Zerstörungsfreie Konturprüfung für CNC-bearbeitete Komponenten

Der Kernnutzen zerstörungsfreier Konturprüfungen in der modernen Fertigung

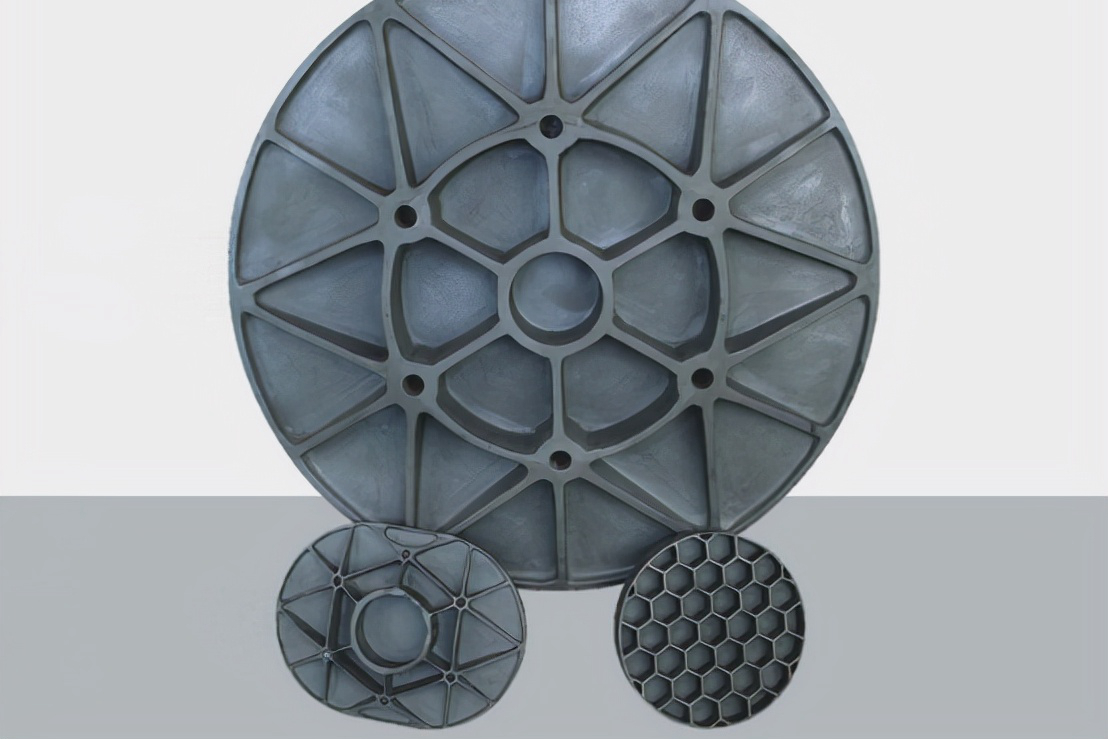

In der modernen Präzisionsfertigung sind zerstörungsfreie Konturprüfungen zu einem unverzichtbaren Bestandteil des Qualitätskontrollsystems geworden. Als Qualitätsingenieure bei Neway kennen wir die entscheidende Bedeutung dieser Technologie für die Sicherstellung der Maßhaltigkeit und die Reduzierung von Qualitätsrisiken sehr genau. Anders als klassische taktile Messverfahren ermöglicht die zerstörungsfreie Konturprüfung die präzise Vermessung komplexer Geometrien, ohne die Oberfläche des Bauteils zu beschädigen.

Im Luft- und Raumfahrtsektor sind unsere Anforderungen an die Konturprüfung von Triebwerkskomponenten besonders streng. Am Beispiel von Turbinenschaufeln zeigt sich dies deutlich: Ihre komplexen aerodynamischen Profile stehen in direktem Zusammenhang mit der Gesamtleistung des Triebwerks. Durch zerstörungsfreie Konturprüfungen können wir Maßabweichungen bereits vor der Montage erkennen und kostspielige Nacharbeit vermeiden. Ebenso stellt diese Technologie in der Medizintechnik für Implantate sicher, dass Implantate präzise zu den menschlichen Knochenstrukturen passen.

