高精度EDM深穴加工サービス – カスタム部品製作

放電加工(EDM)による深穴加工は、従来のドリル加工では対応できない複雑な材料に対して、高アスペクト比の穴を形成するための精密加工技術です。ミクロンレベルの精度と最小限の熱変形が求められる製造アプリケーションで広く使用されています。

Newayでは、専用のEDM加工サービスを、包括的なCNC加工能力と統合することで、深く・狭く・形状が複雑な穴を持つカスタム部品を高精度に製造しています。これらの能力は、精度と一貫性が性能を左右する航空宇宙、医療、エネルギー、自動車などの分野で不可欠です。

EDM深穴加工とは?

EDM(Electrical Discharge Machining:放電加工)深穴加工は、電気放電(スパーク)によって導電性材料を除去する非接触型の加工プロセスです。この方法は、深さ/直径比が20:1を超える穴の加工に優れており、300mmを超える深さでも高い寸法精度を維持することができます。

EDMは、従来のツイストドリルやガンドリルとは異なり機械的な切削力を加えないため、薄肉構造や繊細な形状、脆い材料の加工に最適です。このプロセスでは、中空電極を使用し、電極内部を通る絶縁液(誘電液)によって放電ギャップを冷却・洗浄しながら、蒸発・溶融した材料と加工屑を効率的に排出します。

EDM深穴加工は、従来の工具では加工が困難、あるいは不可能な超合金、チタン、焼入れ鋼、導電性セラミックスなどの部品に特に適しています。

深穴用途におけるEDMの主な利点

EDM深穴加工は、従来のドリル加工や他の特殊加工方法と比較して、明確な優位性を備えています。これらのメリットは、先進材料や極端な形状が求められる航空宇宙・自動車・エネルギー分野においてとくに重要です。

1. 超高精度と高い再現性

EDM深穴加工では、位置精度±0.01mm、内面粗さRa 0.2μmクラスの仕上げを日常的に達成できます。これは、燃料噴射ノズル、熱交換器の流路、高圧継手など、厳密な流量制御やシール性能が要求される部品に不可欠です。

2. 非接触加工方式

機械的な切削とは異なり、EDMは切削力を一切加えないため、薄肉部品や繊細なジオメトリを変形させることがありません。剛性が極めて低い部品や脆性材料に対しても、寸法精度を維持しつつ安全に加工できます。

3. 優れた深さ/直径比の実現

深さ/直径比100:1クラスの深穴でも、高い一貫性と精度で加工することが可能です。このようなジオメトリは、ジェットエンジンの冷却通路、医療機器、産業用センサー部品などで一般的に要求されます。

4. 難削材への高い対応力

EDMは、従来のドリル加工が困難なインコネルや、超硬合金、焼入れ工具鋼なども容易に加工できます。工具摩耗や熱亀裂によって品質が損なわれやすい部品に対して、EDMは極めて有効な手段です。

5. バリのほとんどない優れた内面仕上げ

プロセスの特性上、EDMはバリのない穴と優れた内面粗さを同時に実現しやすく、面取りやバリ取り、内面研磨といった二次加工の工数を大幅に削減できます。

これらの特長により、EDM深穴加工は、精度・材料適合性・コスト効率の面で従来工法が対応しきれない複雑な部品設計に対する、最適なソリューションとなっています。

EDM深穴加工と従来型深穴加工の比較

高精度用途に最適な加工方法を選定するには、EDM深穴加工と伝統的な機械式深穴加工を正しく比較・理解することが重要です。それぞれの方式は、精度、材料適合性、加工速度、形状複雑性などの点で異なる特性を持っています。

項目 | EDM深穴加工 | 従来型深穴加工(例:ガンドリル) |

|---|---|---|

加工メカニズム | 非接触の電気放電による除去 | ドリル工具による機械的切削 |

対応可能な材料 | 導電性材料全般(超合金、焼入れ鋼、チタンなど) | 中硬度までの金属が中心 |

深さ/直径比 | 最大100:1程度まで対応可能 | 一般的には20:1〜30:1程度が限界 |

内面粗さ | Ra 0.2〜0.8 μm | Ra 1.6〜3.2 μm程度 |

バリ発生 | ほぼなし | バリや工具痕が発生しやすい |

工具摩耗 | 比較的少ない(電極の均一な消耗) | 摩耗により寸法誤差・たわみが発生しやすい |

熱影響層 | 局所的な放電のため非常に小さい | 摩擦熱により広範囲に生じる |

代表的な用途 | 航空エンジン冷却穴、医療用微小穴、深い流体チャンネルなど | エンジンブロック、油圧配管、比較的単純なシャフトなど |

大量生産で高い加工速度が求められる低〜中精度用途では機械式ドリリングが有利な場合もありますが、寸法精度、材料硬度、微細形状が重要な場面では、EDM深穴加工が他に代えがたい優位性を発揮します。

