Resin and Plastic 3D Printing Service | Stereolithography (SLA)

Introduction: Why SLA Is the Top Choice for High-Precision Plastic Prototypes?

In today’s fast-paced product development environment, time and accuracy are critical factors that determine project success. Since its inception, stereolithography (SLA) 3D printing technology has maintained an irreplaceable position in plastic prototype manufacturing with its exceptional printing accuracy and superior surface quality. Whether for finely detailed concept validation models or assembly test parts requiring tight dimensional tolerances, SLA consistently delivers reliable solutions. As additive manufacturing engineers at Neway, we see every day how SLA helps our customers significantly shorten development cycles while effectively controlling development costs.

Deep Dive into SLA Technology: How Light Shapes Precision Parts

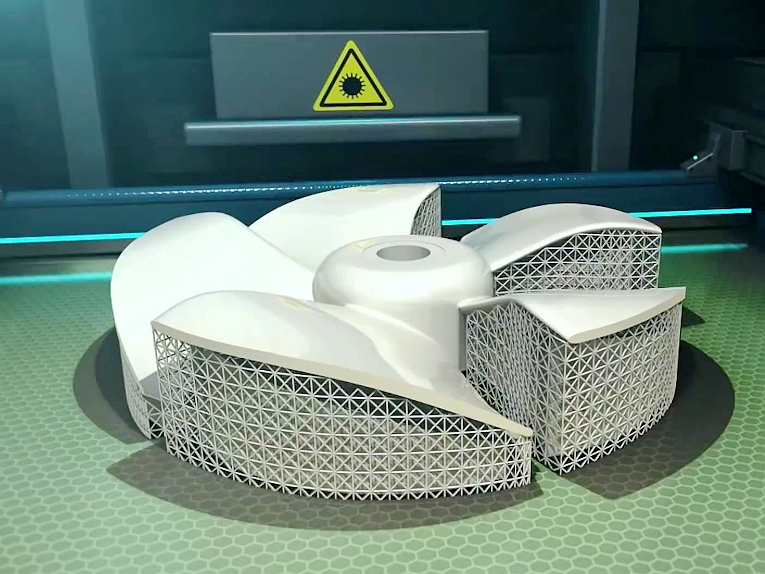

The core principle of SLA is based on the selective curing of photosensitive polymers. In this process, a high-power UV laser acts like an invisible sculpting tool, scanning precisely across the surface of liquid photopolymer resin according to sliced data from the 3D model. The irradiated regions undergo photopolymerization, transforming from liquid to solid and forming a thin cross-sectional layer of the part.

A comprehensive SLA workflow comprises several highly controlled stages. It begins with 3D model preparation and the intelligent generation of support structures—both of which are critical to ensuring successful printing. Next, the build platform is submerged into the resin tank, and the laser starts curing the first layer. After one layer is completed, the platform is raised by exactly the thickness of one layer, a fresh resin film is formed, and the laser continues scanning the next layer. This cycle repeats until the entire part is built. After printing, the part must undergo isopropyl alcohol (IPA) cleaning, post-curing, and support removal before becoming a finished component.

A Comprehensive Resin Portfolio: Matching the Best Performance to Your Application

Selecting the right resin is essential for successful SLA printing. Our material library includes a range of rigorously validated engineering-grade resins, each with distinct performance characteristics.

Standard resins offer an excellent cost-performance balance. With well-rounded mechanical properties and smooth surface finishes, they are ideal for concept validation prior to CNC Machining Prototyping. This material allows engineers to quickly transform design ideas into physical models and identify potential issues at an early stage.

For functional test parts that must withstand mechanical loads, tough resins are the optimal choice. These materials simulate the behavior of engineering plastics such as ABS and PP, making them particularly suitable for snap-fit components, housings, and other parts that require repeated assembly and testing in demanding Prototyping Service scenarios.

For high-temperature applications, high-temperature resins deliver outstanding thermal stability. They can maintain shape and functionality within the 80–200°C range, making them ideal for under-the-hood engine components, thermal fluid test fixtures, and other specialized applications.

Typical Post-Processing and Finishing Options for SLA 3D Printing

Post-processing is a crucial factor in determining the final quality of SLA parts. Proper finishing not only improves aesthetics but also enhances durability and functionality.

Support removal and basic cleaning are mandatory steps for every SLA part. Our technicians carefully remove all supports and perform initial touch-ups on residual marks to ensure that critical features remain uncompromised.

