Онлайн-сервис быстрого прототипирования заказных деталей

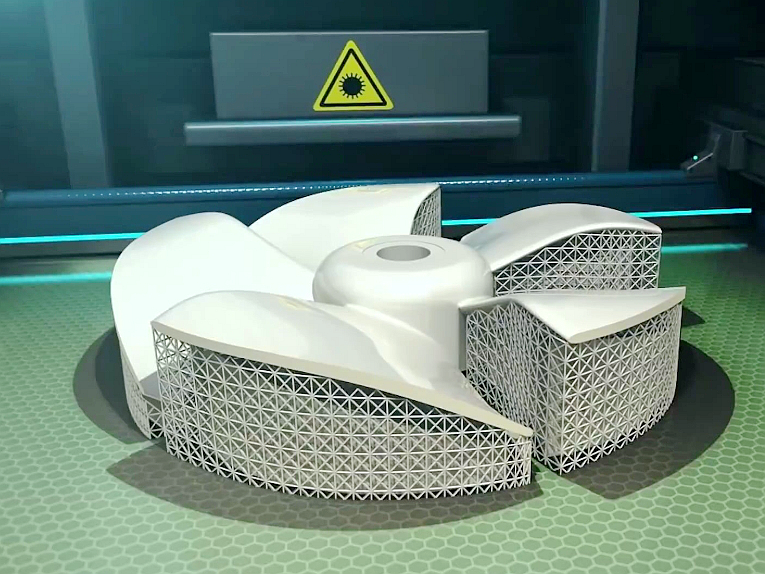

Neway предлагает онлайн-сервис быстрого прототипирования заказных деталей, обеспечивая быстрые и точные прототипы с использованием ЧПУ-обработки, 3D-печати и быстрого формования. Наш сервис гарантирует быструю обработку, высокую точность и индивидуальные решения для ваших уникальных требований.

