ISO認証CMM品質保証:CNC加工部品の精度と適合性を確保

CNC品質保証におけるCMM検査の概要

高精度製造において、寸法精度の確保は、CNC加工部品の機能性、嵌合性、信頼性に直結する最重要要素です。航空宇宙、医療、産業機器など、どの分野においても、設計意図からのわずかな逸脱が、組立不良やフィールドでの故障につながる可能性があります。

この課題に対応するため、メーカーは座標測定機(CMM)のような高度な検査技術を用いて、部品形状をミクロンレベルの精度で検証します。ISO 9001認証された枠組みの中では、CMM検査は堅牢な品質マネジメントシステムに不可欠な要素であり、多軸のCNC加工サービスで製造される複雑部品の厳しい公差を検証する上で、とくに重要な役割を果たします。

品質保証におけるこの重要な検査ツールの役割を理解するには、CNC加工部品に対するCMM検査の詳細ガイドを参照するとよいでしょう。そこでは、CMMがどのようにしてコンプライアンス、一貫性、そして各加工部品への信頼性を担保するかが解説されています。

座標測定機(CMM)とは?

座標測定機(CMM)は、加工された部品の幾何学的特徴を高精度で測定するための検査システムです。X・Y・Zの3軸に基づき、表面の座標値、輪郭、寸法を正確に取得することで、CNC加工部品が設計意図どおりに製作されているかどうかを検証するための不可欠なツールとなっています。

CMMの動作原理と構成

基本的にCMMは、プローブシステムを用いて部品表面のさまざまな点を接触または非接触で測定します。最も一般的な構成は、可動ガントリーを備えたブリッジ型構造で、プローブが3つの直線軸全てに沿って移動できるようになっています。プローブは接触式のタッチトリガ方式のほか、レーザーやビジョンシステムなどの非接触方式で動作する場合もあります。

最新のCMMは、取得した測定データを3D CADモデルと直接照合するソフトウェアと統合されています。これにより、自動的な合否判定が可能となり、オペレーターの主観を排除して測定の一貫性を高めます。取得された座標データは、FAIR(初回品検査報告書)の作成や、部品ライフサイクル全体にわたる完全なトレーサビリティを確保するうえでも重要な役割を果たします。

CMMの種類:接触式と非接触式

CMMは、そのプロービング方式に基づいて、主に次の2種類に分類されます。

接触式CMM:機械的なスタイラスが部品表面に物理的に接触して測定を行います。複雑な金属部品に対する高精度の寸法検査に適しています。

非接触式CMM:レーザーや白色光などの光学システムを用いて、柔らかい材料や繊細な部品を非接触で測定します。

複雑な形状を検査する場合には、多軸ポジショニングの活用が重要です。5軸CMMは、角度付き形状の高精度測定を可能にし、検査中の姿勢替え時間を短縮します。同様に、多軸加工を導入しているメーカーは、製造時と同じ自由度を持つ5軸CMM検証を組み合わせることで、より精度の高い検査が可能になります。

部品の幾何学的複雑さ、材料特性、公差要求に合わせて適切なCMM構成を選定することで、検査戦略と製品要件を高いレベルで整合させることができます。

ISO 9001とCMM:認証された品質システムの構築

ISO 9001は、製造現場全体で一貫した生産、リスク管理、継続的改善を実現するための要件を定めた、国際的に認知された品質マネジメントシステム(QMS)の規格です。CNC加工に適用すると、ISO 9001は厳格な検査および検証プロセスを要求しており、その中でも座標測定機(CMM)による検査は中心的な役割を担います。

ISO 9001準拠ワークフローにおけるCMMの役割

ISO 9001認証を受けた工場では、品質管理手順がCNC加工の各段階に組み込まれています。原材料受入検査から最終製品検査に至るまで、CMM検査は、加工結果と設計意図とのギャップを埋める「データに基づく幾何学精度の証拠」を提供する役割を果たします。

