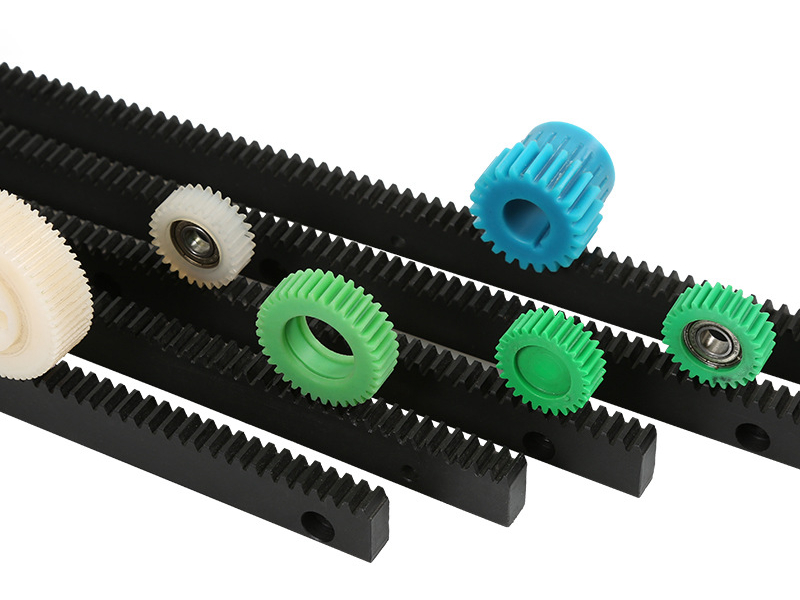

CNC Machining of Precision UPE Gear Racks for THK Linear Motion Systems

Project Background: Lightweight, Wear-Resistant Gear Rack for Linear Motion

THK, a global leader in linear motion control systems, required a precision-machined polymer gear rack solution for use in a new generation of lightweight, corrosion-resistant actuator assemblies. The part was expected to maintain excellent dimensional accuracy and wear performance under dry-running conditions. Neway was selected to deliver the gear rack from UPE (Ultra-high Molecular Weight Polyethylene) using specialized plastic CNC techniques.

Why UPE Was Selected for Gear Rack Applications

UPE offers outstanding wear resistance, impact strength, and low friction—ideal for dry-running mechanical transmission parts.

Property | Value |

|---|---|

Tensile Strength | ≥40 MPa |

Impact Resistance | Excellent |

Coefficient of Friction | ~0.1 (dry sliding) |

Water Absorption | <0.01% |

Machinability | High (with sharp tools and low heat generation) |

UPE (also known as UHMW-PE) provides a long service life in sliding components and can operate without lubrication. Learn more about UPE CNC Machining.

CNC Machining Workflow

CNC Milling for Profile and Tooth Structure

3-axis CNC milling was used to rough out the gear rack body and cut the tooth profiles. Special attention was given to chip removal and tool clearance to avoid material buildup and overheating.

CNC Boring for Shaft Mounting Holes

Precision CNC boring was applied to produce mounting bores with a diameter tolerance of ±0.02 mm. This ensured stable engagement between rack and pinion assemblies.

CNC Drilling for Fastener Holes

Fastener mounting holes were machined using CNC drilling with sharp, high-clearance drills. Peck drilling cycles were used to minimize thermal softening and ensure perpendicularity across long bores.

Quality Control & Dimensional Validation

Profile Accuracy: Gear tooth spacing and form verified using optical comparators

Hole Tolerances: Bore and fastener diameters were inspected using plug gauges and CMM

Flatness & Warpage Control: Entire rack body checked using dial indicators to ensure ≤0.05 mm flatness over 800 mm length

Production Outcome

Neway delivered a batch of 2,500 gear racks with zero warpage rejections and >99.7% dimensional pass rate. THK’s engineering team reported stable meshing, excellent dry-running performance, and long wear life in prototype motion systems.

Why Neway for Precision Plastic Motion Components

Plastic CNC Machining: Expert process control for engineering plastics like UPE, POM, and PA

CNC Boring Service: Achieves tight tolerance bores with consistent concentricity in polymer substrates

CNC Drilling Service: Ideal for high-precision fastener hole patterns and long-hole alignment

FAQs

How does UPE perform in gear rack applications without lubrication?

What is the best strategy for controlling UPE material warpage during machining?

What tolerances can be maintained in bored holes on UPE parts?

Can UPE gear racks be used in wet or corrosive environments?

How does UPE compare to POM and Nylon in CNC machined drive components?