What’s the tightest tolerance achievable for CNC milled plastic parts?

What’s the Tightest Tolerance Achievable for CNC Milled Plastic Parts?

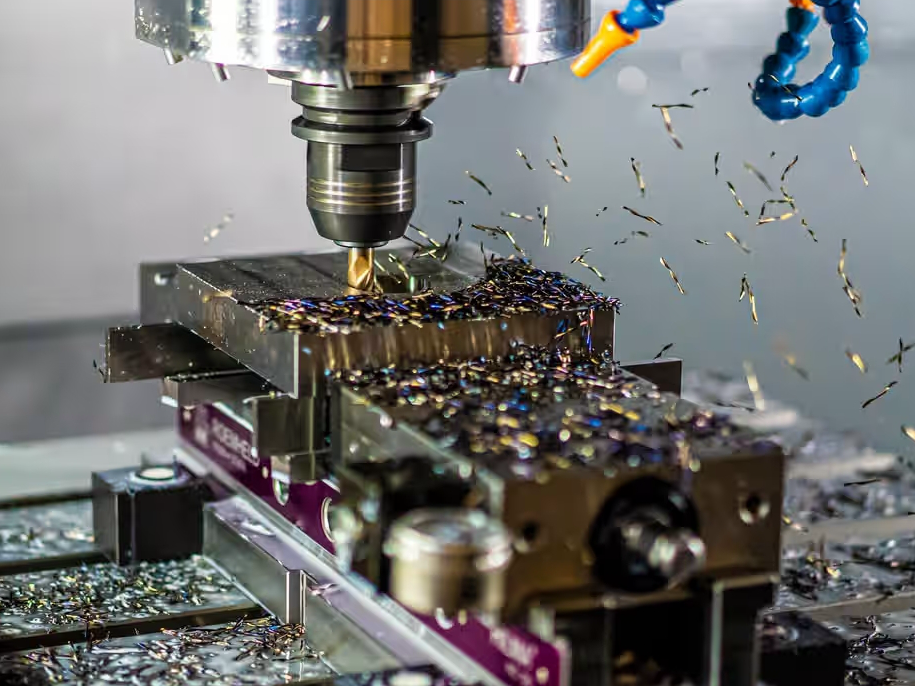

CNC milling of plastic components offers excellent dimensional control, but plastics behave differently from metals under cutting forces, thermal conditions, and humidity. At Neway, we apply material-specific tolerance strategies to ensure repeatability without overengineering cost.

Typical Tolerance Range for CNC Plastic Parts

Tolerance Category | Tolerance (mm) | Use Case |

|---|---|---|

Standard Tolerance | ±0.10 – ±0.20 | General housings, brackets, panels |

Precision Tolerance | ±0.05 – ±0.08 | Functional snap fits, bushings |

High-Precision Tolerance | ±0.01 – ±0.03 | Bearing seats, optical housings, guides |

Under controlled conditions and proper design, ±0.01 mm can be achieved on stable materials like POM (Acetal) or PEEK. However, this level requires environmental controls, specialized tooling, and pre-conditioned material.

Material-Specific Considerations

POM (Acetal): Excellent dimensional stability; can hold ±0.01 mm in dry or semi-humid environments.

PEEK: High strength, low thermal expansion, suitable for tight-tolerance precision parts.

ABS: Subject to warping and moisture absorption—±0.10 mm is more realistic.

Polycarbonate: Prone to stress cracking; ±0.05 mm achievable with minimal internal stress.

Key Factors Influencing Plastic Machining Tolerance

Thermal expansion: Plastics have 5–10× higher coefficients than metals.

Moisture absorption: Hygroscopic materials swell, altering size over time.

Residual stress: From improper fixturing or sharp toolpaths, may cause warping after release.

Surface finish requirement: Tighter tolerances often correlate with smoother finishes, which increases cycle time.

Design Recommendations

Avoid over-specifying tolerances for cosmetic or non-critical areas.

Add relief cuts and chamfers to reduce internal stress.

Use dowel pin holes or inserts only where alignment is essential.

Manufacturing Services You May Need

Neway provides plastic CNC machining services with material-specific process controls to achieve tight tolerances. We offer solutions in POM, PEEK, and polycarbonate, supporting global delivery and ±0.01 mm accuracy where required.