Serviço de Fabricação de Peças Personalizadas em Baixo Volume

A fabricação de peças personalizadas em baixo volume oferece flexibilidade, prazos rápidos e eficiência de custos para desenvolvimento de protótipos ou pequenos lotes. Reduz custos gerais, minimiza desperdício, permite iterações de design e garante alta precisão com materiais e processos adaptados.

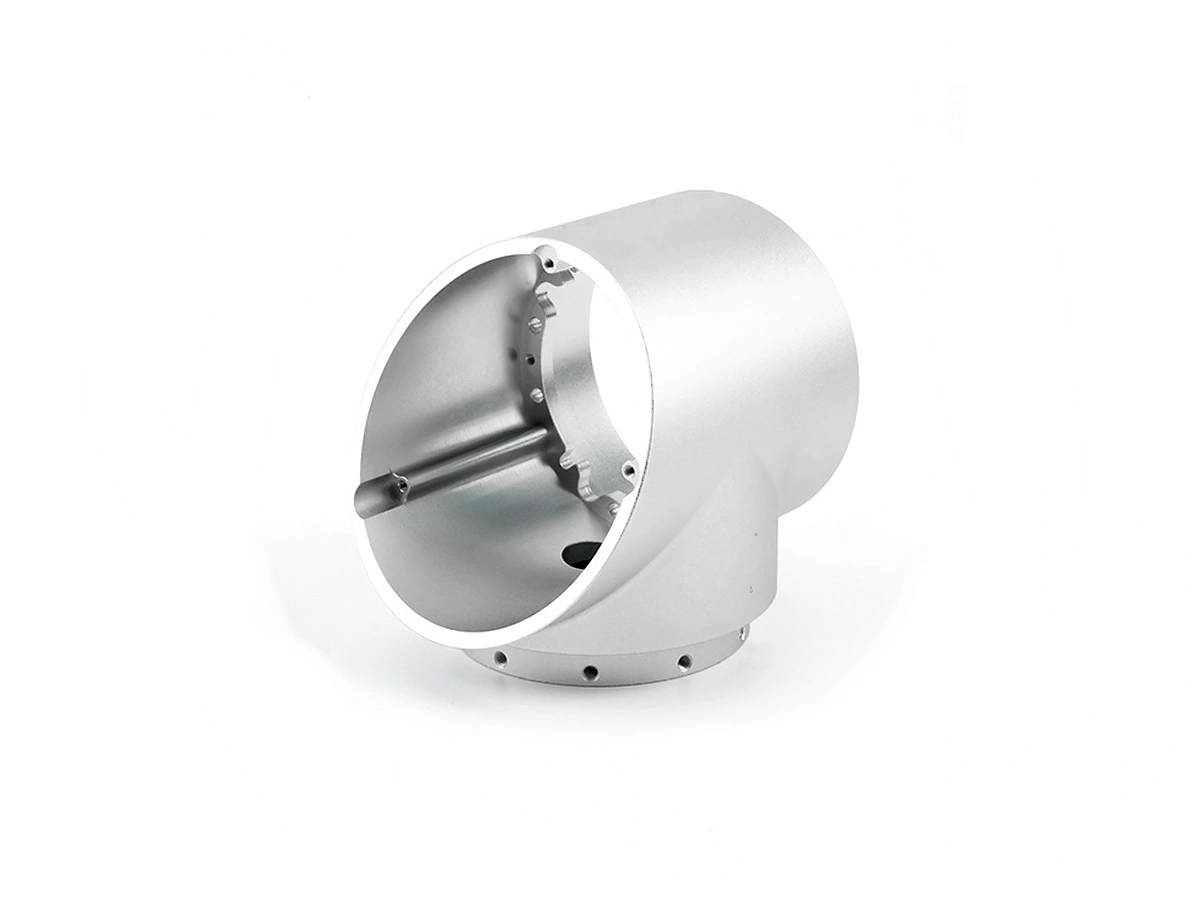

- Serviço de Fabricação CNC em Baixo Volume

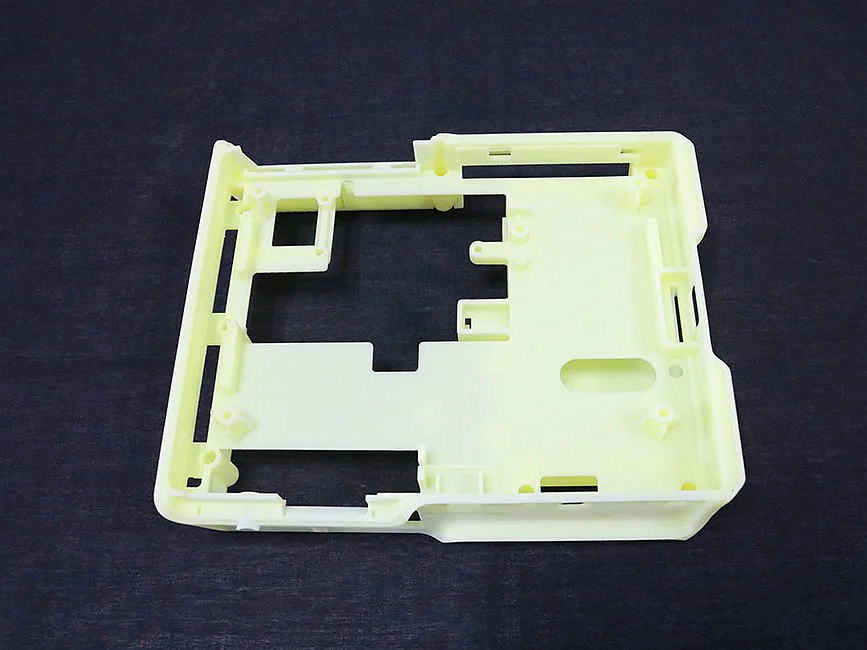

- Serviço de Impressão 3D em Baixo Volume

- Serviço de Produção Rápida de Moldes em Baixo Volume

- Serviço de Produção Acelerada em Baixo Volume >>

Envie-nos os seus desenhos e especificações para um orçamento gratuito

Todos os ficheiros carregados são seguros e confidenciais

Capacidades de Fabricação em Baixo Volume

A fabricação em baixo volume oferece soluções precisas e econômicas com capacidades como usinagem CNC, fresagem, torneamento, furação, alargamento, retificação e usinagem multieixo. Garante peças de alta qualidade com prototipagem rápida, flexibilidade para mudanças de design e técnicas avançadas como EDM para geometrias complexas.

Seleção de Materiais para Fabricação em Baixo Volume

