हाई-टॉलरेंस CNC डीप होल ड्रिलिंग – कोटेशन प्राप्त करें

सीमाओं से आगे: एडवांस्ड मैन्युफैक्चरिंग में हाई-प्रिसीजन डीप होल ड्रिलिंग की关键 भूमिका

प्रिसीजन मैन्युफैक्चरिंग में डीप होल मशीनीकरण को लंबे समय से किसी भी कंपनी की तकनीकी क्षमता का एक महत्वपूर्ण मानदंड माना जाता है। Neway में एक सीनियर प्रोसेस इंजीनियर के रूप में, मैं अच्छी तरह जानता हूँ कि हर एक डीप होल तकनीकी उत्कृष्टता की चरम追求 का प्रतिनिधित्व करता है। जब लंबाई-से-व्यास अनुपात 10:1 से अधिक हो जाता है, तो पारंपरिक मशीनीकरण विधियाँ बहुत जल्दी अपनी सीमा तक पहुँच जाती हैं — टूल डिफ्लेक्शन, चिप निकासी (चिप एवैक्यूएशन) में कठिनाई, खराब हीट डिसिपेशन, और अस्थिर सतह गुणवत्ता जैसे कारक पार्ट प्रदर्शन को सीमित करने वाले मुख्य तत्व बन जाते हैं।

आधुनिक हाई-एंड इक्विपमेंट मैन्युफैक्चरिंग में डीप होल अब केवल साधारण थ्रू होल या थ्रेड बॉटम नहीं रहे; वे फ्यूल डिलीवरी, हाइड्रॉलिक ट्रांसमिशन, कूलिंग सर्कुलेशन आदि के लिए ज़िम्मेदार महत्वपूर्ण फ़ंक्शनल फीचर्स में विकसित हो चुके हैं। चाहे बात एयरोस्पेस इंजन के फ्यूल नोज़ल्स की हो या सर्जिकल रोबोट्स के प्रिसीजन ड्राइव शाफ्ट्स की, डीप होल के डायामीटर टॉलरेंस, स्ट्रेटनेस, पोजिशन सटीकता और सतह फिनिश के लिए आवश्यकताएँ बेहद कठोर होती हैं। यहीं पर हमारी डीप होल ड्रिलिंग सेवाएँ वास्तविक मूल्य प्रदान करती हैं — ग्राहकों के लिए डीप होल मशीनीकरण की सबसे चुनौतीपूर्ण समस्याओं को हल करते हुए।

