خدمة تصنيع تشغيل مخرطة CNC عبر الإنترنت

تقدم خدمتنا لتصنيع تشغيل مخرطة CNC المخصصة دقة عالية في تشغيل الأجزاء المعقدة باستخدام تقنيات تشغيل متقدمة. نقوم بإنتاج مكونات عالية الجودة من مواد متنوعة تشمل المعادن والبلاستيك، مع تسامحات ضيقة وتسليم سريع لتلبية متطلبات العملاء المحددة.

- خدمة النماذج الأولية السريعة لتشغيل المخرطة CNC

- خدمة تشغيل مخرطة CNC بحجم إنتاج منخفض

- خدمة تشغيل مخرطة CNC للإنتاج الضخم

- خدمة تشغيل مخرطة CNC الشاملة

أرسل لنا تصميماتك ومواصفاتك للحصول على عرض سعر مجاني

كل الملفات المحملة آمنة وسرية

تطبيقات تشغيل مخرطة CNC

تشمل تطبيقات تشغيل مخرطة CNC المخصصة تصنيع مكونات دقيقة لصناعات مثل الطيران، السيارات، الطبية، والإلكترونيات. تغطي خدماتنا أجزاءً مثل الأعمدة، البوش، والوصلات، مصممة لتلبية المواصفات الدقيقة بكفاءة عالية.

مواد تشغيل مخرطة CNC

يُستخدم تشغيل مخرطة CNC على نطاق واسع في تصنيع مواد متنوعة مثل السبائك الفائقة، التيتانيوم، الألمنيوم، النحاس، النحاس الأصفر، البرونز، الفولاذ الكربوني، الفولاذ المقاوم للصدأ، البلاستيك، والسيراميك. تُستخدم هذه المواد في صناعات مثل الطيران، السيارات، الطبية، النفط والغاز، والمنتجات الاستهلاكية. يضمن تشغيل المخرطة CNC دقة ومتانة وتشطيبات عالية الجودة لأجزاء معقدة وعالية الأداء.

معالجة السطح لأجزاء تشغيل مخرطة CNC

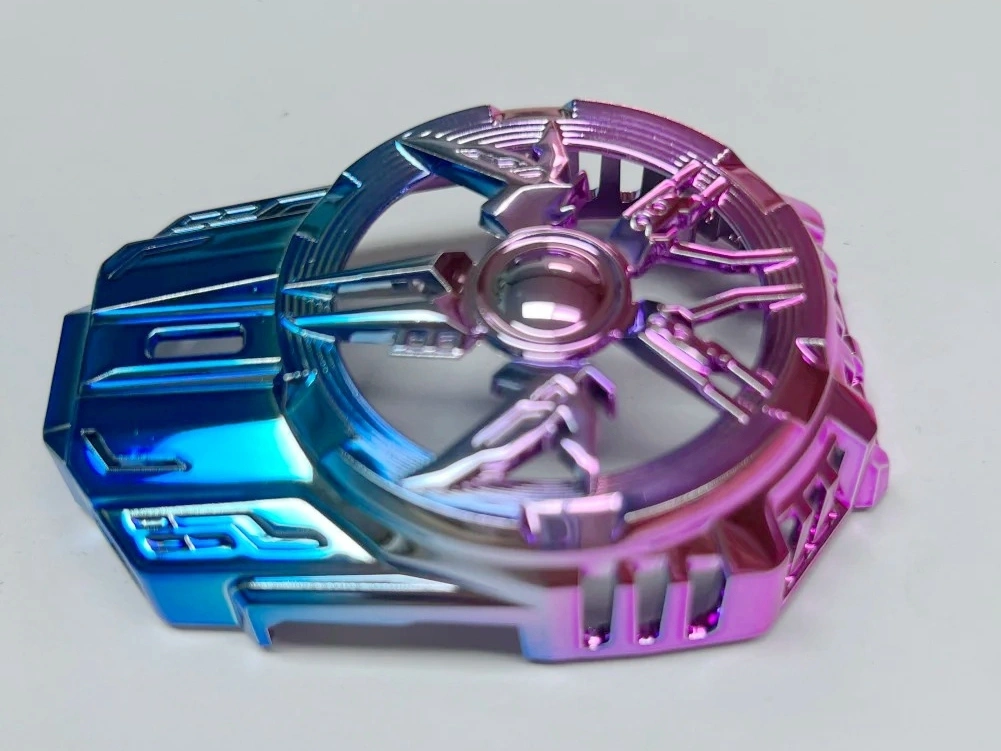

تعزز معالجة السطح لأجزاء تشغيل المخرطة CNC المتانة، مقاومة التآكل، وتشطيب السطح. نقدم مجموعة متنوعة من المعالجات بما في ذلك الأكسدة الأنودية، الطلاء الكهربائي، الطلاء بالمسحوق، والتلميع، مصممة لتلبية متطلبات الصناعات المختلفة لأجزاء عالية الأداء وطويلة العمر.

