High temperature alloy

Material Introduction

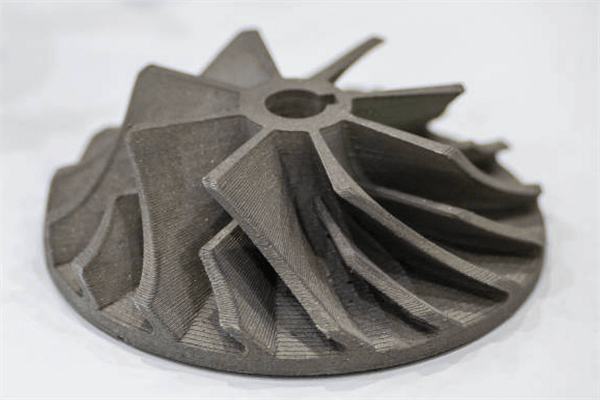

High-temperature alloys for 3D printing are engineered to withstand extreme mechanical loads, thermal cycling, oxidation, creep, and corrosive atmospheres. In additive manufacturing, these alloys offer exceptional stability across a broad temperature range, often exceeding 700–1,000°C depending on the alloy family. Their ability to maintain mechanical integrity at elevated temperatures makes them ideal for aerospace propulsion modules, energy-sector turbine components, and high-performance automotive systems. Modern 3D printing methods—especially DMLS, SLM, and EBM—enable the creation of complex geometries that were previously impossible using cast or wrought processes. Many high-temperature alloys also exhibit excellent weldability during layer-by-layer fusion, allowing designers to reduce part count and enhance thermal efficiency in mission-critical systems.

International Names or Representative Alloys

Region | Common Names / Representative Alloys |

|---|---|

USA | Inconel, Hastelloy, Stellite, Rene Alloy |

Europe | Nimonic Series, Nickel-Chromium Alloys |

China | GH Series, K-Series Superalloys |

Japan | SUH High-Temp Alloys |

Aerospace Industry | Inconel 718, Rene 41, Nimonic 90 |

Power Generation | Hastelloy C-276, Inconel 738 |

Alternative Material Options

Depending on application requirements, several material families can serve as alternatives to high-temperature alloys. When oxidation resistance and thermal fatigue behavior are primary concerns, nickel-based superalloys, such as Inconel 718 or Hastelloy C-276, offer robust alternatives. For ultra-high strength-to-weight ratios in aerospace structures, titanium alloys such as Ti-6Al-4V (TC4) offer superior lightweight performance. When electrical or thermal conductivity is required, copper alloys such as Copper C102 are suitable for use in heat exchangers or RF components. In corrosive chemical environments, cobalt-based alloys such as Stellite 6 significantly outperform typical high-temperature grades. For cost-sensitive, medium-temperature applications, stainless steels like SUS310 or SUS321 are economical alternatives.

Design Purpose

High-temperature 3D printing alloys were developed to enable parts that can withstand prolonged exposure to heat, stress, and corrosive or high-pressure atmospheres without loss of mechanical integrity. Their microstructure is engineered to resist creep, maintain tensile strength at elevated temperatures, and prevent premature oxidation or grain growth. These alloys empower industries to manufacture mission-critical components with reduced mass, improved cooling efficiency, and highly optimized internal channels.

Chemical Composition (Typical Nickel-Based Alloy Example)

Element | Percentage (%) |

|---|---|

Ni | 50–60 |

Cr | 15–25 |

Fe | 5–15 |

Mo | 2–10 |

Nb/Ta | 3–5 |

Ti | 0.5–2 |

Al | 0.5–1.5 |

Physical Properties

Property | Value |

|---|---|

Density | 8.1–8.5 g/cm³ |

Melting Range | 1,250–1,350°C |

Thermal Conductivity | 10–15 W/m·K |

Electrical Resistivity | 1.0–1.3 μΩ·m |

Thermal Expansion | 12–16 µm/m·°C |

Mechanical Properties

Property | Value |

|---|---|

Tensile Strength | 1,200–1,500 MPa |

Yield Strength | 900–1,200 MPa |

Elongation | 10–25% |

Hardness | 35–45 HRC |

Creep Resistance | Excellent at 700–1,000°C |

Key Material Characteristics

High-temperature alloys offer a range of advantages that make them indispensable for additive manufacturing.

