Titanium

Material Introduction

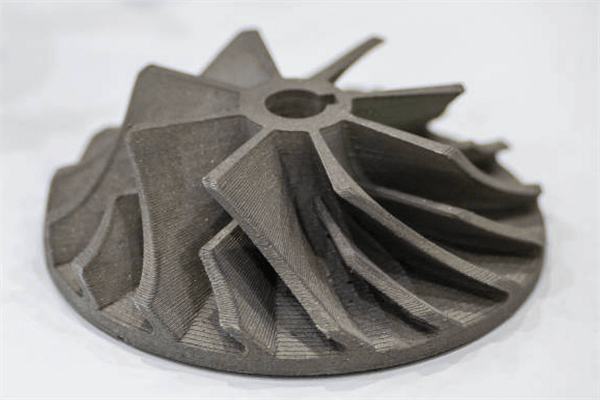

Titanium for 3D printing has become one of the most strategically important materials in advanced manufacturing due to its exceptional strength-to-weight ratio, fatigue resistance, corrosion resistance, and biocompatibility. In additive manufacturing—especially SLM, DMLS, and EBM—titanium enables the creation of highly optimized, lightweight, and structurally complex parts that traditional manufacturing cannot produce. Its excellent thermal stability and mechanical robustness make it indispensable in aerospace propulsion systems, medical implants, automotive lightweighting programs, and high-performance industrial components. The most commonly used titanium alloys in 3D printing are Ti-6Al-4V (TC4) and Ti-6Al-4V ELI (Grade 23), both of which offer superb printability, mechanical stability, and biological compatibility.

International Names or Representative Grades

Region | Representative Grades |

|---|---|

USA | Ti-6Al-4V, Ti-6Al-4V ELI, Ti-3Al-2.5V |

Europe | Grade 5, Grade 23, Titanium Alloy 3.7165 |

China | TC4, TA15, TC11 |

Aerospace | Ti-6Al-4V, Ti-5Al-5V-5Mo-3Cr (Ti5553) |

Medical | Ti-6Al-4V ELI, CP Titanium |

Automotive | Grade 12, Beta C |

Alternative Material Options

Depending on design needs, there are several alternatives to titanium. When ultra-high temperature stability is required, nickel-based superalloys such as Inconel 718 or Hastelloy C-276 outperform titanium in hot-gas or turbine environments. For corrosion-intensive chemical applications, Monel 400 or Stellite 6 offers superior resistance. When electrical or thermal conductivity is required, copper alloys like C102 Oxygen-Free Copper are more suitable. For cost-sensitive designs that do not require titanium’s high strength-to-weight performance, stainless steels such as SUS316L or SUS304 are economical options.

Design Purpose

Titanium for additive manufacturing was designed to achieve lightweight, high-strength structures while offering corrosion resistance and fatigue performance beyond traditional metal systems. Its purpose is to enable engineers to build consolidated components with internal channels, lattice structures, and precision geometries that maximize performance while minimizing weight—critical for aerospace, medical implants, power-dense industrial systems, and next-generation mobility platforms.

Chemical Composition (Ti-6Al-4V Example)

Element | Percentage (%) |

|---|---|

Ti | Balance |

Al | 5.5–6.75 |

V | 3.5–4.5 |

Fe | ≤0.3 |

O | ≤0.2 |

Physical Properties

Property | Value |

|---|---|

Density | 4.4–4.5 g/cm³ |

Melting Point | ~1,660°C |

Thermal Conductivity | 6–7 W/m·K |

Electrical Resistivity | 1.7–1.9 μΩ·m |

Elastic Modulus | 110 GPa |

Mechanical Properties

Property | Value |

|---|---|

Tensile Strength | 900–1,100 MPa |

Yield Strength | 830–960 MPa |

Elongation | 10–15% |

Hardness | 32–36 HRC |

Fatigue Strength | Excellent |

Key Material Characteristics

Titanium offers several performance advantages that make it ideal for 3D printing applications:

Outstanding strength-to-weight ratio, enabling structural efficiency in lightweighting designs.

Excellent corrosion resistance in seawater, chemical environments, and oxidizing atmospheres.

High fatigue resistance, ideal for aerospace load-bearing structures and medical implants.

Fully biocompatible, making it suitable for use in orthopedic and dental implants without risk of rejection.

Exceptional performance in SLM, DMLS, and EBM due to its stable melt pool behavior.

Superior fracture toughness, resisting cracking under impact or dynamic conditions.

Capable of forming complex internal cooling channels and lattice structures.

Low thermal expansion, providing high dimensional stability.

A natural oxide layer provides long-term protection against corrosion.

Lightweight, reducing mass in aerospace turbines and automotive high-performance parts.

Processing Performance Across Manufacturing Methods

Titanium is one of the most suitable materials for metal 3D printing due to its clean melting behavior and predictable solidification:

Powder-bed fusion methods, including SLM, DMLS, and EBM, achieve high density and mechanical uniformity.

EBM produces coarse grains optimized for high-temperature fatigue and creep performance.

Binder Jetting offers cost-effective prototyping that can be densified via sintering.

UAM and WAAM enable the production of large-scale titanium structural parts for aerospace frames.

Machining after printing is often required, and titanium responds well to CNC milling and EDM for final tolerances.

Heat treatment enhances mechanical properties and eliminates internal stresses.

Excellent compatibility with hybrid manufacturing methods that combine AM with precision machining.

Suitable and Common Post-Processing Methods

Titanium parts made by additive manufacturing often undergo post-processing to enhance properties:

Stress-relief heat treatment to stabilize microstructure.

HIP processing to remove porosity and improve fatigue life.

CNC polishing to achieve smooth, medical-grade surface finishes.

PVD coatings for wear resistance.

Sandblasting for clean, matte uniform surfaces.

Chemical Polishing and Electropolishing for Orthopedic Implant Surfaces.

Anodizing-style coloring treatments for aesthetic or identification requirements.

Shot peening to improve fatigue resistance.

Machining refinements using CNC turning for critical dimensions.

Common Industries and Applications

Titanium’s strength, lightness, and corrosion resistance make it ideal for:

Aerospace turbine blades, brackets, housings, and structural connectors.

Medical implants, including hip cups, dental implants, spinal hardware, and surgical instruments.

Automotive high-performance components such as connecting rods and exhaust systems.

Robotics and automation require lightweight strength.

Marine and offshore components are exposed to seawater.

Energy-sector parts, including high-efficiency heat exchangers.

Sporting goods, drones, and high-end consumer technology.

When to Choose Titanium for 3D Printing

Titanium is the ideal choice when:

Weight reduction is essential without sacrificing mechanical strength.

The application demands biocompatibility and corrosion resistance.

Parts require internal lattice structures or complex channels not possible with machining.

The component must withstand cyclic loading and long-term fatigue stress.

The operating environment includes saltwater, body fluids, chemicals, or high humidity.

Designers require powder-bed fusion materials that offer high dimensional precision.

Aerospace certification or medical standards require predictable mechanical performance.

Hybrid manufacturing depends on seamless integration with CNC machining.

Titanium’s superior durability outweighs material cost.