各CMM測定では、指定公差への適合を示すデジタル測定記録が生成されます。これらの記録は、初回品検査、工程内監査、統計的工程管理(SPC)ルーチンに直接利用されます。また、CNC試作加工と組み合わせることで、開発初期段階で形状と嵌合を検証でき、大量生産時の逸脱を最小限に抑えることができます。

ISO認証CMMプログラムのメリット

ISO 9001準拠システムにCMMを統合することで、運用面・ビジネス面の両方で次のようなメリットが得られます。

トレーサビリティの向上:すべてのCMM測定は、タイムスタンプ、オペレーターID、校正履歴とともに記録され、ISOが求める文書化およびトレーサビリティ要件を満たします。

リスク低減:CMMによる寸法検証は、不適合品の流出リスクを最小化し、航空宇宙や医療機器のようなクリティカル産業でとくに重要です。

顧客からの信頼向上:カスタム精密加工サービスを調達するバイヤーは、社内規格や法規制を満たすためにISO準拠の証拠を求めることが増えています。

認証された品質システムとCMMのような高度な計測技術を組み合わせることで、不良削減、顧客満足度向上、プロセス能力の向上を、定量的かつ継続的に実現できます。

CNC加工部品におけるCMMの適用

座標測定機(CMM)は、複雑形状、厳しい公差、クリティカルな嵌合部が存在するCNC加工部品の検査において、不可欠な役割を担っています。その客観的かつ定量的な測定手法は、とくに航空宇宙・医療・産業オートメーションといった高仕様分野における安定した品質確保を強力に支援します。

航空宇宙向けCNC部品

航空宇宙業界では、寸法公差が±0.005 mmレベルに達することも多く、高度な検査技術が必要です。たとえば、航空宇宙向けCNC加工部品の検査では、タービン部品の内部冷却チャンネル、ベアリングハウジングの同心度、構造アセンブリ用取付穴の位置などをCMMで検証します。

5軸CMMシステムを用いることで、部品の付け替えなしに角度付き形状や深いキャビティの測定が可能となり、検査スピードと再現性を大幅に向上させます。

医療グレード部品

CMMは、チタン製外科用インプラント、整形プレート、脊椎固定システムなど、医療グレード部品の幾何学検証にも欠かせません。これらの部品は有機的で自由曲面に富んだ形状を持ち、表面プロファイル公差を確認するために数百点もの測定点が必要になることもありますが、CMMプローブや光学センサーを用いることで効率よく取得できます。

ねじ穴位置、ねじ形状、輪郭公差などの検証により、命に関わる用途における機能的適合性が確保されます。

産業・オートメーション部品

高いスループットが求められる自動化システムでは、CMM検査によって、カスタムダウエルピン、モータースピンドル、支持ブッシングなどの標準部品を検証します。たとえば、自動化用治具に使用される炭素鋼製クランプアクセサリーでは、ボアの芯出しや平行度などが重要であり、CMMはこれらのパラメータの検証に最適です。

試作段階や量産前のパイロット生産時に寸法検証を行うことで、ロボットシステムや高速生産ラインにおける部品の位置ズレや組立不良リスクを大幅に低減できます。

材料別のユースケース

CMMの適用は金属部品だけに限られません。プラスチックやセラミック部品、とくにセラミックCNC加工やプラスチック加工と組み合わせた場合にも、寸法検証に活用できます。レーザースキャナなどの非接触CMMシステムを用いれば、柔らかい材料であっても表面を変形させることなく、正確な輪郭測定が可能です。

材料特性や部品形状に合わせてCMM能力を最適化することで、多様なカテゴリの部品に対して、効率的かつ確実な検査ルーチンを構築できます。

CMM検査プロセス:セットアップからレポート作成まで

座標測定機(CMM)検査の有効性は、その高い精度のみならず、再現性・トレーサビリティ・CNC品質管理システムとの統合性を担保する体系的なワークフローによって支えられています。標準的なCMM検査プロセスは、部品セットアップ、測定プログラム作成、データ取得、結果レポートの4つの重要フェーズで構成されます。