EDM深穴加工における材料適合性

EDM深穴加工は、極めて硬い材料や熱に敏感な材料に対しても高い加工能力を持ち、先端製造分野で欠かせない技術となっています。唯一の条件は、「ワークが導電性であること」です。

代表的な対応材料

超合金

インコネル、ハステロイ、ルネ系合金など、航空宇宙タービンや原子力関連設備で用いられる材料は、高硬度かつ耐熱性に優れるため、EDMに非常に適しています。詳しくは、当社の超合金CNC加工サービスをご覧ください。

チタン合金

チタンは高い比強度と優れた耐食性を備えており、航空宇宙および医療用インプラントに最適な材料です。EDMを用いることで、従来加工では難しいチタンの深穴・バリレス加工を実現できます。詳細は当社のチタン加工サービスをご参照ください。

焼入れ工具鋼

H13やD2といったグレードは、金型や耐摩耗部品として広く使用されていますが、機械加工による深穴あけは非常に困難です。EDMであれば、亀裂や寸法ドリフトを抑えつつ、高精度な穴加工が可能です。当社の炭素鋼CNC加工サービスとも高い親和性があります。

ステンレス鋼

304や316Lといったグレードは、医療、食品、産業機器向け部品に多用される材料です。EDMを適用することで、高精度な流路、微小穴、冷却チャンネルなどを安定して形成できます。詳しくはステンレス鋼加工サービスをご覧ください。

導電性セラミックスおよび特殊合金

導電性を持つ先進セラミックスや金属基複合材料(MMC)も、EDMによる加工が可能です。高温部品や電気・電子部品など、極めて微細な穴が必要となる用途で有効です。

このように、EDM深穴加工は、材料面での柔軟性と高い一貫性を備えており、極めて高い寸法安定性と構造信頼性が要求される特殊部品に最適なソリューションです。

業界別に見るEDM深穴加工部品の用途

EDM深穴加工は、微細精度、耐熱性、構造的信頼性が求められる多くの産業を支えています。以下に、主な業界ごとの適用例を示します。

航空宇宙

ジェットエンジン、ノズル、冷却流路には、超合金に微細かつ深い穴を加工する必要があります。EDMは、高い耐熱性を保ちながら、変形を抑えて精密なジオメトリを実現します。直径1mm未満・深さ50mm超といった穴は、タービンブレードでは標準的な要求仕様です。

医療機器

高精度な外科用プローブ、整形外科用インプラント、流体供給システムなどでは、チタンやステンレス鋼に対する微小穴加工が欠かせません。EDMにより、灌流・吸引・薬液投与用として直径0.2mmクラスの穴を高精度に形成できます。

自動車

高性能エンジン部品における精密なオイル通路、燃料噴射ノズル、焼入れされたバルブシートなどに、EDM深穴加工が活用されています。1045や4140といった合金鋼が、代表的な対象材料です。

発電・エネルギー

タービンブレードや熱交換器では、インコネルやハステロイなどの合金に、冷却用の細長い流路を形成する必要があります。機械的な応力をほとんど与えず、長く・狭い通路を加工できる点が、EDMの大きな強みです。

産業オートメーション

サーボモータスピンドルや高精度ダウエルピンなど、複雑な内部形状を持つ流体部品やセンサー部品の製造に、EDM深穴加工が用いられています。

このようにEDMは、材料・業界を問わず、高精度・少量生産・カスタム部品の製造において不可欠なコア技術となっています。

EDM深穴加工における設計上の重要ガイドライン

EDM深穴加工の能力を最大限に引き出すためには、プロセス特有の公差・電極形状の制約・材料特性を設計段階から考慮することが重要です。以下は、設計エンジニア向けの主要な推奨事項です。

