Ti-8Al-1Mo-1V(Grade 20)

Introduction to Ti-8Al-1Mo-1V (Grade 20)

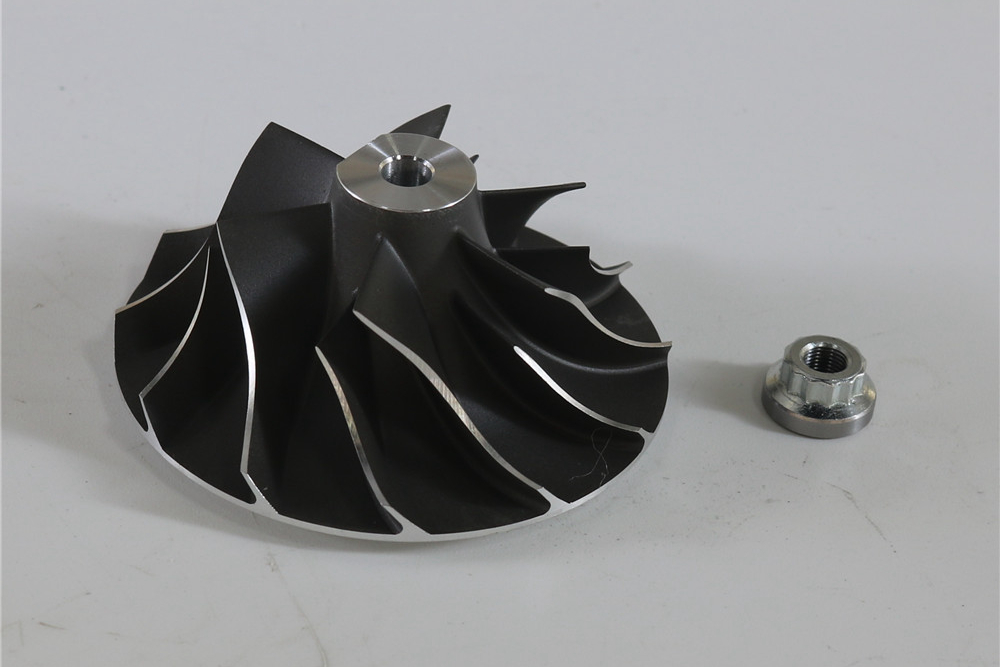

Ti-8Al-1Mo-1V, or Grade 20, is a near-alpha titanium alloy engineered for applications requiring superior thermal stability, elevated-temperature strength, and strong oxidation resistance. Its relatively high aluminum content increases stiffness while maintaining low density, making it well-suited for aerospace structures, hot-section hardware, and high-temperature industrial components.

Grade 20 is well-suited for precision CNC machined titanium parts that must remain stable in thermal and oxidative environments. These parts are typically produced using high-accuracy CNC machining services that meet strict aerospace and turbine tolerance, surface integrity, and traceability requirements.

Chemical, Physical, and Mechanical Properties of Ti-8Al-1Mo-1V (Grade 20)

Chemical Composition (Typical)

Element | Composition Range (wt.%) | Key Role |

|---|---|---|

Titanium (Ti) | Balance | Provides base strength and corrosion resistance |

Aluminum (Al) | 7.5–8.5 | Alpha stabilizer that increases strength and stiffness |

Molybdenum (Mo) | 0.7–1.3 | Beta stabilizer, improves creep and elevated-temperature response |

Vanadium (V) | 0.7–1.3 | Supports strength and thermal stability |

Oxygen (O) | ≤0.15 | Interstitial strengthener; must be controlled to preserve ductility |

Hydrogen (H) | ≤0.015 | Kept low to avoid hydrogen embrittlement |

Carbon (C) | ≤0.08 | Residual element influencing hardness and stability |

Iron (Fe) | ≤0.30 | Residual element |

Nitrogen (N) | ≤0.03 | Controlled to minimize embrittlement and preserve fatigue strength |

Physical Properties

Property | Value (Typical) | Test Standard/Condition |

|---|---|---|

Density | 4.47 g/cm³ | ASTM B311 |

Melting Range | 1620–1670°C | ASTM E1268 |

Thermal Conductivity | 6.5 W/m·K at 100°C | ASTM E1225 |

Electrical Resistivity | 1.66 µΩ·m at 20°C | ASTM B193 |

Thermal Expansion | 8.8 µm/m·°C | ASTM E228 |

Specific Heat Capacity | 560 J/kg·K at 20°C | ASTM E1269 |

Elastic Modulus | 120 GPa | ASTM E111 |

Mechanical Properties (Annealed Condition)

Property | Value (Typical) | Test Standard |

|---|---|---|

Tensile Strength | 850–950 MPa | ASTM E8/E8M |

Yield Strength (0.2%) | 800–880 MPa | ASTM E8/E8M |

Elongation | ≥10% | ASTM E8/E8M |

Hardness | 280–320 HB | ASTM E10 |

Creep Resistance | Excellent up to 500°C | ASTM E139 |

Fatigue Resistance | High | ASTM E466 |

Key Characteristics of Ti-8Al-1Mo-1V (Grade 20)

High-Temperature Strength: Retains tensile performance and creep resistance at temperatures up to 500°C, suitable for aerospace and turbine environments.

