超合金CNC加工の8つの重要ポイント

はじめに:超合金加工の課題を克服するための体系的アプローチ

Newayで 超合金CNC加工サービス に長年携わるなかで、私は「超合金加工の成功には、高度な加工技術だけでなく、包括的で体系的な思考が不可欠」であることを強く実感してきました。卓越した高温強度・耐食性・クリープ耐性を備えた超合金は、航空宇宙、エネルギー、医療などの重要産業において代替不可能な役割を担っています。しかし、こうした優れた特性は同時に加工を非常に難しくする要因にもなります。

あらゆる超合金部品の成功した製造は、材料工学・加工技術・堅牢な品質管理システムが高いレベルで統合された結果です。本記事では、Newayが蓄積してきた豊富なエンジニアリング経験に基づき、超合金CNC加工における8つの重要なポイントを体系的にご紹介し、加工品質と加工効率の両面から総合的なレベルアップを図るための指針を示します。

要点I:材料特性と熱処理状態の深い理解

材料特性の十分な理解は、成功する加工の出発点です。超合金はグレードによって加工挙動が大きく異なります。 インコネル625(Inconel 625) を例にとると、その固溶強化機構により加工中の加工硬化傾向が非常に強く、一般的な材料とは根本的に異なるプロセス戦略が求められます。

熱処理条件が被削性に与える影響も同様に重要です。同一グレードであっても、溶体化処理、時効処理、焼鈍処理などの状態によって硬さ・強度・切削性能は大きく変化します。 ハステロイC-276(Hastelloy C-276) の加工において、焼鈍材は溶体化材と比較して切削抵抗が約15~20%低いことが分かっており、実際の材料状態に応じて加工パラメータを迅速に調整する必要があります。

当社の CNCフライス加工サービス では、各材料の機械的特性、熱物性値、推奨加工条件を記録した包括的な材料データベースを構築しています。このデータベースは、プロセス設計の重要な基盤であると同時に、加工品質を保証するための強力な支えとなっています。

要点II:合理的な工具選定と管理戦略の構築

工具材種とコーティングの科学的選定

工具選定は、加工効率とコストに直結します。当社では主に、超微粒子超硬母材にAlTiN・AlCrNなどの先進PVDコーティングを組み合わせた工具を採用しています。 Waspaloy を加工する際には、高温環境下でも安定した性能を発揮できるよう、コーティングの耐熱性と耐酸化性を特に重視しています。

工具形状の最適設計

工具形状は、対象とする加工内容に合わせて最適化する必要があります。一般的に10~15°の大きめのすくい角を採用し、切削抵抗を低減するとともに、適切なエッジプレパレーションによって耐摩耗性を向上させています。 CNC旋削サービス では、 Rene 41 専用の工具形状を開発し、工具寿命を30%以上延長することに成功しました。

工具寿命モニタリングと交換基準

当社はオンライン監視と定期点検を組み合わせた包括的な工具管理システムを構築し、常に最適な状態で工具が稼働するようにしています。 Haynes 282 の加工では、逃げ面摩耗が0.3 mmに達した時点で即時交換する厳格な基準を設け、過度な摩耗による品質トラブルを未然に防いでいます。

要点III:切削パラメータ組み合わせの最適化

切削速度のバランス

切削速度の選定は、加工効率と工具寿命のバランスを取る作業です。当社では、多数のプロセス試験を通じて各材料ごとの最適速度レンジを定義しています。 精密機械加工サービス では、一定表面速度制御(CSS)を活用し、加工全体を通じて安定した切削条件を維持しています。

送りの精密制御

送り量は、表面品質と生産性の両方に大きな影響を及ぼします。当社では「小さな切込み・やや大きな送り」という原則に従い、工具とワークの接触時間を短縮することで切削温度を低減しています。このアプローチは、 インコネル718(Inconel 718) のような材料の加工硬化を抑制するうえで特に有効です。

切込み量の合理的配分

切込み量は、機械剛性・工具性能・部品形状との関係を踏まえて決定しなければなりません。当社の 多軸加工サービス では、ステップダウン戦略を用い、軸方向・半径方向の切込みを段階的に配分することで安定した加工を実現しています。薄肉部品の場合は、小さめの切込みを採用し、切削抵抗を抑えて変形リスクを低減させます。

