Selective Laser Sintering (SLS) | Metal Parts 3D Printing Service

Introduction: Unlocking the Ultimate Freedom in Metal Part Manufacturing

In modern high-end manufacturing, the demand for metal parts with complex geometries is steadily increasing. Traditional manufacturing methods often struggle to handle components that incorporate intricate internal flow channels, lattice structures, or highly integrated functional features. Metal Selective Laser Sintering (SLS), as a key branch of additive manufacturing, is overcoming these limitations with its unique technical advantages. By sintering metal powder layer by layer, this technology enables the direct production of dense, high-performance metal components, unlocking unprecedented design freedom for engineering applications.

Metal SLS Technology Explained: The Journey from Powder to Dense Metal Part

The core principle of metal SLS is to use a high-power laser beam to selectively scan a metal powder bed, fully melting the powder particles at precisely controlled temperatures so that they solidify and fuse into shape. This process must be carried out in a controlled protective atmosphere to prevent oxidation of the metal at high temperatures.

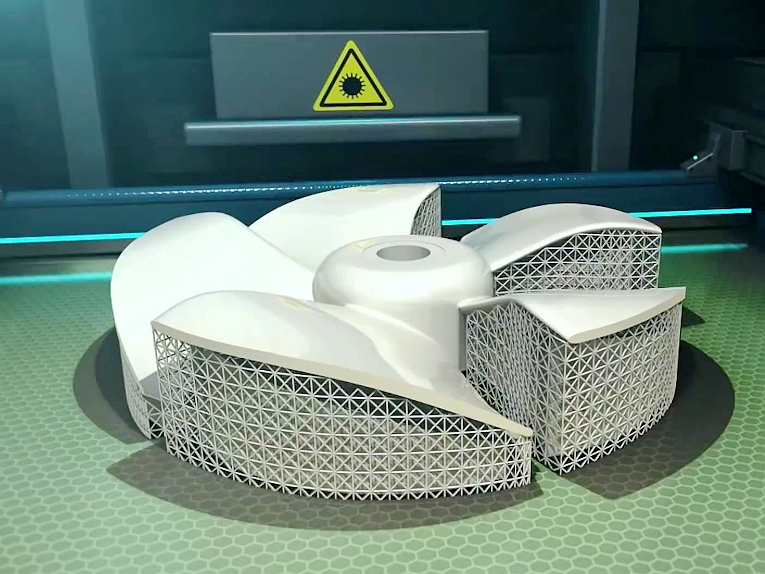

A complete manufacturing workflow consists of several tightly controlled steps. It begins with 3D model preparation and support structure design, both of which are critical to ensuring successful printing. Next, the build chamber is evacuated and filled with inert gas (typically argon or nitrogen) to create ideal environmental conditions for printing. During the build, the recoater system spreads a very thin layer of metal powder over the build plate, and the laser scans and melts the powder according to the defined cross-sectional geometry. Once a layer is completed, the build platform descends by the thickness of one layer, and the powder spreading and laser scanning steps are repeated until the entire part is built.

This technology is similar in principle to plastic SLS, but the process requirements are significantly more stringent. As a high-end process within the broader 3D Printing technology landscape, metal SLS requires precise control of laser power, scan speed, layer thickness, and other parameters to ensure stable and reliable part quality.

Key Materials for Metal SLS and Their Properties

Metal SLS supports a wide range of materials to meet diverse performance requirements across different applications.

Among stainless steels, Stainless Steel SUS316L stands out for its excellent corrosion resistance. It is particularly suitable for parts used in harsh environments, such as chemical processing equipment and marine engineering. Its balanced mechanical and corrosion-resistant properties make it one of the most widely used materials in metal SLS printing.

Tool steels and mold steels also play an important role in metal SLS. With high hardness and outstanding wear resistance, they are ideal for producing conformal cooling inserts in Rapid Molding. Using metal SLS, mold inserts with complex internal cooling channels can be manufactured to significantly improve injection molding efficiency and part quality.

High-temperature alloys are another key material category in metal SLS. Inconel 718, with its exceptional high-temperature strength and fatigue resistance, is an ideal choice for hot-section components in aerospace engines. Inconel 625, renowned for its exceptional fatigue resistance and oxidation resistance, is widely utilized in the chemical processing and energy industries.

Titanium alloys hold a special position in metal SLS. Ti-6Al-4V (TC4), the most commonly used titanium alloy, combines an excellent strength-to-weight ratio with biocompatibility, making it a preferred material for aerospace structural components and medical implants.

For lightweight structures, aluminum alloys provide unique advantages. Aluminum 6061 offers well-balanced mechanical properties, while Aluminum 7075, with its high strength and good corrosion resistance, is widely used for aerospace structural parts requiring weight reduction and high performance.

Five Decisive Advantages of Choosing Metal SLS

Metal SLS delivers transformative benefits to modern manufacturing, with its core advantages reflected in several key aspects.

