Resins

Material Introduction

Resins for 3D printing are highly specialized photopolymer materials engineered for precision, exceptional surface quality, and the ability to replicate fine details far beyond what thermoplastic-based printing can achieve. Used primarily in SLA, DLP, and CLIP additive manufacturing technologies, resins offer a wide range of mechanical and functional behaviors—from flexible elastomers and high-impact engineering resins to transparent, heat-resistant, and biocompatible formulations. Neway’s advanced 3D printing service enables engineers to produce finely detailed prototypes, medical models, lenses, microfluidic components, functional housings, and high-resolution consumer product parts with exceptional accuracy. When combined with finishing operations such as CNC machining, polishing, or coating, resin-printed parts achieve remarkable mechanical reliability and aesthetic refinement, making them suitable for professional and industrial use.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | Photopolymer Resin | Standard, Engineering, Dental, Castable |

Europe | UV-Curable Resin | Tough Resin, Clear Resin |

Japan | Light-Sensitive Resin | ABS-like Resin, Flexible Resin |

China | Photosensitive Resin | Rigid Resin, High-Temp Resin |

3D Printing Industry | Performance Resins | SLA/DLP Engineering Resins |

Alternative Material Options

Depending on performance requirements, several alternative materials may offer advantages over resins. For durable, load-bearing parts, metals such as aluminum or carbon steels provide higher structural strength. For lightweight engineering parts, high-performance polymers such as ABS, Nylon, and PEEK offer superior fatigue performance. In high-temperature conditions, nickel alloys such as Inconel 625 ensure thermal stability. Where conductivity is essential, copper and brass stand out. Elastomeric resins can be replaced with engineering-grade TPE or TPU for enhanced durability. These alternatives enable engineers to precisely match materials to mechanical, thermal, or functional requirements.

Design Purpose

Resins were engineered to enable extremely high-resolution printing with smooth surfaces, sharp edges, and precise micro-features. Their chemistry enables rapid photopolymerization, allowing for thin-layer printing with exceptional accuracy for small and finely detailed parts. They were designed to mimic the mechanical behavior of traditional plastics, support casting workflows, enable dental and medical applications, and produce transparent or flexible components. With their ability to reproduce intricate geometries, resins fulfill the need for realistic prototyping, micro-scale engineering, and production of aesthetic, functional, or dimensionally critical parts that thermoplastics cannot replicate.

Chemical Composition (Typical)

Component | Description |

|---|---|

Oligomers | Base resin determining mechanical properties |

Monomers | Viscosity reducers aiding polymer cross-linking |

Photoinitiators | React to UV light to trigger curing |

Additives | Modifiers for toughness, clarity, color, heat resistance |

Physical Properties

Property | Typical Value |

|---|---|

Density | 1.05–1.30 g/cm³ |

Heat Deflection Temperature | 60–230°C |

Shrinkage | Very low (high dimensional accuracy) |

Surface Finish | Extremely smooth |

Transparency | Available in clear or opaque variations |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 30–80 MPa |

Elastic Modulus | 1.5–3.2 GPa |

Elongation at Break | 5–50% |

Hardness | Shore D 70–90 |

Impact Strength | Moderate (varies with resin type) |

Key Material Characteristics

Extremely high resolution and accuracy ideal for fine-detail parts and miniature components.

Exceptional surface smoothness compared with thermoplastic 3D printing methods.

Wide range of properties, including rigid, flexible, tough, transparent, and heat-resistant blends.

Excellent for aesthetic prototypes that require premium visual quality.

Biocompatible resin options enable the creation of dental devices, medical models, and surgical planning tools.

Casting resins allow direct production of molds for jewelry and precision metal parts.

Clear resin grades produce optical-quality surfaces with proper polishing.

Engineering resins mimic the mechanical behavior of ABS, Nylon, and PC for functional components.

Low thermal conductivity and strong dielectric propertiesare suitable for electrical insulation.

Fast-curing, supporting rapid prototyping and short production cycles.