A seleção de materiais para fabricação em baixo volume inclui uma ampla gama de opções, como superligas, titânio, alumínio, cobre, latão, bronze, aço carbono, aço inoxidável, plásticos e cerâmicas. Esses materiais são escolhidos com base na resistência, durabilidade, propriedades térmicas e necessidades específicas da aplicação.

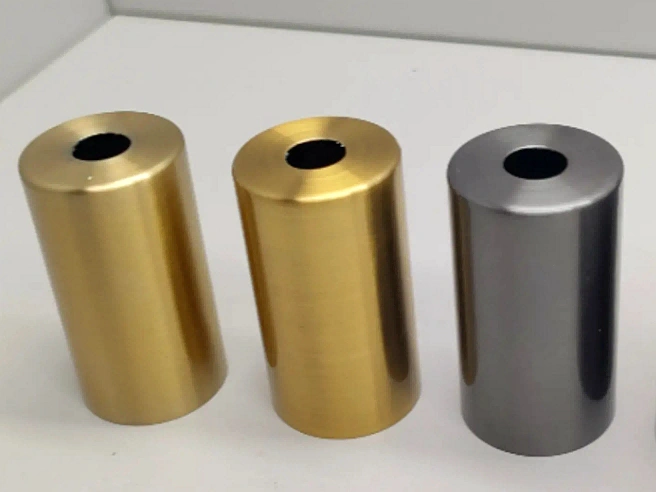

Tratamento de Superfície para Peças Usinadas CNC

O tratamento de superfície para peças usinadas CNC melhora desempenho, durabilidade e estética. Processos comuns incluem polimento, que suaviza superfícies para um acabamento brilhante; anodização, que aumenta a resistência à corrosão, especialmente para alumínio; e pintura em pó, que fornece uma camada durável e decorativa. Eletropolimento melhora a suavidade e resistência à corrosão, enquanto passivação cria uma camada protetora de óxido em aço inoxidável. PVD e eletrodeposição oferecem revestimentos decorativos e funcionais, como ouro ou cromo. Outros tratamentos como jateamento, escovação e óxido preto melhoram a textura da superfície, enquanto tratamento térmico fortalece o material. Esses tratamentos otimizam as peças para aplicações industriais específicas.

