Heißisostatisches Pressen (HIP): Verbesserung von CNC-bearbeiteten Hochtemperaturlegierungsteilen

Einführung: HIP-Technologie – Schlüsselprozess zur Ausschöpfung des Leistungspotenzials von Hochtemperaturlegierungsbauteilen

In der High-End-Fertigung bestimmt die innere Qualität von Hochtemperaturlegierungsbauteilen direkt deren Einsatzverhalten und Lebensdauer. Als Werkstofftechnik-Experten bei Neway wissen wir, dass selbst präzise bearbeitete Bauteile noch mikroskopische, schwer nachweisbare Defekte enthalten können. Diese Defekte wirken wie Zeitbomben, die unter den harten Einsatzbedingungen von hoher Temperatur und hohem Druck zu katastrophalen Ausfällen führen können.

Beim Heißisostatischen Pressen (HIP) werden hohe Temperatur und hoher Gasdruck kombiniert, um diese inneren Defekte wirksam zu eliminieren und das Material in einen nahezu theoretisch dichten Zustand zu überführen. In sicherheitskritischen Bereichen wie Luft- und Raumfahrt oder Energietechnik ist HIP heute ein Standardprozess, um die Zuverlässigkeit wichtiger Komponenten sicherzustellen. Unsere HIP-Services sind genau darauf ausgelegt, diese Anforderungen zu erfüllen und Kunden zu helfen, das Werkstoffpotenzial vollständig auszuschöpfen.

Prinzip des Heißisostatischen Pressens: „Heilung“ des Materials unter hoher Temperatur und hohem Druck

Synergetischer Wirkmechanismus von drei Schlüsselfaktoren

Der Kern der HIP-Technologie liegt in der präzisen Abstimmung von Temperatur, Druck und Zeit. Typischerweise werden Temperaturen von 1000–1200 °C und Drücke von 100–200 MPa über eine definierte Haltezeit angewendet. Über Diffusionskriechen und plastische Fließmechanismen werden innere Poren, Lunker und ähnliche Defekte dauerhaft geschlossen. Dieser „Heilungsprozess“ eliminiert nicht nur Defekte, sondern verbessert zugleich die Mikrostruktur des Materials.

Wissenschaftliche Grundlage der Werkstoffverdichtung

Bei erhöhten Temperaturen sinkt die Streckgrenze des Materials deutlich, während der hohe Außendruck eine ausreichende Triebkraft für plastische Deformation liefert. Unter diesen Bedingungen schrumpfen innere Hohlräume durch das Zusammenspiel aus Oberflächenspannung und äußerem Druck schrittweise und verschwinden schließlich. Für typische Hochtemperaturlegierungen wie Inconel 718 lässt sich mit optimierten HIP-Prozessparametern eine Dichte von 99,99 % oder höher erreichen.

Wesentliche Verbesserungen durch HIP bei Hochtemperaturlegierungsbauteilen

Deutliche Steigerung der Ermüdungsfestigkeit

Innere Poren und Defekte sind die Hauptursache für die Entstehung von Ermüdungsrissen. Nach HIP-Behandlung und der Entfernung dieser Defekte kann die Ermüdungslebensdauer von Bauteilen typischerweise um das Drei- bis Fünffache steigen. Dies ist insbesondere für Triebwerkskomponenten der Luftfahrt, die unter wechselnden Lasten arbeiten, von entscheidender Bedeutung. Unsere Prüfdaten zeigen, dass HIP-behandelte Turbinenschaufeln bei gleichen Betriebsbedingungen eine deutlich verlängerte Einsatzdauer aufweisen.

Verbesserte Gleichmäßigkeit der mechanischen Eigenschaften

HIP erhöht nicht nur das absolute Eigenschaftsniveau, sondern vor allem auch dessen Konstanz. Durch die Eliminierung zufälliger innerer Defekte stellen wir sicher, dass Bauteile unterschiedlicher Chargen ebenso wie verschiedene Bereiche im selben Bauteil eine möglichst homogene mechanische Performance zeigen. Diese Gleichmäßigkeit ist für unsere Präzisionsbearbeitungsservices von zentraler Bedeutung.

Typische HIP-Prozessparameter und Arbeitsablauf

Präzise Prozesssteuerung

Unsere HIP-Anlagen sind mit modernen Computersystemen ausgestattet, die Aufheizraten, Druckprofile und Haltezeiten exakt regeln. Für verschiedene Hochtemperaturlegierungen haben wir spezifische Prozessspezifikationen definiert. So setzen wir für Inconel 625 typischerweise Parameter von 1180 °C, 100 MPa und 4 Stunden ein.