اعرف المزيد

الطلاء الحراري

اعرف المزيد

التشطيب كما هو بعد التشغيل

اعرف المزيد

الطلاء

اعرف المزيد

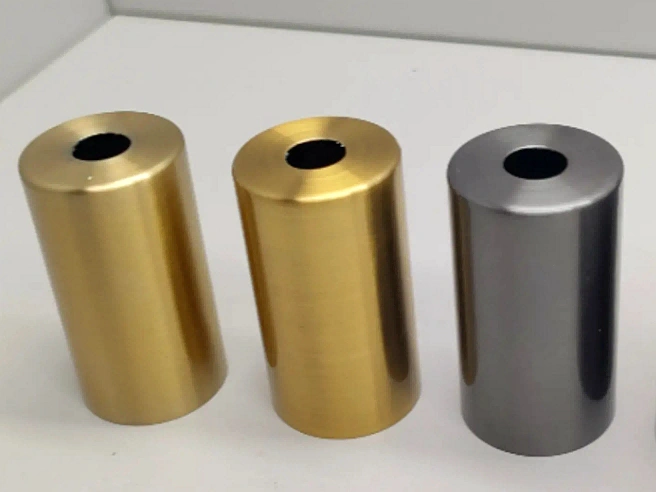

الترسيب الفيزيائي بالبخار (PVD)

اعرف المزيد

الرش الرملي

اعرف المزيد

الطلاء الكهربائي

اعرف المزيد

التلميع

اعرف المزيد

التأكسد الأنودي

اعرف المزيد

طلاء بالبودرة

اعرف المزيد

التلميع الكهربائي

اعرف المزيد

المعالجات السطحية (التشعيب)

اعرف المزيد

التنظيف بالفرشاة

اعرف المزيد

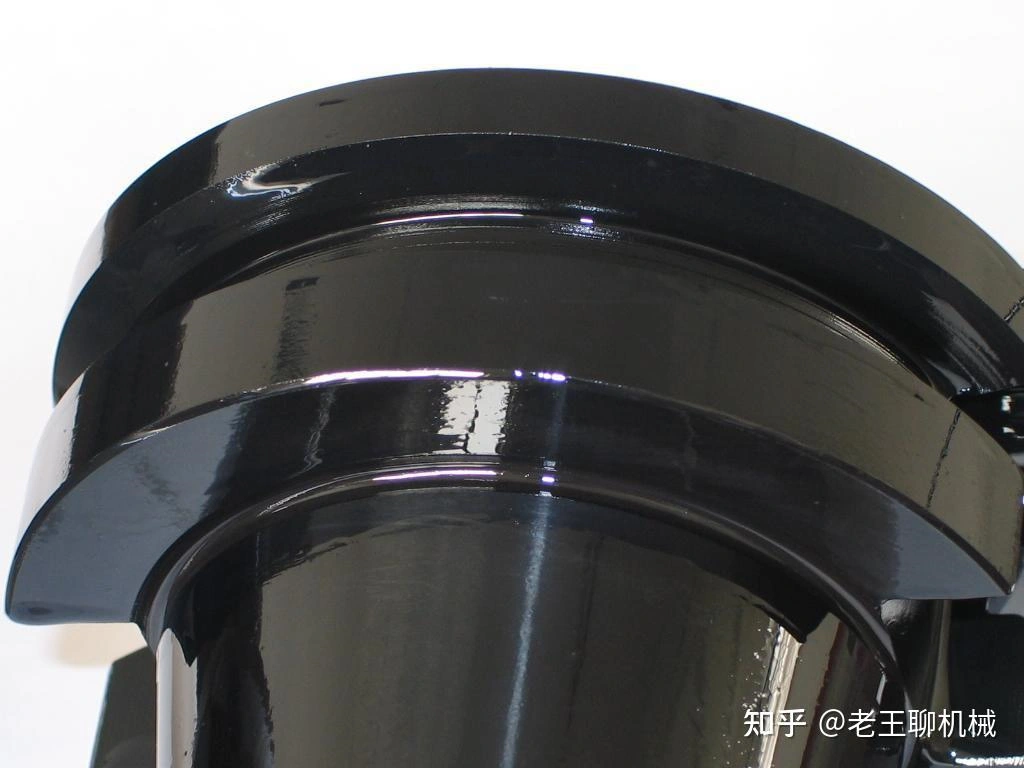

الأكسيد الأسود

اعرف المزيد

المعالجة الحرارية

اعرف المزيد

طلاء حاجز حراري (TBC)

