定制铝与钢CNC铣削零件 – 获取报价

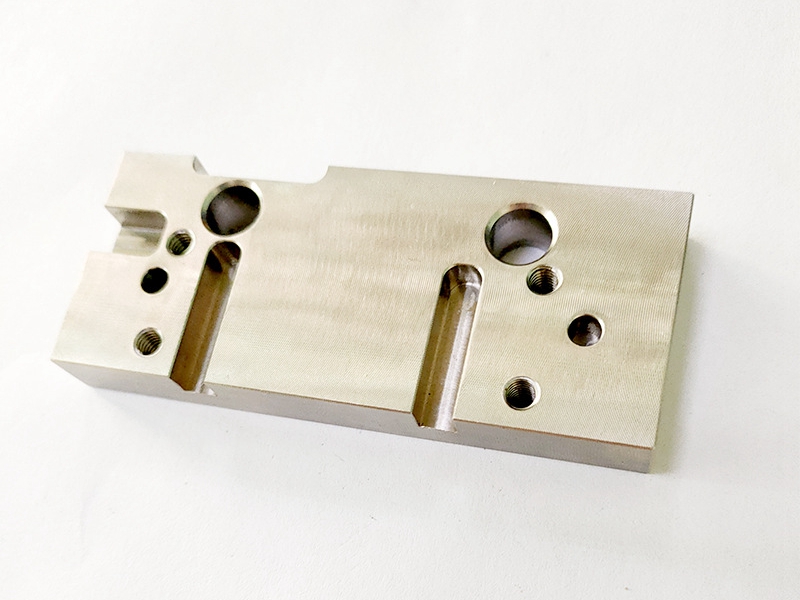

定制 CNC 铣削零件是生产高精度、复杂几何形状和严格公差组件的核心基础。通过 3 轴和 5 轴等减材制造技术,制造商可以在各类应用中实现高度精准的尺寸控制。

Neway 的 CNC 铣削服务 支持定制铝件和钢件的生产,广泛应用于航空航天、医疗器械、能源以及消费电子等行业。无论是原型打样还是批量生产,我们都能在短交期内稳定交付高质量、高一致性的铣削零件。

材料洞察:CNC 铣削零件中的铝与钢如何选择?

选择合适的材料,是优化零件性能、成本和加工效率的关键。由于物理与力学性能差异明显,铝和钢是定制 CNC 铣削零件中最常见的两大材料体系。

铝合金 CNC 铣削

铝具有优异的可加工性、良好的耐腐蚀性以及高比强度。6061、7075、5052 等常用牌号广泛应用于航空结构件、电子产品外壳和汽车总成。铝合金优良的导热性与尺寸稳定性,使其特别适合高速切削和高公差要求的应用。

机身结构件、家电外壳以及精密支架等应用中,经常会采用 铝合金 CNC 加工,借助其轻量化和易成形优势实现更优化的设计。

钢件 CNC 铣削

当对高强度、耐磨性和耐热性有更高要求时,则通常优先选择钢。1018、1045、4140 等碳钢适用于结构件和承载件;304、316L 等不锈钢则在医疗、食品加工和海洋环境中表现出出色的耐腐蚀性能。

典型应用包括发动机缸体、钻孔支撑件以及机架结构。碳钢 CNC 加工 和 不锈钢 CNC 加工 对于追求机械耐久性与长寿命的行业而言,是必不可少的能力。

定制铝件与钢件 CNC 铣削零件的行业应用

在对公差严苛、重复性要求高、且具有特定材料性能需求的领域,定制 CNC 铣削零件发挥着至关重要的作用。无论选择铝还是钢,每个行业都有其独特的技术要求与典型应用场景。

航空航天

航空航天零部件必须兼具轻量化和对机械应力及热循环的高承受能力。铝因其高比强度与耐腐蚀性,常用于涡轮相关部件、隔热罩和机体结构件;钢材则多用于对耐久性与刚度要求更高的发动机支架和关键连接界面。

电力与能源

精密铣削零件是燃气轮机、换热器以及高温密封系统中的关键组成。铝多用于非承载类的热防护壳体,而钢则是承载支撑件和耐热壳体的首选。通过 CNC 铣削服务 制造的定制组件,可在复杂工况下确保结构完整性和热稳定性。

石油与天然气

该领域要求材料能承受高压、腐蚀和磨损。CNC 铣削钢件广泛用于阀体、钻头壳体和平台支架。不锈钢牌号常应用于海上平台等高腐蚀环境中的关键部位。

消费品

在消费电子与家电领域,铝凭借优异外观与易加工性备受青睐。家电外壳、电子设备机壳及高端厨房工具等,通常采用 多轴 CNC 加工 以实现复杂曲面与精致外观。

医疗器械

铝和不锈钢在手术器械、骨科植入物以及牙科设备中均有广泛应用。这类零部件需要高精度几何形状、优良表面质量,并符合医疗级公差要求。通常会结合 PVD 涂层 或电解抛光等工艺,以满足卫生和清洁度标准。

