How much does surface finishing like anodizing or polishing add to the price?

How Much Does Surface Finishing Like Anodizing or Polishing Add to the Price?

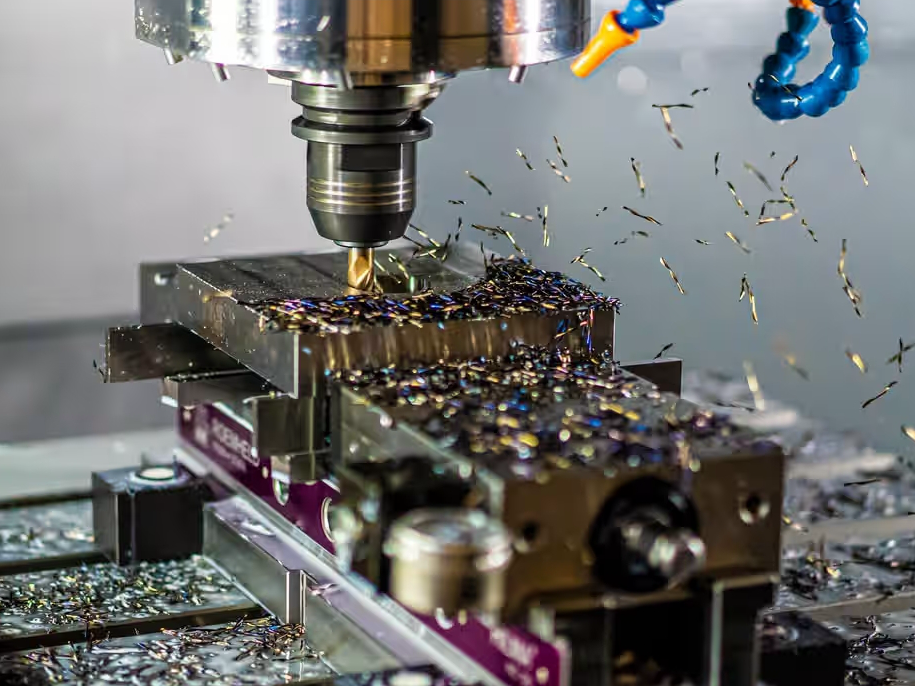

Surface finishing is a crucial step in CNC manufacturing, especially for functional or aesthetic parts. At Neway, we evaluate finishing costs based on part geometry, volume, and finishing type. Two of the most common options—anodizing and polishing—add both value and cost. Understanding the pricing dynamics is essential for cost control.

Typical Price Range by Finish Type

Finish Type | Added Cost (USD/Part) | Typical Applications |

|---|---|---|

Anodizing | $5 – $25 | Aluminum parts, corrosion resistance, color coding |

Polishing | $3 – $15 | Decorative parts, smooth surface requirements |

These values are based on small-to-medium parts under 200 mm, batch size 50–100 pcs, and basic geometries. Highly complex surfaces, large parts, or custom requirements can increase these costs by 30–80%.

Cost Drivers for Anodizing

Anodizing is commonly applied to Aluminum 6061 or Aluminum 7075. Its cost varies depending on:

Color requirement: Clear and black are standard; custom colors may add 20–40% to cost.

Type of anodizing: Type II (decorative) is cheaper than Type III (hard anodizing).

Masking for selective surfaces: Adds labor and setup complexity.

Batch processing volume: Small batches incur higher cost per part.

Reference: For Type II clear anodizing on a standard 100×100×10 mm part, expect to pay $8–$12 per part in medium volumes.

More details: Anodizing Explained

Cost Drivers for Polishing

Polishing is ideal for stainless steel, brass, or decorative plastic components. Pricing depends on:

Material hardness: Softer metals like brass polish faster than stainless steel.

Finish grade: Mirror finishes cost more than satin due to higher labor intensity.

Part geometry: Sharp corners, internal cavities, or blind holes add complexity.

Post-process cleaning or buffing: Additional cleaning steps can add $2–$5 per part.

Reference: A medium-size SUS304 stainless steel part requiring Ra < 0.4 µm mirror polish may cost $12–$18 per part.

More details: Polishing CNC Machining Parts

Key Tip: Combine Finishes in Batch

For cost savings, batch-finishing is essential. Combining parts with the same finish into one anodizing or polishing run can reduce the unit cost by up to 40%. Consider this during production planning.

Manufacturing Services You May Need

Neway provides full finishing capabilities including anodizing, polishing, powder coating, and electropolishing. We support material selection, surface engineering, and end-to-end CNC machining services with ±0.01 mm precision and global shipping.