Saber Mais

Revestimento Térmico

Saber Mais

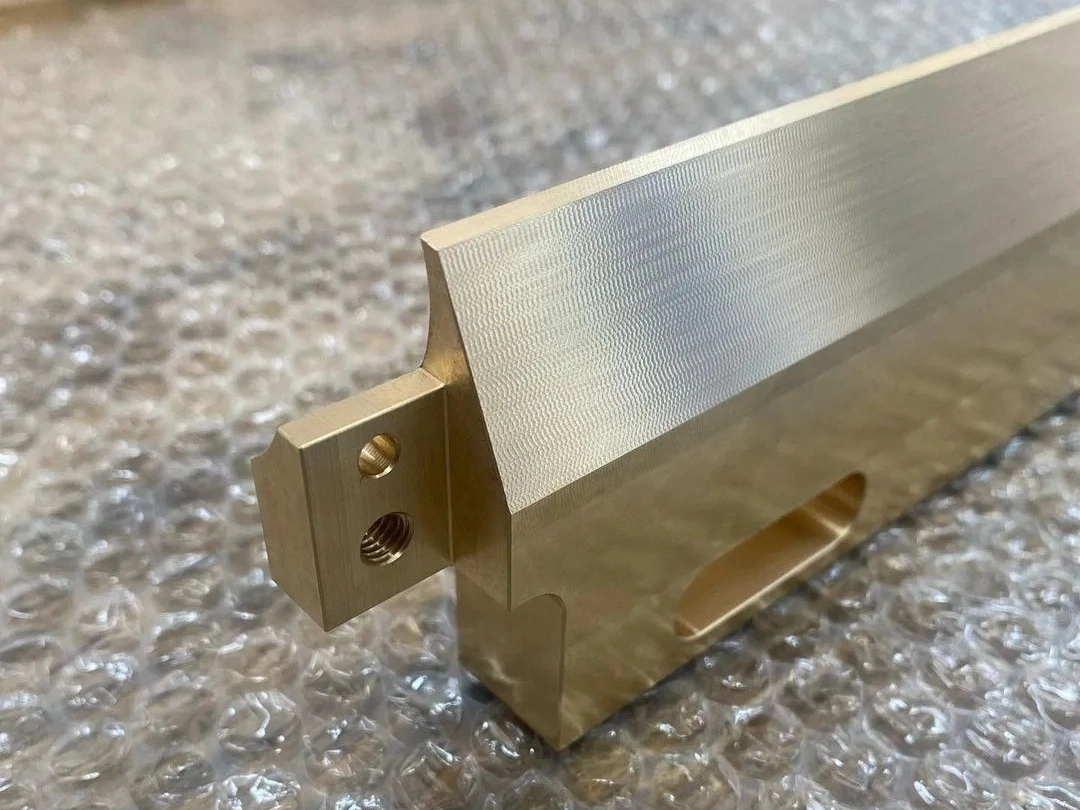

Acabamento Usinado

Saber Mais

Pintura

Saber Mais

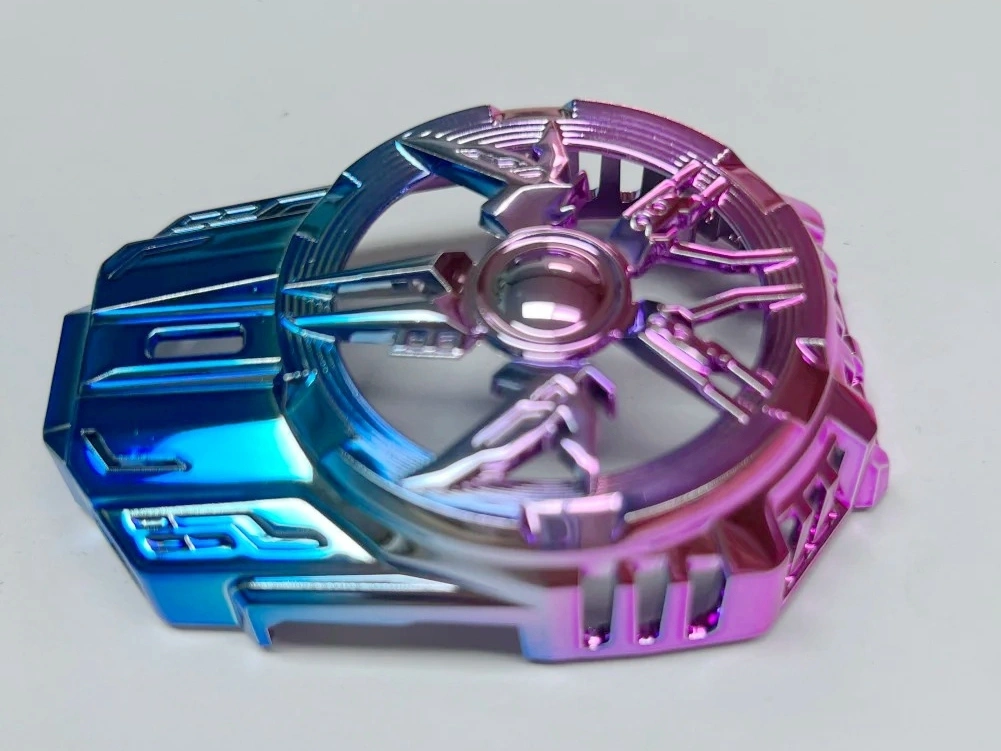

PVD (Deposição Física de Vapor)