Excellent Oxidation Resistance: High Al content supports formation of a stable protective oxide layer, reducing degradation in hot air and exhaust gases.

Low Density and High Stiffness: Strong strength-to-weight ratio and increased modulus benefit weight-sensitive hot-structure designs.

Good Weldability and Structural Integrity: Weldable with inert shielding; proper post-weld stress relief helps maintain performance for service-critical assemblies.

CNC Machining Challenges and Solutions for Grade 20 Titanium

Machining Challenges

Thermal Buildup: Low thermal conductivity concentrates heat at the tool–chip interface, accelerating wear and risking surface damage.

Elastic Recovery: Higher modulus (~120 GPa) can still cause springback in thin sections, impacting profile control and tolerance in finishing.

Galling and Smearing: Adhesion to tool surfaces can degrade surface finish and dimensional consistency without strong lubrication/coolant delivery.

Tool Life Sensitivity: Elevated Al content may increase notch wear and built-up edge under unstable chip formation or insufficient cooling.

Optimized Machining Strategies

Tool Selection

Parameter | Recommendation | Rationale |

|---|---|---|

Tool Material | Fine-grain carbide, high-temperature-grade inserts | Improves edge retention under elevated cutting heat |

Coating | AlTiN or TiSiN (PVD) | Enhances heat resistance and reduces adhesion/galling |

Geometry | Sharp positive rake, lightly honed edge | Reduces cutting forces and supports stable chip formation |

Cutting Speed | 20–50 m/min | Controls tool temperature and minimizes distortion risk |

Feed Rate | 0.10–0.25 mm/rev | Maintains chip load and reduces rubbing/work hardening |

Coolant | High-pressure emulsion ≥100 bar (through-tool preferred) | Maximizes heat removal and chip evacuation |

Ti-8Al-1Mo-1V (Grade 20) Cutting Parameters (ISO 3685 Compliance)

Operation | Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) | Coolant Pressure (bar) |

|---|---|---|---|---|

Roughing | 20–30 | 0.15–0.20 | 2.0–3.0 | 80–100 (Through-tool) |

Finishing | 45–60 | 0.05–0.10 | 0.2–0.5 | 100–150 |

Surface Treatment for Grade 20 Titanium Parts

Hot Isostatic Pressing (HIP) improves fatigue strength and reduces internal voids, supporting higher reliability in aerospace hardware.

Heat Treatment typically includes annealing and stress-relief cycles to enhance dimensional stability and elevated-temperature performance.

Superalloy Welding is performed under inert shielding; post-weld stress relief helps maintain microstructural stability and fatigue performance.

Thermal Barrier Coating (TBC) provides added oxidation resistance and surface thermal protection in hot air/exhaust exposure.

CNC Machining supports tight-tolerance manufacturing (often down to ±0.01 mm) for turbine brackets and heat-exposed aerospace structures.

Electrical Discharge Machining (EDM) enables thin-wall and complex geometry features with minimized mechanical distortion.

Deep Hole Drilling supports L/D > 30:1 with Ra ≤ 1.6 µm for precision cooling or flow channels.

Material Testing includes creep testing, microstructure validation (SEM/XRD), and ultrasonic NDT per aerospace or GB/AMS requirements.

Material Testing and Analysis

Grade 20 components are validated through high-temperature tensile testing, creep rupture evaluation, microstructural analysis (SEM/XRD), and ultrasonic flaw detection to ensure compliance with aerospace and turbine quality standards.

Industry Applications of Ti-8Al-1Mo-1V (Grade 20)

Aerospace: Engine-related structures, hot-area fasteners, brackets, and control system parts exposed to elevated temperature cycles.

Power Generation: Turbine components, burner hardware, and heat-exchanger structures requiring oxidation resistance.

Industrial Equipment: Heat-treat fixtures, thermal shields, and structural supports in hot oxidizing atmospheres.

Defense: Heat-resistant structural frames and propulsion-adjacent components where oxidation resistance is critical.