Rapid 3D Printing Prototyping Service

We offer rapid 3D printing prototyping services for high-temperature alloys, metals, plastics, and ceramics, delivering prototypes in as fast as 24 hours to meet client needs for quick turnaround and high-quality results.

- Stereolithography (SLA)

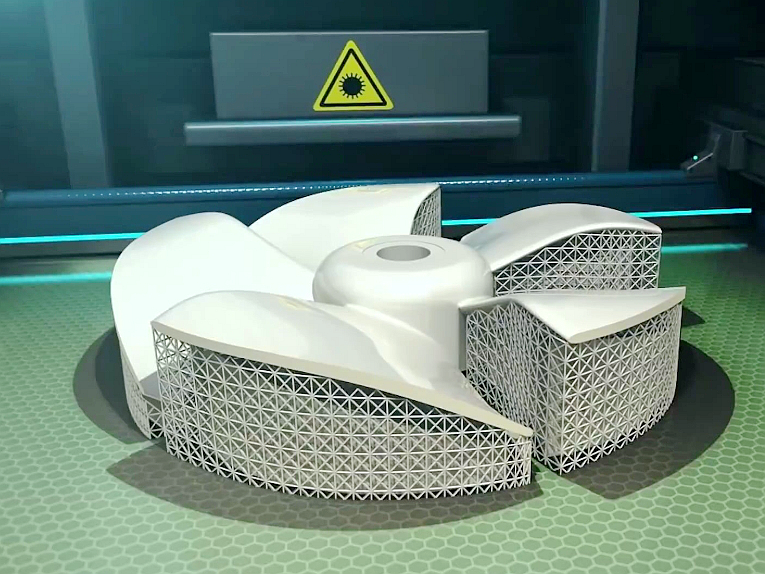

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Multi Jet Fusion (MJF)

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

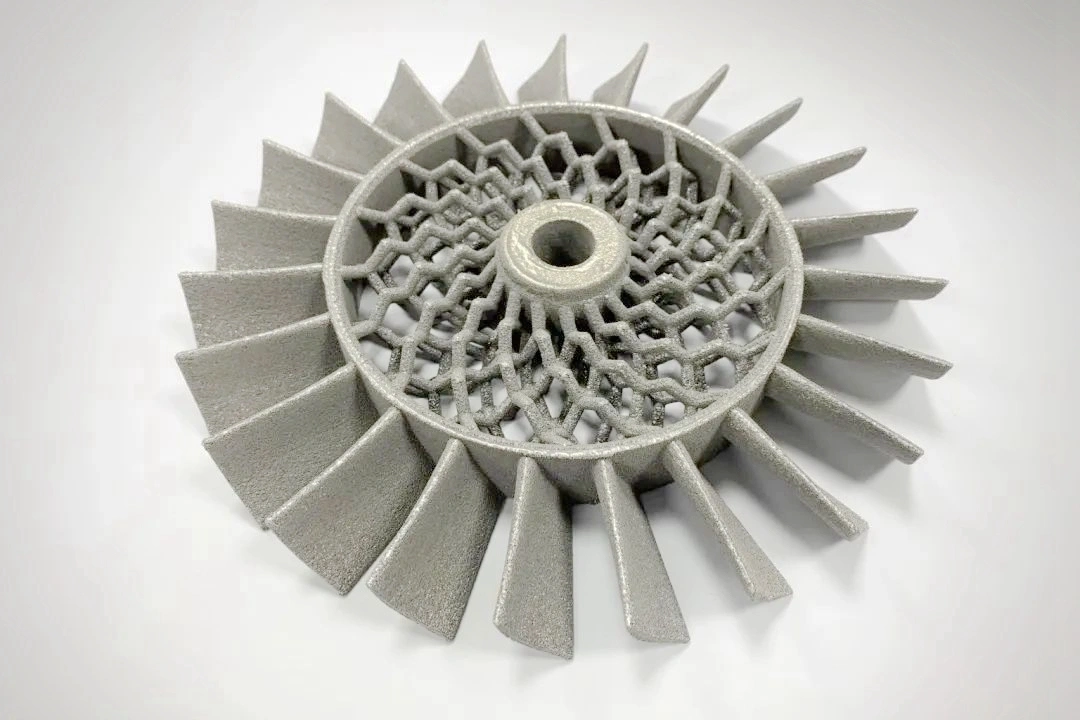

3D Printing Prototyping Service Range

We provide rapid 3D printing prototyping services for high-temperature alloys, metals, plastics, and ceramics, ensuring quick turnaround times, with delivery as fast as 24 hours to support efficient and precise prototyping for various applications.