For applications requiring high gloss, the CNC Part Polishing Service can refine SLA surfaces to near-injection-mold quality with mirror-like finishes. This is especially suitable for show models and appearance-critical samples.

When specific colors or textures are required, the CNC Part Painting Solution offers extensive customization options. Our coating specialists can accurately match customer-specified color codes and deliver a full range of finishes from matte to high-gloss.

To further enhance durability, UV Coating for CNC plastic components provides an additional protective layer. This treatment significantly improves surface hardness and wear resistance while effectively preventing UV-induced yellowing over time.

Key Advantages and Application Scenarios of SLA Technology

SLA’s unique strengths make it a powerful solution in multiple stages of product development. In design validation and visual assessment, SLA enables the rapid fabrication of highly accurate models that faithfully represent the original CAD design. This enables designers and stakeholders to perform intuitive form evaluations early in the process, thereby accelerating decision-making and allowing for market feedback before investing in full-scale tooling.

For engineering verification, high-precision SLA parts provide a reliable platform for assembly checks and functional testing. Engineers can use SLA components to verify complex assembly relationships, validate mechanisms, and detect potential interference issues. This physical validation significantly reduces the risk and cost of tooling modifications later in the development cycle.

For low-volume production, SLA delivers unique value. Combined with Rapid Molding technologies, SLA master patterns can be quickly converted into small-batch production capability, enabling market testing or limited product launches before committing to full-scale molds.

Comparison: SLA vs. Other Plastic 3D Printing Technologies (FDM, SLS)

When selecting the most suitable 3D printing technology, it is essential to understand the strengths and limitations of each process. Compared to FDM, SLA offers clear advantages in accuracy, surface quality, and the reproduction of fine features. SLA can achieve features as small as 0.1 mm, with layer thicknesses in the 25–100 μm range, making it ideal for intricate and detailed parts. However, FDM may offer advantages in build volume, material robustness, and lower equipment and operating costs.