要点IV:加工硬化の効果的な制御

加工硬化は、超合金加工における最大の課題のひとつです。当社では、複数のプロセス手段を組み合わせてその影響を抑えています。第一に、常に工具刃先をシャープに保ち、摩耗したエッジを使用しないよう徹底します。第二に、加工硬化層の下で確実に切削が行われるよう、十分な切込みを与えることで「擦り切り」を防止します。

CNC試作加工 段階では、実験的なプロセス試験を通じて加工硬化を最小限に抑えられる最適パラメータ組み合わせを抽出します。すでに加工硬化の影響を受けている表面に対しては、 熱処理サービス を活用し、応力除去や被削性の回復を図ります。

要点V:切削熱およびクーラント管理

超合金加工における熱管理の課題

超合金は熱伝導率が低いため、切削熱が逃げにくく、工具の過熱や寸法精度の低下を招きやすいという課題があります。当社では、加工パラメータの最適化と効果的な冷却戦略の組み合わせによって切削温度を制御しています。 5軸加工サービス では、複雑な曲面加工時の発熱に特に注意し、あらゆる領域に十分な冷却が行き届くよう設計しています。

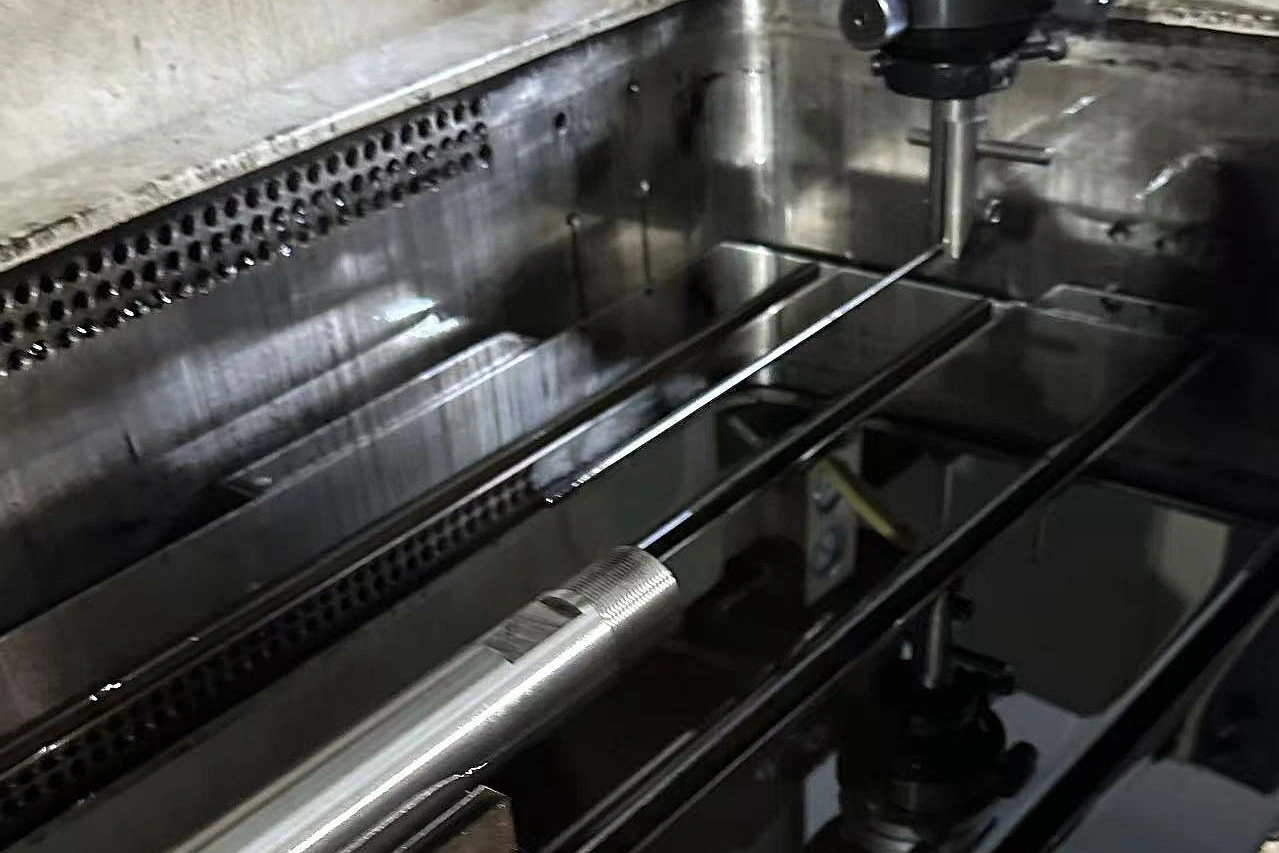

高圧クーラント適用のポイント

当社では70~120 barで運転する高圧クーラントシステムを採用し、クーラントが工具–切りくず界面に確実に到達するようにしています。 CNC穴あけ加工サービス では、高圧クーラントによって切削温度を低減できるだけでなく、切りくず排出性も向上し、穴品質と加工効率の両方が大幅に改善されます。

クーラントパラメータの選定と維持

クーラントの濃度・pH・清浄度は、厳格に管理する必要があります。当社では定期的にクーラント状態を検査し、常に最適な性能が維持されるようにしています。 医療機器 製造では、生体適合性要件を満たすため、専用の医療グレードクーラントを使用しています。

要点VI:ワーク保持と安定性の確保

ワークの保持方法は、加工精度とプロセス安定性に直接影響します。当社では、部品形状に合わせた専用治具を設計し、加工全体を通じて安定したクランプ状態が維持されるようにしています。薄肉部品や複雑形状部品については、加工工程を分割し、複数回のクランプで加工応力を分散させる戦略を採用しています。

試作サービス では、さまざまなワーク形状に迅速に対応できるモジュラー治具システムを活用しています。この柔軟なアプローチにより、クランプ効率の向上と精度の確保を同時に実現し、後続の 量産サービス に向けた堅実な土台を築いています。