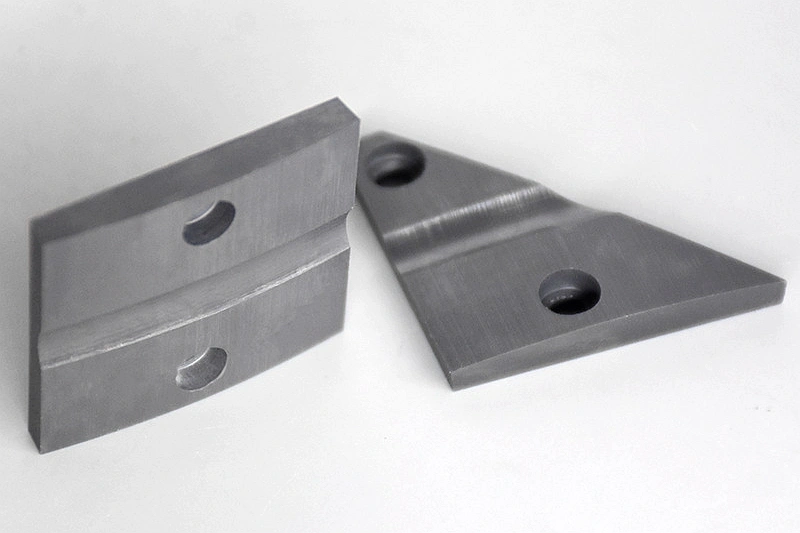

Typical 3D Printing Materials

Common aluminum alloys used in CNC machining include 6061, 7075, 2024, and 5052, offering a range of properties like high strength, corrosion resistance, and machinability. These alloys are used in aerospace, automotive, marine, and structural applications.