اعرف المزيد

التلميع بالتدوير

اعرف المزيد

ألودين (حماية من التآكل للألمنيوم)

اعرف المزيد

طلاء الكروم

اعرف المزيد

الفوسفاتية

اعرف المزيد

النتريد

اعرف المزيد

الجلفنة

اعرف المزيد

طلاء الأشعة فوق البنفسجية (UV)

اعرف المزيد

طلاء الورنيش

اعرف المزيد

طلاء تفلون

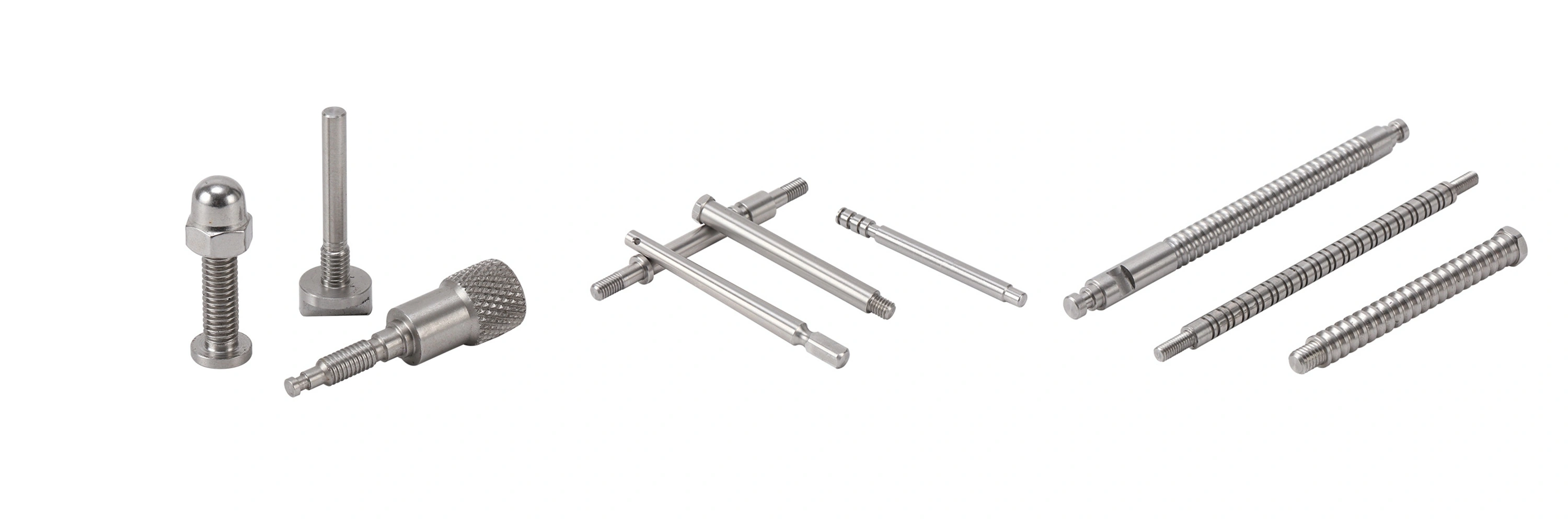

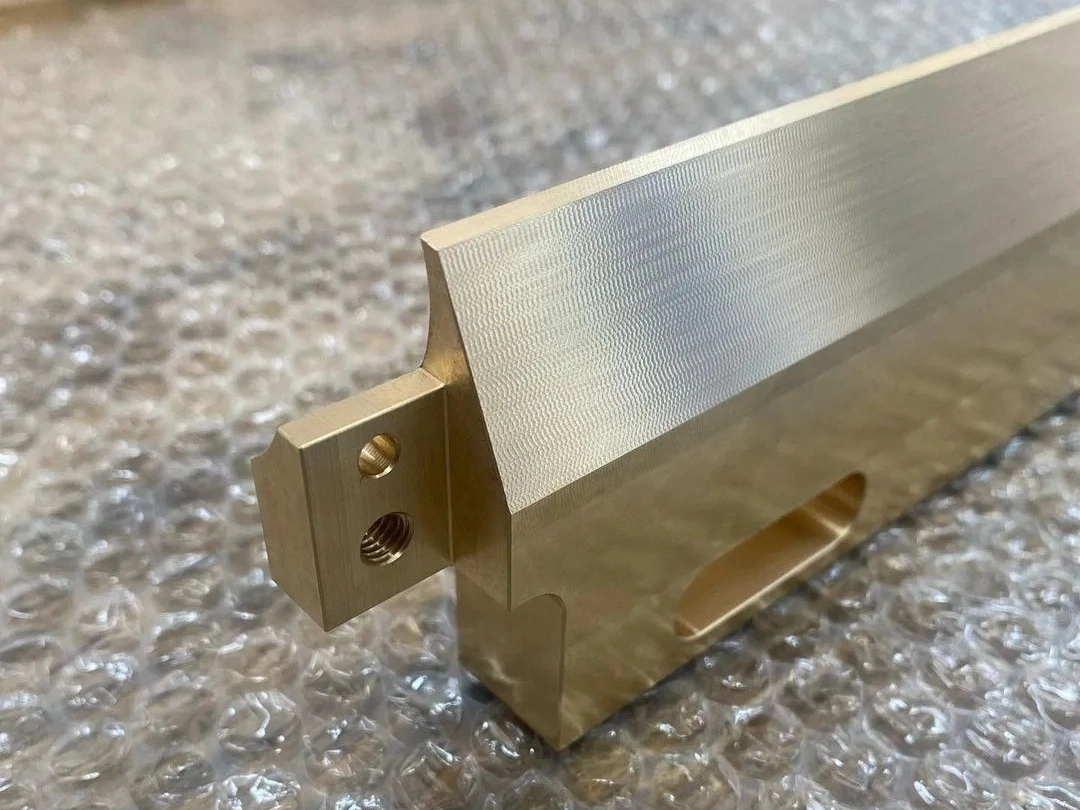

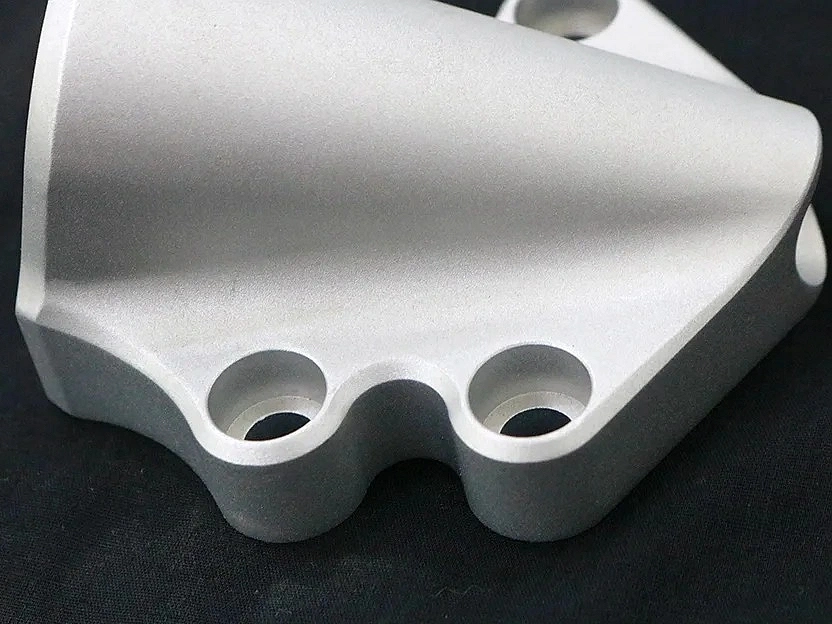

معرض قطع تشغيل مخرطة CNC مخصصة

يعرض معرض قطع تشغيل مخرطة CNC المخصصة مجموعة واسعة من المكونات المصنعة بدقة، بما في ذلك الأعمدة، البوش، والوصلات، مصممة لتلبية احتياجات صناعية متنوعة. كل جزء مصنوع بدقة عالية واهتمام بالتفاصيل لتحقيق أفضل أداء.

لنبدأ مشروعًا جديدًا اليوم

اقتراحات تسامح تشغيل مخرطة CNC

توفر اقتراحات تسامح تشغيل المخرطة CNC إرشادات لتحقيق قطع دقيقة وموثوقة. للتطبيقات العامة، التسامح القياسي هو ±0.1 مم، بينما يمكن للأجزاء الدقيقة تحقيق تسامحات تصل إلى ±0.02 مم، حسب تعقيد التصميم ونوع المادة.

دليل تصميم تشغيل مخرطة CNC

يقدم دليل تصميم تشغيل المخرطة CNC أفضل الممارسات لإنشاء قطع بأداء ودقة مثالية. يشمل توصيات حول التسامحات، تصميم الثقوب، الأنصاف قطرية، مواصفات الخيوط، سمك الجدار، فواصل الأدوات، وتشطيبات السطح لضمان نتائج تشغيل فعالة وعالية الجودة.