セラミックCNC加工で達成できる公差と表面仕上げレベルとは?

セラミック材料は、精密加工分野の中でも最もチャレンジングでありながら、大きな付加価値を生み出す領域のひとつです。最適な結果を得るためには、高度な専門知識と専用設備が不可欠です。Newayでは、セラミックCNC加工サービスを磨き上げ、さまざまな先進セラミック材料に対して高精度かつ優れた表面品質を実現し、複数の産業分野における要求の厳しい用途への適用を可能にしています。

セラミック加工における公差能力

セラミックスは非延性材料であるため、厳しい公差を維持するうえで特有の課題がありますが、専用プロセスを用いることで、非常に高い精度レベルを実現しています。

標準公差範囲

多くのセラミック材料に対して、当社の標準加工能力は以下のとおりです。

寸法公差:重要寸法に対して ±0.01 mm(±0.0004 inch)

幾何公差:真直度および平面度 0.005 mm/25 mm(0.0002 inch/inch)以内

穴位置公差:高精度ボアパターンに対して ±0.005 mm(±0.0002 inch)

同心度:回転部品に対して 0.003 mm(0.0001 inch)以内

これらの標準値は、アルミナ(Al₂O₃)やジルコニア(ZrO₂)といった材料に適用され、豊富な加工実績に基づいた予測可能で再現性の高い結果を提供しています。

高精度公差の実現

特に厳しい精度が求められる用途に対しては、強化されたプロセスを適用し、以下のような性能を達成しています。

超高精度公差:重要箇所において ±0.002 mm(±0.00008 inch)まで対応可能

サブミクロンレベルの形状精度:光学グレードの平面度要求に対して 0.0005 mm 未満

直径精度管理:高精度ベアリング面やシール部品に対して 0.001 mm 以内

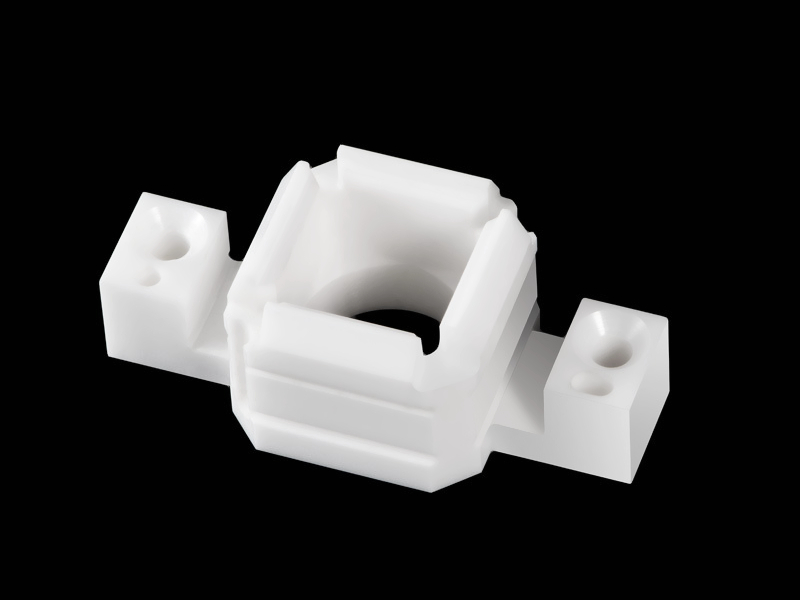

これらの能力は、セラミックインプラントや外科用ツールなど、最高レベルの精度が求められる医療機器業界の部品に特に有用です。

セラミック部品における表面仕上げの達成レベル

セラミック部品の表面仕上げ品質は、耐摩耗性、耐食性、および生体関連用途での性能に大きな影響を与えます。

標準的な表面仕上げ能力

当社の標準的なセラミック加工プロセスでは、通常以下の表面粗さレベルを実現しています。

加工そのままの表面仕上げ:多くの構造用途に対して Ra 0.4~0.8 μm(16~32 μin)

改善された加工仕上げ:最適化された条件と工具により Ra 0.2~0.4 μm(8~16 μin)

高品位加工表面:優れた表面健全性が求められる用途向けに Ra 0.1~0.2 μm(4~8 μin)

