Ti-6Al-4V ELI(Grade 23)

Introduction to Ti-6Al-4V ELI (Grade 23)

Ti-6Al-4V ELI (Grade 23) is the Extra-Low Interstitial (ELI) version of the widely used Ti-6Al-4V alloy, engineered with reduced oxygen, nitrogen, carbon, and iron levels to deliver higher ductility, improved fracture toughness, and excellent biocompatibility. These characteristics make it a preferred material for critical medical implants, aerospace fasteners, and cryogenic hardware where purity, fatigue resistance, and reliability are non-negotiable.

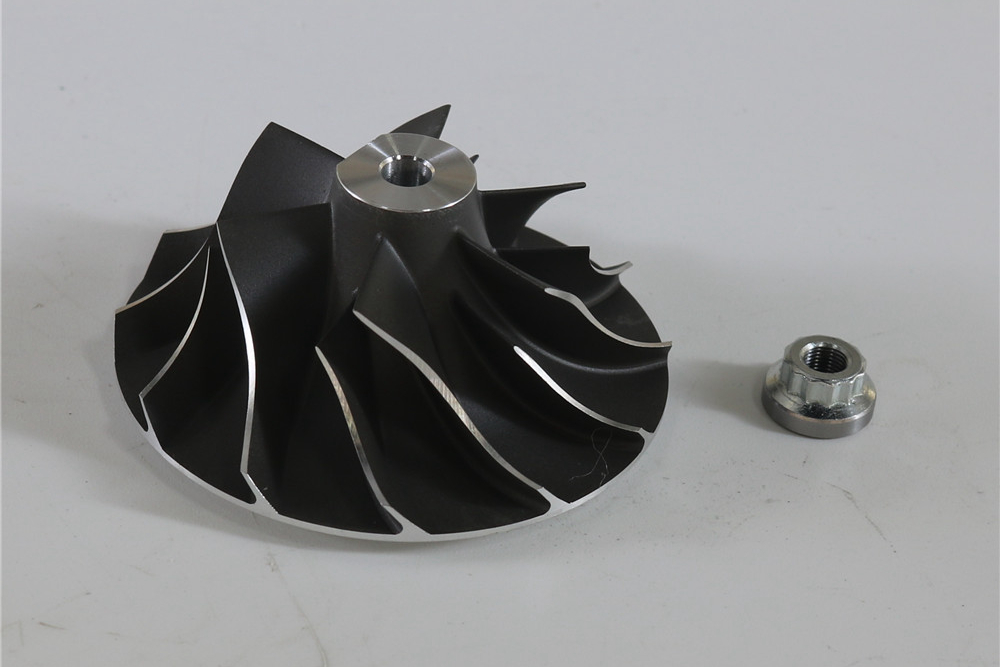

Grade 23 is typically produced through precision CNC machining services due to its high performance and stringent surface integrity requirements. Tight-tolerance CNC machined titanium parts made from Ti-6Al-4V ELI are widely used in high-stakes applications such as orthopedic implants, engine mounts, and deep-sea components, where even minor defects can compromise service life.

Chemical, Physical, and Mechanical Properties of Ti-6Al-4V ELI (Grade 23)

Chemical Composition (Typical)

Element | Composition Range (wt.%) | Key Role |

|---|---|---|

Titanium (Ti) | Balance | Base element with excellent corrosion resistance |

Aluminum (Al) | 5.5–6.5 | Alpha stabilizer, improves strength and thermal performance |

Vanadium (V) | 3.5–4.5 | Beta stabilizer, enhances strength and ductility |

Oxygen (O) | ≤0.13 | Lower interstitial level improves ductility and fracture toughness |

Iron (Fe) | ≤0.25 | Residual element, limited to preserve toughness |

Carbon (C) | ≤0.08 | Controlled to maintain weldability and toughness |

Nitrogen (N) | ≤0.05 | Reduced to minimize embrittlement and improve fatigue life |

Hydrogen (H) | ≤0.0125 | Extra-low for biocompatibility and corrosion performance |

Physical Properties

Property | Value (Typical) | Test Standard/Condition |

|---|---|---|

Density | 4.43 g/cm³ | ASTM B311 |

Melting Range | 1604–1660°C | ASTM E1268 |

Thermal Conductivity | 6.7 W/m·K at 100°C | ASTM E1225 |

Electrical Resistivity | 1.65 µΩ·m at 20°C | ASTM B193 |

Thermal Expansion | 8.8 µm/m·°C | ASTM E228 |

Specific Heat Capacity | 560 J/kg·K at 20°C | ASTM E1269 |

Elastic Modulus | 114 GPa | ASTM E111 |

Mechanical Properties (Annealed Condition)