ステップ1:部品セットアップと治具アライメント

測定を開始する前に、部品をCMMテーブル上に確実に固定し、適切に位置合わせする必要があります。適切な治具設計・固定は、プロービング中の安定性を確保し、変形のリスクを排除します。ISO 9001認証環境では、基準点(データム)をCAD座標系と一致させるための位置合わせ手順が標準化されています。

このフェーズでは、部品の清浄度や表面状態の確認も行います。とくに、アルマイト処理や黒染め処理後の検査では、光学プローブの精度に影響を与える表面反射の確認が、精度確保において重要となります。

ステップ2:測定プログラムの作成

ほとんどの最新CMMは、図面のGD&T仕様や3D CADデータに基づくCNC制御ソフトウェアで動作します。オペレーターは、測定点数、プローブパス、検査対象公差などを定義して測定ルーチンを構築します。高度なソフトウェアでは実行前にシミュレーションが可能であり、干渉やプローブたわみのリスクを最小化できます。

オフラインプログラミングは、CNC試作加工で一般的な「多品種少量生産」においてとくに有効で、実機の検査スケジュールを中断することなく、新しい測定プログラムを事前に準備できます。

ステップ3:データ取得と測定実行

プログラムが検証されたら、CMMはタッチトリガまたはスキャニングプローブを用いて測定を実行します。部品の複雑さにもよりますが、数分のうちに数百から数千点の座標データを取得することが可能です。