डीप होल ड्रिलिंग तकनीकों की व्याख्या: गन ड्रिलिंग, BTA और इजेक्टर सिस्टम

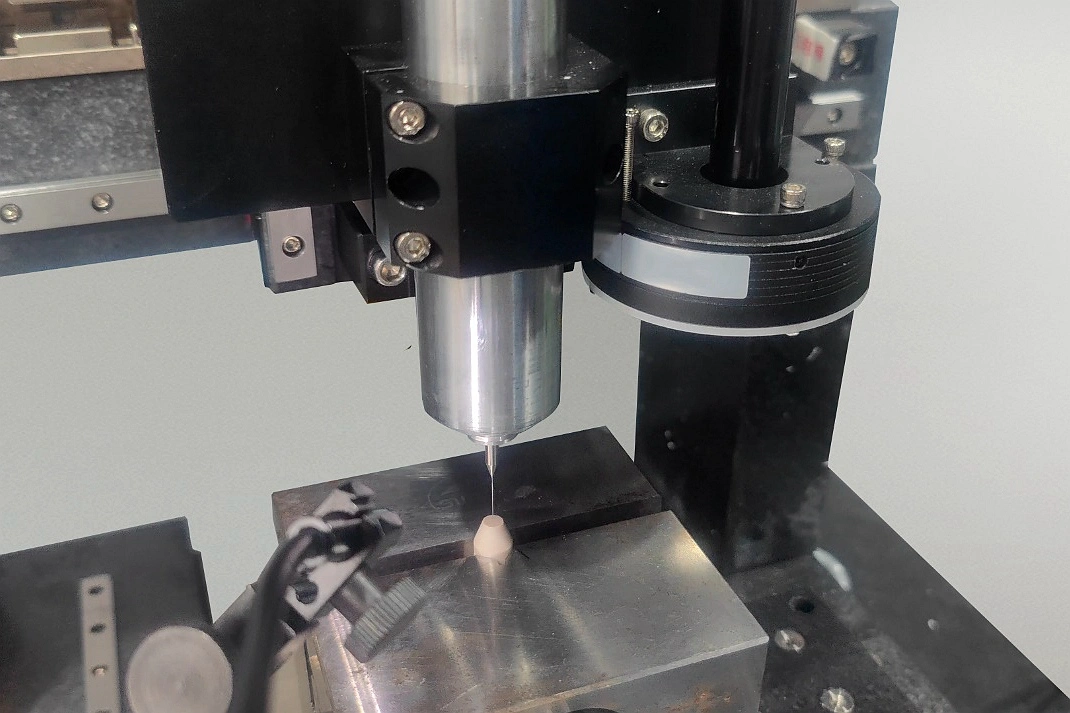

गन ड्रिलिंग: छोटे-व्यास वाले डीप होल्स के लिए प्रिसीजन पसंद

गन ड्रिलिंग छोटे-व्यास वाले डीप होल्स के लिए हमारी पसंदीदा विधि है। यह सिंगल-ट्यूब सिस्टम हाई-प्रेशर कूलेंट का उपयोग करता है, जो ड्रिल ट्यूब के अंदर V-आकार की ग्रूव से चिप्स को बाहर निकालता है। इसकी अनोखी कटिंग हेड ज्योमेट्री और कूलेंट चैनल कॉन्फ़िगरेशन पूरे मशीनीकरण के दौरान स्थिरता और चिप्स की स्मूद निकासी सुनिश्चित करते हैं। हमारा गन ड्रिलिंग उपकरण 1.5 मिमी से 20 मिमी व्यास वाले डीप होल्स को विश्वसनीय रूप से मशीन कर सकता है और लंबाई-से-व्यास अनुपात 100:1 तक प्राप्त कर सकता है — जो पारंपरिक ट्विस्ट ड्रिल से लगभग असंभव है।

