CNC加工件表面处理:从基础光滑到专业涂层

引言

CNC加工零件的表面处理在其性能、外观和使用寿命中起着关键作用。从降低机械系统中的摩擦,到提升在严苛环境下的耐腐蚀能力,选择合适的表面处理方式都会直接影响零件的功能表现和全生命周期。

了解每一种表面处理工艺的能力——从原始机加工表面到先进的热喷涂涂层——对于优化产品性能和制造价值至关重要。

CNC加工零件的基础表面处理方式

这些表面处理工艺通常在机加工完成后立即进行,用于去除毛刺和锐边、提升外观,或满足基本尺寸与表面要求。虽然被称为“基础”处理,但它们对于确保零件满足功能与安全标准至关重要。

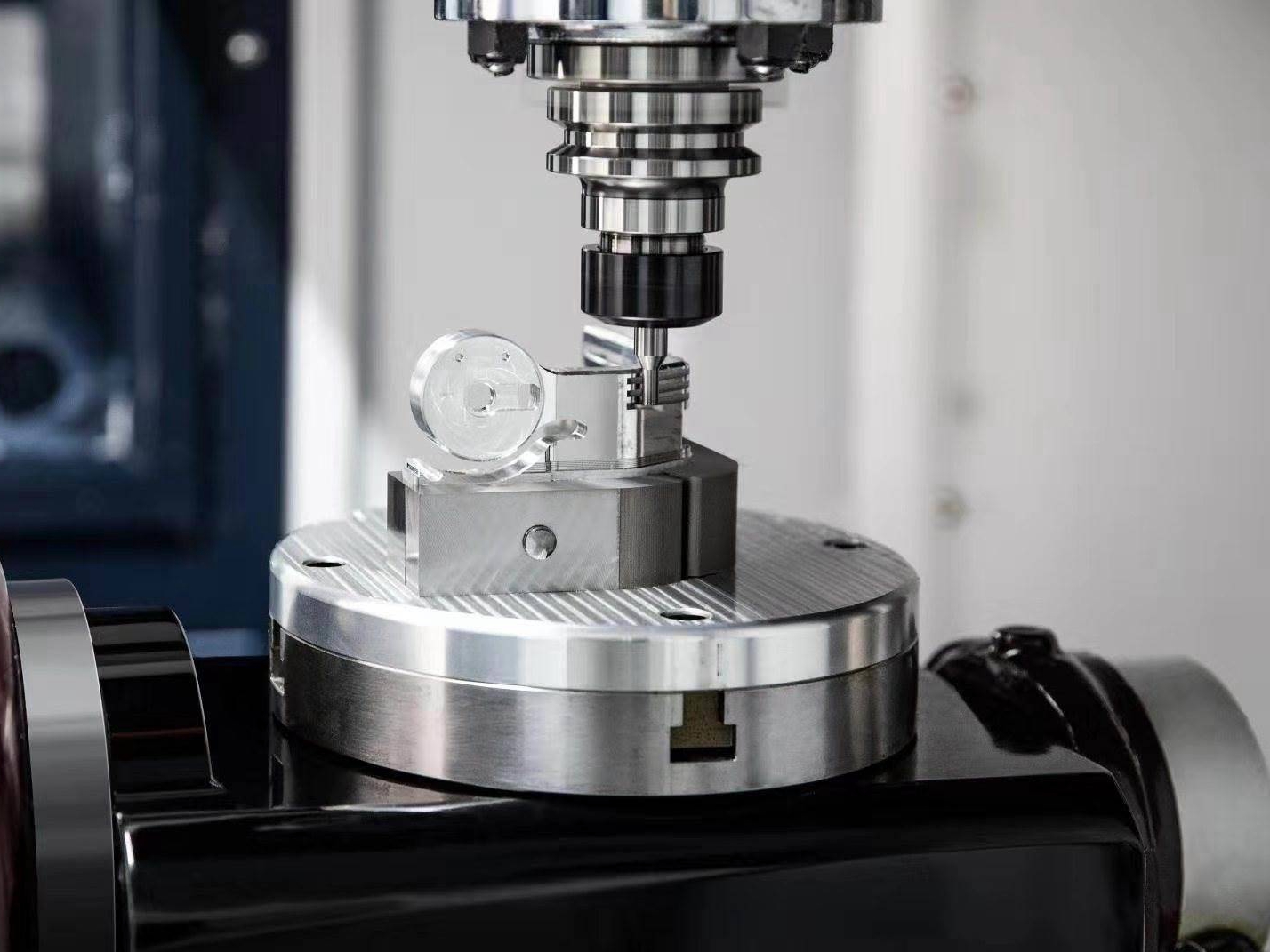

1. 原始机加工表面(As-Machined Finish)

原始机加工表面是指零件在铣削、车削或切削后未做进一步表面处理时的状态。表面保留可见刀痕,典型表面粗糙度约为 Ra 3.2 µm。

这种表面非常适用于内部机械零件或对外观要求不高的非装饰性部件,此时表面精度与尺寸更为重要。许多内部工业部件都会采用这种表面,以避免不必要的成本,同时保持严格公差。