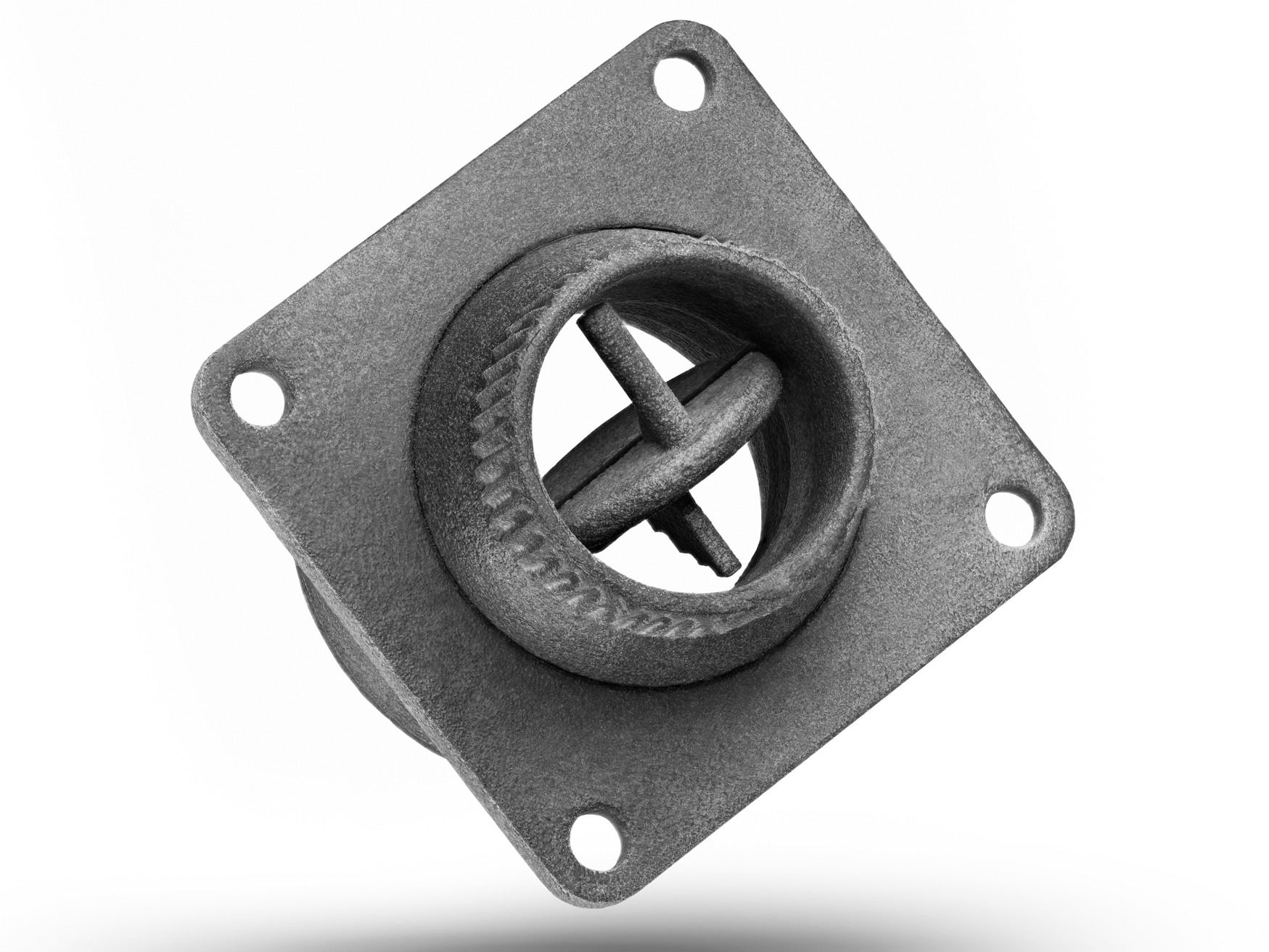

First is the unmatched design freedom. Metal SLS enables the production of complex internal cooling channels, lightweight lattice structures, and topologically optimized geometries that are extremely challenging or impossible to achieve using traditional processes. Designers can focus on functional and performance optimization, rather than being constrained by conventional manufacturing limitations.

In terms of material performance, metal SLS parts can achieve very high densities (typically above 99.5%), with mechanical properties that approach or even surpass those of forged components. With appropriate post-process heat treatment, printed parts can reliably meet the requirements of demanding operating conditions.

Functional integration and part consolidation represent another major advantage. Using metal SLS, engineers can redesign assemblies originally composed of multiple components into a single integrated part. This reduces assembly steps, improves production efficiency, and significantly enhances reliability and service life by eliminating potential leakage paths and mechanical joints.

Metal SLS also offers a rapid response capability. Since no molds are required, production can proceed directly from digital models to physical parts, greatly shortening the development cycle. For low-volume manufacturing Service, this technology provides a cost-effective and flexible solution.

