3D-печать металлом: нержавеющая сталь, углеродистая сталь, алюминий и медь

Введение: как аддитивное производство металлов меняет подход к изготовлению деталей

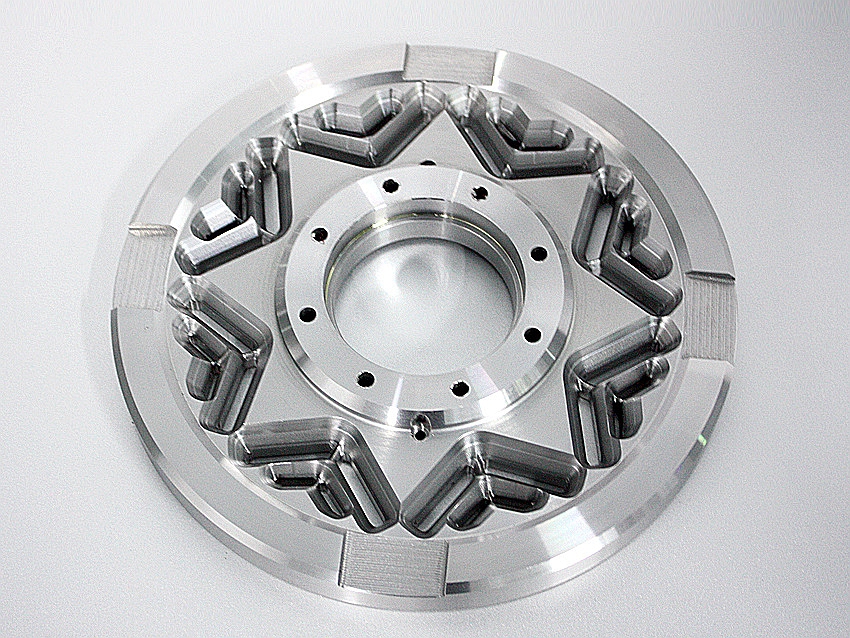

В условиях современной высококонкурентной промышленности скорость продуктовых итераций и требования к характеристикам изделий растут беспрецедентными темпами. Металлическая 3D-печать, или аддитивное производство металлов (AM), давно вышла за рамки инструмента для быстрого прототипирования и превратилась в одну из основных технологий прямого изготовления высокопроизводительных конечных деталей. Послойное наращивание материала полностью снимает конструкционные ограничения традиционных методов съёмной обработки, обеспечивая уникальные преимущества при реализации сложной геометрии, интегрированных функциональных структур и экономически выгодного малосерийного производства. В этой статье мы сосредоточимся на четырёх наиболее востребованных инженерных материалах — нержавеющей стали, углеродистой стали, алюминиевых и медных сплавах — и рассмотрим их особенности, области применения и потенциал в сфере металлической 3D-печати.

Ключевые технологии металлической 3D-печати: обзор принципов SLM и DMLS

Основу металлической 3D-печати составляют технологии селективного лазерного плавления (SLM) и прямого лазерного спекания металлов (DMLS). Их принципы схожи: тонкий слой металлического порошка микронного диапазона равномерно наносится на платформу построения; затем мощный волоконный лазер, управляемый двумерными сечениями, полученными из 3D-CAD-модели, точно сканирует порошковый слой, полностью расплавляя (SLM) или спекая (DMLS) порошок, который после этого затвердевает. После завершения одного слоя платформа опускается, система нанесения формирует новый порошковый слой, и лазер сканирует следующее сечение. Этот цикл повторяется до тех пор, пока деталь не будет «выращена» целиком. Эта прогрессивная технология 3D-печати не просто заменяет традиционные методы съёмной обработки, такие как ЧПУ-обработка, — во многих случаях они образуют мощную связку и совместно формируют полный контур современной цифровой фабрики.

Сравнение четырёх основных материалов для металлической 3D-печати

Нержавеющая сталь: оптимальный баланс прочности и коррозионной стойкости

Нержавеющая сталь получила широкое распространение в металлической 3D-печати благодаря отличной обрабатываемости, высокой прочности и хорошей коррозионной стойкости. Среди таких материалов нержавеющая сталь SUS304, аустенитный «рабочий» стандарт, обеспечивает сбалансированные механические свойства и устойчивое качество построения, что делает её подходящим выбором для различных конструкционных элементов с типичными требованиями к коррозионной стойкости. Для более агрессивных сред, таких как морская или химическая, сталь SUS316L с повышенным содержанием молибдена обеспечивает улучшенную стойкость к точечной и щелевой коррозии и идеально подходит для сложных корпусов арматуры, насосов и рам медицинских устройств.

