热障涂层服务:高温合金热障涂层(TBC)

前言:热障涂层——当“金属本身”已不够时的高温部件防护方案

随着涡轮进口温度、燃烧负荷以及效率指标不断提升,仅依赖基体合金已难以同时兼顾安全性与经济性。热障涂层(TBC,Thermal Barrier Coatings)已成为突破高温部件传统极限的核心技术之一。通过在 高温合金 等耐热基体表面构建工程化陶瓷涂层系统,经过合理的设计与工况匹配,TBC 可以将金属基体温度降低约 100–300°C,从而显著延长零件寿命、提高可靠性,并支持更高的热效率指标。

在 Neway,我们的 热喷涂/热障涂层服务 始终围绕这一使命展开:将精密机加工、先进涂层技术与严格工艺控制深度集成,为航空航天、燃气发电、油气行业及苛刻工业环境提供可靠、按应用定制的 TBC 解决方案。

热障涂层的工作机理:核心功能与作用机制

1. 热隔热功能:陶瓷层阻断热流传递

TBC 的核心是具有极低导热系数(通常为 1–3 W/m·K)的陶瓷面层,它在高温燃气与金属基体之间形成热屏障。通过合理设计(材料体系、厚度、孔隙率与显微结构),该隔热层可以:

显著降低基体金属的工作温度;

减小温度梯度与热疲劳风险;

在不更换基体合金的前提下,允许更高的燃气通道温度。

Neway 会针对每个具体应用精确调整涂层厚度与结构设计,在隔热性能、应变容纳能力与应力分布之间取得平衡,而不是简单地“把涂层做得越厚越好”。

2. 高温氧化与热腐蚀防护

除了隔热,设计完善的 TBC 体系还可以有效减缓:

镍基、钴基高温合金在高温下的氧化行为;

来自燃料与空气中硫酸盐、钒酸盐等腐蚀性物种的攻击;

由此引起的微观组织劣化与性能衰退。

对于关键 高温合金部件 而言,这种化学防护功能往往与隔热功能同等重要。

分层体系设计:每一层都有明确分工

陶瓷面层:真正实现热障的“工作层”

最外层陶瓷涂层通常以部分稳定氧化锆(YSZ)为基础,设计目标包括:

低导热率,实现高效隔热;

在服役温度范围内具备良好相稳定性;

与下层金属/合金具有兼容的热膨胀匹配;

通过适当孔隙和微裂纹结构实现良好的应变容纳与抗热震能力。

粘结层:陶瓷与基体之间的功能桥梁

在陶瓷层与金属基体之间,通常会设计一层金属粘结层——典型体系为 MCrAlY(M = Ni、Co 或 Ni/Co 组合),其主要作用包括:

为陶瓷面层提供牢固附着界面;

在服役过程中形成稳定的 Al₂O₃ 热生长氧化膜(TGO);

充当化学与氧化屏障,保护基体合金不被直接侵蚀。

Neway 会针对 Inconel 625、 Hastelloy X、 Rene 41 等不同高温合金,定制粘结层成分与工艺窗口,确保体系兼容性与长期稳定性。

关键工艺一:大气等离子喷涂(APS)