Funktionsprinzip und Genauigkeitsvorteile der Blaulicht-3D-Scanning-Technologie

Das Blaulicht-3D-Scanning ist eine unserer wichtigsten Methoden für zerstörungsfreie Konturprüfungen. Basierend auf dem Prinzip des Streifenlichts projiziert diese Technologie codierte Blaulicht-Streifenmuster auf die Bauteiloberfläche. Zwei Kameras erfassen die verformten Streifen, und über Triangulation wird die dreidimensionale Kontur des Bauteils rekonstruiert. Im Vergleich zu klassischen Laserscans bietet Blaulicht-Scanning eine höhere Genauigkeit und eine bessere Störunempfindlichkeit.

In der Praxis nutzen wir Blaulicht-3D-Scanning-Services beispielsweise zur Prüfung von 5-Achs-gefrästen Impellern. Bei einem bestimmten Automobil-Turbolader-Impeller lässt sich so eine Scangenauigkeit von ±0,008 mm erzielen, was die einschlägigen Branchenstandards vollständig erfüllt. Für Aluminiumlegierungsteile mit komplexen Freiformflächen erfasst das Blaulicht-Scanning schnell vollständige Oberflächendaten und steigert so die Prüfeffizienz erheblich.

Spezielle Einsatzfälle von industrieller CT in der internen Konturprüfung

Wenn interne Konturen oder verdeckte Merkmale geprüft werden müssen, spielt die industrielle Computertomographie (CT) ihre einzigartigen Stärken aus. Diese Technologie erzeugt Mehrwinkel-Röntgenaufnahmen des Bauteils und rekonstruiert daraus eine dreidimensionale Innenstruktur – eine echte „zerstörungsfreie Sicht ins Innere“.

In der hochpräzisen Spritzgießwerkzeugfertigung nutzen wir die industrielle CT-Prüfung, um Layout und Abmessungen der Kühlkanäle zu verifizieren. Besonders bei Formen mit komplexen konturnahen Kühlkanälen erlaubt die CT-Technologie die exakte Überprüfung der Abstandsgleichmäßigkeit zwischen Kanälen und Formkavität und stellt so die thermische Balance des Werkzeugs sicher. Für bestimmte medizinische Komponenten aus Edelstahl 316L mit innenliegenden Hohlräumen ist CT oft die einzige technisch sinnvolle zerstörungsfreie Prüfmethode.

Fünfstufiger Implementierungsprozess: Vom Scannen bis zur Datenanalyse

Neway hat für zerstörungsfreie Konturprüfungen einen standardisierten Fünf-Schritte-Prozess etabliert, um für jedes Prüfprojekt verlässliche Ergebnisse sicherzustellen. Der erste Schritt ist die Prüfplanung, bei der anhand der Bauteilgeometrie und der geforderten Genauigkeit die passende Scanstrategie und Messpunktverteilung festgelegt werden. Der zweite Schritt ist die Scanvorbereitung, inklusive Bauteilreinigung, Anbringen von Referenzmarken und Kalibrierung des Scanners.

Im dritten Schritt erfolgt die Datenerfassung: Hochpräzise Scansysteme nehmen die dreidimensionalen Punktwolken des Bauteils auf. Bei Teilen mit komplex bearbeiteten Oberflächen setzen wir Multiwinkel-Scanstrategien ein, um Messblindzonen zu vermeiden. Der vierte Schritt ist die Datenaufbereitung, bei der die Punktwolke über professionelle Software in ein auswertbares 3D-Modell überführt wird. Der fünfte Schritt ist die Vergleichsanalyse: Die Messdaten werden mit dem CAD-Modell ausgerichtet, um einen detaillierten Prüfbericht zu generieren.

Typische Anwendungsszenarien (Impeller / Werkzeuge / Medizinische Implantate)

Bei der Impellerprüfung aus Titanlegierungen spielt die zerstörungsfreie Konturprüfung eine Schlüsselfunktion. Über Blaulicht-Scanning erfassen wir das reale Schaufelprofil und analysieren wichtige Parameter wie Schaufelquerschnitt, Verdrehung sowie Dickenverteilung. Diese Daten dienen nicht nur der Qualitätsabnahme, sondern liefern auch essenziellen Input für die Prozessoptimierung.

Bei Präzisionsformen konzentrieren wir uns auf die Kontur der Trennfuge und die Kavitätenmaße. Am Beispiel einer Werkzeugform für einen Pkw-Scheinwerfer konnten wir mittels zerstörungsfreier Konturprüfung eine Profilabweichung von 0,02 mm rechtzeitig erkennen und korrigieren – und so spätere Qualitätsprobleme in der Serienfertigung vermeiden. In der Medizintechnik unterziehen wir künstliche Gelenkimplantate einer umfassenden Konturprüfung, um die anatomische Kompatibilität mit dem menschlichen Knochen sicherzustellen.

