Aluminum

Material Introduction

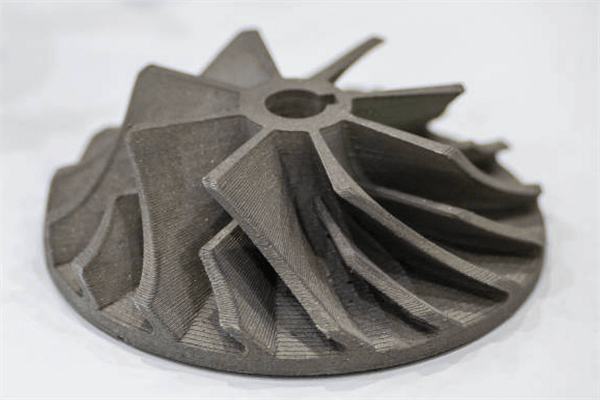

Aluminum for 3D printing is highly valued for its exceptional combination of low density, high strength, high thermal conductivity, and excellent corrosion resistance. In additive manufacturing—especially SLM and DMLS—aluminum alloys enable the creation of lightweight yet durable components with precise geometries, fine surface detail, and efficient heat dissipation. Aluminum’s printability continues to improve due to the development of specialized powder grades and alloy systems that reduce cracking during solidification. Popular aluminum alloys for 3D printing include AlSi10Mg and AlSi7Mg, offering a balance of strength, thermal stability, and surface finish quality, making them ideal for aerospace housings, automotive heat exchangers, robotic arms, and consumer electronics structures.

International Names or Representative Grades

Region | Representative Grades |

|---|---|

USA | AlSi10Mg, AlSi7Mg, 6061, 7075 |

Europe | EN AC-43000, EN AW-6082 |

China | ADC12, A380, 6061-T6 |

Aerospace | AlSi10Mg, 7050, 7075 |

Automotive | 6061, 5083, ADC12 |

Alternative Material Options

Aluminum may be substituted with other metals depending on the application. For high-temperature or high-stress environments, nickel-based alloys such as Inconel 718 offer superior mechanical performance in extreme heat conditions. When greater strength-to-weight efficiency is required, titanium alloys like Ti-6Al-4V offer exceptional fatigue and corrosion resistance. If higher thermal and electrical conductivity is needed, copper grades such as C102 Oxygen-Free Copper are preferred. For budget-sensitive parts that do not require aluminum's specific combination of performance and lightness, stainless steels such as SUS304 or SUS316L provide good manufacturability and durability.

Design Purpose

Aluminum alloys for additive manufacturing were designed to enable lightweight, thermally efficient, and cost-effective structural components with design freedom beyond the limits of casting or machining. Their purpose is to provide strong yet light parts that can integrate cooling channels, lattice structures, and internal features to reduce weight, increase performance, and improve assembly efficiency in aerospace, automotive, and electronics applications. Aluminum AM also reduces production lead times, allowing rapid prototyping and low-volume production at competitive costs.

Chemical Composition (AlSi10Mg Example)

Element | Percentage (%) |

|---|---|

Al | Balance |

Si | 9–11 |

Mg | 0.2–0.5 |

Fe | ≤0.55 |

Cu | ≤0.05 |

Physical Properties

Property | Value |

|---|---|

Density | 2.65–2.70 g/cm³ |

Melting Point | ~570–590°C |

Thermal Conductivity | 150–180 W/m·K |

Electrical Resistivity | 3.5–4.0 μΩ·m |

Elastic Modulus | 70–80 GPa |

Mechanical Properties

Property | Value |

|---|---|

Tensile Strength | 320–420 MPa |

Yield Strength | 200–260 MPa |

Elongation | 5–12% |

Hardness | 75–95 HB |

Fatigue Strength | Moderate |

Key Material Characteristics

Aluminum for 3D printing offers a range of valuable advantages across industries:

Exceptional lightweight performance, reducing mass in aerospace and automotive systems.

High thermal conductivity is ideal for heat exchangers, battery housings, and electronics enclosures.

Good corrosion resistance in humid, marine, and industrial environments.

Suitable for highly detailed parts with thin walls and smooth surfaces.

Excellent compatibility with SLM and DMLS due to predictable melting and solidification.

Good dimensional stability after stress-relief heat treatment.

Ability to create complex internal channels and lightweight lattices.

Cost-effective material pricing compared with titanium and nickel alloys.

Suitable for rapid prototyping due to its short print times and ease of post-processing.

Resistant to deformation from cyclic thermal loads due to stable microstructure.

Processability Across Manufacturing Methods

Aluminum performs well in a variety of additive and subtractive manufacturing workflows:

Powder-bed fusion processes, such as SLM and DMLS, achieve high density and excellent mechanical properties.

Binder Jetting enables economical large-batch aluminum prototyping.

Post-processing machining is common; aluminum is easily finished using CNC milling and CNC drilling.

Heat treatment enhances the strength and relieves residual stresses that can occur after printing.

Surface polishing enhances the surface quality of consumer products and aerospace components.

Aluminum AM powders support hybrid manufacturing, where printed structures are connected with precision machining to achieve tight tolerances.

WAAM and LMD techniques enable the fabrication of medium- to large-scale aluminum structures at high deposition rates.

Suitable and Common Post-Processing Methods

Aluminum AM components typically undergo finishing steps to enhance appearance and performance:

Stress-relief heat treatment to stabilize microstructure.

Anodizing for corrosion resistance, hardness, and appearance.

Sandblasting for uniform matte finishes.

Electropolishing for improved smoothness.

Powder coating for durable color finishes.

Alodine coating for aircraft-grade corrosion protection.

CNC machining for precision critical features.

Shot peening to improve fatigue life.

Polishing for consumer electronics and aesthetic parts.

Common Industries and Applications

Aluminum 3D printing is widely used across performance-oriented industries:

Aerospace brackets, housings, heat exchangers, and UAV structures.

Automotive lightweight components, battery casings, and thermal management parts.

Consumer electronics enclosures require lightweight durability.

Robotics structures where stiffness and low mass are crucial.

Power-generation cooling components and heat sinks.

Industrial equipment housings and flow components.

Sporting goods, drones, and optical devices.

When to Choose Aluminum for 3D Printing

Aluminum is ideal when:

Lightweight structural efficiency is required to reduce energy consumption or improve performance.

Components require high thermal conductivity for effective cooling or heat dissipation.

Corrosion resistance is important in outdoor or marine applications.

Complex internal channels are needed for heat exchangers or fluid systems.

Cost-effective metal printing is desired for rapid prototyping or short-run production.

Dimensional accuracy and smooth surface finish are important in final assemblies.

The application demands a balance of strength, weight, and manufacturability.

Hybrid processes combine aluminum 3D printing with CNC machining to achieve high-precision dimensions.