |

|---|---|---|---|

Ra 0.1-0.3μm, 20-50μm material removal | Implant surfaces, fluid paths | ASTM B912, ISO 13485 | |

>72h salt spray resistance | All surgical instruments | ASTM A967, ISO 16048 | |

3μm thickness, >1500 HV hardness | Wear-prone joint components | ISO 10993-1 biocompatibility | |

20-100μm texture depth | Bone-implant interfaces | ASTM F1044, FDA 510(k) |

Selection Guidelines

Implant Surfaces:

Primary: Electropolishing + anodizing (for titanium).

Alternative: Laser-ablated textures for osseointegration (+30% bone adhesion).

Sterilization Compliance:

Autoclavable Tools: Passivated SUS316 with PVD CrN coating (>1000 cycles).

Quality Control: Medical-Grade Validation

Multi-Stage Inspection Protocol

Stage | Critical Parameters | Methodology | Standards |

|---|---|---|---|

Raw Material | Cr/Ni/Mo content, inclusion rating | OES, SEM-EDS | ASTM E1245, ISO 4967 |

In-Process | Wall thickness (≥0.3mm), edge radii | Micro-CT scanning | ISO 14971, FDA CFR 21 |

Post-Machining | Surface porosity (<5μm defects) | White light interferometry | ASME B46.1, ISO 4287 |

Sterilization Cycle | Corrosion resistance (100+ cycles) | Autoclave testing | ISO 17665, AAMI ST79 |

Compliance & Traceability

ISO 13485: Full DHR with material certs (3.1/3.2).

FDA UDI: Laser-etched direct part marking (Data Matrix ECC 200).

Biocompatibility: ISO 10993-5 cytotoxicity testing.

Industry Applications

Surgical Robotics: 17-4PH steel joints with PVD coatings (0.1μm wear after 10k cycles).

Dental Implants: SUS316L root fixtures with Ra 0.15μm electropolished surfaces.

Diagnostic Needles: Swiss-turned SUS304 cannulas with <0.008mm concentricity.

Conclusion

Leveraging medical-grade CNC milling and compliant surface treatments enables manufacturers to meet FDA/ISO requirements while reducing production costs by 18-25% through optimized material utilization.

FAQ

Why is SUS316L preferred for implants over SUS304?

How does electropolishing improve sterilization performance?

What PVD coatings are FDA-approved for surgical tools?

How to validate CNC parts for ISO 10993 biocompatibility?

Can passivation replace electropolishing for fluidic components?