Vergleichsanalyse zwischen Prüfdaten und CAD-Modellen

Das Erfassen von Scandaten ist nur der erste Schritt – der eigentliche Schlüssel liegt in der effektiven Datenanalyse. Wir nutzen spezialisierte Prüfsoftware, um die gemessene Punktwolke automatisch mit dem ursprünglichen CAD-Modell zu alignen und Abweichungsanalysen durchzuführen. Die Software erzeugt farbcodierte Abweichungskarten, die die Höhe und Verteilung der Abweichungen in unterschiedlichen Bereichen visuell darstellen.

In unseren Erstmusterprüfservices ist diese Analysemethode besonders wichtig. Wir betrachten nicht nur die globalen Abweichungen, sondern achten auch auf Muster und Trends. Werden beispielsweise systematische Abweichungen sichtbar, kann dies auf Probleme mit den Werkzeugbahnen oder der Maschinengenauigkeit während der Bearbeitung hinweisen. Durch eine gründliche Analyse dieser Daten können wir sehr gezielte Empfehlungen zur Prozessverbesserung ableiten.

Branchenspezifische Anforderungen (Luft- und Raumfahrt / Automobil / Medizintechnik)

Verschiedene Branchen stellen unterschiedliche Anforderungen an zerstörungsfreie Konturprüfungen. In der Luft- und Raumfahrt ist die durchgängige Rückverfolgbarkeit im gesamten Prüfprozess entscheidend. Alle Rohdaten und Auswertungsprotokolle müssen vollständig gespeichert werden. Bei der Prüfung von Luft- und Raumfahrtkomponenten müssen wir die strengen Vorgaben des AS9100-Qualitätsmanagementsystems einhalten und sicherstellen, dass jeder Prüfschritt lückenlos dokumentiert ist.

Die Automobilindustrie legt mehr Gewicht auf Prüfeffizienz und Kostenkontrolle. Bei der Prüfung von Turbolader-Impellern im Automotive-Bereich führen wir die Messungen in der Regel liniennah durch, um in kürzester Zeit Ergebnisse zu erhalten und Bearbeitungsparameter schnell nachstellen zu können. In der Medizintechnik stehen Materialbiokompatibilität und Oberflächenintegrität im Vordergrund; während der Prüfung müssen alle Schritte, die das Materialverhalten negativ beeinflussen könnten, strikt vermieden werden.

Neways Prüftechnik und Qualitätssicherungssystem

Neway hat erheblich in den Aufbau eines modernen Labors für zerstörungsfreie Konturprüfungen investiert. Wir verfügen über mehrere hochpräzise Blaulicht-Scansysteme und industrielle CT-Anlagen, mit denen wir Messanforderungen von kleinsten medizinischen Instrumenten bis hin zu großformatigen Werkzeugen abdecken. Sämtliche Anlagen werden regelmäßig kalibriert und gewartet, um genaue und verlässliche Ergebnisse sicherzustellen.

Unser Team von Prüfingenieuren verfügt über umfangreiche Branchenerfahrung und einschlägige Qualifikationen. So sind wir in der Lage, für unterschiedliche Bauteile – abgestimmt auf deren Geometrie und Genauigkeitsanforderungen – jeweils optimale Prüfkonzepte zu entwickeln. Während des gesamten Prüfprozesses setzen wir konsequent das Labormanagementsystem nach ISO 17025 um, um jede Prozessstufe unter Kontrolle zu halten. Mit dieser umfassenden Qualitätssicherungsstruktur bieten wir unseren Kunden verlässliche zerstörungsfreie Konturprüfungen und helfen ihnen, Produktqualität und Wettbewerbsfähigkeit nachhaltig zu steigern.

Häufig gestellte Fragen

Worin unterscheiden sich Blaulicht-Scanning und KMG bei der Konturprüfung?

Welche maximale Genauigkeit lässt sich mit zerstörungsfreien Konturprüfungen erreichen?

Wie lässt sich eine vollflächige Konturprüfung an großformatigen Werkstücken durchführen?

Wie lange dauert es vom Scannen bis zum fertigen Prüfbericht?