2. 去毛刺与滚筒抛光(Deburring and Tumbling)

滚筒抛光是一种机械工艺,将加工后的零件放入装有研磨介质的振动或滚筒式容器中,通过相互摩擦去除毛刺和锐边,从而提升操作安全性和装配精度。表面粗糙度通常可改善至 Ra 1.6–3.2 µm。

该工艺特别适用于中小尺寸、批量生产的金属和塑料零件,尤其是具有复杂几何形状或边缘特征的部件。

3. 喷砂与喷珠(Bead Blasting and Sandblasting)

喷砂或喷珠是通过高压空气将磨料颗粒喷射到零件表面,以实现清理和表面纹理处理。它能够获得均匀的亚光或绸面效果,并去除轻微的表面污染物或机加工刀痕。

典型应用包括:

作为涂层或阳极氧化前的预处理

为外露机械零件提供一致的外观

为手持零件提供防滑或握持纹理

Ra 通常在 1.6–3.2 µm 范围内,具体取决于磨料类型和喷射压力。

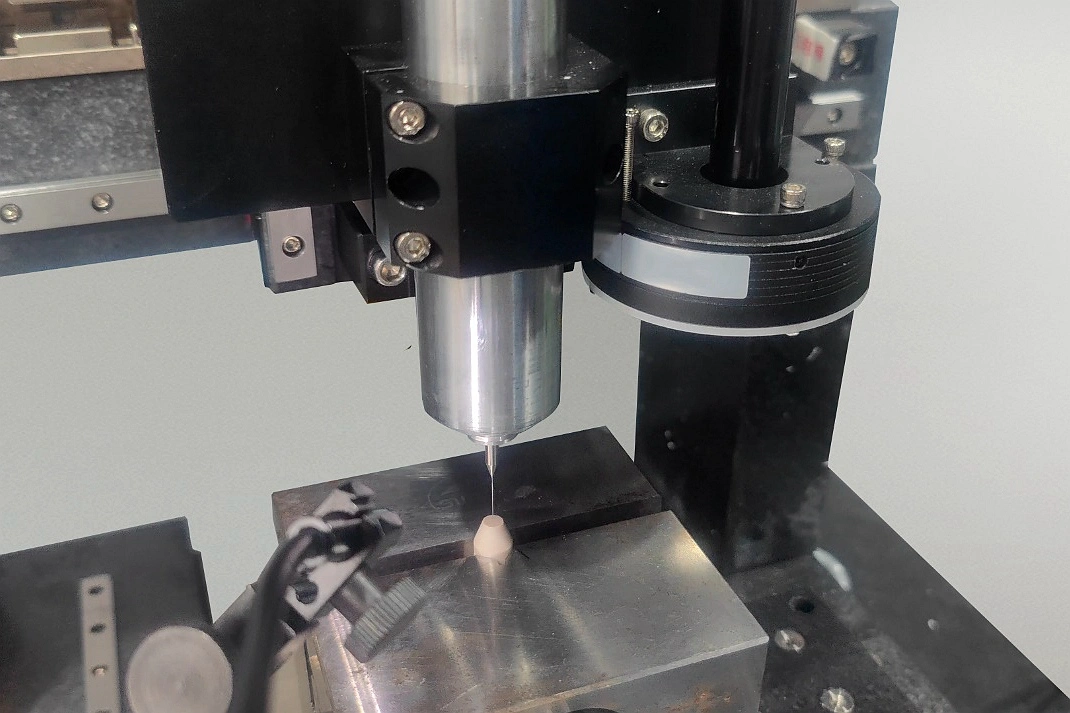

4. 抛光(Polishing)

CNC 抛光可以是手工或机械过程,用于获得光滑、光亮且粗糙度极低的表面。这对于医疗器械、反光件或外观件等将表面质量视为产品体验一部分的应用尤为关键。

机械抛光可将表面粗糙度降低至 Ra 0.2 µm 以下

对于不锈钢的电解抛光:可获得超光滑且表面钝化的效果

典型应用包括医用级外科零件以及高精度光学夹具等。

功能性表面涂层与处理

在基础平滑处理之外,CNC 加工零件往往还需要更为专业的表面处理,以提升耐腐蚀性、电性能、耐高温能力和耐磨性。这类处理在航空航天、医疗、汽车以及电子行业中尤为常见。

5. 阳极氧化(Type I、II、III)

阳极氧化是一种电化学工艺,可在铝零件表面形成可控的氧化膜。它能够提升硬度、耐磨性和耐腐蚀性,并可通过着色实现识别或装饰效果。

Type I(铬酸阳极氧化): 膜层较薄,对尺寸影响极小

Type II(硫酸阳极氧化): 装饰性强,可着色,厚度约 10–25 µm

Type III(硬质阳极氧化): 用于高磨损环境,膜层厚度可达 100 µm

常见应用包括航空支架、无人机外壳和电子设备外壳等。

6. 电镀(镍、铬、锌)