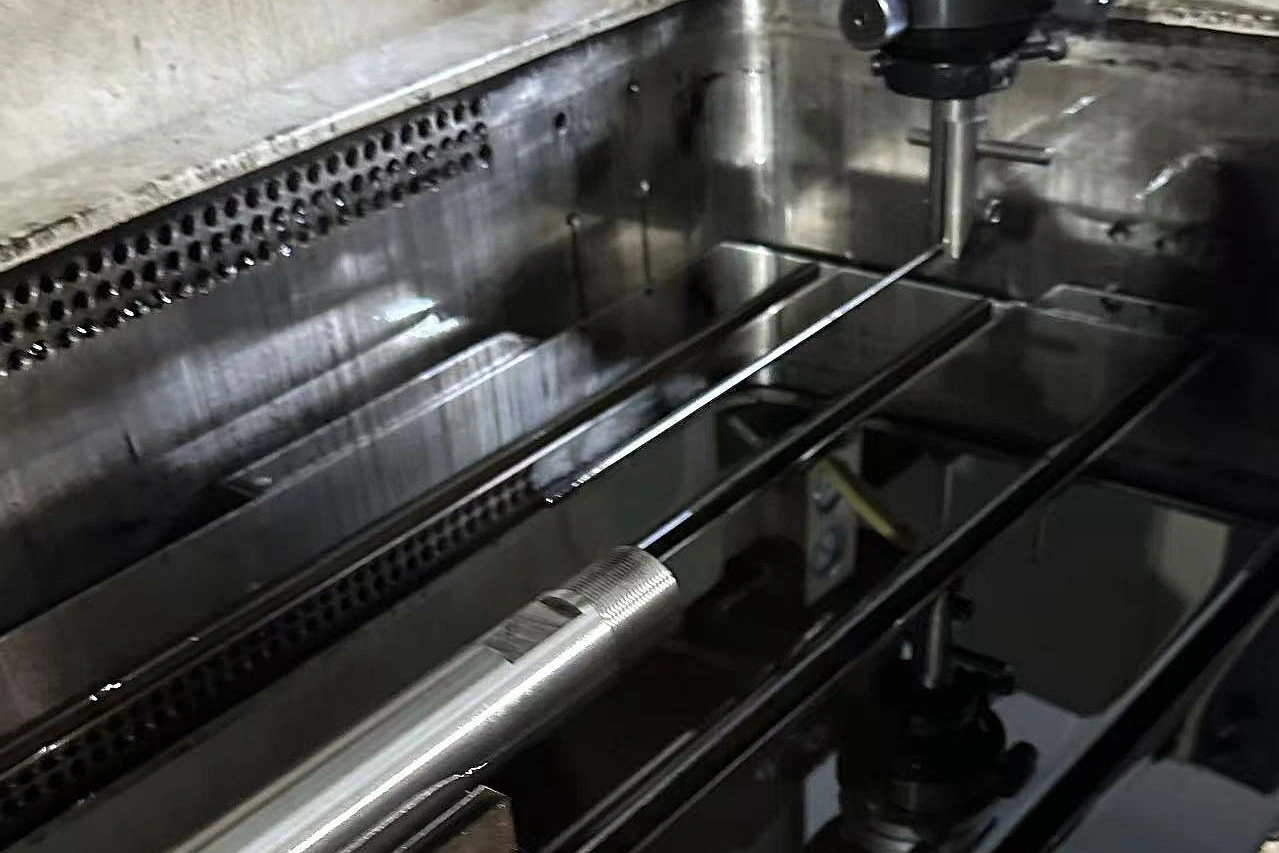

BTA सिस्टम: मध्यम और बड़े-व्यास वाले डीप होल्स का कुशल मशीनीकरण

20 मिमी से अधिक व्यास वाले डीप होल्स के लिए हम BTA (Boring and Trepanning Association) सिस्टम का उपयोग करते हैं। इस डुअल-ट्यूब कॉन्फ़िगरेशन में हाई-प्रेशर कूलेंट ड्रिल ट्यूब और होल वॉल के बीच की रिंगनुमा गैप से प्रवेश करता है, जबकि चिप्स ड्रिल ट्यूब के अंदरूनी बोअर से बाहर निकलते हैं। BTA सिस्टम उच्च उत्पादकता और बेहतर सतह फिनिश प्रदान करता है, जिससे यह मध्यम और बड़े-व्यास वाले डीप होल्स के मास प्रोडक्शन के लिए आदर्श बन जाता है। हमारे मल्टी-एक्सिस मशीनीकरण सेंटर्स पर BTA सिस्टम एक ही सेटअप में जटिल कंपोनेंट्स पर कई डीप होल्स का मशीनीकरण संभव बनाता है।

डायामीटर, डेप्थ रेश्यो और मटेरियल के आधार पर सर्वोत्तम प्रक्रिया कैसे चुनें

सही डीप होल ड्रिलिंग प्रक्रिया का चयन करने के लिए कई कारकों का समग्र मूल्यांकन आवश्यक होता है। होल डायामीटर और लंबाई-से-व्यास अनुपात के अलावा, सामग्री के गुण भी महत्वपूर्ण निर्णय मानदंड हैं। सुपरएलॉय जैसे कठिन-मशीनीकरण योग्य मटेरियल्स के लिए हम विशेष टूल ज्योमेट्री और कूलेंट पैरामीटर्स चुनते हैं। टाइटेनियम एलॉय के लिए हम प्रतिकूल माइक्रोस्ट्रक्चरल परिवर्तन से बचने के लिए तापमान नियंत्रण पर विशेष जोर देते हैं। हमारी प्रोसेस इंजीनियरिंग टीम प्रत्येक प्रोजेक्ट के लिए सबसे उपयुक्त मशीनीकरण समाधान तैयार करने में समृद्ध अनुभव रखती है।