高度な表面仕上げ技術

特に優れた表面品質が要求される場合、当社では以下のような特殊仕上げプロセスを採用しています。

高精度ラッピング・ポリッシング:光学部品やベアリング用途向けに、Ra 0.025 μm(1 μin)までの仕上げを実現

レーザーマイクロマシニング:特定機能に合わせて、Ra 0.05~0.5 μm の制御された表面テクスチャを形成

ダイヤモンド研削:当社のCNC研削加工サービスとダイヤモンドホイールを活用し、Ra 0.05 μm レベルまで一貫した表面仕上げを実現

材料別に見た性能の違い

セラミック材料の種類によって加工特性は大きく異なり、達成可能な公差や表面仕上げにも影響します。

酸化物セラミックス

アルミナ(Al₂O₃):一般的に Ra 0.2~0.6 μm の表面粗さと、±0.01 mm の寸法公差を達成

ジルコニア(ZrO₂):優れた破壊靱性により、Ra 0.1~0.4 μm のより細かい仕上げと、±0.005 mm の厳しい公差が可能

非酸化物セラミックス

窒化ケイ素(Si₃N₄):窒化ケイ素部品は、高い強度を維持しながら Ra 0.2~0.5 μm の表面粗さを達成

炭化ケイ素(SiC):炭化ケイ素は Ra 0.3~0.8 μm の仕上げが可能で、特殊プロセスによりさらに細かい仕上げも実現

窒化アルミニウム(AlN):窒化アルミニウムは、優れた熱伝導率を維持しながら Ra 0.4~0.8 μm の表面粗さを達成

セラミック加工精度に影響する重要要因

セラミック加工で一貫した結果を得るには、いくつかの重要な要因を厳密に管理する必要があります。

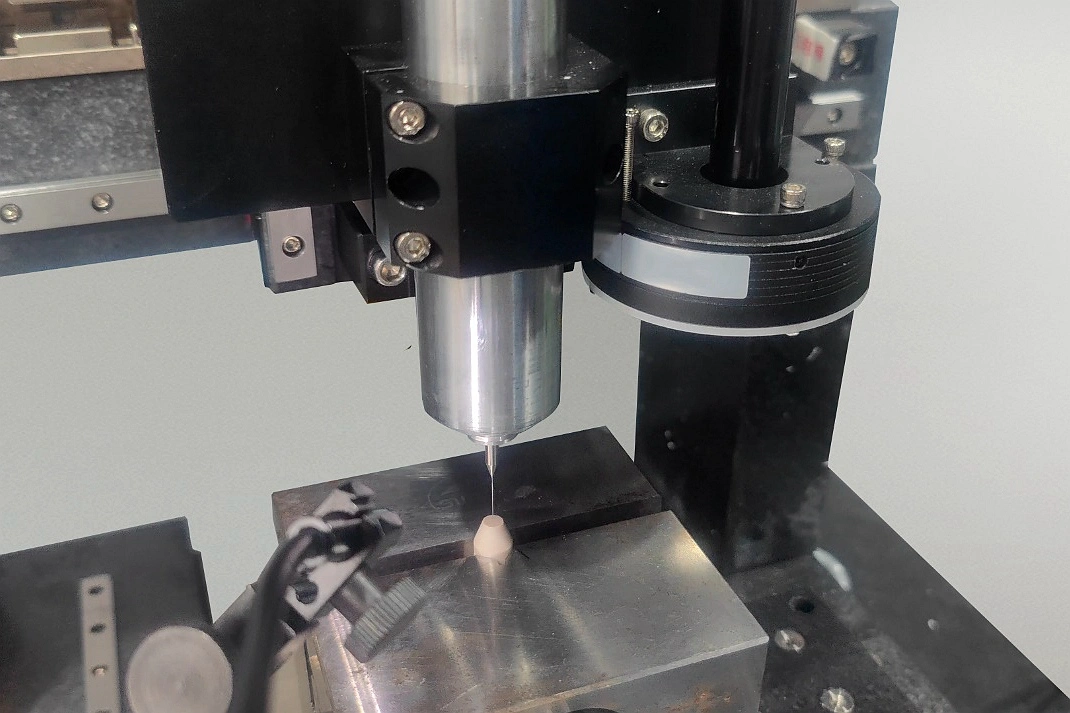

工作機械の能力

高剛性構造:剛性の高い機械構造により振動やたわみを最小化

高度な制御システム:サブミクロン分解能を持つ精密な位置決め制御

熱安定性:温度変化による寸法ドリフトを抑える安定した熱環境

専用工具:セラミック材料に最適化されたダイヤモンド工具などの特殊工具

プロセス最適化

加工条件の開発:材料ごとに最適な回転数、送り、切込み量を設定

