How can I reduce the cost of CNC milling for complex parts?

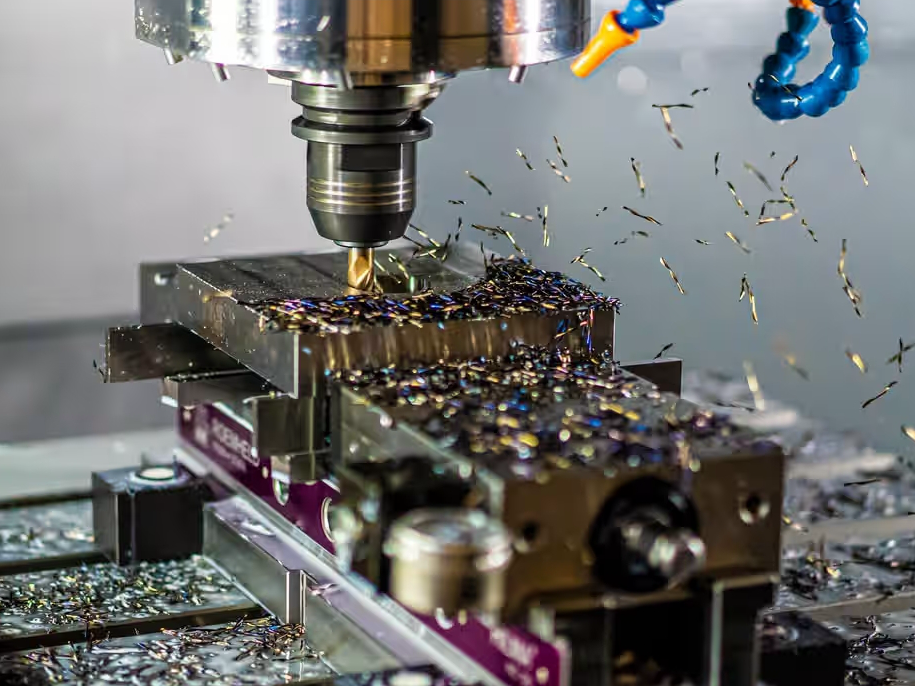

How to Reduce the Cost of CNC Milling for Complex Parts

Reducing CNC milling costs for complex parts requires engineering foresight, process optimization, and smart material selection. As Neway engineers, we address these challenges by balancing precision and efficiency to support our global buyers with ±0.01 mm tolerances and dependable lead times.

Material Selection and Sizing Strategy

Choose machinable materials such as Aluminum 6061 or Brass C360 that offer excellent chip removal characteristics and lower tool wear. Opt for standard stock sizes to minimize raw material waste and reduce setup adjustments.

Simplify Part Geometry Where Possible

Avoid unnecessary internal cavities, undercuts, or deep pockets that require CNC milling. For instance, a pocket depth greater than 4× tool diameter significantly increases machining time and tool deflection risk. Design radii that match standard end mills (e.g., R3, R5) to reduce custom tooling needs.

Consolidate Tolerances Intelligently

Limit tight tolerances (±0.01 mm) only to functional features. Unnecessary application of high-precision standards across the entire part drives up inspection time and cutting complexity. Use precision CNC machining only where performance requires it.

Use Modular or Split-Part Design

Breaking a complex part into simpler sections for 3-axis CNC milling, then assembling them, often costs less than machining a monolithic structure with 5-axis setups. This strategy also simplifies fixturing and allows parallel manufacturing.

Optimize Toolpaths and Fixturing

Advanced CAM strategies like adaptive clearing and rest machining can shorten cycle times. Custom fixtures and low-volume CNC machining improve throughput for symmetrical parts. Engage with your CNC supplier early for design-for-manufacturability (DFM) feedback to ensure efficient setups.

Apply Batch Manufacturing for Similar Parts

Combine orders or redesign to share features with other components. This allows CNC prototyping batches to benefit from amortized setup time, tooling, and fixture investment.

Choose the Right Surface Finish

Elaborate finishes such as anodizing or powder coating can add 10–30% to cost. Use basic as-machined finishes when surface appearance or corrosion resistance isn't critical.

Manufacturing Services You May Need

Neway provides one-stop CNC machining solutions from CNC milling and EDM to surface treatments. We deliver ±0.01 mm precision, rapid turnaround, and full material traceability worldwide.