हाई-प्रिसीजन डीप होल ड्रिलिंग में Neway की कोर क्षमताएँ और तकनीकी विनिर्देश

Neway का डीप होल मशीनीकरण विभाग विश्व-स्तरीय समर्पित मशीनरी से सुसज्जित है, जिनमें मल्टी-एक्सिस डीप होल ड्रिलिंग मशीनें, गन ड्रिलिंग सिस्टम और BTA उपकरण शामिल हैं। हमारी क्षमताएँ 1.5 मिमी से 50 मिमी व्यास के डीप होल्स को कवर करती हैं, अधिकतम लंबाई-से-व्यास अनुपात 150:1 तक — जो हमें उद्योग के अग्रणी स्तर पर रखता है। टॉलरेंस नियंत्रण की दृष्टि से हम डायामीटर टॉलरेंस IT7 स्तर तक, स्ट्रेटनेस डेविएशन 0.02 मिमी प्रति 100 मिमी से कम, और पोजिशनल सटीकता 0.05 मिमी के भीतर प्राप्त कर सकते हैं।

सतह गुणवत्ता डीप होल मशीनीकरण प्रदर्शन का एक关键 संकेतक है। कटिंग पैरामीटर्स और कूलेंट सिस्टम को ऑप्टिमाइज़ करके हम आंतरिक सतह की रफनेस Ra 0.4 μm तक प्राप्त कर सकते हैं। इससे न केवल आगे की फिनिशिंग ऑपरेशंस की आवश्यकता कम होती है, बल्कि अधिक महत्वपूर्ण यह है कि यह कठोर ऑपरेटिंग कंडीशंस में विश्वसनीयता सुनिश्चित करता है। जिन पार्ट्स के अंदरूनी बोअर पर इलेक्ट्रोपॉलिशिंग की आवश्यकता होती है, उनके लिए हमारी मशीनीकृत सतह एक आदर्श बेस प्रदान करती है।

मटेरियल विशेषज्ञता: कठिन-मशीनीकरण योग्य एलॉय में डीप होल चुनौतियों पर विजय

सुपरएलॉय और टाइटेनियम एलॉय के लिए डीप होल रणनीतियाँ

सुपरएलॉय और टाइटेनियम एलॉय डीप होल मशीनीकरण के लिए सबसे चुनौतीपूर्ण मटेरियल्स में से माने जाते हैं। उनकी उच्च मज़बूती और कम थर्मल कंडक्टिविटी गंभीर वर्क हार्डनिंग और तेज़ टूल वियर का कारण बन सकती है। एडवांस्ड टूल कोटिंग्स, ऑप्टिमाइज़्ड कटिंग पैरामीटर्स और कस्टमाइज्ड कूलेंट फ़ॉर्म्युलेशन का उपयोग करके हम इन चुनौतियों का प्रभावी ढंग से सामना करते हैं। उदाहरण के लिए, Inconel 718 का मशीनीकरण करते समय हम प्रोग्रेसिव फ़ीड स्ट्रैटेजीज़ और हाई-प्रेशर इंटरनल कूलेंट का उपयोग करते हैं, ताकि समय पर चिप निकासी सुनिश्चित हो सके और चिप पैकिंग के कारण टूल फेल्योर से बचा जा सके।