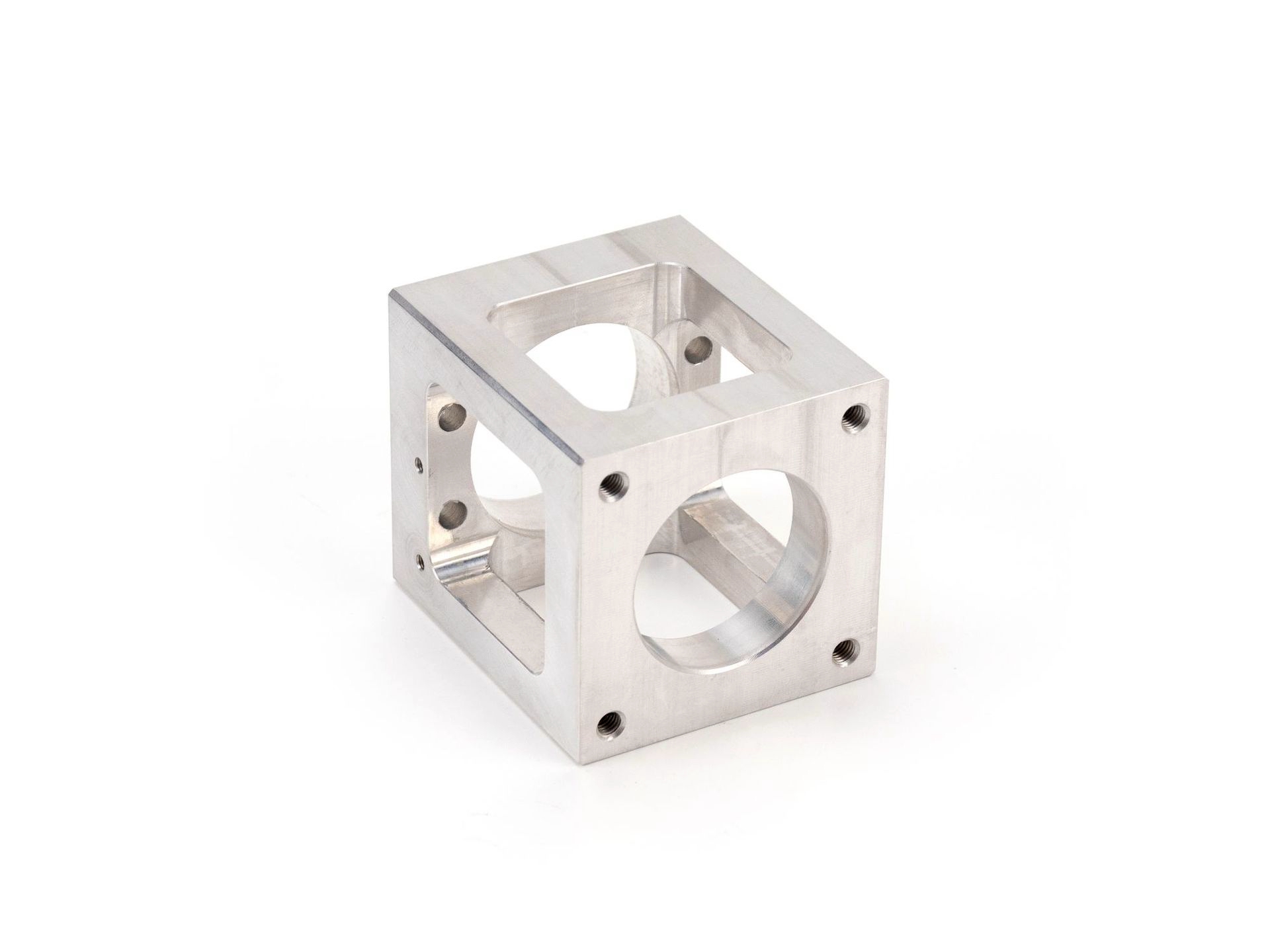

平面度、平行度、円筒度、穴位置などの特徴量が、CAD上のノミナル値と比較されます。多軸部品(例:アルミ製ロボットジョイント)の場合、全体のボリュームマッピングにより、角度付き面や複合曲面のオフセットを総合的に検証します。

ステップ4:レポート作成とデータ解析

最終ステップでは、取得した測定データを検査レポートとして取りまとめます。レポートでは、公差からの偏差、合否判定、必要に応じて工程能力や傾向などの統計情報が示されます。規制対応や顧客承認が必要な部品に対しては、CMMトレーサビリティを含む初回品検査報告(FAIR)が作成されます。

これらの検査データは品質管理ダッシュボードと連携させることができ、PDCA(Plan-Do-Check-Act)サイクルにおけるフィードバックループや、長期的なプロセス改善に活用されます。とくに、欠陥の事後対応ではなく未然防止を重視する認証済み精密加工環境において、この仕組みは非常に重要です。

CNC加工部品検査にCMMを用いるメリット

座標測定機(CMM)は、要求の厳しい用途における複雑なCNC加工部品の検査に対し、精度・一貫性・文書化の面で他の手法にはない優位性を提供します。試作から量産まで、CMMベースの検査は技術的・運用的・商業的な観点で大きなメリットを生み出します。

高精度な寸法検証

従来のゲージや手持ちノギスとは異なり、CMMはサブミクロンレベルの分解能を有し、三次元形状、穴位置、形状誤差、GD&T呼び出しを高精度で検証できます。これは、とくに多くの機能特徴と熱変形管理が必要となる超合金CNC加工部品などの分野で非常に重要です。

また、リアルタイムのデジタルフィードバックを通じて、工具摩耗や工程ドリフトを早期に検出し、不良品が後工程まで到達する前に対策を講じることができます。

再現性と客観性の向上

手作業による検査方法は、作業者の癖や読み取り誤差などにより、結果がばらつきやすいという課題があります。一方、CMM検査は自動化と標準化によって主観を排除します。一度作成した測定プログラムは、同一条件で繰り返し使用できるため、時間や担当者が変わっても再現性の高い結果が得られます。

この一貫性は、エンジンバランスや組付け性に直結する自動車エンジン部品のような製品において、特に不可欠です。

高速かつ非破壊の検査

最新のCMMは、最小限の部品ハンドリングで高速スキャンを実行できるため、従来の測定工具と比べて検査時間を大幅に短縮できます。これにより、多軸加工部品に対する工程内検査を、生産フローを妨げることなく実施できます。

非接触光学プローブは、研磨後や鏡面仕上げ、粉体塗装など、表面健全性を損ないたくない部品の検査にも適しており、表面を傷つけることなく測定が行えます。

デジタル文書化とトレーサビリティ

各測定は、タイムスタンプ、プローブ校正データ、合否結果とともにデジタル記録として保存されます。これらの記録は、品質監査、サプライヤー認定、規制認証において重要な証拠となります。CMMデータは一般にPDCAベースの品質管理システムと連携しており、根本原因分析や是正処置計画を支援します。