- Прототипирование ЧПУ

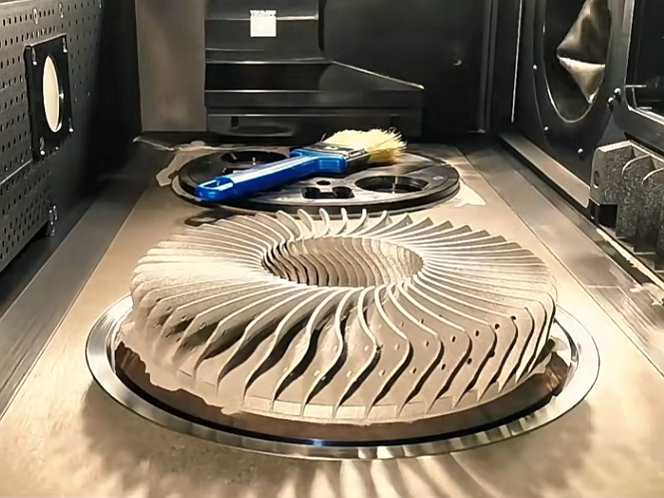

- Прототипирование 3D-печатью

- Прототипирование быстрым формованием

- Экспресс-прототипирование >>

Отправьте нам ваши чертежи и спецификации для получения бесплатного расчета

Все загруженные файлы надежно защищены и конфиденциальны

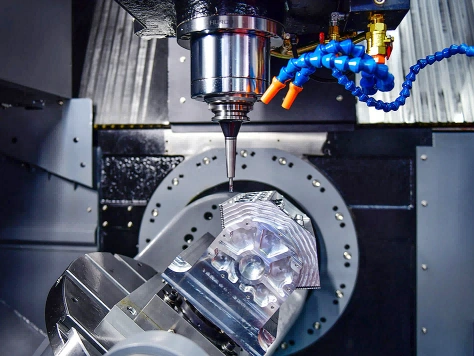

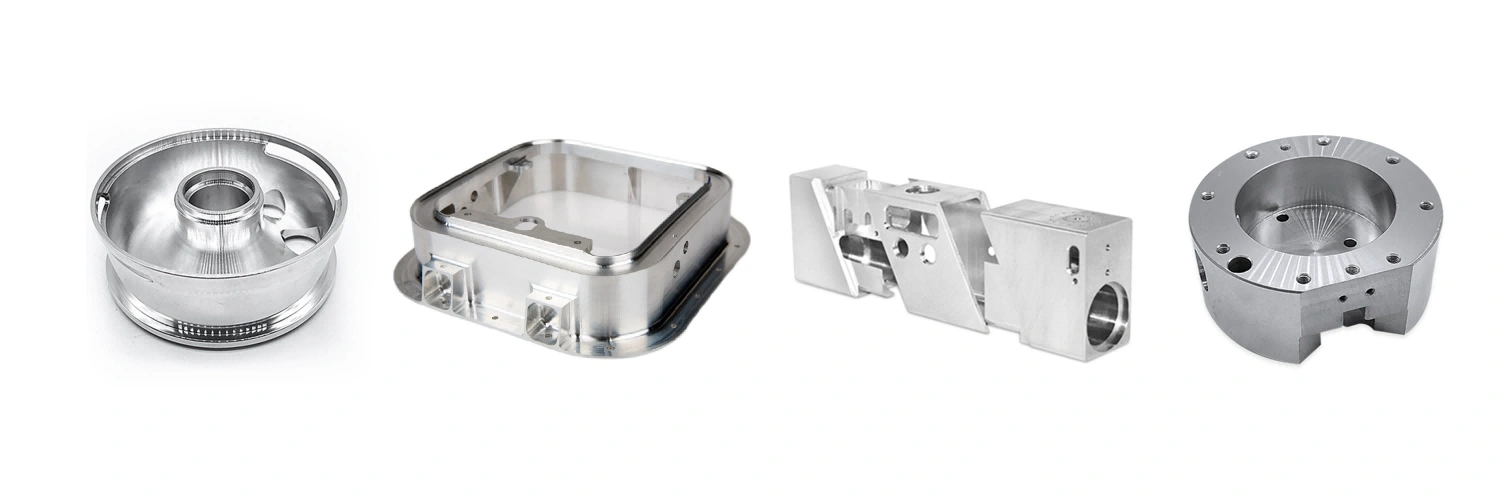

Возможности прототипирования с помощью обработки

Возможности прототипирования Neway включают ЧПУ-обработку, фрезерование ЧПУ, токарную обработку ЧПУ, сверление ЧПУ, расточку ЧПУ, шлифование ЧПУ, многоосевую обработку, прецизионную обработку и электроэрозионную обработку (EDM). Мы обеспечиваем прототипы высокой точности с исключительной аккуратностью и быстрым исполнением.