स्टेनलेस स्टील्स में डीप होल मशीनीकरण और चिप कंट्रोल

अपनी टफनेस और बिल्ट-अप एज बनाने की प्रवृत्ति के कारण स्टेनलेस स्टील्स डीप होल ड्रिलिंग में अक्सर लंबी, सतत चिप्स उत्पन्न करते हैं, जो चिप निकासी में समस्याएँ पैदा करते हैं। हम कस्टम चिप ब्रेकर ज्योमेट्री, पल्स्ड फ़ीड स्ट्रैटेजीज़ और कूलेंट प्रेशर के सटीक नियंत्रण का उपयोग करके इस समस्या को हल करते हैं। 316 स्टेनलेस स्टील में डीप होल्स के लिए हम बोअर सतह पर वर्क हार्डनिंग को कम से कम रखने पर भी विशेष ध्यान देते हैं, जिससे आगे की प्रक्रियाएँ अधिक सुगम हो जाती हैं।

एल्यूमिनियम एलॉय के लिए कुशल डीप होल ड्रिलिंग और सतह संरक्षण

हालाँकि 7075 एल्यूमिनियम एलॉय अपेक्षाकृत आसानी से मशीन होने वाला मटेरियल है, डीप होल मशीनीकरण फिर भी विशिष्ट चुनौतियाँ प्रस्तुत करता है। यह नरम मटेरियल बर्स बनाने की प्रवृत्ति रखता है और सतह खरोंचों के प्रति संवेदनशील होता है। हम हाई-स्पीड, लो-फ़ीड कटिंग स्ट्रैटेजीज़ और विशेष एल्यूमिनियम कटिंग फ्लूड्स का संयोजन अपनाते हैं, ताकि दक्षता और बोअर गुणवत्ता दोनों बनाए रखी जा सके। क्रिटिकल कंपोनेंट्स के लिए हम मशीनीकरण के तुरंत बाद सफाई करते हैं, जिससे एल्यूमिनियम सतह पर ऑक्सिडेशन या जंग से बचाव हो सके।

डीप होल ड्रिलिंग के प्रमुख गुणवत्ता मेट्रिक्स और हमारा निरीक्षण आश्वासन

निरीक्षण डीप होल मशीनीकरण सटीकता सुनिश्चित करने वाली अंतिम और सबसे महत्वपूर्ण सुरक्षा रेखा है। हमने डीप होल इन्स्पेक्शन की एक व्यापक प्रणाली स्थापित की है, जो कच्चे माल से लेकर तैयार पार्ट्स तक हर चरण को कवर करती है। मशीनीकरण के दौरान हम कटिंग फ़ोर्स, कूलेंट प्रेशर और फ्लो रेट की निरंतर निगरानी करते हैं, ताकि स्थिर कटिंग कंडीशंस बनी रहें। मशीनीकरण के बाद हम समर्पित बोअर गेज, एयर गेज और कोऑर्डिनेट मीज़रिंग मशीनों का उपयोग डायामीटर, राउंडनेस और सिलिंड्रिसिटी को सटीक रूप से मापने के लिए करते हैं।

स्ट्रेटनेस वेरिफिकेशन के लिए हम एडवांस्ड लेज़र-आधारित मापन सिस्टम का उपयोग करते हैं, जो पूरे होल की गहराई के साथ स्ट्रेटनेस डेविएशंस का मैप बना सकते हैं। इससे हमें टूल वियर या मशीन सटीकता से संबंधित समस्याओं का तुरंत पता लगाने और सुधार करने में मदद मिलती है, और यह सुनिश्चित होता है कि हर डीप होल डिज़ाइन स्पेसिफ़िकेशंस के अनुरूप हो। विशेष रूप से हीट ट्रीटमेंट के बाद हम महत्वपूर्ण डीप होल्स को दोबारा मापते हैं, ताकि डिस्टॉर्शन के प्रभाव का मूल्यांकन किया जा सके और यह पुष्टि की जा सके कि आयामी टॉलरेंस अभी भी सीमाओं के भीतर हैं।

