Usinage CNC du titane : solutions sur mesure pour l’aérospatiale

Introduction : exigences particulières relatives aux pièces en alliage de titane dans l’aéronautique

Après de nombreuses années dans la fabrication de précision chez Neway, j’ai acquis une profonde compréhension de la quête de performances extrêmes en matière de matériaux dans l’industrie aéronautique. Grâce à son excellent rapport résistance/poids, à sa remarquable résistance à la corrosion et à son bon comportement à haute température, l’alliage de titane est devenu un matériau clé indispensable dans l’aéronautique moderne. Des structures de cellule aux composants de cœur de moteur, les alliages de titane sont omniprésents – et leurs défis d’usinage spécifiques nous poussent en permanence à explorer des solutions toujours plus optimisées.

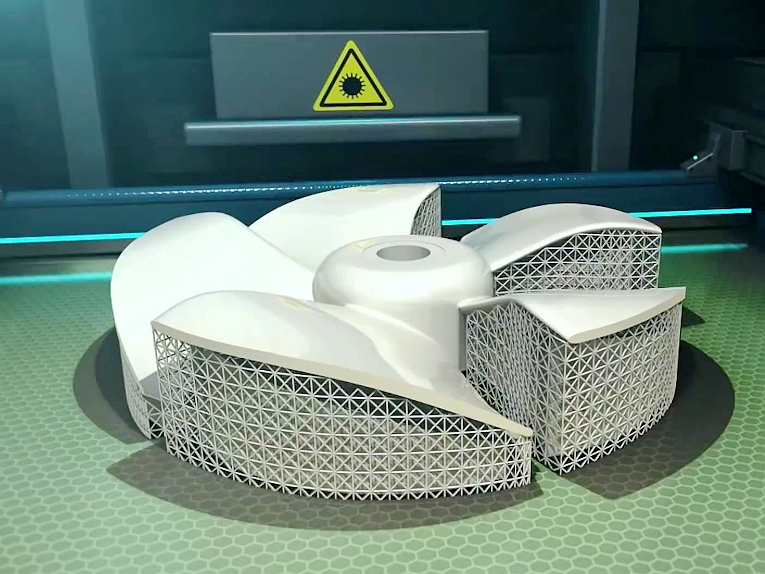

Dans le secteur de l’aéronautique, la fabrication de chaque pièce est directement liée à la sécurité de vol et aux performances. Nous devons non seulement atteindre une précision dimensionnelle au micron, mais aussi garantir l’intégrité microstructurale et la stabilité des performances à long terme. Forts de cette compréhension, nous avons développé une solution complète de services personnalisés d’usinage CNC d’alliages de titane, afin de fournir aux clients aéronautiques un service « one-stop » allant de la sélection du matériau jusqu’aux pièces finies.

Applications clés et valeur des alliages de titane dans l’aéronautique

Structures de cellule : la clé de la conception allégée

La réduction de poids est un thème constant dans la conception des aéronefs modernes. Les alliages de titane ont une densité d’environ 60 % de celle de l’acier, tout en offrant une résistance comparable, ce qui en fait des matériaux idéaux pour les cadres, les cloisons et les éléments de liaison structurels. Les pièces en Ti-6Al-4V (TC4) que nous usinons garantissent l’intégrité structurelle tout en réduisant significativement le poids de l’appareil et en améliorant l’efficacité énergétique. Grâce à des procédés d’usinage optimisés, nous pouvons réaliser des structures complexes quasi finies en un seul montage, réduisant le nombre de fixations et d’assemblages et améliorant encore la fiabilité de la structure.

Composants de moteur : combinaison idéale de résistance à haute température et de résistance mécanique

Les turboréacteurs imposent des exigences extrêmement élevées aux matériaux : ils doivent supporter de hautes températures et de fortes pressions tout en conservant des performances stables sur le long terme. Pour les aubes de compresseur et les carters réalisés en Ti-5Al-2,5Sn (Grade 6), nous garantissons d’excellentes propriétés mécaniques dans une plage de températures de fonctionnement de 300 °C à 500 °C. En appliquant des services d’usinage de précision spécialisés, nous assurons la fiabilité de ces composants critiques dans des conditions extrêmes.

Trains d’atterrissage et systèmes hydrauliques : garantir résistance et durée de vie en fatigue

Le système de train d’atterrissage est soumis à d’énormes charges d’impact à l’atterrissage, ce qui impose des exigences très strictes en termes de résistance et de tenue en fatigue du matériau. Nous utilisons le Ti-6Al-2Sn-4Zr-2Mo (Grade 4), qui offre une résistance plus élevée et une meilleure ténacité à la rupture. Combiné à des procédés d’usinage optimisés et à des technologies de traitement de surface adaptées, cela améliore significativement la durée de vie en fatigue et garantit la sécurité et la fiabilité des trains d’atterrissage.