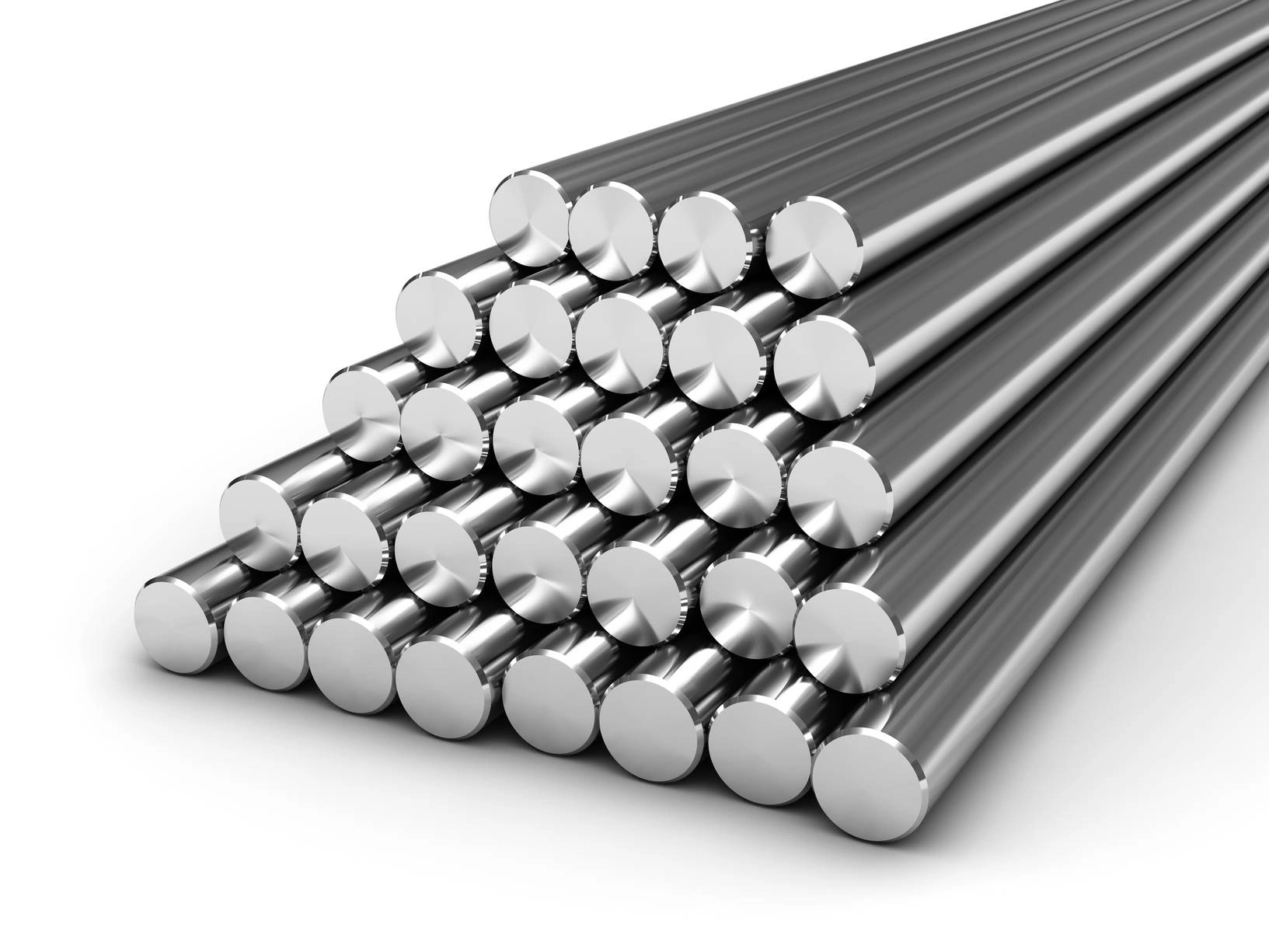

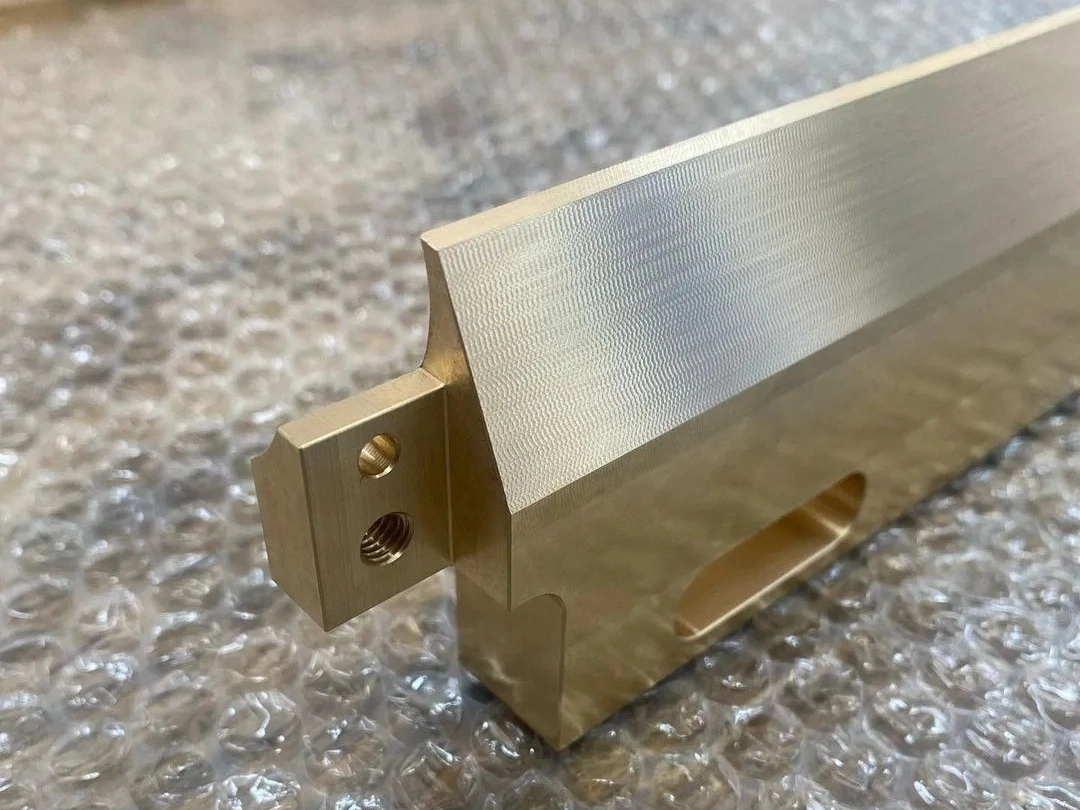

Решения по материалам для прототипирования с обработкой

Решения Neway по материалам для прототипирования с обработкой предлагают широкий выбор материалов, включая суперсплавы, титан, алюминий, медь, латунь, бронзу, углеродистую сталь, нержавеющую сталь, пластик и керамику, обеспечивая высокопроизводительные прототипы с превосходным качеством, точностью и свойствами материалов.

Обработка поверхности для прототипов

Обработка поверхности Neway для прототипов включает анодирование, покрытие, полировку, гальванизацию и термообработку. Эти процедуры улучшают свойства материала, повышают долговечность, коррозионную стойкость и качество поверхности, обеспечивая функциональные и качественные прототипы для требовательных применений.