इंडस्ट्री सॉल्यूशंस: महत्वपूर्ण क्षेत्रों में डीप होल ड्रिलिंग के अनुप्रयोग

एयरोस्पेस: फ्यूल नोज़ल्स और हाइड्रॉलिक एक्टुएटर सिलिंडर्स

एयरोस्पेस सेक्टर में हम इंजन नोज़ल्स में माइक्रोन-स्तर के फ्यूल इंजेक्शन होल्स का मशीनीकरण करते हैं। इन होल्स का व्यास आमतौर पर केवल 0.1–0.3 मिमी होता है और लंबाई-से-व्यास अनुपात 20:1 से अधिक होता है। प्रिसीजन गन ड्रिलिंग के माध्यम से हम प्रत्येक ऑरिफिस के लिए सुसंगत फ्लो रेट सुनिश्चित करते हैं, जिससे इष्टतम दहन दक्षता (कम्बशन एफिशिएंसी) प्राप्त होती है। हाइड्रॉलिक एक्टुएटर सिलिंडर्स में डीप होल्स के लिए भी अत्यंत उच्च स्ट्रेटनेस और सतह फिनिश की आवश्यकता होती है, ताकि सील वियर और लीकेज को रोका जा सके।

मेडिकल डिवाइस: सर्जिकल इंस्ट्रूमेंट्स, एंडोस्कोप कंपोनेंट्स और इम्प्लांट गाइड होल्स

मेडिकल डिवाइस क्षेत्र में डीप होल आवश्यकताएँ और भी अधिक कठोर होती हैं। सर्जिकल इंस्ट्रूमेंट्स में होल्स को छोटे डायामीटर, बड़े डेप्थ रेश्यो और उत्कृष्ट सतह फिनिश का संयोजन करना होता है। एंडोस्कोप कंपोनेंट्स के लिए हम 1.2 मिमी डायामीटर और 120 मिमी गहराई वाले इमेज बंडल चैनल्स मशीन करते हैं, जिनकी स्ट्रेटनेस 0.05 मिमी के भीतर नियंत्रित की जाती है — जो किसी भी मशीनीकरण प्रक्रिया के लिए एक अत्यधिक चुनौती है। ऑर्थोपेडिक इम्प्लांट्स में गाइड होल्स भी सर्जिकल सटीकता और रोगी सुरक्षा सुनिश्चित करने के लिए अत्यंत सटीक आयाम और उच्च सतह गुणवत्ता की माँग करते हैं।

ऑयल एंड गैस: वॉल्व बॉडीज़ और लॉगिंग टूल हाउसिंग्स

ऑयल एंड गैस उद्योग में वॉल्व बॉडीज़ के डीप होल्स अत्यधिक प्रेशर और संक्षारक (कोरोज़िव) वातावरण में कार्य करते हैं। ऑप्टिमाइज़्ड प्रक्रियाओं और सख्त गुणवत्ता नियंत्रण के माध्यम से हम इन महत्वपूर्ण फीचर्स की दीर्घकालीन विश्वसनीयता और टिकाऊपन सुनिश्चित करते हैं। लॉगिंग टूल हाउसिंग्स में अक्सर ऐसे डीप होल्स होते हैं जो कई चैम्बर्स से होकर गुजरते हैं और जिनके पोजिशनल टॉलरेंस बेहद कड़े होते हैं; हमारी मल्टी-एक्सिस मशीनीकरण क्षमताएँ ऐसे मांगपूर्ण कंपोनेंट्स के लिए आवश्यक सटीकता प्रदान करती हैं।

हाई-प्रिसीजन डीप होल ड्रिलिंग के लिए Neway को अपना पार्टनर क्यों चुनें?