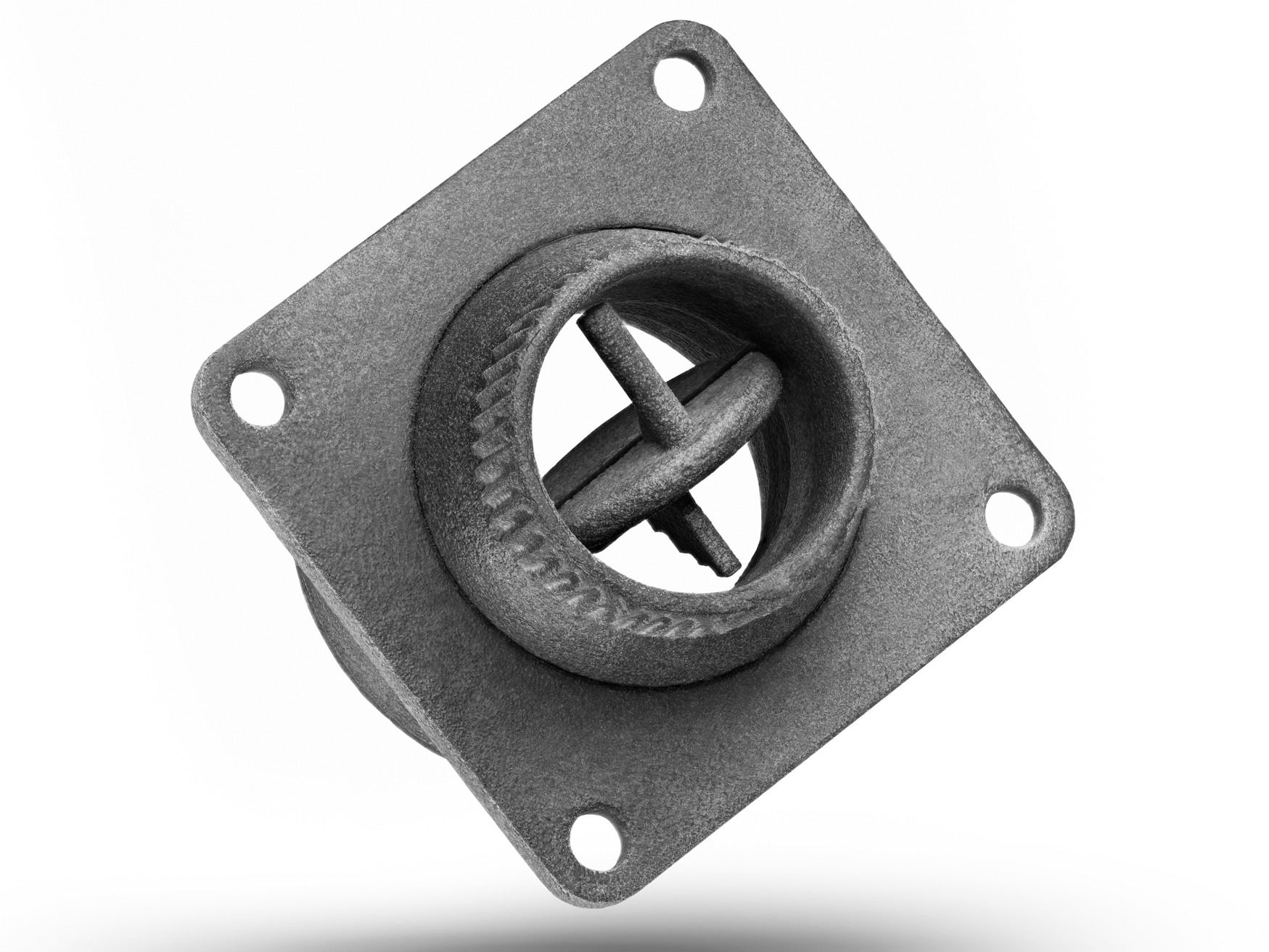

Compared with SLS, SLA does not require complex powder-handling systems and is generally easier to operate. SLS excels at producing highly complex internal cavities and interlocking assemblies without the need for support structures. However, SLA usually surpasses SLS in surface smoothness and dimensional accuracy.

A simplified decision path is as follows: when your project demands superior surface finish, tight dimensional tolerance, and fine feature resolution, SLA is the best choice; when complex internal geometries and robust functional parts are the priority, SLS may be more suitable; when budget constraints are tight or the parts are large and less detail-critical, FDM can provide the best cost-effectiveness.

Industry Use Cases of SLA 3D Printing Services

In the Consumer Products sector, SLA is widely used for design verification of electronic device housings. Designers can evaluate ergonomics, button feel, and assembly details using physical prototypes. These models also serve as powerful tools for marketing presentations and user testing.

Medical device manufacturers extensively leverage the high precision of SLA. In the Medical Device field, biocompatible resins and SLA-printed surgical guide prototypes aid surgeons in planning complex procedures. SLA-printed enclosures and handles are also used for grip evaluation and functional testing during the development of devices.

The automotive industry is another key application area for SLA. In Automotive R&D, SLA interior trim prototypes enable designers to assess visual appearance and tactile quality. Headlamp manufacturers use transparent SLA resins to fabricate lens and housing prototypes for optical and assembly validation. SLA models are also used to verify routing and packaging of under-hood piping and components.

Why Choose Neway for SLA 3D Printing Services?

Choosing Neway means accessing a professional and dependable SLA printing experience. Our multiple industrial-grade SLA systems ensure consistent and repeatable print quality. Each machine is meticulously calibrated and maintained to continuously deliver high-precision parts that meet demanding requirements.

We provide a complete one-stop service, covering everything from early-stage design optimization and parameter tuning during printing to diverse post-processing options. When parts require further refinement, our CNC Part Tumbling and Deburring services help ensure flawless quality.

Our integrated technology ecosystem guarantees end-to-end manufacturing capability. When project requirements exceed the scope of the SLA, we can seamlessly transition to Precision Machining Service or other 3D Printing technologies to deliver the most suitable solution. Whether you need a single prototype or are planning for Low-Volume Manufacturing Services, we can provide the corresponding support.

Get an Instant Quote for Your SLA Project

Obtaining a professional quote is simple and transparent. Just upload your 3D model file via our online platform, select the desired materials and post-processing options, and our system will generate a detailed quotation in the shortest possible time. For complex projects, our engineers will proactively communicate with you to offer expert suggestions, optimize designs, and reduce costs.

We understand that every project is unique, so we take a customized approach. Whether in material selection, process parameters, or finishing options, we tailor our recommendations to your specific needs. Let our professional technical team support your innovation and rapidly transform your designs into high-quality physical parts.

FAQs

Will SLA resin parts yellow or lose performance over long-term use?

What minimum feature size and maximum build volume does SLA offer?

How to achieve high transparency with clear resin and what post-processing is needed?

Which resins suit functional tests needing high heat resistance and strength?

Can SLA prototypes be tapped, bonded, painted, or post-processed further?