Узнать больше

Термозащитное покрытие

Узнать больше

Обработка без отделки

Узнать больше

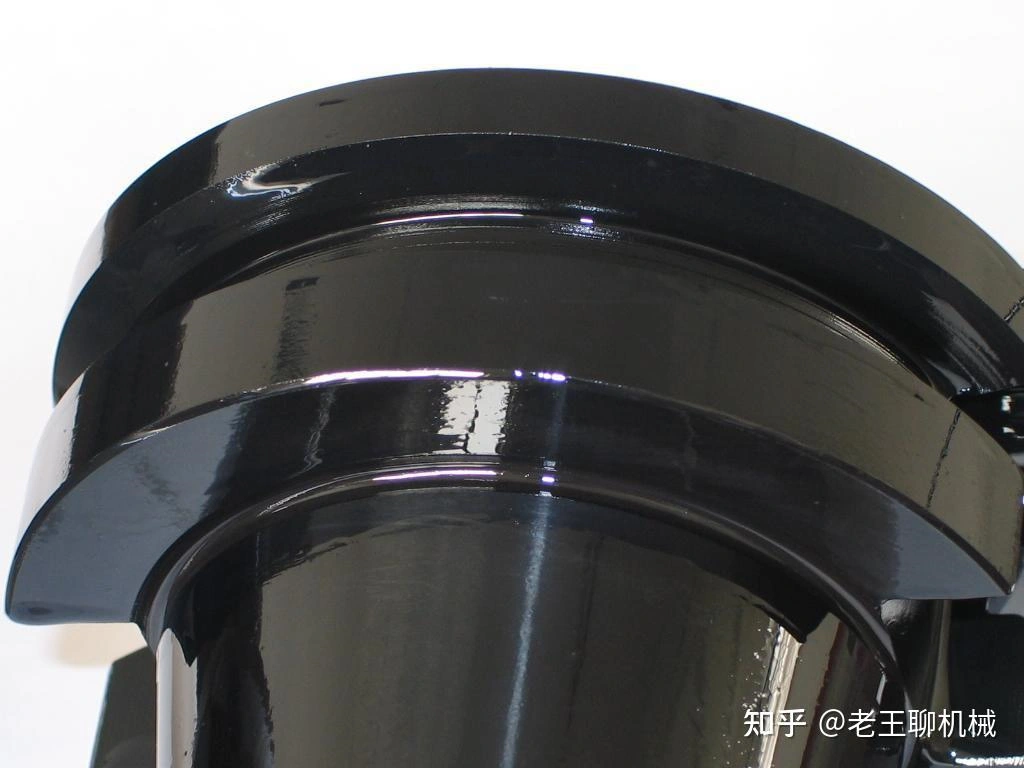

Покраска

Узнать больше

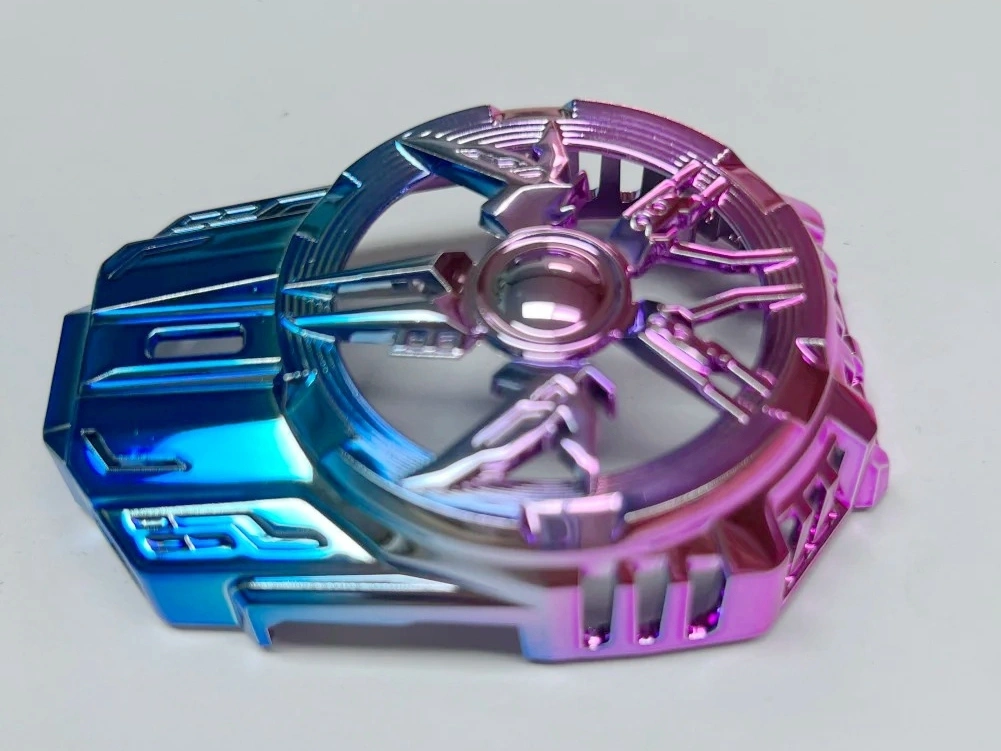

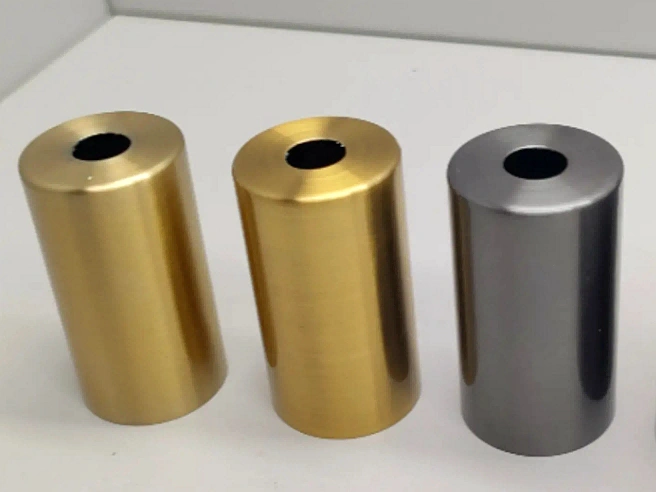

PVD (Физическое осаждение паров)

Узнать больше

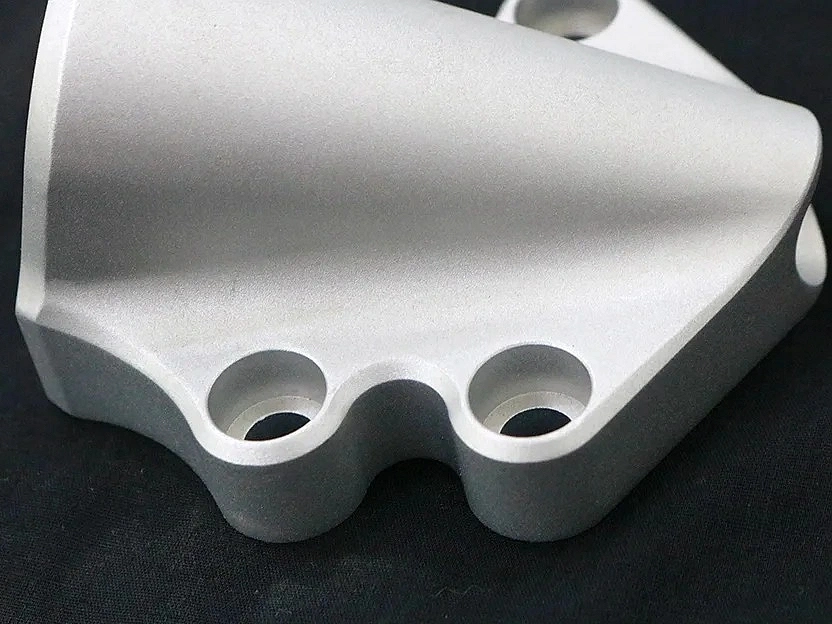

Пескоструйная обработка

Узнать больше

Гальваника

Узнать больше

Полировка

Узнать больше

Анодирование

Узнать больше

Порошковое покрытие

Узнать больше

Электрополировка

Узнать больше

Пассивация

Узнать больше

Щеточная обработка

Узнать больше

Чёрный оксид

Узнать больше

Термообработка

Узнать больше

Термоизоляционное покрытие (TBC)

Узнать больше

Обработка в барабане

Узнать больше

Алодин

Узнать больше

Хромирование

Узнать больше

Фосфатирование

Узнать больше

Нитрование

Узнать больше

Гальванизация

Узнать больше

УФ-покрытие

Узнать больше

Лакокрасочное покрытие

Узнать больше

Тефлоновое покрытие

Кейс прототипирования с использованием обработки

Кейс прототипирования Neway демонстрирует успешное использование суперсплавов, титана, алюминия, меди, латуни, бронзы, углеродистой стали, нержавеющей стали, пластика и керамики. Мы предоставляем точные и высокопроизводительные прототипы для различных отраслей, соответствующие требованиям клиентов с исключительным качеством и эффективностью.

Начните новый проект сегодня

Рекомендации для прототипирования на ЧПУ

Руководство по проектированию прототипов на ЧПУ включает выбор материала, равномерную толщину стенок, достижимые допуски и доступные функции. Ключевые принципы: избегать острых углов, минимизировать удаление материала, обеспечивать правильный дизайн отверстий и симметрию для оптимизации эффективности обработки, стоимости и качества детали.