Durchgängige Qualitätsüberwachung

Während des gesamten HIP-Zyklus erfassen wir Temperatur-, Druck- und Zeitdaten kontinuierlich und stellen so eine vollständige Rückverfolgbarkeit des Prozesses sicher. Aufbauend auf der Erfahrung aus unseren Vakuum-Wärmebehandlungsservices haben wir eine umfassende HIP-Prozessdatenbank aufgebaut, um für unterschiedliche Werkstoffe jeweils optimal abgestimmte Prozesslösungen anbieten zu können.

Revolutionäre Rolle von HIP in der Nachbearbeitung additiv gefertigter Bauteile

Eliminierung inhärenter Defekte der Additiven Fertigung

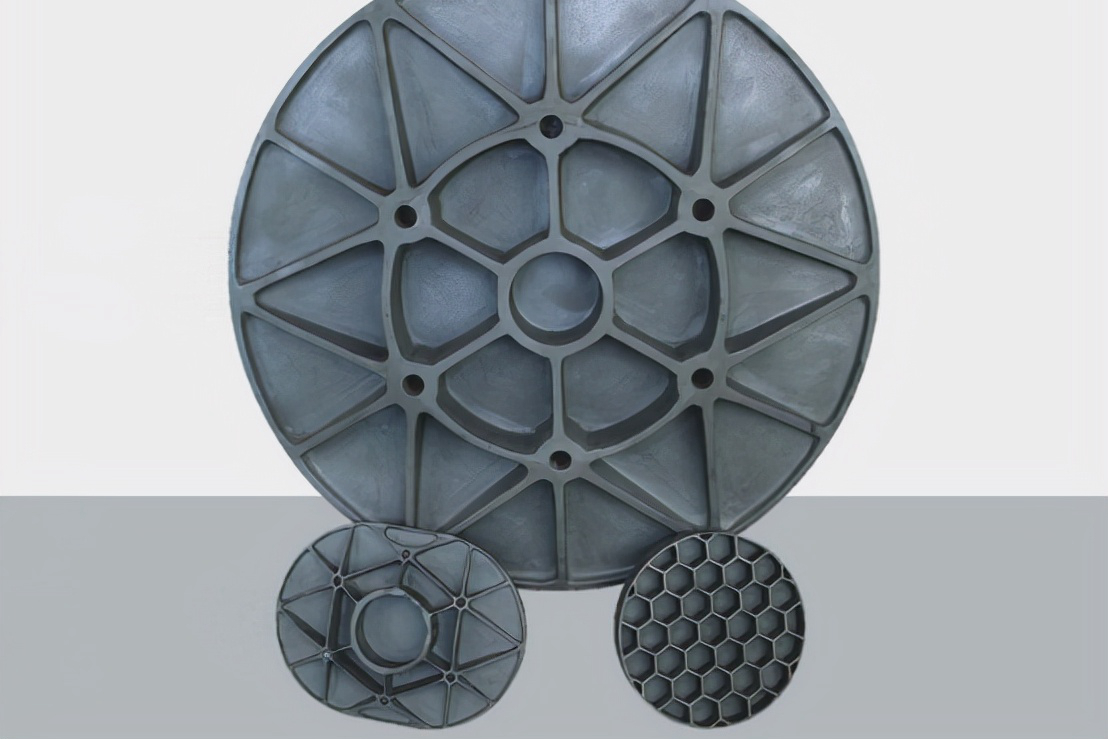

Obwohl die 3D-Drucktechnologie einzigartige Vorteile bei der Herstellung komplexer Geometrien bietet, weisen additiv gefertigte Bauteile häufig Poren, Bindefehler und andere innere Defekte auf. Durch HIP können diese Defekte wirksam beseitigt werden, sodass additiv gefertigte Teile das Leistungsniveau konventioneller Schmiedeteile erreichen oder sogar übertreffen. Dies ist insbesondere für komplexe Strukturen in der Luft- und Raumfahrt von großer Bedeutung.

Verbesserung der Isotropie der Eigenschaften

Durch HIP-Behandlung lassen sich richtungsabhängige Eigenschaftsunterschiede in additiv gefertigten Bauteilen reduzieren und die Isotropie verbessern. Diese Eigenschaft ist besonders wichtig für Komponenten, die unter komplexen Spannungszuständen arbeiten.

Synergien und Unterschiede zwischen HIP und konventioneller Wärmebehandlung

Optimierte Auslegung der Prozessreihenfolge

In der praktischen Fertigung wird HIP in der Regel mit Wärmebehandlungsprozessen kombiniert. Abhängig von Werkstoffcharakteristik und Zielanforderungen planen wir die Abfolge von HIP und Wärmebehandlung sorgfältig. Für die meisten Hochtemperaturlegierungen empfehlen wir, zuerst HIP zur Defektbeseitigung durchzuführen und im Anschluss die Wärmebehandlung zur Mikrostrukturoptimierung.