治具ソリューション:脆性材料をストレスなく確実に固定する専用治具

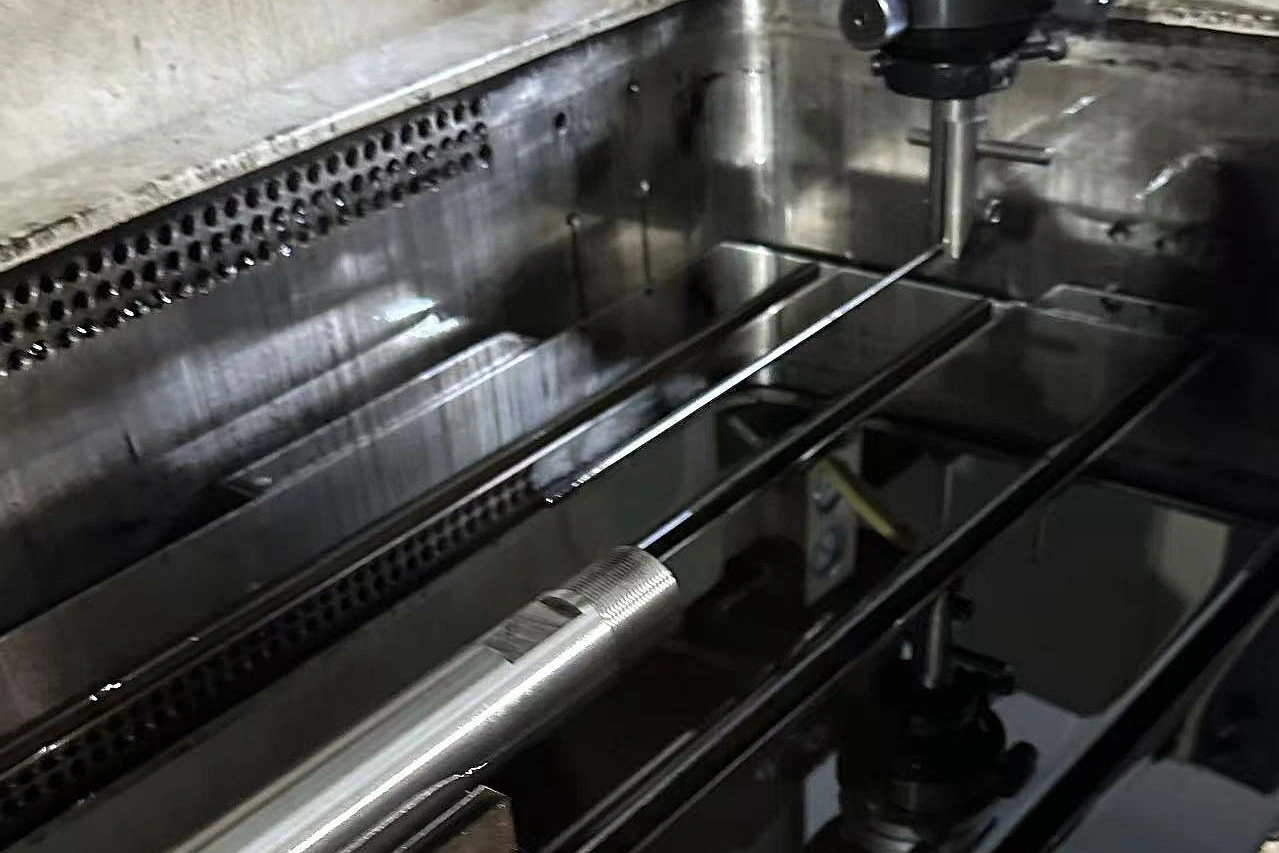

クーラント戦略:発熱と切りくず排出を適切に管理する冷却・潤滑方法

工程内監視:品質へ影響する前に問題を検知するリアルタイムモニタリング

品質保証と検査

セラミック部品の品質検証には、専用の計測アプローチが必要です。

非接触測定:表面ダメージを避けるための光学式プロジェクタや画像測定システム

高度な表面プロフィロメトリ:3D表面解析による Ra・Rz などのパラメータ検証

形状測定:重要部位の真円度、平面度、円筒度を確認

材料健全性試験:微細組織を評価し、内部損傷やサブサーフェスダメージがないことを確認

用途別の性能要求

産業ごとに、公差と表面仕上げの要求組み合わせは異なります。

医療・歯科用途

医療機器向けのセラミック部品には、一般的に以下が求められます。

生体適合性に優れた表面:細菌付着や組織刺激を最小限に抑えるため Ra < 0.2 μm

高精度な嵌合:インプラント部品向けに ±0.005 mm の公差

親水性/疎水性の制御:特定の生体反応に合わせた表面エネルギーの調整

産業・耐摩耗用途

産業機器向け部品では、主に以下の性能が重視されます。

耐摩耗性表面:適切な潤滑保持性を得るため、Ra 0.4~0.8 μm の制御された粗さ

寸法安定性:適切な組付けと機能を確保するため ±0.01 mm の公差

熱マネジメント:制御された加工プロセスにより材料特性(熱特性)を維持

航空宇宙・防衛用途

航空宇宙・航空産業向けセラミック部品には、次のような要件があります。

高温下での安定性:熱サイクル環境下でも公差を維持

浸食抵抗:空力部品向けに Ra 0.2~0.5 μm の最適化された表面仕上げ

構造健全性:非破壊検査(NDT)によりサブサーフェスダメージが最小であることを確認

Newayは、セラミック加工に特化した専門技術と継続的なプロセス改善を通じて、最も厳しい公差および表面仕上げ要求を満たすセラミック部品を提供し、先進セラミックスが持つ優れた性能を多様な用途で最大限に引き出します。