Property | Value (Typical) | Test Standard |

|---|---|---|

Tensile Strength | 825–900 MPa | ASTM E8/E8M |

Yield Strength (0.2%) | 795–860 MPa | ASTM E8/E8M |

Elongation | ≥15% | ASTM E8/E8M |

Hardness | 280–320 HB | ASTM E10 |

Fracture Toughness | >75 MPa√m | ASTM E399 |

Fatigue Resistance | Excellent | ASTM E466 |

Key Characteristics of Ti-6Al-4V ELI (Grade 23)

High Biocompatibility: Extra-low interstitial content supports implant safety and is commonly specified for ISO 10993 and ASTM F136 compliant medical devices.

Excellent Fracture Toughness: Improved toughness, especially at cryogenic temperatures and under dynamic loads, supports critical aerospace and surgical applications.

Corrosion and Oxidation Resistance: Strong resistance to chlorides, saline, and bodily fluids with stable TiO2 passive film formation.

Weldability and Precision Machinability: Weldable with inert shielding and machinable to tight tolerances using optimized tooling, cutting parameters, and coolant strategies.

CNC Machining Challenges and Solutions for Grade 23 Titanium

Machining Challenges

Heat Generation and Low Conductivity: Heat concentrates in the cutting zone, accelerating tool wear and risking surface damage if cooling is insufficient.

Elastic Recovery: The modulus (~114 GPa) can cause springback in thin sections, affecting finishing tolerance control.

Galling and Notching: Adhesion and notch wear can occur during dry cutting or poor lubrication, reducing accuracy and surface integrity.

High Surface Finish Requirements: Medical/aerospace parts may require Ra < 0.4 µm, demanding stable cutting and controlled post-finishing processes.

Optimized Machining Strategies

Tool Selection

Parameter | Recommendation | Rationale |

|---|---|---|

Tool Material | Fine-grain carbide or coated carbide | Maintains edge strength under thermal load |

Coating | AlTiN or TiCN (≥3 µm) | Reduces adhesion and oxidation-related wear |

Geometry | Sharp edge, positive rake | Lowers cutting force and heat buildup |

Cutting Speed | 20–45 m/min | Controls tool temperature and surface integrity |

Feed Rate | 0.10–0.20 mm/rev | Ensures stable chip thickness and evacuation |

Coolant | Water-based emulsion ≥100 bar | Enhances cooling and improves surface finish |

Ti-6Al-4V ELI (Grade 23) Cutting Parameters (ISO 3685 Compliance)

Operation | Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) | Coolant Pressure (bar) |

|---|---|---|---|---|

Roughing | 20–30 | 0.15–0.20 | 2.0–3.0 | 80–100 (Through-tool) |

Finishing | 40–50 | 0.05–0.10 | 0.2–0.5 | 100–150 |

Surface Treatment for Grade 23 Titanium Parts

Hot Isostatic Pressing (HIP) improves fatigue performance and reduces internal porosity, which is particularly important for biomedical implants and flight-critical parts.

Heat Treatment typically includes stress relieving and controlled annealing/aging to improve microstructural uniformity and dimensional stability.

Superalloy Welding (inert shielding required) ensures high-integrity joints for aerospace housings and specialized medical tools.

Thermal Barrier Coating (TBC) can be applied when parts face extreme thermal cycling, such as engine mount interfaces.

CNC Machining supports high-tolerance fabrication for implants and precision aerospace fittings with accuracy down to ±0.01 mm.

Electrical Discharge Machining (EDM) enables micro-features and complex profiles without introducing cutting stresses.

Deep Hole Drilling enables high aspect ratio bores (L/D > 30:1) with Ra ≤ 1.6 µm for medical and aerospace flow passages.

Material Testing includes tensile testing, microstructure evaluation, and NDT (ultrasonic/eddy current) to support specifications such as ASTM F136 and AMS 4930.

Material Testing and Analysis

Grade 23 components are validated through tensile testing, fracture toughness evaluation, corrosion testing, SEM microstructure review, and ultrasonic flaw detection to ensure compliance with medical and aerospace quality requirements.

Industry Applications of Ti-6Al-4V ELI (Grade 23)

Medical Devices: Orthopedic implants, bone screws, trauma plates, dental frameworks, and surgical hardware requiring high fatigue resistance and biocompatibility.

Aerospace: High-reliability fasteners, brackets, engine mounts, and cryogenic fuel system components.

Power Generation: Corrosion-resistant components in turbines and high-pressure systems where fatigue performance matters.

Industrial Equipment: Cleanroom hardware, chemical processing fixtures, marine fittings, and deep-sea components requiring durability and corrosion resistance.