1. 穴径と深さ/直径比

高い寸法精度を得るには、深さ/直径比は最大100:1を目安としてください。

直径1mm未満の微小穴の場合、特別な段取りを行わない限り、深さは約50mm程度までに抑えるのが理想的です。

直径1mm以上の穴であれば、ステップ電極を用いることで100mmを超える深さにも対応可能です。

2. 最小形状サイズ

実務上の最小有効穴径は、おおよそ0.1mm程度です(高精度の黄銅電極やタングステン電極を使用)。

これより小さい穴は、放電の安定性や洗浄性が悪化し、品質のばらつきが大きくなる可能性があります。

3. 入口・出口側のクリアランス

電極がワークに対して直線的に挿入できるクリアな経路を確保してください。

傾斜面からの斜め進入は、専用の多軸EDMヘッドを用いない限り避けるのが望ましいです。

4. 材料選定のポイント

電気伝導度が均一な材料を選ぶことが重要です。介在物が多い合金や層状構造を持つ材料は、スパークの安定性を損なう場合があります。

適合材料については、当社のCNC加工・材料サービスも参照していただけます。

5. 公差と表面粗さ

一般に、穴径・位置に対して±0.01mm程度、条件によってはそれ以上の精度も達成可能です(穴径・深さに依存)。

表面粗さは、放電条件と電極摩耗補正の最適化により、Ra 0.2〜0.8μmクラスまで仕上げることができます。

6. フラッシング(洗浄)戦略

設計段階でフラッシングポートを設ける、または逆フラッシングが可能な構造にするなど、洗浄性を考慮してください。不十分なフラッシングは、加工屑の堆積やテーパの悪化を招きます。

7. 可能であれば止まり穴を避ける

貫通穴は、テーパ制御や加工屑の排出が比較的容易です。止まり穴も加工可能ですが、より高度なフラッシング技術と段取りが必要となります。

これらの設計指針に従うことで、EDMの段取りコストを抑えつつ、寸法の一貫性を高め、試作から少量生産に至るまで優れた穴品質を確保できます。

カスタムEDM深穴加工部品ならNewayを選ぶべき理由

Newayは、精密工学とプロセス統合能力を組み合わせることで、最も厳しい技術仕様にも対応するカスタムEDM深穴加工ソリューションを提供しています。世界中のメーカーが当社を信頼する主な理由は次のとおりです。

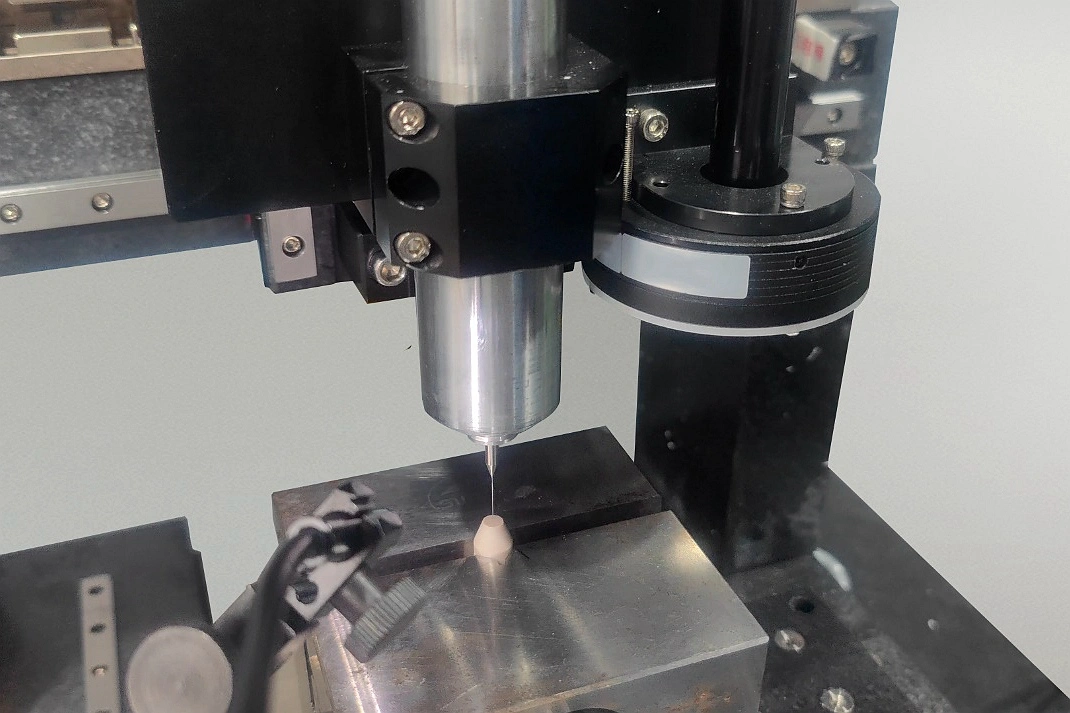

1. 専用EDM深穴加工ワークステーション

当社は、最小0.1mm径の穴から、深さ/直径比100:1超の深穴まで加工可能な高周波CNC EDMドリリング機を運用しています。多軸位置決めやカスタムフラッシングセッティングにも対応し、複雑なジオメトリの穴加工を実現します。

2. 材料技術のノウハウ

超合金、チタン、ステンレス鋼、銅合金など、あらゆる導電性材料に対して最適な放電条件を設定し、高品質な加工を行います。高合金精密部品向けには、耐熱性に優れた電極材の選定も行っています。