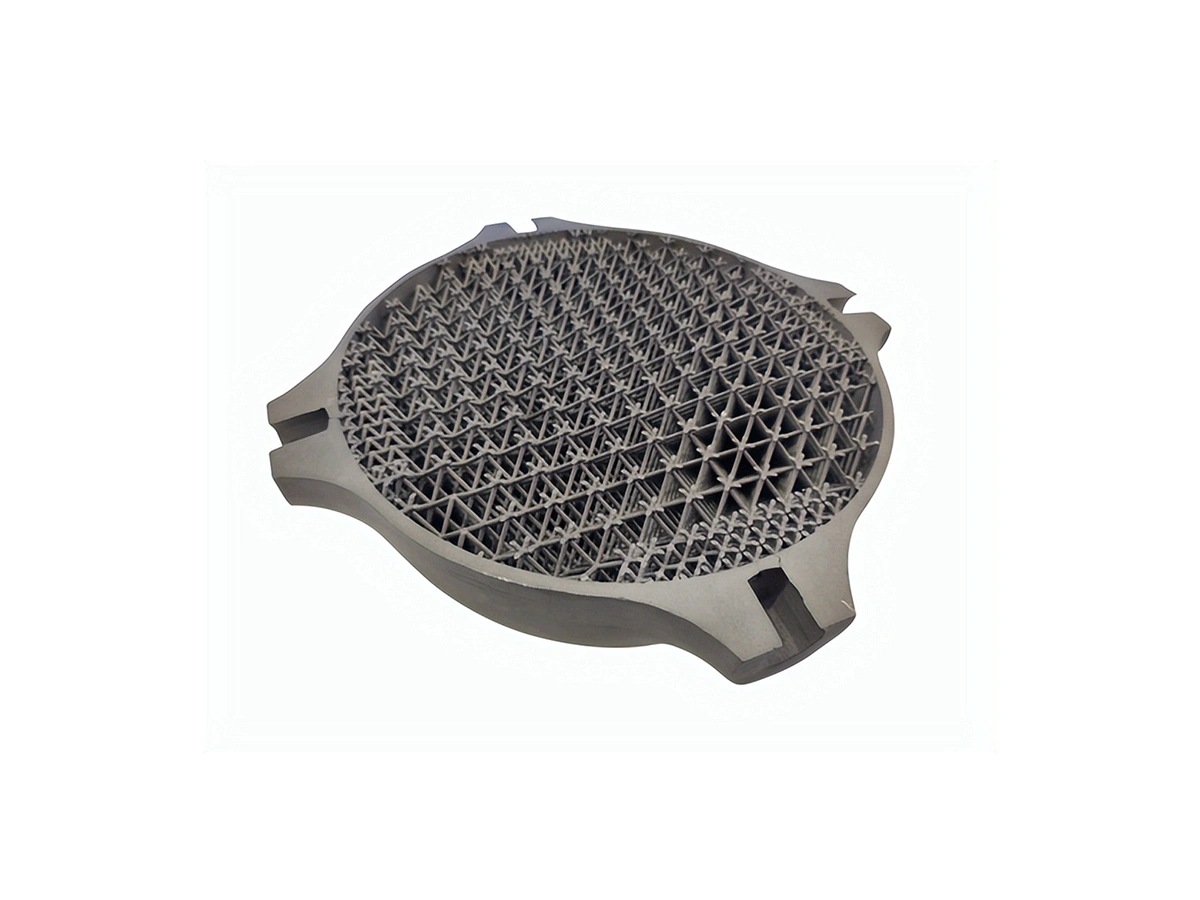

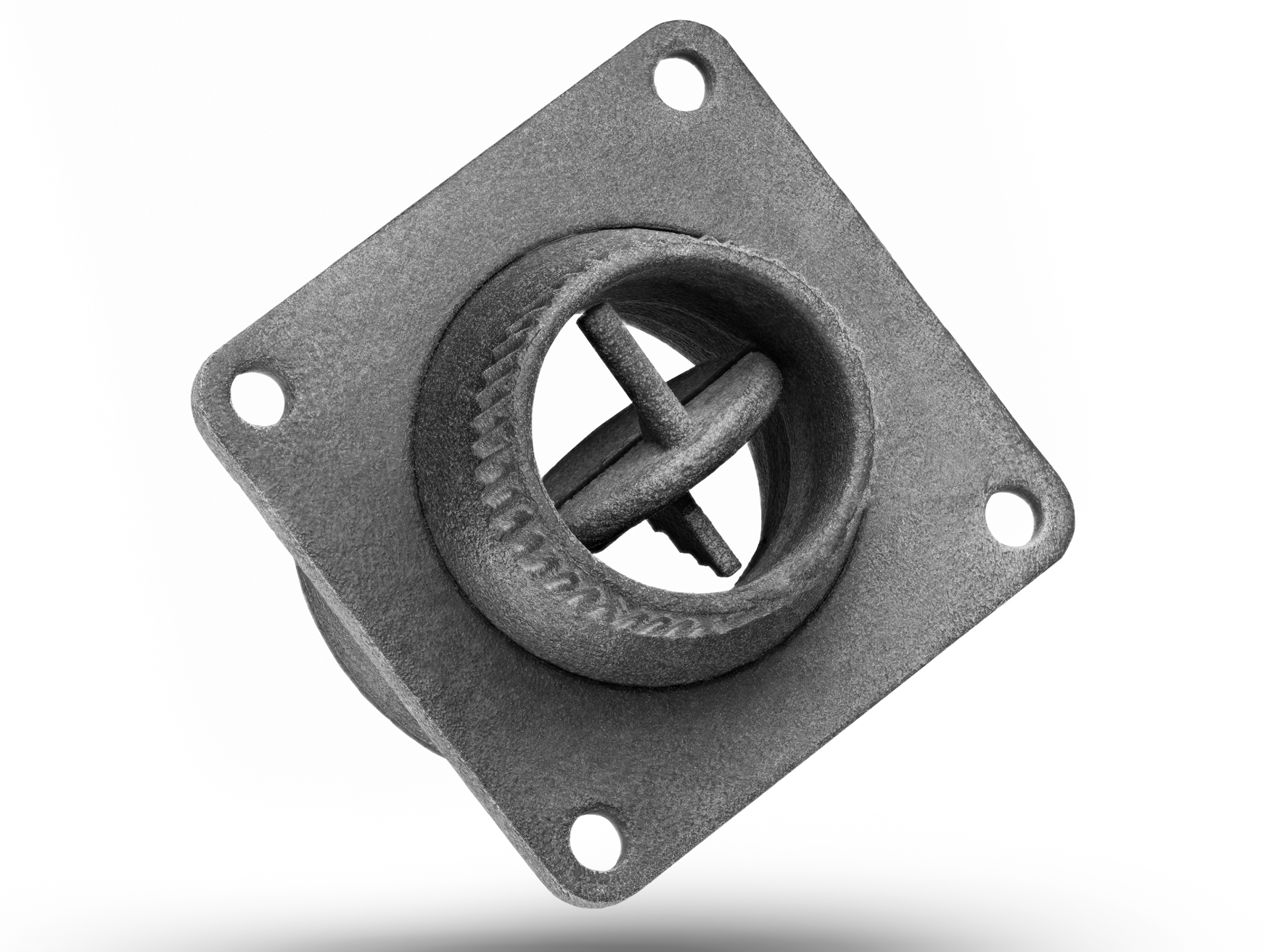

Custom 3D Printing Parts Case Study

A custom 3D printing case study showcases the creation of complex, high-performance parts using advanced materials like superalloys and composites. The process involves design optimization, rapid prototyping, and post-processing to meet specific industry requirements, ensuring quality, precision, and durability.

Let's Start A New Project Today

Suggestions for 3D Printing Parts

CNC prototype design guidelines emphasize material selection, uniform wall thickness, achievable tolerances, and accessible features. Key principles include avoiding sharp corners, minimizing material removal, and ensuring proper hole design and symmetry to optimize machining efficiency, cost, and part quality.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Machining Precision Works Ltd.All Rights Reserved.