Nickel-based alloys

Material Introduction

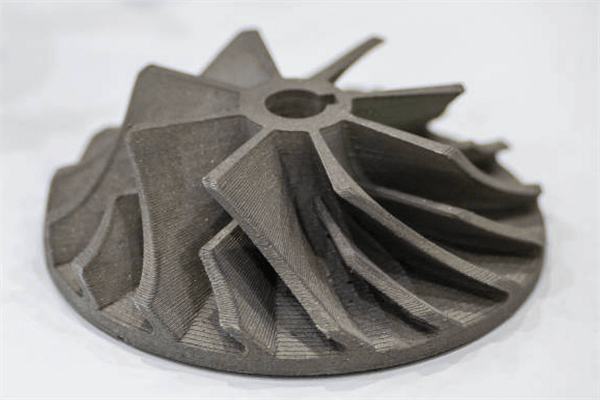

Nickel-based alloys for 3D printing are high-performance, heat-resistant materials engineered for demanding environments where extreme temperatures, corrosion, mechanical fatigue, and oxidation resistance are critical. These alloys—including well-known grades such as Inconel 625, Inconel 718, and Inconel 939—excel in aerospace turbines, power-generation systems, chemical processing, tooling, and high-temperature mechanical assemblies. Metal additive manufacturing enables these alloys to be printed with exceptional microstructural uniformity, near-net shapes, and complex internal channels not possible through casting or machining alone. Neway’s advanced metal 3D printing services ensure tight dimensional accuracy, high density, and stable performance, enabling engineers to create optimized, lightweight, and long-lasting nickel-alloy components for mission-critical applications.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | Nickel-Based Superalloys | Inconel 625, Inconel 718 |

Europe | Ni-Cr Superalloys | Alloy 625, Alloy 718 |

Japan | Heat-Resistant Nickel Alloys | NCF 625, NCF 718 |

China | Ni-Base Superalloys | GH4169, GH3625 |

Aerospace Industry | High-Temperature Alloys | Inconel 939, Rene Alloys |

Alternative Material Options

Where very high temperature capabilities are not required, several alternative materials may offer design or cost advantages. For lightweight aerospace structures, titanium alloys provide excellent strength-to-weight ratios and corrosion resistance. For cost-efficient mechanical parts and prototypes, carbon steels and stainless steels offer stable performance at lower temperatures. For superior thermal and electrical conductivity, copper alloys provide unmatched heat transfer capabilities. Applications requiring wear resistance may benefit from cobalt-based materials such as Stellite 6. If chemical inertness and high-temperature stability are required at lower density, high-performance ceramics such as SiC may be appropriate. These alternatives provide flexibility in balancing weight, strength, heat tolerance, and cost.

Design Purpose

Nickel-based alloys were engineered to maintain mechanical strength and oxidation resistance at extremely high temperatures—conditions far beyond the limits of steels and titanium. These alloys were originally designed for aerospace turbine blades, combustion systems, and high-temperature tooling, where creep resistance, thermal fatigue strength, and corrosion stability are critical. For additive manufacturing, their purpose expanded to include optimized internal cooling channels, lightweight lattice structures, high-strength thin walls, and complex geometries that reduce thermal stress and improve part life. Their design intent aligns with 3D printing’s ability to achieve microstructural consistency, directional solidification, and high-density performance for mission-critical components.

Chemical Composition (Typical)

Element | Composition (%) |

|---|---|

Nickel (Ni) | 50–70 |

Chromium (Cr) | 15–25 |

Iron (Fe) | 1–20 |

Molybdenum (Mo) | 3–10 |

Niobium (Nb) | 3–6 |

Titanium (Ti) | 0.5–2 |

Aluminum (Al) | 0.5–1.5 |

Cobalt (Co) | Optional (up to 10%) |

Physical Properties

Property | Value |

|---|---|

Density | ~8.1–8.6 g/cm³ |

Thermal Conductivity | 10–15 W/m·K |

Electrical Resistivity | ~1.2–1.4 μΩ·m |

Melting Range | 1300–1400°C |

Oxidation Resistance | Excellent at 800–1100°C |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 900–1400 MPa |

Yield Strength | 700–1100 MPa |

Hardness | 30–45 HRC |

Elongation | 10–25% |

Creep Resistance | Excellent at high temperature |

Key Material Characteristics

Exceptional high-temperature strength, retaining mechanical performance above 800°C.

Outstanding oxidation and corrosion resistance for harsh chemical or thermal environments.

Stable microstructure during thermal cycling, suitable for aerospace and power-generation systems.

Excellent fatigue and creep resistance under sustained high loads.

High density and robustness for mission-critical rotating components.

Compatible with complex geometries produced via metal 3D printing.

Machinability improved through post-printing heat treatment and CNC grinding.

Strong weldability and repairability for hybrid manufacturing applications.

Minimal distortion during post-processing compared with conventional casting.

Long-term durability in corrosive, high-pressure, or combustion environments.

Manufacturability in Different Processes

Additive manufacturing: Powder bed fusion produces high-density, performance-critical components using Neway’s metal AM technologies.

CNC machining: Nickel-alloy printed parts can be refined using multi-axis machining and turning.

EDM: Complex features and tight contours can be produced using EDM machining.

Heat treatment: Solution treatment and aging optimize strength and microstructure.

Welding: Nickel alloys provide excellent weldability for repair or hybrid build designs.

Grinding: Precision finishing using CNC grinding ensures surface integrity.

Suitable Post-Processing Methods

Heat treatment for precipitation hardening, stress relief, and structural stability.

Hot Isostatic Pressing (HIP) to eliminate internal porosity and achieve full density.

Precision finishing using precision machining for tight tolerances.

Surface strengthening via nitriding or shot-peening.

Coatings such as PVD, chrome plating, or TBC for thermal protection.

Polishing and surface refinement for aerodynamic or high-pressure components.

Common Industries and Applications

Aerospace turbine blades, combustion chambers, and structural elements.

Power-generation turbine parts, heat-resistant housings, and flow components.

Automotive turbocharger components and high-temperature exhaust systems.

Oil and gas equipment requiring corrosion-resistant alloys.

Industrial machinery exposed to high-pressure, high-heat, or corrosive environments.

Defense components requiring extreme mechanical and thermal reliability.

When to Choose This Material

When designing components for environments above 600–1000°C.

When corrosion, oxidation, or chemical attack resistance is crucial.

When producing turbine, combustion, or exhaust components that require a long service life.

When high-pressure and high-load stability are required under thermal cycling.

When geometries involve internal cooling channels or topology-optimized structures.

When fatigue resistance under continuous mechanical stress is essential.

When extremely uniform microstructure and high density are required.

When additive manufacturing reduces costs compared to machining from wrought superalloy stock.