Exceptional thermal stability, enabling long-term operation at temperatures exceeding 700°C.

High tensile and yield strength at elevated temperatures due to precipitation-hardening mechanisms.

Superior creep resistance under sustained loads, essential for aerospace turbine blades and power-generation rotors.

Excellent resistance to oxidation and carburization, preventing structural degradation in hot gas environments.

Compatibility with complex hollow structures and conformal cooling channels using SLM and DMLS processes.

Reliable microstructural uniformity after powder-bed fusion, supporting consistent mechanical performance.

Excellent weldability during layer fusion, minimizing the formation of cracks.

High corrosion resistance against acids, molten salts, and combustion by-products.

Long service life under thermal cycling, vibration, and shock loads.

Tailored compositions available for aerospace, nuclear, automotive, energy, and aerospace propulsion systems.

Processability Across Manufacturing Methods

High-temperature alloys respond well to multiple modern manufacturing processes:

Powder-bed fusion methods, such as SLM, DMLS, and EBM, ensure the production of dense and precise structures.

Electron-beam melting enhances grain structure uniformity, thereby improving high-temperature fatigue performance.

Binder Jetting offers economical production for large volumes, which can be further strengthened through sintering and HIP.

UAM and WAAM enable the fabrication of large-scale, thick-walled structural parts.

Post-AM machining is feasible using EDM or precision machining to achieve tight tolerances.

Compatible with heat treatment for stress relief and mechanical enhancement.

Performs well in hybrid manufacturing setups combining additive and CNC machining.

Grain refinement and precipitation control processing ensure reliable long-term high-temperature operation.

Suitable and Common Post-Processing Methods

High-temperature alloys benefit from various finishing and strengthening processes:

Heat treatment to increase yield strength and fatigue resistance.

Thermal barrier coatings for extreme hot-gas environments.

Surface polishing for turbine aerodynamic performance.

Electropolishing to remove micro-defects after printing.

PVD coatings for enhanced wear resistance.

Sandblasting for uniform matte surfaces.

Anodizing alternatives where applicable for multi-material hybrid parts.

HIP processing to eliminate residual porosity.

Chemical passivation for corrosion-critical environments.

Coating systems for nuclear, marine, aerospace, and combustion atmospheres.

Common Industries and Applications

High-temperature alloys serve demanding applications across multiple sectors:

Aerospace turbines, hot-section blades, nozzles, and combustion chambers.

Power-generation equipment, including HRS components and turbine vanes.

Automotive turbocharger housings and exhaust manifold inserts.

Nuclear-industry structural elements are exposed to radiation and high heat.

Oil & gas drilling tools and downhole high-pressure parts.

High-performance robotics and automation require thermal stability.

Heat exchangers, thermal shields, and burner components.

When to Choose This Material

High-temperature alloys for 3D printing are ideal when:

Components operate above 600–1,000°C and require stable mechanical properties.

Corrosion, oxidation, and hot-gas erosion are critical design constraints.

Parts require complex cooling channels or lattice structures, not possible with casting or forging.

The application demands high creep resistance in long-duration thermal exposure.

Mission-critical aerospace, nuclear, or power generation standards require superior fatigue and thermal shock performance.

Lightweight designs with high structural integrity must be produced as a single piece.

Prototyping and low-volume production require fast iteration using additive processes.

Hybrid manufacturing benefits from seamless integration with CNC machining for final tolerances.

Durability, reliability, and safety are more important than cost.

Extreme environmental conditions will cause failure in stainless steel, titanium, or aluminum alloys.