Défi I : faible conductivité thermique et réactivité élevée à haute température des alliages de titane

Les alliages de titane présentent une faible conductivité thermique – environ un quinzième de celle de l’aluminium et un cinquième de celle de l’acier – ce qui rend difficile la dissipation de la chaleur générée pendant l’usinage. Il en résulte facilement une surchauffe de l’outil et une usure accélérée. Lors de l’usinage du Ti-6Al-4V ELI (Grade 23), nous accordons une attention particulière à la gestion thermique, en optimisant les paramètres de coupe et les méthodes de refroidissement afin de maintenir la température de coupe dans une plage maîtrisée.

Les alliages de titane sont chimiquement réactifs à haute température et ont tendance à réagir avec les matériaux d’outil, entraînant une usure par diffusion et une usure par oxydation. En utilisant des revêtements d’outils dédiés et des formulations de fluide de coupe optimisées, nous supprimons efficacement ces réactions chimiques. Dans nos services de fraisage CNC, nous adoptons des stratégies de coupe intermittente qui laissent à l’outil suffisamment de temps de refroidissement, prolongeant ainsi significativement sa durée de vie.

Défi II : maîtrise des contraintes d’usinage et prévention de la déformation des pièces

En raison du module d’élasticité relativement faible des alliages de titane, des déformations élastiques se produisent facilement pendant l’usinage, ce qui affecte la précision dimensionnelle, en particulier pour les structures à parois fines. Nous maîtrisons efficacement la génération et la libération des contraintes d’usinage grâce à des solutions de bridage optimisées et à des stratégies d’usinage par étapes.

Lors de l’usinage d’alliages de titane β à haute résistance tels que le Ti-10V-2Fe-3Al (Grade 19), nous appliquons un usinage symétrique pour obtenir une répartition des contraintes plus uniforme. En planifiant soigneusement la séquence des opérations – usiner d’abord les zones les plus rigides, puis les parois fines – nous minimisons la déformation des pièces. Dans nos services de tournage CNC, nous utilisons des outils très tranchants et des paramètres de coupe soigneusement sélectionnés afin de maintenir de faibles efforts de coupe.

Solution personnalisée I de Neway : base de données de procédés spécifique aux matériaux

Sur la base de nombreuses années d’expérience, nous avons développé une base de données complète des procédés d’usinage du titane. Pour chaque grade de titane, nous maintenons un ensemble validé de paramètres d’usinage optimisés pour cette nuance spécifique. Par exemple, lors de l’usinage de l’ alliage de titane Beta C, nous utilisons des vitesses de coupe relativement faibles et des avances modérées afin d’équilibrer efficacité et durée de vie des outils.

Notre base de données de procédés couvre non seulement les paramètres de coupe, mais aussi le choix des outils, les formulations de fluides de coupe, les stratégies de bridage, etc. Pour l’ alliage de titane TA15, les indications issues de cette base de données nous permettent de déterminer rapidement des schémas d’usinage optimaux, raccourcissant considérablement les cycles de développement des procédés et améliorant l’efficacité de production.

Solution personnalisée II de Neway : outillage avancé et technologies de refroidissement

Matériaux d’outils spécialisés et conception de géométrie

En collaboration avec des fabricants d’outils, nous avons développé des outils spécifiques dédiés à l’usinage du titane. Ces outils utilisent des substrats en carbure à grain ultra-fin et des revêtements avancés pour offrir une excellente dureté à chaud tout en conservant une ténacité suffisante. Dans nos services d’usinage multi-axes, nous adaptons dynamiquement les paramètres de coupe en fonction des conditions d’engagement de l’outil, de façon à ce qu’il fonctionne toujours dans sa fenêtre de travail optimale.

Importance du refroidissement haute pression à travers l’outil

Le refroidissement haute pression à travers l’outil est crucial pour résoudre les problèmes de dissipation de chaleur lors de l’usinage du titane. À l’aide de systèmes de fluide de coupe haute pression de 70 à 100 bar, nous acheminons le fluide de coupe directement vers l’interface outil–copeau via des canaux internes. Dans nos services de perçage CNC, cette approche réduit non seulement efficacement la température de coupe, mais améliore aussi considérablement l’évacuation des copeaux, évitant ainsi le bourrage et la casse des outils.

