What’s the best material for low-cost prototyping with CNC milling?

What’s the Best Material for Low-Cost Prototyping with CNC Milling?

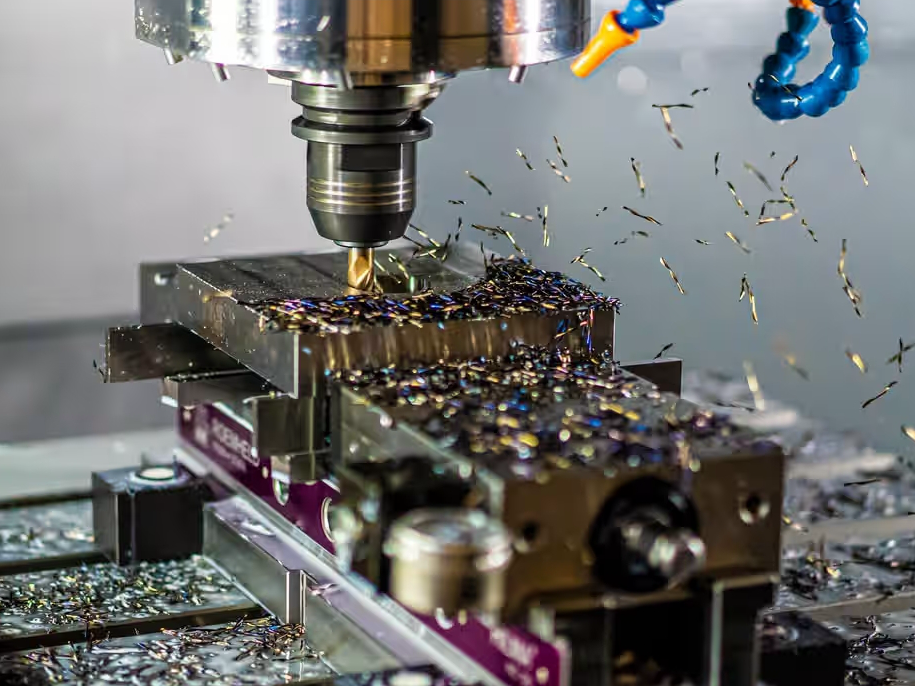

When cost is the top concern for CNC prototyping, material selection plays a decisive role. At Neway, we recommend materials that balance machinability, availability, and dimensional stability to reduce production time and tooling wear. The goal is to simulate real part behavior without inflating prototype budgets.

Top Low-Cost CNC Prototyping Materials

Material | Machinability | Relative Cost | Common Use Cases |

|---|---|---|---|

Aluminum 6061 | Excellent | Low | Structural prototypes, enclosures |

ABS Plastic | High | Very Low | Consumer devices, housings |

POM (Acetal) | High | Low | Gears, mechanical fit parts |

Brass C360 | Excellent | Medium | Threads, valve bodies |

1. Aluminum 6061 – The Universal Prototyping Metal

Aluminum 6061 offers a near-ideal combination of affordability, corrosion resistance, and easy machinability. It supports ±0.01 mm tolerances, short chip formation, and dry cutting. For functional metal prototypes, it's typically 30–40% cheaper to machine than stainless steel, with faster cycle times.

2. ABS Plastic – Lowest Material and Machining Cost

ABS is a go-to option for low-stress prototypes that don't require high thermal or mechanical performance. It cuts cleanly, produces little burr, and is perfect for appearance models or enclosure fit testing. Material cost is approximately $2–$4 per kg, and CNC time is 30% shorter than metals.

3. Acetal (POM) – Best for Functional Mechanical Prototypes

POM (Acetal) is an engineering-grade plastic with tight dimensional stability, making it ideal for snap fits, bearings, or sliding components. Its cost is slightly higher than ABS but delivers better mechanical accuracy and finish for wear testing.

4. Brass C360 – For Threaded and Precision Fit Prototypes

Brass C360 is self-lubricating and machines with exceptional surface finish. Though more expensive than aluminum, it's ideal for small parts with complex threads, tight tolerances, or visual evaluation.

When to Use Low-Cost Materials

Design validation before committing to costly superalloys

Fit checks for mechanical mating

Preliminary testing in low-load environments

Prototypes for iterative design changes

Avoid low-cost materials for high-temperature or structural testing, where behavior may differ significantly from production-grade alloys.

Manufacturing Services You May Need

Neway provides CNC prototyping services using aluminum, plastics, and brass for rapid turnaround at optimized cost. We support DFM reviews, material selection, and provide global delivery with ±0.01 mm accuracy.