このデジタル履歴へのアクセスにより、顧客は完全なコンプライアンス検証を受け取ることができ、寸法不適合に関するトラブルや紛争を大幅に減らすことができます。

医療・航空宇宙・産業プロジェクトからのユースケース

ISO認証CNC環境におけるCMM検査の具体的なメリットを理解するうえで、実際の事例を確認することは非常に有効です。以下の医療・航空宇宙・産業オートメーションのケーススタディは、CMMによる品質管理がどのように寸法精度、コンプライアンス、性能信頼性を支えているかを示しています。

医療:PVDコーティングを施したチタン外科用インプラント

医療用途、とくにインプラントでは、寸法精度と表面仕上げの一貫性が患者の生命に直結します。チタン外科用インプラントの製造では、CMMを用いて曲面プロファイル、ねじ部、挿入部の嵌合形状を測定しました。さらに、PVDコーティング後には膜厚および全体寸法を再検証する必要がありました。

この二段階の検査プロセスにより、生体適合性と機械的適合性が確保され、ISO 13485規格への完全な準拠とリコールゼロという結果につながりました。

航空宇宙:多軸加工ロボットジョイント

アルミ6061製の航空宇宙グレードロボットジョイントアセンブリでは、多軸CNC加工とアルマイト処理により、厳しい嵌合公差を持つ角度付き形状が製作されました。CMM検査では、6面にわたる平面度、直角度、真位置を検証し、航空機組立ラインで使用されるロボットアームの動作範囲と動的性能に直接影響するパラメータを確認しました。

CMMシステムは、アルマイト処理時の熱膨張によって生じた微小な偏差を検出し、治具補正やプログラム修正による改善につなげました。

産業オートメーション:炭素鋼クランプアクセサリー

自動化分野では、CNC加工された炭素鋼製クランプアクセサリーが、治具アセンブリにおいて繰り返し精度を支えています。これらの部品には、ボア径、平行度、複数取付点との位置関係に対する厳格な管理が求められます。

プログラム化されたCMMルーチンを用いることで、ロット生産において100%検査を実現しました。CMMデータをSPCダッシュボードに統合した結果、手直し率が35%削減され、リードタイムと歩留まりが大幅に改善されました。

CMM運用におけるISO 9001および国際規格への準拠

規制産業や高仕様用途に製品を供給するメーカーにとって、国際的な品質マネジメント規格への準拠は「選択肢」ではなく「必須要件」です。CNCワークフローにCMMを統合する場合、その運用はISO 9001:2015だけでなく、AS9100(航空宇宙)、ISO 13485(医療)、IATF 16949(自動車)といった業界別の要件にも整合している必要があります。

品質フレームワークの基盤としてのISO 9001

ISO 9001において、CMM検査は「生産およびサービス提供の管理」を定めた8.5.1条および「製品およびサービスのリリース」を定めた8.6条に直接関係します。これらの条項は、出荷前に要求事項への適合を示す客観的証拠を求めており、CMMが生成する検査レポートはまさにこの役割を果たします。

Neway Precisionのようなメーカーは、CMMシステムをデジタル品質ループに組み込むことで、トレーサビリティ、監査準備性、体系的な是正処置を実現しています。各測定ルーチンは文書化され、バージョン管理され、標準にトレーサブルな計測器による校正データとともに検証されています。

ISO 17025に基づく校正とメンテナンス

ISO 9001認証環境で使用されるCMM設備は、ISO 17025またはNISTやDINなどの国家規格に基づいて校正されなければなりません。ステップゲージやボールバーといった認証アーティファクトを用いた定期的な性能検証は、監査時に求められるシステム精度と信頼性を保証します。

定期メンテナンス、プローブ検証の記録、ソフトウェアバージョンのトレーサビリティは、認証済みCNC加工サービス環境における標準的な運用要件です。これらの手順により、SUS304医療用ファスナーのような高ボリューム部品においても、一貫した検査結果が確保されます。