电镀是在零件表面沉积一层金属镀层,以提升外观、耐磨性以及电导率。

镍镀层: 提高耐腐蚀性和润滑性

铬镀层: 提供镜面光泽和高表面硬度

锌镀层: 用于通用钢件的防腐保护

电镀零件广泛应用于消费电子、汽车装饰件以及液压接头等领域。

7. PVD 涂层(物理气相沉积)

PVD 涂层通过沉积金属或陶瓷薄膜来提高表面硬度、降低摩擦,并提供特定颜色或反射效果。常见涂层包括氮化钛(TiN)、氮化锆(ZrN)以及类金刚石涂层(DLC)。

典型涂层厚度:1–5 µm

硬度可高达约 2500 HV

常见颜色:金色、银色、黑色、青铜色等

广泛用于切削刀具、高磨损消费零件,以及既需卫生又需高视觉品质的外科器械。

8. 热喷涂与 Cerakote 涂层

热喷涂涂层(如等离子喷涂、电弧喷涂或火焰喷涂)通过将熔融颗粒喷射到零件表面,形成牢固结合的涂层,以抵抗高温、磨损和化学侵蚀。Cerakote 是一种陶瓷–聚合物复合涂层,常用于枪械、航空航天及海洋零件。

可承受高达约 1000°C 的温度

适用于处于高应力磨损或强腐蚀环境中的零件

如何选择合适的表面处理:技术与成本考量

选择合适的表面处理方式远不止“好不好看”这么简单。工程师需要综合考虑性能要求、尺寸公差、零件几何形状以及成本影响等多方面因素。

关键选择标准:

材料适配性: 并非所有处理方式都适用于所有材料。例如,阳极氧化只适用于铝,而 PVD 更适合钢、钛以及高速工具钢等材料。

尺寸影响: 硬质阳极氧化每侧可增加多达 100 µm 的厚度,可能会超出关键尺寸公差范围;而抛光或电解抛光则会去除材料,设计尺寸时需要提前考虑这一点。

功能需求:

降低摩擦 → 抛光或 PVD 涂层

防腐保护 → 阳极氧化、电镀或 PTFE 涂层

提升外观 → 喷珠、铬镀或清漆涂层

耐高温 → 热喷涂或陶瓷类涂层

成本与性能权衡: 表面处理通常会使零件成本增加约 10–50%,具体取决于工序复杂度和后处理顺序。但同时,它们往往能大幅延长产品寿命,降低长期维护成本和失效风险。

按表面处理类型划分的行业应用示例

行业 | 使用的表面处理 | 主要目的 |

|---|---|---|

医疗 | 电解抛光、PVD 涂层 | 便于灭菌、提升生物相容性 |

航空航天 | 硬质阳极氧化、热喷涂 | 减轻重量、提升耐腐蚀与耐高温性能 |

消费电子 | 喷珠、阳极氧化 | 获得统一外观和高质感表面 |

汽车 | 铬镀、PTFE 涂层 | 提升外观、增强耐磨与保护性能 |

国防 | Cerakote、PVD 涂层 | 降低摩擦、提高耐磨与耐高温性能 |

表面处理性能对比表

表面处理类型 | 表面粗糙度(Ra,µm) | 耐腐蚀性 | 耐磨性 | 外观质量 | 成本影响 |

|---|---|---|---|---|---|

原始机加工(As-Machined) | ~3.2 | 低 | 低 | 较差 | 极低 |

滚筒抛光(Tumbling) | 1.6–3.2 | 低 | 低 | 中等 | 低 |

喷珠(Bead Blasting) | 1.6–3.2 | 中等 | 中等 | 良好 | 中等 |

抛光(Polishing) | ≤0.2 | 低 | 低 | 极佳 | 高 |

阳极氧化(Anodizing) | 0.5–1.5 | 高 | 中等 | 良好 | 中等 |

电镀(Electroplating) | 0.2–1.0 | 高 | 高 | 极佳 | 中等–偏高 |

PVD 涂层 | ≤0.5 | 高 | 极高 | 良好 | 高 |

热喷涂(Thermal Spray) | 可变 | 极高 | 极高 | 中等 | 高 |

结论

通过合适的表面处理,CNC 加工零件可以发生显著改变——从满足功能公差的基础平滑处理,到提供保护、绝缘与美观效果的高级涂层。正确选择表面处理方式,不仅关系到零件本身的性能表现,还会影响产品的全生命周期成本、用户满意度以及是否符合行业标准。

对于航空航天、国防、医疗和电子等以精度驱动的行业而言,表面处理并不是“可选的外观升级”,而是一项至关重要的工程决策。无论是为航空铝零件进行硬质阳极氧化,还是为高光泽汽车装饰件进行铬电镀,正确的工艺选择都能在长期内带来显著的机械性能和经济收益。

在 Neway,我们为客户提供从表面处理咨询到批量量产的一体化支持,将CNC 加工服务与多样化表面处理能力相结合,以满足不同材料和应用市场的严苛要求。