Neway में हम तकनीकी नवाचार के माध्यम से मैन्युफैक्चरिंग को आगे बढ़ाने के लिए प्रतिबद्ध हैं। हमारी डीप होल मशीनीकरण टीम अनुभवी इंजीनियरों और तकनीशियनों से बनी है, जिनमें से प्रत्येक ने कठोर प्रशिक्षण और सर्टिफिकेशन प्राप्त किया है। एडवांस्ड उपकरणों के स्वामित्व से आगे बढ़कर, हमने जटिल डीप होल चुनौतियों को हल करने में व्यापक ज्ञान और अनुभव संचित किया है। प्रोटोटाइपिंग चरण में प्रक्रिया वैलिडेशन से लेकर स्मॉल-बैच ट्रायल्स और फुल-स्केल प्रोडक्शन तक हम संपूर्ण लाइफसाइकल तकनीकी समर्थन प्रदान करते हैं।

हमारा वन-स्टॉप सेवा मॉडल सुनिश्चित करता है कि ग्राहकों को पूर्ण और इंटीग्रेटेड समाधान मिलें। डीप होल मशीनीकरण से लेकर हीट ट्रीटमेंट, सतह फिनिशिंग और अंतिम निरीक्षण तक हम पूरे मैन्युफैक्चरिंग चेन का प्रबंधन करते हैं। यह इंटीग्रेशन न केवल दक्षता बढ़ाता है, बल्कि सभी चरणों में गुणवत्ता की सुसंगतता भी सुनिश्चित करता है।

Neway में हम हर डीप होल मशीनीकरण प्रोजेक्ट को अपनी प्रिसीजन मैन्युफैक्चरिंग क्षमताओं को प्रदर्शित करने का अवसर मानते हैं। आपका पार्ट कितना भी जटिल क्यों न हो या आपकी आवश्यकताएँ कितनी भी कठोर क्यों न हों, हम सर्वोत्तम तकनीकी समाधान देने के लिए पूरी तरह प्रतिबद्ध हैं। हमें पूर्ण विश्वास है कि हमारी विशेषज्ञता और कठोर गुणवत्ता दृष्टिकोण आपको हाई-प्रिसीजन डीप होल ड्रिलिंग के लिए सबसे विश्वसनीय पार्टनर प्रदान करते हैं।

आपके RFQs के लिए आवश्यक जानकारी: सटीक कोट जल्दी कैसे प्राप्त करें

यह सुनिश्चित करने के लिए कि हम सटीक और समय पर कोटेशन प्रदान कर सकें, हम अनुशंसा करते हैं कि आप अपने RFQ में निम्न जानकारी शामिल करें: पार्ट ड्रॉइंग्स या 3D मॉडल (जिनमें सभी डीप होल आयाम, टॉलरेंस और तकनीकी आवश्यकताएँ स्पष्ट रूप से चिह्नित हों), मटेरियल स्पेसिफिकेशन (ग्रेड और कंडीशन), अनुमानित ऑर्डर मात्रा, सतह ट्रीटमेंट आवश्यकताएँ और कोई भी विशेष निर्देश। इन जानकारियों के आधार पर हमारे इंजीनियर 24 घंटों के भीतर विस्तृत तकनीकी प्रस्ताव और प्रतिस्पर्धी कोटेशन प्रदान करेंगे।

अक्सर पूछे जाने वाले प्रश्न (FAQ)

क्या डीप होल मशीनीकरण हीट ट्रीटमेंट के बाद पार्ट्स के प्रदर्शन को प्रभावित करता है?

आप ब्लाइंड डीप होल्स के बॉटम शेप और आयामी सटीकता को कैसे सुनिश्चित करते हैं?

डीप होल मशीनीकरण के बाद गुणवत्ता सुधारने के लिए कौन-से आंतरिक सतह ट्रीटमेंट्स की अनुशंसा की जाती है?

किसी डीप होल ड्रिलिंग प्रोजेक्ट के लिए RFQ से अंतिम डिलीवरी तक सामान्यतः कितना लीड टाइम होता है?