Copper

Material Introduction

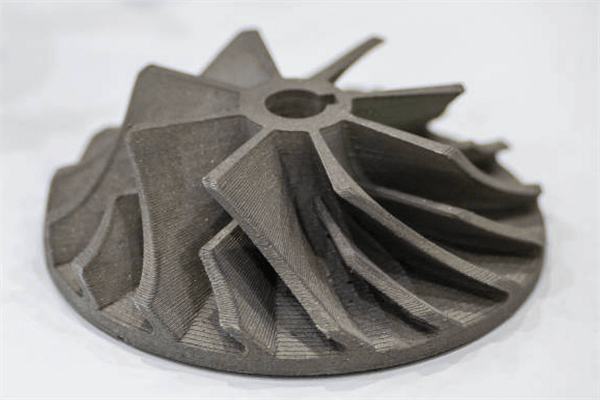

Copper for 3D printing is a high-performance metal material valued for its exceptional thermal and electrical conductivity, making it indispensable for advanced engineering applications. Modern additive manufacturing enables the processing of pure copper and copper alloys with high density and precision, producing complex geometries that are difficult or impossible to achieve through traditional manufacturing methods. With Neway’s advanced 3D printing service, engineers can create high-conductivity heat exchangers, induction coils, electronic components, and RF devices with optimized internal channels and thin-wall structures. Copper’s superior conductivity, anti-microbial properties, and solid mechanical strength make it an outstanding choice for prototyping and mass-production components in aerospace, power generation, electronics, and industrial equipment. Combined with post-processing options such as CNC machining, polishing, and protective coatings, copper delivers high-precision, production-ready results for demanding technical applications.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | Copper Alloy | C101, C110 |

Europe | Electrolytic Copper | Cu-ETP, Cu-OF |

Japan | Tough-Pitch Copper | C1100, C1020 |

China | Red Copper | T1, T2, TU0 |

Electrical Industry | High-Conductivity Copper | Oxygen-Free Copper Grades |

Alternative Material Options

Several metals offer complementary performance advantages depending on thermal, mechanical, or environmental requirements. For lightweight structures that require conductivity and corrosion resistance, aluminum alloys are often selected. When high strength, heat resistance, and oxidation stability are crucial, nickel-based alloys such as Inconel 625 or Inconel 718 provide exceptional durability. For electrical components that require mechanical strength and fatigue resistance, brass alloys offer both machinability and stability. For high-wear environments, cobalt-based materials such as Stellite 6 ensure extreme durability. Where ultra-high precision and heat resistance are required, high-performance titanium alloys deliver superior strength-to-weight ratios. These alternatives allow engineers to balance conductivity, strength, weight, and environmental performance as needed.

Design Purpose

Copper was originally engineered to provide unmatched thermal and electrical conductivity for power transmission, heat management, and the design of electronic components. In 3D printing, copper enables the production of optimized thermal structures such as internal cooling channels, lattice-reinforced heat spreaders, and compact RF components that cannot be produced through subtractive machining. The material was also intended for applications requiring natural anti-microbial functionality, stability at elevated temperatures, and efficient electrical current flow. Additive manufacturing enhances these advantages by enabling the production of lighter, more complex, and more efficient copper-based components.

Chemical Composition (Typical)

Element | Composition (%) |

|---|---|

Copper (Cu) | ≥ 99.9 |

Oxygen (O) | ≤ 0.04 |

Phosphorus (P) | ≤ 0.03 |

Silver (Ag) | ≤ 0.01 |

Iron (Fe) | Trace |

Physical Properties

Property | Value |

|---|---|

Density | ~8.96 g/cm³ |

Thermal Conductivity | ~380–400 W/m·K |

Electrical Conductivity | 97–102% IACS |

Specific Heat | ~385 J/kg·K |

Melting Point | 1083°C |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 200–260 MPa (annealed) |

Yield Strength | 60–120 MPa |

Hardness | 45–80 HB |

Elongation | 25–45% |

Conductivity | Excellent |

Key Material Characteristics

Exceptional thermal conductivity ideal for heat exchangers, cooling plates, and thermal-management structures.

Outstanding electrical conductivity for coils, busbars, antennas, and microwave components.

Excellent machinability using copper CNC machining for fine tolerances and smooth finishing.

High corrosion resistance suitable for electrical and environmental exposure applications.

Naturally anti-microbial surface properties for medical, food-handling, and hygiene-critical components.

Stable performance across temperature variations with high oxidation resistance when properly finished.

Ability to form complex internal channels via powder bed fusion for improved cooling efficiency.

Good fatigue performance for conductive structural elements.

Compatible with high-density additive manufacturing, producing near-wrought mechanical strength.

Highly recyclable and sustainable for long-term industrial use.

Manufacturability in Different Processes

Additive manufacturing: Powder bed fusion enables the production of high-density parts; Neway’s 3D printing process ensures precision, conductivity, and microstructural homogeneity.

CNC machining: Copper prints can be further refined using CNC milling, turning, and drilling for high-tolerance requirements.

EDM: Fine details and micro-features can be produced using EDM machining when necessary.

Heat treatment: Annealing enhances ductility and structural uniformity, depending on the application's needs.

Brazing and soldering: Copper assemblies can be joined effectively using thermal joining processes.

Surface finishing techniques, including brushing, polishing, and blasting, enhance surface functionality and electrical performance.

Suitable Post-Processing Methods

Precision machining via precision machining for smooth electrical contact surfaces.

Polishing and mirror finishing using industrial polishing techniques.

Electroplating using electroplating to enhance corrosion resistance and conductivity.

Protective coatings such as powder coating or UV coating for environmental exposure.

Thermal treatments for stress relief and microstructure stability.

HIP processing for improved part density and uniformity.

Common Industries and Applications

Heat management systems, including heat sinks, cold plates, and heat exchangers.

Electrical and electronic components, including busbars, circuit elements, and connectors.

Induction coils, RF waveguides, antennas, and microwave components.

Aerospace and automotive thermal systems require optimized internal flow designs.

Medical devices benefiting from copper’s anti-microbial properties.

Industrial machinery components require high conductivity and stability.

When to Choose This Material

When maximum thermal or electrical conductivity is essential for functional performance.

When producing complex internal channels for advanced cooling and heat-dissipation systems.

When designing RF, electromagnetic, or microwave components that require high frequency efficiency.

When needing corrosion-resistant conductive components with precise geometries.

When manufacturing high-density industrial parts with excellent machinability.

When anti-microbial performance is required for safety-critical environments.

When components must combine structural reliability with high conductivity.

When lightweighting and geometric optimization are important for system efficiency.