Carbon Steels

Material Introduction

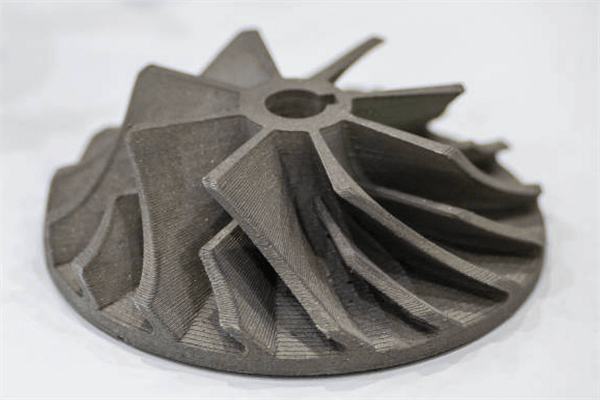

Carbon steels for 3D printing represent a versatile class of iron-based alloys that combine strength, affordability, and ease of processing for functional prototypes and end-use mechanical parts. While traditionally associated with machining and fabrication, advancements in metal additive manufacturing have enabled carbon steels to be processed through technologies such as powder bed fusion and directed energy deposition. These materials offer a balanced combination of tensile strength, toughness, and wear resistance, making them suitable for tooling elements, structural brackets, jigs, fixtures, and industrial components. When enhanced with appropriate finishing steps such as polishing, Teflon coating, or carbon steel surface treatment, carbon steels can deliver performance comparable to traditionally manufactured parts. Neway’s advanced 3D printing service enables engineers to transform carbon-steel powders into dense, dimensionally accurate, production-grade components suitable for a wide range of industrial applications.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | Carbon Steel | 1018, 1045, A36 |

Europe | Non-Alloy Steel | C15, C45 |

Japan | Carbon Structural Steel | S15C, S45C |

China | Carbon Steel | Q235, 45# Steel |

Manufacturing Industry | General-Purpose Carbon Steel | Low-, Medium-, High-Carbon Grades |

Alternative Material Options

Depending on strength, weight, and environmental requirements, several alternative materials may offer performance advantages over carbon steels. For superior corrosion resistance and structural stability, stainless steels are frequently selected for harsh or moisture-rich environments. When lightweight performance is critical, aluminum alloys offer excellent strength-to-weight ratios and thermal conductivity, making them ideal for brackets, housings, and precision enclosures. For extreme heat or high-load service, nickel-based options such as Inconel 718 deliver outstanding creep and oxidation resistance. Applications requiring high toughness and exceptional hardness may benefit from tool steels or cobalt-based alloys, such as Stellite 6. For components requiring chemical resistance, plastics such as PEEK offer valuable engineering performance. These alternatives allow designers to tailor material selection to the required mechanical, thermal, and environmental conditions.

Design Purpose

Carbon steels were originally designed to provide a scalable, cost-efficient structural material with mechanical properties tailored by carbon content—ranging from high ductility in low-carbon grades to superior hardness and strength in high-carbon compositions. In 3D printing, carbon steels serve as a practical solution for producing durable mechanical components that require a balance of strength and manufacturability without the premium cost of tool steels or superalloys. Their predictable heat-treatment response, machinability, and weldability make them a strong choice for functional prototypes, tooling fixtures, and industrial assemblies produced through additive manufacturing.

Chemical Composition (Typical)

Element | Composition (%) |

|---|---|

Iron (Fe) | Balance |

Carbon (C) | 0.05–1.0 |

Manganese (Mn) | 0.3–1.2 |

Silicon (Si) | 0.1–0.5 |

Phosphorus (P) | ≤0.04 |

Sulfur (S) | ≤0.05 |

Physical Properties

Property | Value |

|---|---|

Density | ~7.85 g/cm³ |

Thermal Conductivity | 45–60 W/m·K |

Electrical Resistivity | ~0.15 μΩ·m |

Specific Heat | ~490 J/kg·K |

Melting Range | 1425–1540°C |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 350–900 MPa |

Yield Strength | 250–700 MPa |

Hardness | 120–250 HB (annealed) |

Elongation | 10–25% |

Impact Toughness | Moderate to high depending on carbon content |

Key Material Characteristics

Broad mechanical property range depending on carbon percentage, supporting various structural requirements.

Excellent balance of strength, ductility, and cost, making carbon steels widely accessible for industrial design.

Good weldability in low-carbon grades and strong hardenability in higher carbon grades.

Reliable dimensional stability during finishing operations such as CNC turning and CNC milling.

Suitable for producing functional mechanical assemblies through metal additive manufacturing.

Compatible with diverse heat-treatment paths to achieve target hardness and microstructure.

High wear resistance in medium- and high-carbon formulations after quenching and tempering.

Excellent fatigue resistance for components exposed to repetitive mechanical cycling.

Readily machinable using CNC machining after printing for precision fit and finish.

Stable performance across jigs, fixtures, housings, brackets, and tooling components.

Manufacturability in Different Processes

Additive manufacturing: Powder bed fusion transforms carbon steel powders into dense, functional parts using advanced 3D printing workflows.

CNC machining: Ideal for secondary machining after printing, including CNC drilling and CNC grinding for tight-tolerance surfaces.

Multi-axis machining: Complex geometries can be refined using multi-axis machining to achieve intricate contours.

EDM: High-precision details can be produced via EDM machining when printing alone cannot achieve required geometries.

Heat treatment: Carbon steels respond well to quenching, normalizing, and tempering, which improves both hardness and structural integrity.

Welding: Low-carbon steels exhibit strong weldability, making them useful for hybrid printed-and-fabricated assemblies.

Suitable Post-Processing Methods

Heat treatment for targeted hardness, strength adjustments, and refinement of microstructure.

Hot Isostatic Pressing (HIP) to enhance density and eliminate internal porosity in additively manufactured parts.

Precision machining using precision machining to achieve dimensional tolerances.

Polishing and brushing using surface brushing to improve appearance and reduce roughness.

Surface strengthening such as phosphating and nitriding for wear and corrosion resistance.

Painting and powder coating via powder coating and industrial painting for surface durability.

Common Industries and Applications

Industrial machinery components and structural supports.

Tooling fixtures, jigs, and alignment devices used across factories.

Automotive brackets, housings, and functional prototypes.

Aerospace ground-support tools and mechanical components.

Consumer product mechanisms requiring wear resistance.

Agricultural machinery elements that benefit from cost-efficient durability.

When to Choose This Material

When cost-effective mechanical strength is required for prototyping or production.

When components must withstand moderate to high mechanical loads without the use of premium alloys.

When secondary machining, drilling, or finishing is expected after printing.

When manufacturing jigs, fixtures, or industrial tooling components.

When heat treatment versatility is important for achieving target hardness or toughness.

When parts benefit from hybrid additive and machining workflows.

When designing durable structures with predictable mechanical performance.

When applications require both manufacturability and strong fatigue resistance.