Saber Mais

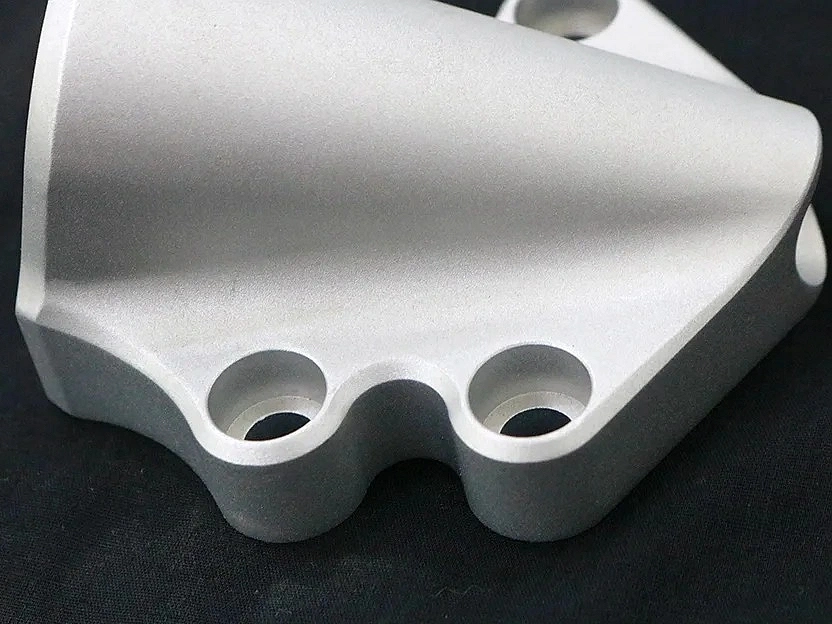

Jateamento de Areia

Saber Mais

Eletrodeposição

Saber Mais

Polimento

Saber Mais

Anodização

Saber Mais

Pintura em Pó

Saber Mais

Eletropolimento

Saber Mais

Passivação

Saber Mais

Escovação

Saber Mais

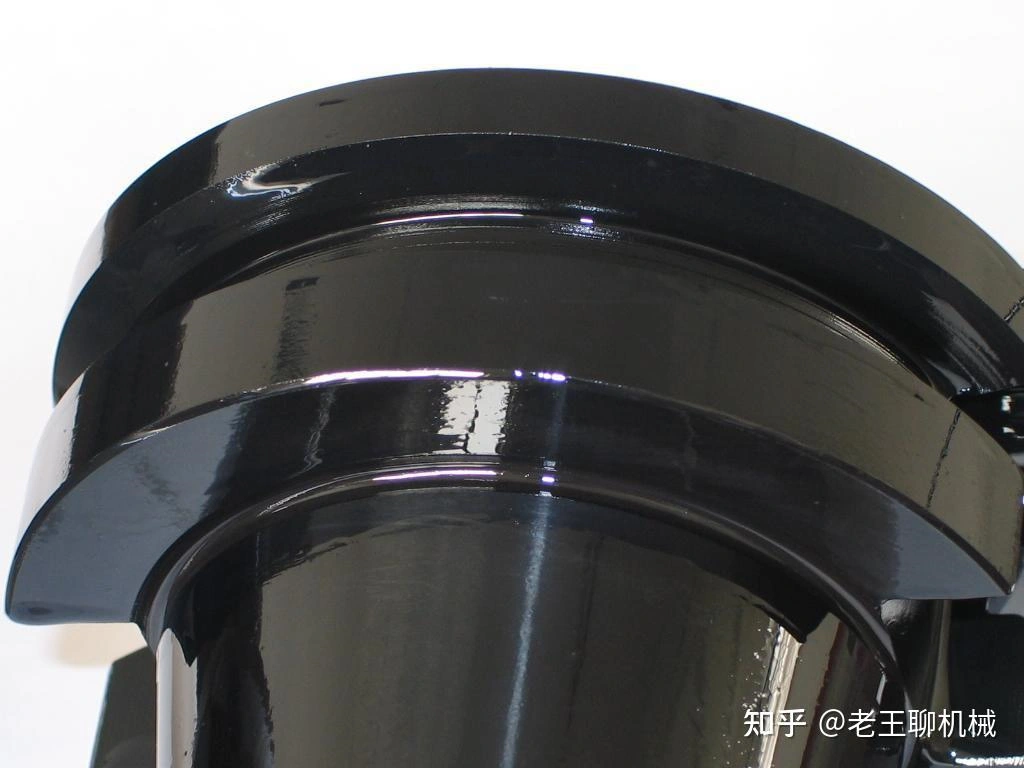

Óxido Preto

Saber Mais

Tratamento Térmico

Saber Mais

Revestimento de Barreira Térmica (TBC)

Saber Mais

Tumbling

Saber Mais

Alodine

Saber Mais

Cromagem

Saber Mais

Fosfatização

Saber Mais

Nitretação

Saber Mais

Galvanização

Saber Mais

Revestimento UV

Saber Mais

Revestimento de Verniz

Saber Mais

Revestimento de Teflon

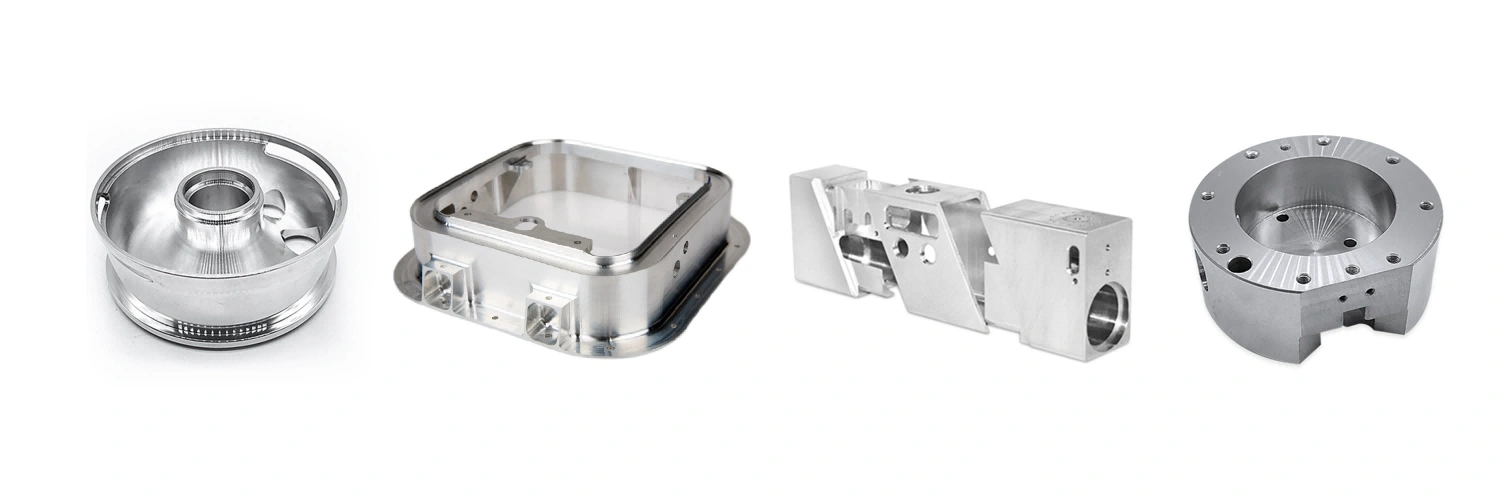

Estudo de Caso de Fabricação em Baixo Volume

Um estudo de caso de fabricação em baixo volume destaca a redução de custos de produção, prazos mais rápidos e melhoria da qualidade do produto. Demonstra flexibilidade em iterações de design, precisão com técnicas avançadas de usinagem e capacidade de atender requisitos específicos do cliente com desperdício mínimo.

Comece um novo projeto hoje

Sugestões para Usinagem em Baixo Volume

As diretrizes de projeto para usinagem CNC em baixo volume enfatizam a seleção de materiais, espessura uniforme das paredes, tolerâncias alcançáveis e características acessíveis. Princípios-chave incluem evitar cantos agudos, minimizar remoção de material e garantir design adequado de furos e simetria para otimizar eficiência, custo e qualidade da peça.