Choix et application précise des fluides de coupe

Nous utilisons des fluides de coupe spécialement formulés pour l’usinage du titane, offrant d’excellentes propriétés de dissipation thermique et de lubrification. En contrôlant avec précision la concentration, le débit et l’angle des buses, nous assurons une couverture de refroidissement suffisante dans la zone de coupe. Lors de l’usinage de tubes hydrauliques en Ti-3Al-2,5V (Grade 12), notre stratégie de refroidissement optimisée permet un usinage de trous profonds à la fois de haute qualité et à haute efficacité.

Solution personnalisée III de Neway : usinage multi-axes et maîtrise des vibrations

L’usinage 5 axes simultanés joue un rôle essentiel dans la fabrication de composants aéronautiques en titane. L’usinage continu le long de surfaces complexes élimine la nécessité de multiples remises en position et les erreurs de repositionnement associées, tout en maintenant des conditions de coupe stables. Pour des pièces complexes, telles que les blisks et disques aubagés, nous utilisons nos services de rectification CNC pour la finition finale, afin de garantir que la précision de profil réponde strictement aux spécifications de conception.

La maîtrise des vibrations est essentielle pour obtenir une qualité d’usinage élevée. Nous les supprimons efficacement en optimisant le porte-à-faux de l’outil, en augmentant la rigidité du système et en utilisant des outils anti-vibratoires. Dans nos services d’usinage par décharge électrique (EDM), nous optimisons les paramètres de décharge afin de minimiser l’épaisseur de la couche recristallisée et de préserver les performances en fatigue.

Solution personnalisée IV de Neway : post-traitement professionnel et protection de surface

Le traitement de surface est déterminant pour les performances en service des composants en titane. Nos services de passivation forment des films d’oxyde denses à la surface du titane, améliorant fortement la résistance à la corrosion. Contrairement à l’anodisation de l’aluminium, l’anodisation du titane requiert un contrôle de procédé plus précis ; grâce à une gestion stricte des paramètres, nous garantissons une qualité de traitement constante.

Les services de grenaillage introduisent une couche de contraintes résiduelles de compression en surface, améliorant considérablement la durée de vie en fatigue. Nous optimisons l’intensité et la couverture du grenaillage en fonction de la géométrie de la pièce et de ses conditions de service. Dans nos services de polissage de pièces usinées CNC, un polissage de précision en plusieurs étapes permet d’obtenir des surfaces quasi miroir, réduisant les concentrations de contraintes.

Étude de cas : comment Neway répond à des exigences aéronautiques particulièrement strictes

Dans le cadre d’un projet de développement de prototype pour un carter de moteur en alliage de titane, nous avons été confrontés à des défis techniques majeurs. La pièce présentait une structure complexe avec des épaisseurs de parois très variables, ce qui la rendait extrêmement sensible à la déformation pendant l’usinage. Grâce à nos solutions personnalisées, nous avons résolu avec succès plusieurs problèmes critiques.

Tout d’abord, nous avons utilisé l’analyse par éléments finis pour prédire la répartition des contraintes pendant l’usinage et optimisé en conséquence la séquence des opérations. Ensuite, nous avons adopté des outils à arrosage interne spécifique et des systèmes de refroidissement haute pression pour maîtriser la température de coupe. Lors de l’étape de finition, l’usinage 5 axes simultanés a permis d’assurer la précision des profils sur les surfaces complexes. Enfin, grâce à nos services de fabrication en petites séries, nous avons livré des pièces de haute qualité répondant pleinement aux exigences du client.

Conclusion : faites de Neway votre partenaire professionnel pour l’usinage aéronautique du titane

Chez Neway, grâce à notre modèle de service intégré « one-stop », nous intégrons de manière fluide la science des matériaux et la fabrication de précision. Notre équipe d’ingénieurs ne maîtrise pas seulement les technologies d’usinage, elle comprend aussi les conditions de service réelles des composants, ce qui nous permet d’optimiser les solutions de fabrication avec une approche orientée application.

Des dispositifs médicaux et applications automobiles à la robotique et à l’aéronautique, nous avons acquis une vaste expérience en usinage d’alliages de titane dans de nombreux secteurs. Grâce à nos services de production de masse, nous offrons aux clients des solutions de fabrication à la fois de haute qualité et à haute efficacité.

Nous sommes convaincus que seule une compréhension approfondie des caractéristiques intrinsèques des matériaux permet de libérer pleinement leur potentiel grâce à des procédés d’usinage avancés et de fabriquer des pièces véritablement haut de gamme capables de résister à l’épreuve du temps. En choisissant Neway, vous gagnez non seulement un fournisseur d’usinage, mais aussi un partenaire technique digne de confiance.