Stainless Steels

Material Introduction

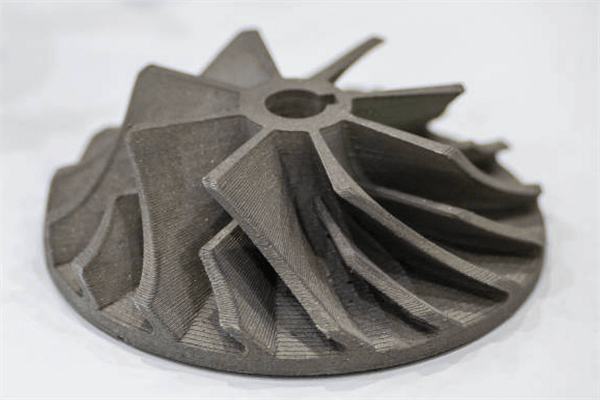

Stainless steel for 3D printing is one of the most versatile and widely adopted metal materials in additive manufacturing. It offers an excellent balance of strength, toughness, corrosion resistance, and affordability, making it suitable for a broad range of industrial, medical, and consumer applications. In powder-bed fusion technologies, such as SLM and DMLS, stainless steel powders consistently melt, producing dense, high-precision components with fine surface detail. Popular 3D printing grades include 316L, 304, and 17-4PH, each offering unique strengths—316L for corrosion resistance, 17-4PH for high hardness and strength, and 304 for cost-effective prototyping. Stainless steel AM parts can withstand mechanical loads, chemicals, moisture, and temperature variations, making them highly reliable for end-use manufacturing.

International Names or Representative Grades

Region | Representative Grades |

|---|---|

USA | 304, 316L, 17-4PH |

Europe | X5CrNi18-10, X2CrNiMo17-12-2 |

China | SUS304, SUS316L, SUS630 |

Medical | 316L Biomedical Grade |

Industrial | 17-4PH High-Strength Steel |

Alternative Material Options

Depending on performance requirements, several materials can be considered as alternatives to stainless steel. For lightweight and corrosion-resistant structures, titanium alloys such as Ti-6Al-4V offer superior strength-to-weight ratios. When extreme heat resistance is required, nickel-based superalloys such as Inconel 625 or Hastelloy C-276 offer superior high-temperature performance. For high thermal and electrical conductivity, copper materials such as C102 Oxygen-Free Copper are ideal. If chemical inertness and dielectric performance are required, Zirconia or Silicon Nitride ceramics may be superior alternatives.

Design Purpose

Stainless steel for additive manufacturing was developed to offer reliable, mechanically strong, and corrosion-resistant parts with intricate geometries suited for real-world applications. Its design purpose is to enable the production of small-batch or end-use stainless components that are difficult or costly to produce using casting or machining. Stainless steel 3D printing enables engineers to design internal channels, lattice structures, conformal cooling paths, and consolidated assemblies, while maintaining high structural integrity and surface durability.

Chemical Composition (316L Example)

Element | Percentage (%) |

|---|---|

Fe | Balance |

Cr | 16–18 |

Ni | 10–14 |

Mo | 2–3 |

Mn | ≤2 |

C | ≤0.03 |

Physical Properties

Property | Value |

|---|---|

Density | 7.8–8.0 g/cm³ |

Melting Point | 1,370–1,400°C |

Thermal Conductivity | 14–16 W/m·K |

Electrical Resistivity | 0.7–0.75 μΩ·m |

Elastic Modulus | 190–210 GPa |

Mechanical Properties

Property | Value |

|---|---|

Tensile Strength | 500–750 MPa |

Yield Strength | 200–550 MPa |

Elongation | 30–50% |

Hardness | 150–300 HV |

Fatigue Strength | Good |

Key Material Characteristics

Stainless steel offers several advantages for additive manufacturing applications:

Excellent corrosion resistance in industrial, marine, and chemical environments.

High toughness and ductility, reducing risk of brittle fracture.

High strength suitable for load-bearing components.

Good dimensional stability after stress-relief heat treatment.

Ability to form complex lattice or hollow structures for lightweighting.

Cost-effective for prototyping and production runs.

Non-reactive and food-safe options for medical and consumer applications.

Good wear resistance when post-treated.

Compatible with hybrid machining for precision interfaces.

Processing Performance Across Manufacturing Methods

Stainless steel shows strong manufacturability across various processes:

Powder-bed fusion produces dense stainless components with excellent accuracy.

Binder Jetting is suitable for low-cost, high-volume stainless parts.

CNC milling and CNC turning are commonly used after printing for precision surfaces.

EDM machining enables the achievement of tight tolerances in complex geometries.

Heat-treatable grades, such as 17-4PH, can be further strengthened through precipitation hardening.

Supports hybrid manufacturing strategies for combining additive cores with machined finishes.

Polishing and passivation enhance corrosion performance and appearance.

Suitable and Common Post-Processing Methods

Stainless steel AM parts benefit from a range of finishing methods:

Stress-relief heat treatment for dimensional stability.

Passivation to improve corrosion resistance.

Electropolishing for smooth, shiny surfaces.

Sandblasting for uniform textures.

PVD coating for enhanced wear resistance and aesthetic appeal.

Powder coating for durable colors.

CNC machining for high-precision features.

Shot peening for improved fatigue properties.

Passivation or nitriding for extended corrosion and wear resistance.

Common Industries and Applications

Stainless steel 3D printing supports a wide range of industries:

Aerospace brackets, housings, and structural hardware.

Medical surgical tools, orthopedic instrument parts, and dental devices.

Automotive exhaust components, brackets, and functional prototypes.

Food processing equipment requires hygienic surfaces.

Industrial automation components and robotic actuators.

Oil & gas high-pressure components.

Consumer electronics and appliance hardware.

When to Choose Stainless Steel for 3D Printing

Stainless steel is the ideal choice when:

Corrosion resistance is required in humid, chemical, or marine environments.

Moderate to high mechanical strength must be maintained across temperature changes.

Biocompatibility, or the behavior of food-grade materials, is required.

Parts must be durable, impact-resistant, and fatigue-resistant.

High precision and fine surface detail are required.

Cost-effective metal AM solutions are preferred over titanium or nickel alloys.

Hybrid manufacturing requires printed cores with machined surfaces.

The application demands reliable structural integrity under repeated stress or vibration.