Finally, metal SLS demonstrates excellent material utilization. Unfused metal powder from the build process can be recovered and reused after proper sieving and quality control, resulting in significantly higher material utilization compared to traditional subtractive methods. This advantage is particularly significant for high-value alloys.

Key Post-Processing Steps for Metal SLS Parts

Proper post-processing is critical to ensuring the final quality of metal SLS components. The first step is to remove support and perform basic cleaning. Parts are typically separated from the build plate using wire EDM or cutting, followed by careful removal of support structures. This step requires skilled operation to prevent damage to delicate features.

Heat treatment plays a crucial role in enhancing performance. Through tailored Heat Treatment for CNC Machining processes, internal residual stresses generated during printing can be effectively relieved, and the microstructure can be optimized to significantly enhance mechanical properties. Some materials also require specific aging or precipitation hardening treatments.

For high-spec applications such as aerospace, hot isostatic pressing (HIP) is often indispensable. By subjecting parts to high temperature and high isostatic pressure, HIP further eliminates internal micro-defects, greatly improving fatigue performance and overall reliability.

Surface finishing is selected according to application requirements. Electropolishing for Precision Parts can significantly reduce surface roughness while enhancing corrosion resistance. For parts requiring specific surface textures or mirror finishes, the CNC Part Polishing Service is used to achieve the desired surface quality.

Metal SLS vs. Other Metal Manufacturing Processes

Selecting the optimal manufacturing process for metal parts requires a comprehensive technical and economic evaluation.

Compared with traditional CNC machining, metal SLS offers clear advantages in geometric complexity, material utilization, and design flexibility, making it particularly suitable for parts with internal channels, lattice structures, or unconventional features. However, for simple geometries and high-volume production, conventional precision machining services are usually more cost-effective.

Compared with metal casting, metal SLS eliminates the need for molds, which significantly reduces cost and lead time during product development and iteration. Metal SLS parts also provide higher dimensional accuracy and more consistent material properties. That said, for very large batches, traditional casting may still hold advantages in overall cost.

In real-world production, hybrid manufacturing often delivers the best results. By combining metal SLS with Multi-Axis Machining Services, near-net-shape blanks can be produced via SLS, and then critical mating surfaces and precision features can be finished using multi-axis CNC machining. This approach preserves geometric freedom while ensuring tight dimensional accuracy where it matters most.

Innovative Applications of Metal SLS in High-End Industries

In the aerospace sector, metal SLS is driving new design philosophies. Aerospace and Aviation manufacturers use this technology to produce engine fuel nozzles, lightweight brackets, turbine blades, and other critical components. Through topology optimization and lattice structures, significant weight reduction can be achieved while maintaining or improving mechanical performance—directly contributing to higher efficiency and better thrust-to-weight ratios.

The medical industry is another major beneficiary of metal SLS. In Medical Device manufacturing, SLS is used to produce customized orthopedic implants with porous structures that promote bone ingrowth and long-term stability. Additionally, surgical guides, dental prosthetic frameworks, and other precision instruments can be manufactured with high accuracy to meet stringent clinical requirements.

In the automotive sector, especially in high-performance motorsports, metal SLS is widely adopted. Automotive manufacturers use it to produce engine components, lightweight suspension elements, and customized thermal management modules. These parts not only deliver optimized performance but also enable rapid design iterations, allowing for quick responses to testing feedback and tracking conditions.

Neway’s Metal SLS Capabilities and Quality Commitment

At Neway, we are committed to delivering industry-leading metal SLS manufacturing solutions. Equipped with advanced metal SLS systems and robust process control frameworks, we ensure every part meets stringent quality standards. Our engineering team combines deep materials expertise with extensive process knowledge to provide comprehensive support, from material selection and design for additive manufacturing (DFAM) to parameter optimization.

We offer a complete One Stop Service Service, covering design optimization, additive manufacturing, heat treatment, and precision machining. Our quality assurance system is fully equipped with advanced inspection equipment to verify dimensional accuracy, surface integrity, and internal quality, ensuring compliance with demanding standards in aerospace, medical, and other critical industries.

Conclusion: Embracing the Limitless Potential of Metal Additive Manufacturing

Metal SLS is reshaping the landscape of high-end manufacturing. It is not only a tool for rapid prototyping but also a robust solution for directly producing high-performance end-use metal components. As technology advances and more high-performance materials become available, metal SLS will continue to unlock new possibilities across an increasingly diverse range of industries. We sincerely invite partners from all sectors to collaborate with Neway, explore the vast potential of metal SLS technology, and drive innovation and industrial upgrading together.

FAQs

Can heat-treated metal SLS parts match the strength of forged components?

What support materials are used in metal SLS, and how hard are they to remove?

Can metal SLS make complex parts with internal cavities, and how is powder removed?

Can SLS titanium parts be used as implants, and what post-processing?

What is the typical build volume of metal SLS machines, and how are larger parts handled?