顧客固有QAプロトコルとの整合

グローバルOEMは、多くの場合FAIR(初回品検査報告)、PPAP(量産部品承認プロセス)、バルーン図面と測定データのリンクなど、追加のQAプロトコルを要求します。CMMは、寸法ごとの適合データを自動生成し、これらの顧客フォーマットに容易にマッピングできるため、このプロセスを大幅に簡素化します。

このような状況では、CMMは単なる計測ツールではなく、生産チェーン全体が社内・社外の基準を満たすことを保証する「コンプライアンスエネーブラー」として機能します。

CMMと他のCNC検査技術の統合

座標測定機(CMM)は、CNC加工における寸法検証の「ゴールドスタンダード」である一方、補完的な検査技術と組み合わせることで、より強力で柔軟な品質保証システムを構築することができます。このハイブリッドアプローチは、とくに複雑な形状、内部構造、高ボリュームのワークフローにおいて効果を発揮します。

自由曲面検証のための3Dスキャン

基準データが明確でない複雑な自由曲面や有機形状を扱う場合、3Dスキャニング測定はCMM検査を補完する有効な手段となります。構造化光やレーザースキャナにより高解像度の点群データを生成し、CADモデルと比較することで、反りや収縮、過剰切削などの異常を検出できます。

これは、冷却過程で変形が起こりやすいプラスチックや複合材の部品で特に有用です。3Dスキャンで表面の異常を素早く可視化し、CMMで重要寸法の詳細検証を行う、といった組み合わせが可能です。

内部欠陥検出のためのX線・超音波検査

高精度産業用工具や深穴加工シャフトなど、内部欠陥の検出が必要な用途では、接触式CMMだけでは評価が不十分なことがあります。そのような場合には、X線検査や超音波探傷といった非破壊検査(NDT)技術が有効です。

X線システムは、鋳物や加工部品の内部に存在するボイド、クラック、ポロシティを検出でき、超音波センサーは積層構造の結合状態や肉厚を評価できます。CMMとこれらNDT技術を組み合わせることで、表面から内部までをカバーする総合的な品質保証が可能となります。

現場での迅速確認のための輪郭・ハイトゲージ

ハイトゲージや輪郭測定器などのツールは、段差高さ、エッジプロファイル、同心度といった特定の特徴量を迅速に評価できるため、工程内の短時間確認に適しています。これらは、最終CMM検査の前段階として、異常品を早期に検知する目的で併用されることも多くあります。

CMMの全寸法精度と、現場メトロロジーのスピードを組み合わせることで、CNCラインから出てくる部品をリアルタイムで管理し、応答性と初回合格率を高いレベルで維持できます。

結論:ISO認証CMMシステムによるCNC検査の未来

多くの産業で精度、トレーサビリティ、グローバルコンプライアンスへの要求が高まる中、ISO認証を受けた座標測定機(CMM)は、CNC加工における検査チェーンの中核として、今後も不可欠な存在であり続けます。CMMが提供する再現性の高いミクロンレベルの精度は、統計的工程管理(SPC)、デジタル品質保証、顧客仕様の文書要求といった、現代の要求事項に直接対応するものです。

先進的なメーカーはすでに、CMMをデジタルツイン、クローズドループプロセスフィードバック、MES(製造実行システム)と統合し、リアルタイムのアダプティブマニュファクチャリングを実現しつつあります。これにより、CMMからの寸法データは単なる検証用途にとどまらず、工具経路の最適化、送り・回転数の調整、異常の早期検知など、上流工程の意思決定そのものを駆動する役割を担います。

CMM検査を、自動化・リアルタイムデータ・多層メトロロジーに支えられた広義のCNC加工サービスエコシステムの中に組み込むことで、工場はISO 9001の原則に忠実でありながら、スピード、信頼性、顧客からの信頼を最大化することができます。

アルミ製ロボット部品、チタンインプラント、自動車用スチールシャフトなど、どのような部品を検査する場合でも、CMMシステムは個々の寸法だけでなく、企業としての品質へのコミットメントそのものを検証し続けるのです。