CNC Milling, Drilling, and Surface Finishing for Aluminum 1100 Mobile Phone Stands

CNC Machining of Mobile Phone Stands: Lightweight and Aesthetic Solutions for Consumer Products

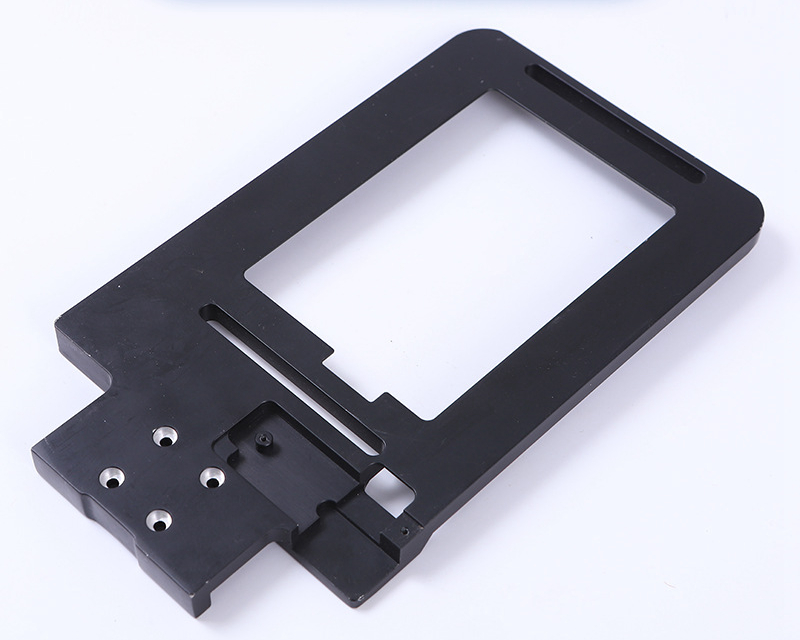

Mobile phone stands require precise dimensions, modern aesthetics, and structural reliability to support everyday use across home, office, and travel environments. For lightweight, corrosion-resistant, and cost-effective designs, Aluminum 1100 is an ideal choice. At Neway, we provide CNC milling and CNC drilling services tailored for consumer product applications, including elegant and durable mobile phone holders.

To enhance both visual appeal and surface durability, we apply sandblasting and high-quality spray coating, delivering a smooth, scratch-resistant, and color-customizable finish.

Why Aluminum 1100 Is Ideal for Phone Stand Manufacturing

Excellent Formability and Surface Appearance

Aluminum 1100 offers superior corrosion resistance, thermal stability, and a naturally reflective surface. It is highly workable and perfect for applications requiring smooth curves, lightweight frames, and decorative finishes.

Eco-Friendly and Lightweight

With a density of only 2.7 g/cm³, Aluminum 1100 provides strength without weight, enhancing product portability while supporting sustainability through recyclability and minimal environmental impact.

CNC Machining Workflow for Aluminum Mobile Phone Stands

CNC Milling for Base and Frame Shaping

We use high-speed vertical and 4-axis CNC mills to form sleek, ergonomic structures with integrated features such as:

Cable routing grooves

Device support shelves with protective angles

Folding slots or alignment features

Milling tolerances: ±0.02 mm for flatness, contour precision, and hinge interface fit.

CNC Drilling for Assembly Points and Fastener Locations

Drilled features enable mechanical assembly or hinge integration. All holes are finished with chamfers or counterbores for:

Screw and rivet fits

Rubber pad placement

Mounting base alignment

Positioning accuracy: ±0.02 mm.

Surface Finish: Sandblasting and Spray Coating

Sandblasting for Uniform Texture

Sandblasting creates a smooth, matte texture that enhances tactile quality and provides an ideal substrate for coatings. It also eliminates machining marks and softens edges.

Surface roughness: Ra 1.6–3.2 µm

Visual uniformity across flat and curved surfaces

Spray Coating for Color and Protection

We apply spray painting in a controlled environment to deliver consistent tone and abrasion resistance. Coating benefits include:

Durable protection against scratches and oxidation

Glossy, satin, or matte finishes available

Custom colors for branding, sets, or seasonal SKUs

Film thickness: 30–50 µm with adhesion per ISO 2409 standards.

Quality Control and Cosmetic Inspection

Dimensional check of mating surfaces, angles, and drilled holes

Visual grading under LED panels for coating uniformity and surface defects

Adhesion and durability testing for painted surfaces

Certification: COC, RoHS, REACH, and custom cosmetic QA upon request

Why Choose Neway for Phone Stand CNC Manufacturing

Specialized in Aluminum 1100 machining for decorative and lightweight parts

Integrated sandblasting and spray coating services for premium finish control

Prototyping to batch production with fast turnaround

One-stop CNC manufacturing from raw aluminum to packaged retail-ready products

CNC Services for Consumer Device Accessories

Neway delivers complete CNC and surface finishing solutions for lifestyle electronics and accessories. Services include:

CNC Milling and Drilling: For precise and ergonomic consumer stand geometry

Aluminum 1100 Machining: Lightweight parts with excellent coating compatibility

Sandblasting and Spray Coating: Aesthetic and protective finishes for consumer markets

We help OEMs and brands create functional, attractive, and production-ready accessory components.

FAQs

What surface textures and colors can you offer for aluminum phone stands?

How scratch-resistant is the spray-coated surface under daily use?

Can Neway support collapsible or hinge-based phone stand designs?

What cosmetic inspection standards do you follow for retail products?

Do you offer custom packaging and batch branding services post-machining?