要点VII:加工経路設計と振動制御

最適化された工具経路戦略

当社では、トロコイド加工やヘリカル補間などの高度な工具経路戦略を積極的に採用し、切削負荷を一定に保つことで工具寿命を延ばしています。 放電加工(EDM)サービス においても、電極の運動パターンを最適化することで、加工品質の向上を図っています。

振動発生メカニズムと抑制手法

振動は、加工精度と表面品質に悪影響を及ぼす主要因のひとつです。当社では、パラメータの最適化・システム剛性の向上・防振工具の採用といった手段を組み合わせて振動を効果的に抑制しています。 CNC研削加工サービス では、ホイールの動的バランスを調整し、高速回転時の安定性を確保しています。

残留応力を最小化する手法

対称加工・段階加工・中間熱処理などの手法を組み合わせることで、残留応力を適切に制御しています。 発電分野 では、これらの手法により重要部品の長期的な寸法安定性を確保しています。

要点VIII:品質検査とプロセスモニタリング

工程内検査とリアルタイム調整

当社は、高度な工程内計測システムを用いて、重要パラメータをリアルタイムで監視しています。 小ロット製造サービス においても、このモニタリングにより、各部品が要求された品質仕様を確実に満たすよう管理しています。

表面健全性評価の基準

当社では、表面粗さ・残留応力・微細組織などを含む総合的な表面健全性評価システムを構築しています。 産業機器 分野では、これらの評価基準が、使用中の信頼性と耐久性を保証する重要な指標となっています。

全工程品質トレーサビリティシステム

原材料の受け入れから完成品の出荷に至るまで、当社は全工程にわたる品質トレーサビリティを徹底しています。 表面健全性向上 などの各種処理においても、このトレーサビリティシステムにより、プロセスパラメータの管理と品質の一貫性が確保されています。

Newayのプロフェッショナルな超合金加工ソリューション

Newayは、 ワンストップサービス モデルを通じて、ここまで紹介した8つの要点を加工フレームワーク全体に体系的に組み込んでいます。材料選定、プロセス設計、製造、品質管理に至るまで、あらゆる段階で超合金加工特性への深い理解が反映されています。

当社のエンジニアリングチームは、堅実な理論知識を有するだけでなく、何よりも豊富な現場経験を備えています。私たちは、部品ごとに固有の技術要件が存在することを理解しており、体系的な思考と専門的な技術サポートを通じてはじめて、お客様にとって最適な加工ソリューションを提供できると考えています。