Углеродистая сталь: экономичное решение для высокой прочности и жёсткости

Углеродистые и низколегированные стали являются выгодным вариантом для задач, где 3D-печать должна обеспечить высокую прочность, жёсткость и отличную износостойкость при разумной стоимости. Например, сталь 4140 — классический хромомолибденовый сплав — при 3D-печати и грамотной термообработке демонстрирует механические свойства, сопоставимые с коваными заготовками. Она хорошо подходит для изготовления различной оснастки, функциональных испытательных прототипов, зубчатых колёс и высоконагруженных деталей строительной и промышленной техники, обеспечивая удачный баланс между характеристиками и стоимостью по сравнению с более дорогими сплавами.

Алюминиевые сплавы: идеальный материал для облегчения и теплового менеджмента

Алюминиевые сплавы сочетают низкую плотность и хорошую теплопроводность, поэтому пользуются большим спросом в аэрокосмической отрасли и автоматизации. Сплав Aluminum 6061, относящийся к термоупрочняемым, после 3D-печати и последующей закалки-растворения и искусственного старения обеспечивает хороший баланс прочности и вязкости, что делает его подходящим для рам, кронштейнов и корпусных деталей. Когда требуется ещё более высокая прочность, предпочтение часто отдают Aluminum 7075. Детали, напечатанные из этого сплава, могут достигать прочности, сопоставимой с рядом литейных сталей, и применяются в стойках шасси БПЛА, высоконагруженных элементах гоночных автомобилей и облегчённых аэрокосмических конструкциях, обеспечивая существенное снижение массы.

Медные сплавы: непревзойдённые специалисты по теплу и электричеству

3D-печать чистой меди и медных сплавов — одна из передовых и наиболее сложных областей развития технологий. Из-за высокой отражательной способности меди по отношению к распространённым волоконным лазерам и её отличной теплопроводности добиться стабильного процесса нелегко, но при успешной отработке преимущества огромны. Детали из чистой меди идеально подходят для высокоэффективных теплообменников со сложными внутренними каналами. Сплав бериллиевая бронза (бериллиевая медь) сочетает очень высокую прочность, выдающуюся теплопроводность и хорошую износостойкость. С помощью 3D-печати из неё можно изготавливать сложные вкладыши пресс-форм с конформным охлаждением, высокоэффективные индукторы и камеры сгорания ракетных двигателей — детали, которые традиционными методами производить невозможно или крайне трудно, что значительно повышает эффективность теплового менеджмента.

Почему стоит выбрать металлическую 3D-печать? Разбор ключевых преимуществ

Применение технологии металлической 3D-печати даёт ряд фундаментальных преимуществ:

Свобода дизайна и функциональная интеграция: Технология позволяет создавать детали с внутренними конформными каналами охлаждения и облегчёнными решётчатыми структурами. Узлы, которые раньше требовали сборки из нескольких компонентов, теперь можно напечатать как единую интегрированную деталь, тем самым сократив количество сборочных операций и повысив надёжность конструкции.

Высокие эксплуатационные характеристики материала: При оптимизированных параметрах процесса металлические 3D-детали достигают плотности 99,5 % и выше. Мелкая и однородная микроструктура обеспечивает механические свойства, такие как усталостная и временная прочность, на уровне или даже выше, чем у традиционно кованых деталей.

Поддержка быстрого прототипирования и производства по требованию: Металлическая 3D-печать позволяет быстро превращать цифровые модели в физические детали, органично поддерживая весь путь — от прототипирования до малосерийного производства, — резко сокращая сроки разработки и снижая барьер входа для выпуска небольших партий.

Снижение отходов материала: Как процесс, близкий к формированию «почти готовой» формы, металлическая 3D-печать обеспечивает гораздо более высокий коэффициент использования материала по сравнению с традиционной съёмной обработкой. Основную часть нерасплавленного порошка можно восстановить и повторно использовать, что приносит значительную экономию, особенно при работе с дорогостоящими металлами.

Ключевые этапы постобработки металлических 3D-деталей

Завершение процесса 3D-печати ещё не означает, что деталь готова. Грамотно выстроенная постобработка критически важна для обеспечения точности размеров, качества поверхности и соответствия эксплуатационным требованиям.