3. 超精密公差への対応

当社の品質管理システムは、±0.005mmレベルの公差管理に対応しており、三次元測定機による精密測定と、内部形状の検証に用いる3Dスキャニングを組み合わせて検証しています。

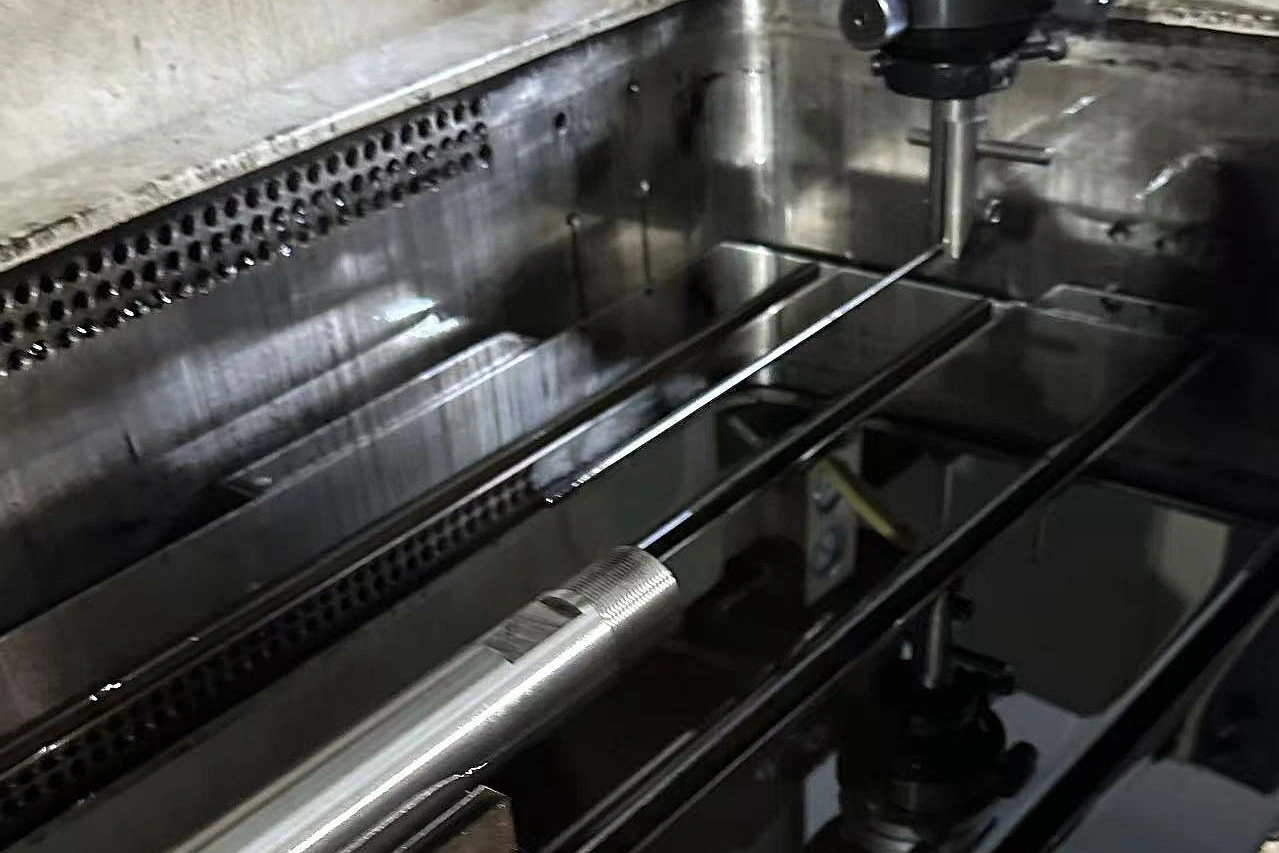

4. ワンストップでのカスタム部品製造

EDM深穴加工は、当社のワンストップCNC加工サービスの中にシームレスに統合されています。旋削、フライス、ボーリング、表面処理、量産対応まで、一連の工程を包括的にサポートします。外科用プローブからタービン冷却システムに至るまで、最終製品として完成した状態でお届けできます。

5. 豊富な業界実績

当社は、チタン製外科用インプラント、サーボモータスピンドル、EDM微細穴構造を持つ高精度ファスナーなど、多様な案件を成功裏に納入してきました。航空宇宙・医療・自動化などの分野で、実績に裏打ちされたパフォーマンスを発揮しています。

NewayのEDM深穴加工サービスは、単に「穴をあける」ためのものではなく、従来不可能と思われていた設計を、確かな信頼性とともに現実のものとするための技術です。