工艺特点

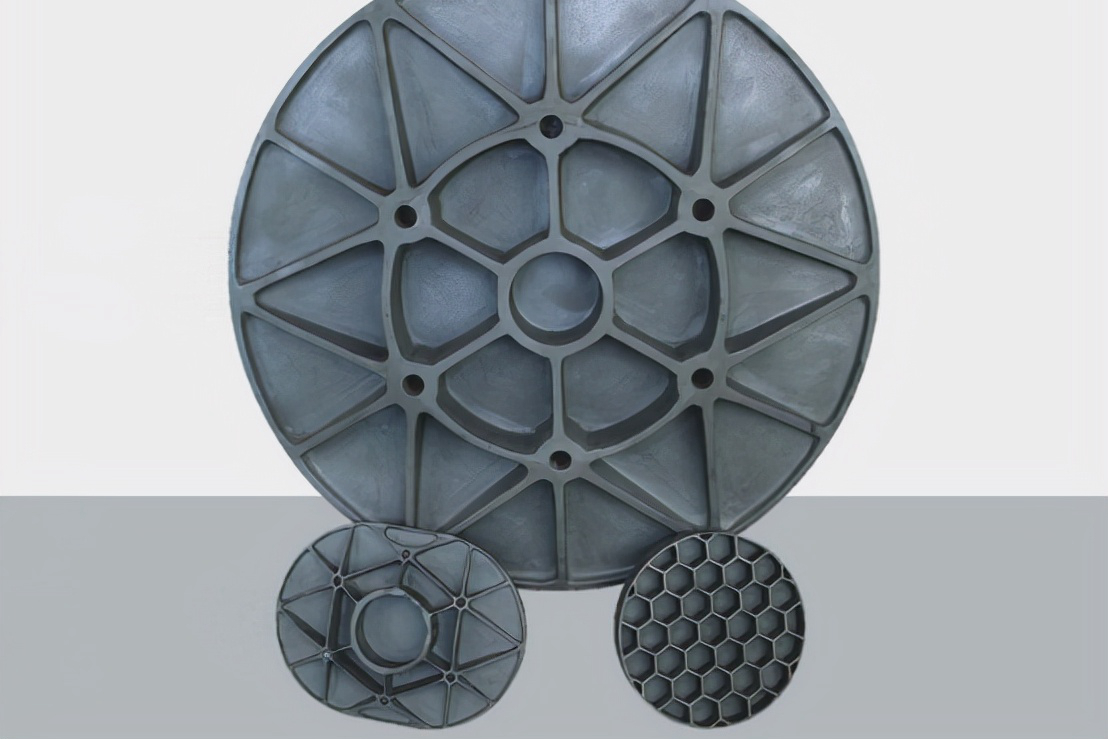

大气等离子喷涂(APS)是应用最广泛的 TBC 沉积方法之一。粉末状材料在等离子射流中被熔化或半熔化,并高速撞击到预处理后的基体表面。借助机器人控制的 APS 系统,Neway 可以实现:

在复杂三维几何表面上获得均匀可控的涂层厚度;

精细调节涂层孔隙率与片层状显微结构;

在单件与批量生产中保持良好的重复性与一致性。

典型应用与性能表现

燃气轮机叶片、导向叶片、燃烧室部件及转接段;

工业燃烧器、炉膛部件以及高温烟道等。

APS 涂层通常通过受控的孔隙和片层微裂纹设计,在提供良好隔热性能的同时,具备较高的应变容纳能力,适应反复热循环载荷。

关键工艺二:电子束物理气相沉积(EB-PVD)

独特的柱状晶显微结构

EB-PVD 在高真空环境下进行,通过电子束蒸发陶瓷靶材,使其在零件表面冷凝,形成柱状晶结构的涂层。这种结构具有:

极佳的热应变吸收能力;

出色的抗热震性能;

光滑的气流冲刷表面,有利于航空发动机的气动效率。

高端航空航天应用

EB-PVD 型 TBC 广泛应用于 航空发动机 中的单晶叶片、导向叶片等关键热端部件,在这里,耐久性、重量、冷却效率与气动特性同样至关重要。Neway 的 EB-PVD 能力与严格的航空质量体系和可追溯性要求相匹配。

涂层材料体系:从经典 YSZ 到下一代陶瓷

钇稳定氧化锆(YSZ)

7–8 wt% YSZ 仍然是当前行业主流材料,原因在于其具备:

较低的导热系数;

在实际服役温度范围内较好的相稳定性;

与镍基高温合金相对匹配的热膨胀系数。

先进稀土陶瓷体系

为支持更高的涡轮进口温度和更长的寿命,Neway 与科研合作伙伴共同开发稀土锆酸盐等新一代陶瓷材料,它们在保持更低导热率的同时,具备更优的高温相稳定性,主要面向下一代 燃气发电 与航空航天平台。

质量保证:我们如何验证 TBC 的可靠性

厚度、结合强度与显微组织

Neway 的检测手段包括:

超声或涡流厚度测量,以及金相截面观察;

涂层附着力/结合强度测试(典型要求 ≥ 30 MPa,视应用而定);

显微组织评估:片层结构、孔隙特征、TGO 生长状态,以及 EB-PVD 涂层的柱状晶形貌等。

热循环与寿命测试

我们会在具有代表性的工况下开展热循环与热冲击试验,并匹配实际工况中的峰值温度、保温时间、升降温速率与冷却方式。这些试验有助于识别主要失效模式,例如:

TGO 过度生长与开裂;

陶瓷面层剥落(spallation);

界面退化与分层。

核心应用领域

航空发动机

TBC 主要应用于:

涡轮叶片与导向叶片;

燃烧室内衬、过渡管、隔热护板等;

喷管及后处理段高温部件。

对于采用 Inconel 718 等合金的关键部件,Neway 能够提供“机加工 + 涂层”一体化解决方案,满足航空级标准要求。

发电与工业高温系统

在燃气发电机组与各类高温工艺设备中,TBC 可以:

提升涡轮效率;

延长检修间隔与维护周期;

保护化工、冶金及热处理设备中的关键高温流道部件。

涂覆 TBC 前的关键设计考量

1. 基体材料与粘结层的兼容性

我们会重点评估:

合金成分及既往热处理历史;

预计工作温度区间与热循环谱;

基体与粘结层体系的抗氧化/抗热腐蚀能力。

2. 服役环境与载荷谱

涂层系统设计会根据以下因素进行优化:

峰值温度与热循环频率;

燃气成分(燃料杂质、腐蚀性物种等);

机械载荷、振动、冲蚀及异物撞击(FOD)风险。

对于 油气行业 和 核能领域 的应用,我们还会综合考虑辐照稳定性及特定腐蚀机理等额外约束。

Neway 的一体化 TBC 解决方案:从机加工毛坯到涂层成品

Neway 能够提供完整的一站式技术链条:

工程化表面预处理:喷砂、遮蔽、清洁度与粗糙度控制;

冶金测试、尺寸检测与寿命评估;

面向航空、能源及工业 OEM 项目的 批量化生产 及完整可追溯体系。

通过这种一体化模式,我们可以缩短交付周期、降低技术风险,并在设计阶段就将涂层性能纳入整体方案,而不是在项目末端“临时加上一层涂层”。