Удаление опор и первичная доводка: После печати опорные структуры необходимо аккуратно удалить. Далее применяются процессы, такие как виброобработка и барабанная полировка деталей, которые используются для первичной очистки, удаления прилипшего порошка и острых заусенцев с поверхности.

Термообработка: Для снятия значительных остаточных напряжений, возникающих в процессе печати, и оптимизации микроструктуры под заданные механические свойства необходима термообработка деталей после ЧПУ-обработки. Например, закалка-растворение с последующим искусственным старением — типичный маршрут для повышения прочности алюминиевых и стальных материалов.

Финишная обработка поверхности: В зависимости от области применения применяются различные методы доводки. Процесс электрополировки прецизионных деталей эффективно снижает шероховатость поверхности и повышает коррозионную стойкость. Для деталей с особыми требованиями к внешнему виду или гидродинамическим характеристикам полировка деталей после ЧПУ-обработки позволяет добиться зеркального финиша. Для высоконагруженных подвижных компонентов могут применяться PVD-покрытия для прецизионных ЧПУ-деталей, при которых на поверхность осаждается тонкая твёрдая плёнка.

Металлическая 3D-печать или традиционная ЧПУ-обработка: как сделать правильный выбор?

Выбор между металлической 3D-печатью и традиционной ЧПУ-обработкой требует комплексной оценки факторов: сложности геометрии, объёмов производства, целевой себестоимости, выбранного материала и конкретных требований к механическим характеристикам. Металлическая 3D-печать особенно эффективна там, где важны свобода дизайна, экономия материала и изготовление сложных деталей малыми партиями. Традиционная высокоточная механообработка, напротив, более рентабельна для простой геометрии, массового производства, ультра-жёстких допусков и превосходного качества поверхности.

Во многих случаях оптимальным решением становится гибридная стратегия: 3D-печать используется для создания сложной заготовки «почти готовой» формы, после чего критически важные посадочные и стыковочные поверхности подвергаются высокоточной вторичной обработке с помощью многоосевой ЧПУ-обработки. Модель единого «one-stop» сервиса Neway как раз и создана для этого: мы планируем оптимальный технологический маршрут «от дизайна до готовой детали» с учётом всех этапов.

Отраслевые примеры: как металлическая 3D-печать решает реальные задачи

Аэрокосмическая отрасль: Печать топливных форсунок и лопаток турбин из титана и суперсплавов, а также применение высокопрочных алюминиевых сплавов для облегчённых петель дверей и кронштейнов позволяет эффективно повысить тяговооружённость и общую эффективность систем.

Автомобилестроение: Индивидуальные впускные коллекторы для гоночных и премиальных автомобилей, облегчённые рычаги подвески и опытные детали трансмиссий, доводимые методом электроэрозионной обработки (EDM), ускоряют разработку и испытания новых решений.

Промышленное оборудование: Изготовление регулирующих клапанов со сложными внутренними каналами течения, индивидуальных захватов и концевых эффекторов роботов, а также вкладышей пресс-форм с конформным охлаждением для массовых производственных линий значительно повышает эффективность и стабильность процессов.

Заключение: как выбрать оптимальный металл и технологию для вашего проекта

Нержавеющая сталь, углеродистая сталь, алюминиевые и медные сплавы занимают свои незаменимые ниши в области металлической 3D-печати. От сбалансированной долговечности нержавеющей стали и доступной прочности углеродистой стали до выдающегося потенциала облегчения алюминия и экстремальных тепловых возможностей меди — понимание особенностей этих материалов является первой ступенью к их успешному применению. Как мощный инструмент цифрового производства, металлическая 3D-печать продолжает расширять границы инженерии и дизайна.

Если вы сталкиваетесь с вызовами в области конструирования, характеристик или эффективности производства, мы приглашаем вас обратиться к инженерной команде Neway. Обладая глубокой экспертизой в области ЧПУ-обработки титана и других передовых технологий, мы предоставляем комплексную поддержку — от выбора материала и определения процесса до поставки готовых деталей.

FAQs

Какой точности размеров и качества поверхности можно достичь при металлической 3D-печати?

Какого уровня прочности обычно достигают материалы 316L и 7075 после 3D-печати?

С какими трудностями сталкиваются при 3D-печати меди и каковы ключевые области её применения?

Какое решение оптимально для сложных деталей с высокоточными стыковочными поверхностями?