农业机械

该领域需要坚固耐磨的零件,如接头、耐磨板和机架结构等。碳钢铣削零件因其机械强度而成为首选;在需要减轻结构重量的运动组件中,则会有选择地使用铝件。

汽车

发动机缸体、涡轮增压器、制动卡钳和底盘零件都可从铝和钢的 CNC 铣削中受益。铝通常用于轻量化性能件,而钢则在吸能安全结构和传动系统零件中不可或缺。我们的汽车 CNC 解决方案展示了材料选择如何提升整车性能与效率。

机器人

精密铣削的机械臂、关节和执行器壳体多由铝与钢组合完成。铝保证轻量与散热性能,钢则在关节等高负载部位提供耐久性。CNC 铣削可实现高公差配合面,这对自动化运动系统至关重要。

自动化

自动化产线中的控制面板、支架、传感器壳体和结构件,需要在长期运行中保持稳定和精确。铝可实现快速加工与良好电绝缘性能,而钢则提供高强度安装与抗冲击能力。

工业设备

泵壳、齿轮箱和机械防护壳体依赖钢材的耐磨性以及不锈钢的抗腐蚀能力;铝则较多用于轻量化盖板和减振组件。

核工业

在这一高风险领域,精度与可靠性至关重要。铣削零件包括反应堆组件、燃料棒导向件以及热防护结构等。仅少数经认证的钢和耐蚀合金可用于该领域,并常配合 钝化处理 以延长寿命并降低污染风险。

表面处理与后加工选项

为了满足机械、热工或外观等方面的综合要求,CNC 铣削后的铝件与钢件通常需要进行表面强化或修饰。合理的后处理不仅提升外观,还会显著影响耐腐蚀性、尺寸稳定性及功能表现。

铝件表面处理

铝对各种表面处理工艺反应良好,常见选项包括:

阳极氧化:提升耐腐蚀性和表面硬度,并可实现多种颜色效果。适用于消费电子外壳、航空支架和隔热罩等。详见 铝件阳极氧化指南。

喷砂:用于涂层前预处理或获得均匀的亚光质感,常作为粉末喷涂或喷漆前的表面预处理步骤。

粉末喷涂:提供厚实、均匀且耐冲击的保护层,广泛用于汽车零部件和家电外壳。更多可参考 CNC 零件粉末喷涂。

抛光与拉丝:提升消费品与精密组件的视觉质感。可参见 CNC 铝件拉丝工艺 的更多说明。

钢件表面处理

钢制 CNC 零件通常需要兼顾耐磨、抗腐蚀和结构完整性,多种工艺可供选择:

发黑处理(Black Oxide):应用于碳钢零件,提供基础防锈和低反光黑色外观,常见于自动化结构件和工具。可查看 钢件发黑涂层指南。

电解抛光:常用于不锈钢,提升表面光洁度并增强耐腐蚀性,是医疗和食品级应用中的常用工艺。详见 电解抛光如何改善 CNC 零件。

磷化:提升耐磨性和涂层附着力,适用于油气与农业设备中的关键钢件。可参考 CNC 零件磷化处理。

电镀铬:为齿轮、轴类等运动接触件提供极高硬度和耐磨表面。相关信息见 CNC 零件铬电镀。

热处理:通过改变钢材的显微组织提升硬度、疲劳强度与韧性,可在加工前或加工后进行。了解更多请参阅 热处理如何提升 CNC 零件强度。

基于材料特性和实际工况选择合适表面处理方案,可显著延长 CNC 铣削零件的服役寿命,并提升整体机械可靠性。

可制造性设计:CNC 铣削定制零件的设计指南

一件成功的定制 CNC 铣削零件,始于与加工能力和材料属性高度匹配的设计。面向可制造性(DFM, Design for Manufacturability)的设计,可缩短生产周期、降低成本,并提高零件性能与一致性。

几何与公差设计

铝与钢在切削力作用下的表现不同。铝适合更高的进给速度和主轴转速,而钢则需要较慢、更可控的加工参数来保证尺寸精度。优化建议包括:

保持较均匀的壁厚:尽量避免局部过厚或过薄,以减少振动和刀具颤振风险。

合理设定公差:多数应用中 ±0.1 mm 的一般公差更具成本优势;诸如 ±0.01 mm 级别的紧公差虽可实现,但会明显增加加工成本。详见关于 CNC 公差选择的说明。

减少深腔和难加工倒扣:此类结构往往需要专用刀具或多次装夹,延长工艺链和交期。

特征可达性设计

铣削刀具需要足够的加工空间才能高效切削。为提高生产效率,建议:

在设计中尽量使主要特征可在一个装夹平面内完成加工。

避免高深宽比的深腔结构,可用肋板或阶梯式几何替代。

考虑刀具直径对内角圆角的影响——内角最小半径通常应 ≥ 刀具半径。

减少刀具更换与装夹次数

采用标准刀具尺寸与简化工序组合,可以显著降低加工复杂度:

尽量将孔位和槽位布置在同一平面,以减少分次装夹。

避免大量不同板厚或台阶高度,以减少频繁调整刀长与刀具类型。

在结构强度允许的前提下,可用倒角替代圆角,以减少特殊刀具需求。

如需更多 DFM 相关建议,可参考 Neway 对 CNC 可制造性设计十条黄金法则 的详细指南,帮助降低返工率、整体成本与交期风险。

铝件与钢件 CNC 铣削零件的典型行业应用一览

定制 CNC 铣削技术使各行业能够获得高度匹配应用需求的高精度零件。铝和钢两大材料体系在不同场景中各有所长。

行业 | 典型铝制零件 | 典型钢制零件 |

|---|---|---|

航空航天 | 机身结构件、支架、隔热罩 | 发动机支架、结构连接件 |

电力与能源 | 轻量化风扇叶片、换热器框架 | 涡轮密封件、支撑壳体 |

石油与天然气 | 仪表面板、轻量化安装板 | 阀体、耐腐蚀钻孔支撑件 |

消费品 | 电子产品外壳、家电面板 | 餐具、耐磨机械零件 |

医疗器械 | 骨科植入物、牙科托盘 | 手术工具、无菌外壳 |

农业机械 | 结构壳体、机罩与防护件 | 机架、耐磨联轴器 |

汽车 | 制动系统零件、中控仪表支架 | 发动机缸体、悬架零件 |

机器人 | 轻量化机械臂、精密面板 | 齿轮、驱动执行机构 |

自动化 | 传感器壳体、控制器安装板 | 支撑支架、锁紧机构 |

工业设备 | 防护壳体、安装底座 | 泵体、耐热刀具支架 |

核工业 | 轻量化结构板件 | 压力容器、屏蔽结构零件 |

如需了解更多实际应用案例,可参考 6061 铝合金机器人关节多轴 CNC 加工与阳极氧化,以及 4140 钢制汽车空压机偏心轴的 CNC 车削与磨削解决方案。

这些案例直观展示了材料选择与应用场景如何共同决定铣削策略。

CNC 铣削零件的检验与质量控制

对 CNC 铣削零件而言,精度不仅来自设计与加工本身,还取决于后续对尺寸一致性、材料完整性和性能可靠性的严格质控。

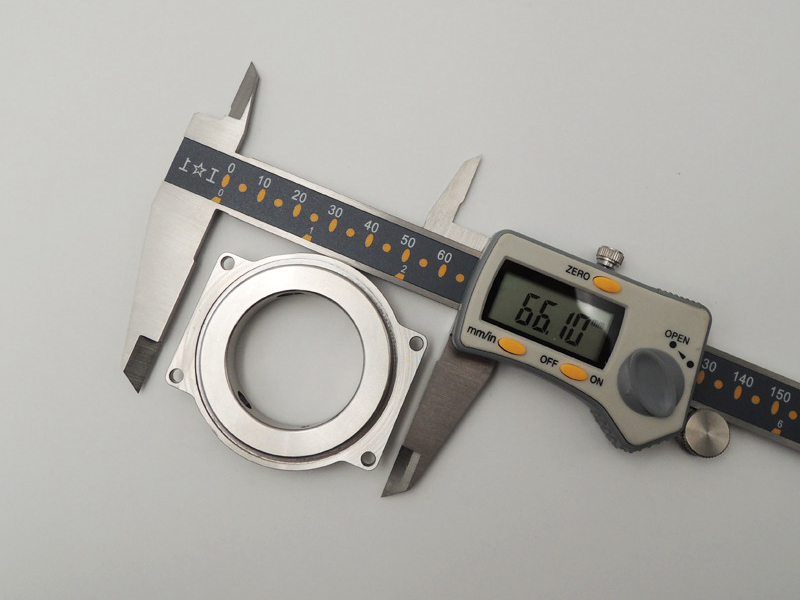

尺寸精度:三坐标测量机(CMM)

三坐标测量机可为高精度零件提供亚微米级尺寸检测,尤其适用于航空和医疗等领域。它能对平面度、垂直度、同轴度等关键尺寸进行验证,确保零件满足 GD&T 几何公差要求。

CMM 重复精度可达 ±0.001 mm 级别。

特别适合具有复杂几何和公差叠加要求的零件。

常用于首件检验(FAI)和批量出货前的最终抽检。

表面粗糙度评估

根据功能需求不同,表面粗糙度(Ra)可以从结构件常见的 3.2 μm,一直到密封面或摩擦副需要的 0.8 μm 或更低。常用的表面评估方法包括:

轮廓仪:用于定量测量表面纹理和粗糙度。

目视检查:用于消费级或外观件的外观标准判定。

关于不同表面处理与粗糙度需求,可参考 CNC 零件表面处理与涂层综述。

材料与缺陷检测

对于安全关键或高可靠性应用:

X 射线检测和超声检测可发现内部缩孔、夹杂等缺陷。

金相显微分析可评估材料的显微组织和强化相分布。

对于钢件,硬度测试可验证热处理工艺的有效性。

在 Neway 博客中,您可以进一步了解 CNC 零件内部缺陷的超声检测方案 以及更多 无损检测技术。

通过多层次的检验体系,Neway 确保每一件出厂零件都能在实际工况中稳定、可靠地发挥应有性能,特别适用于对质量有严格监管要求的行业。