Manufacturability in Different Processes

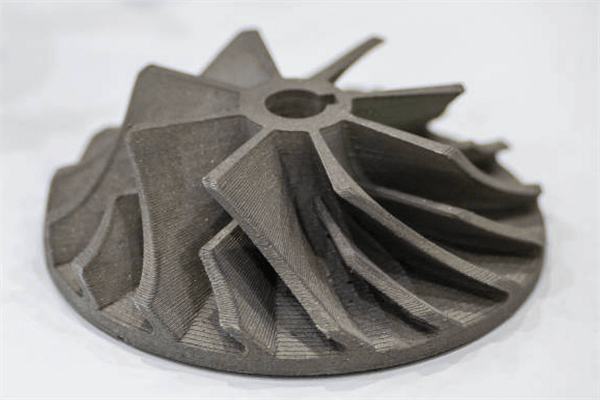

SLA printing: Produces ultra-fine details and smooth surfaces for complex geometries.

DLP printing: Offers high-speed, high-precision results ideal for mass part production.

CLIP processing: Enables continuous printing with exceptional mechanical uniformity.

CNC machining: Resin parts can be post-machined using precision machining for improved fit.

Painting & coating: Excellent adhesion with industrial coatings for surface improvement.

Thermal curing: Additional UV or heat curing increases strength and temperature resistance.

Molding: Some resins used as master models for silicone or metal casting processes.

Suitable Post-Processing Methods

UV post-curing to maximize hardness, strength, and heat performance.

Precision finishing using CNC milling and turning for functional interfaces.

Polishing and sanding for smooth or optical-grade surfaces.

Painting and protective coatings to enhance durability and aesthetics.

Surface texturing through brushing processes.

Solvent smoothing for select resin formulations.

Metal plating, achieved through electroplating, enhances both cosmetic and functional performance.

Common Industries and Applications

Dental models, surgical guides, and medical prototypes requiring precision and biocompatibility.

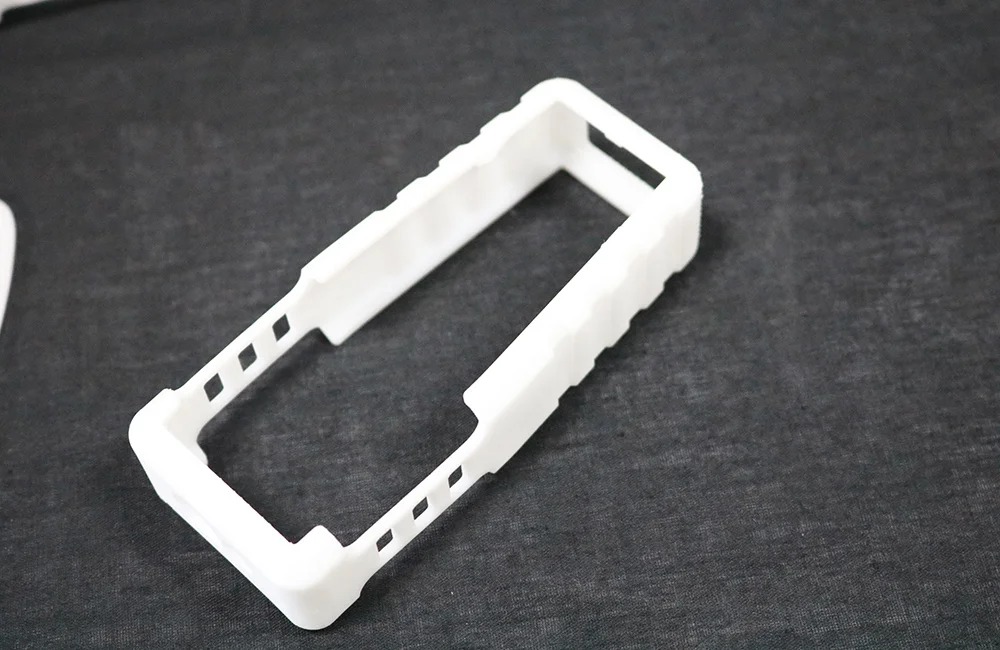

Consumer goods prototypes for fit, finish, and ergonomic validation.

Microfluidic devices and small-scale engineering components.

Automotive and aerospace interior prototypes and functional testing parts.

Optical housings, transparent covers, and light-guiding components.

Jewelry casting models and aesthetic product forms.

When to Choose This Material

When extremely fine details, thin walls, or microstructures are required.

When producing optical, transparent, or aesthetic surfaces with minimal post-processing.

When high-precision functional prototypes are needed for engineering validation.

When biocompatibility or medical-grade materials are required for patient-facing models.

When heat-resistant or chemically stable materials are needed for automotive or electronics prototypes.

When creating casting patterns or highly detailed molds.

When rapid turnaround and high surface quality are project priorities.

When complex geometries exceed the capability of CNC machining or thermoplastic printing.