Komplementäre Leistungssteigerung

HIP fokussiert auf die Verdichtung des Materials, während die Wärmebehandlung primär die Mikrostruktur und Phasenverteilung einstellt. Beide Prozesse ergänzen sich, um eine optimale Gesamteigenschaft des Bauteils sicherzustellen. Unser Prozesstechnikerteam verfügt über umfassende Erfahrung und kann für Kunden die jeweils geeignetste Prozessroute ausarbeiten.

Qualitätsnachweis und zerstörungsfreie Prüfung HIP-behandelter Bauteile

Umfassende Leistungsbewertung

Über unser System zur Materialprüfung und Validierung führen wir eine vollständige Qualitätsbewertung von HIP-behandelten Bauteilen durch. Dazu gehören metallografische Analysen, mechanische Prüfungen sowie Ermüdungstests. So können wir die durch HIP erzielten Leistungsverbesserungen quantitativ belegen.

Fortschrittliche zerstörungsfreie Prüfverfahren

Neben zerstörenden Prüfungen setzen wir moderne zerstörungsfreie Prüfmethoden wie Ultraschallprüfung und industrielle CT-Scanning ein. Diese Technologien ermöglichen eine genaue Beurteilung der Defekteliminierung im Inneren des Bauteils, ohne es zu beschädigen, und eignen sich daher besonders für die Qualitätsüberwachung in der Serienfertigung.

Wichtige Einsatzfelder: Von der Luft- und Raumfahrt bis zur Energieerzeugung

Kritische Komponenten in der Luft- und Raumfahrt

Im Bereich Luft- und Raumfahrt wird HIP umfassend bei sicherheitskritischen Bauteilen wie Turbinenschaufeln, Verdichterscheiben und Gehäusen eingesetzt. Diese Komponenten arbeiten unter extremen Einsatzbedingungen und stellen höchste Anforderungen an die innere Qualität. Für Hochtemperaturlegierungen wie Hastelloy X bieten wir HIP-Services, die Luftfahrtstandards erfüllen.

Energieerzeugung und Medizintechnik

In der Energieerzeugung kommt HIP bei Gasturbinenschaufeln und Komponenten von Kernkraftanlagen zum Einsatz. In der Medizintechnik wird HIP genutzt, um Zuverlässigkeit und Lebensdauer von Implantaten zu erhöhen. Unsere HIP-Services werden auf die spezifischen Anforderungen der jeweiligen Branche zugeschnitten.

Wichtige Kriterien bei der Auswahl von HIP-Services

Bewertung der technischen Fähigkeiten

Bei der Auswahl eines HIP-Dienstleisters sollten Anlagenkapazität, Prozesserfahrung und Qualitätsmanagement sorgfältig bewertet werden. Unsere HIP-Anlagen können große Bauteile mit einem maximalen Durchmesser von 1500 mm und einer Höhe von 2500 mm verarbeiten und decken damit die Anforderungen der meisten industriellen Anwendungen ab.

Kosten-Nutzen-Analyse

Auch wenn HIP die Herstellungskosten zunächst erhöht, führen die resultierenden Leistungssteigerungen und verlängerten Standzeiten häufig zu erheblichen wirtschaftlichen Vorteilen. Wir unterstützen Kunden mit detaillierten Kosten-Nutzen-Analysen, um sicherzustellen, dass der Einsatz von HIP einen maximalen Mehrwert bietet.

Neways HIP-Kompetenz und professionelle Lösungsangebote

Im Rahmen unseres One-Stop-Service-Modells bietet Neway Kunden ganzheitliche Lösungen – von der Rohmaterialbeschaffung bis zum einbaufertigen Bauteil. Unser HIP-Serviceteam verfügt über umfangreiche Industrieerfahrung und entwickelt professionelle Prozesslösungen für eine breite Palette an Hochtemperaturlegierungen.

Wir verfügen über umfassende nachgelagerte Bearbeitungskompetenzen, darunter HIP-Behandlung, Wärmedämmschichten und weitere fortschrittliche Technologien. Durch ein strenges Qualitätskontrollsystem stellen wir sicher, dass jedes HIP-behandelte Bauteil höchsten Qualitätsanforderungen entspricht.

Unsere Serienfertigungskapazitäten ermöglichen die termingerechte Lieferung von Großserien. Ob Titanlegierungskomponenten oder Hochtemperaturlegierungsbauteile – wir bieten professionelle HIP-Services aus einer Hand.